High dynamics and service life without moving parts

With the DKHS1000 series, the Zimmer Group presents a clamping element world first for unpressurised fixing of rotary axes. The DKHS1000 provides the highest angular accuracy under torque absorption whilst simultaneously maintaining high dynamic ability due to closing times exceeding those of the market.

In machine tool applications, the demands on machine dynamics and accuracy are continuously increasing. For example in rotary axes, angular accuracy has more of an effect as the radius increases. In addition, swivel bridges can quickly add up to several hundred kilograms, including the weight of the component, which must also be held in position under process forces with high rigidity.

Meeting the highest requirements

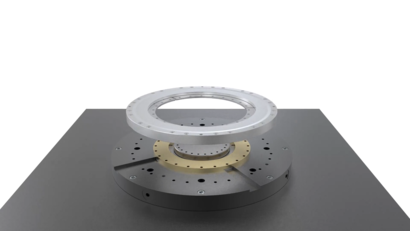

The new DKHS1000 hydraulic clamping element series meets these requirements. It has been designed for highly rigid and precise fixing of rotary axes with high angular accuracy whilst under torque absorption. Thus, the holding torques to be achieved are already specified at a deflection of less than one angular second.

To date, this accuracy can only be resolved by a few high-end angle encoders available on the market. The accuracy achievable is higher than would be possible with an axis under closed-loop control. The increased rigidity and the better dissipation of oscillations and vibrations results in an improved milling pattern.

High dynamics and service life - advantages when used in combination with torque drives

When used in combination with highly dynamic torque drives the DKHS1000 series can show off the advantages of its fast closing time of less than 30 milliseconds. To put this into perspective closing times are almost 10 times faster than with pneumatic solutions. The short closing and opening times are achieved by the high preload of the housing in combination with the low absorption volume.

Based on extensive testing during development and in cooperation with early test customers, the B10d value is over 5 million cycles under application conditions. This service life, which exceeds that of the market, means that the DKHS1000 can be used for the majority of the entire "machine life" without replacement; this enables the greatest possible planning reliability and high system availability.

Innovative and proven active principles used beneficially

Combined with the large piston area, holding torques of up to 8,000 Nm can be achieved utilizing the preload of the housing material. The one-piece housing expands slightly in the elastic range under hydraulic pressure and releases the shaft connection and therefore the axis of rotation.

The preload also offers the customer an integrated emergency function, which ensures that moving components are held securely in the event of pressure loss or failure of the entire system.

Accuracy and holding torque for different requirements

The holding torques are specified in each case as a function of the stiffness at one angular second for use in machining processes and at five angular seconds for design under safety requirements.

To illustrate the achievable accuracy: One angular second, or arc second, describes the 3,600th part of a degree. It is equal to the angle that represents a drop of five millimeters over a lever arm of one kilometer. For the DKHS1460 size, this angular accuracy is maintained when under load of a full-grown racehorse over a lever arm of one meter, which corresponds to a holding torque of 6,000 Nm.

Novel condition query - added value via material stress

In line with the new principle of operation in the area of the rotary axes, the Zimmer Group offers a new condition monitoring option. A strain gauge is applied to the housing, which determines the material stress. This enables high-resolution and permanent status monitoring. In conjunction with the already short closing time, the cycle time is reduced to a minimum.

The choice between IO-Link or digital control enables simple and fast commissioning. For further simplification, PLC modules that are easy to implement are provided.