Tool Changers

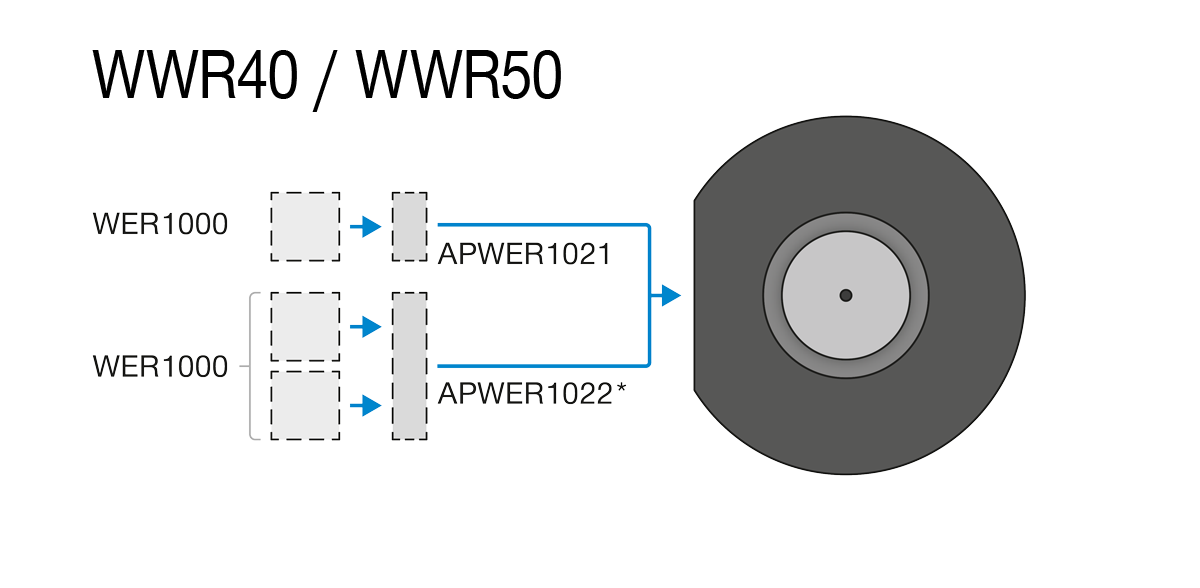

Series WWR

- Secure hold during pressure drop

The combination of spring loaded and a high gear ratio guarantees them a safe machine - Extremely flat design

This structure reduces the moment load for your robot to a minimum and makes it possible to use smaller and more affordable sizes - Inexhaustible variety of media transfer systems

No matter which medium you would like to transmit, we will draw from our wealth of experience in implementing projects and find a solution to suit your needs!

Installation Size: WWR40 | ||||

| Order-No. | Connecting flange according EN ISO 9409-1 | Pneumatic energy transfer | Flow per connector | |

|---|---|---|---|---|

| WWR40F-B | TK 40 | 4 [Quantity] | 150 [l/min] | |

| WWR40L-B | TK 40 | 4 [Quantity] | 150 [l/min] | |

Installation Size: WWR50 | ||||

| Order-No. | Connecting flange according EN ISO 9409-1 | Pneumatic energy transfer | Flow per connector | |

| WWR50F-B | TK 50 | 4 [Quantity] | 150 [l/min] | |

| WWR50L-B | TK 50 | 4 [Quantity] | 150 [l/min] | |

Installation Size: WWR63 | ||||

| Order-No. | Connecting flange according EN ISO 9409-1 | Pneumatic energy transfer | Flow per connector | |

| WWR63F-B | TK 63 | 6 [Quantity] | 170 [l/min] | |

| WWR63L-B | TK 63 | 6 [Quantity] | 170 [l/min] | |

Installation Size: WWR80 | ||||

| Order-No. | Connecting flange according EN ISO 9409-1 | Pneumatic energy transfer | Flow per connector | |

| WWR80F-B | TK 80 | 6 [Quantity] | 170 [l/min] | |

| WWR80L-B | TK 80 | 6 [Quantity] | 170 [l/min] | |

Installation Size: WWR100 | ||||

| Order-No. | Connecting flange according EN ISO 9409-1 | Pneumatic energy transfer | Flow per connector | |

| WWR100F-B | TK 100 | 6 [Quantity] | 330 [l/min] | |

| WWR100L-B | TK 100 | 6 [Quantity] | 330 [l/min] | |

Installation Size: WWR125 | ||||

| Order-No. | Connecting flange according EN ISO 9409-1 | Pneumatic energy transfer | Flow per connector | |

| WWR125F-B | TK 125 | 10 [Quantity] | 500 [l/min] | |

| WWR125L-B | TK 125 | 10 [Quantity] | 500 [l/min] | |

Installation Size: WWR160 | ||||

| Order-No. | Connecting flange according EN ISO 9409-1 | Pneumatic energy transfer | Flow per connector | |

| WWR160F-B | TK 160 | 10 [Quantity] | 500 [l/min] | |

| WWR160L-B | TK 160 | 10 [Quantity] | 500 [l/min] | |

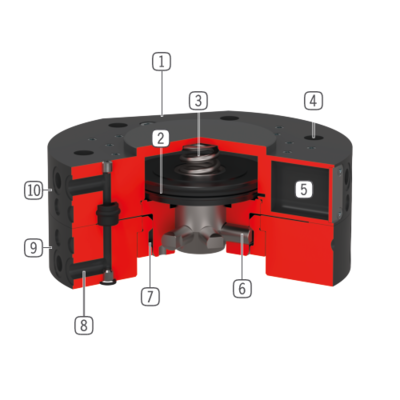

- Mounting for energy element

- Drive

double-acting pneumatic cylinder - Integrated spring

energy storage in case of drop in pressure - Robot flange

partial mounting circle in accordance with EN ISO 9409-1 - Piston position sensing

via magnetic field sensor - Locking bolt

adapted to the clamping sleeve - Locking sleeve

high moment capacity - Integrated air feed-through

Air / vaccum transfer hoseless control possible - Loose part

for tool side assembly - Fix part

For robot side assembly

*When using the APWER1022, the integrated air feed-through No. 4 on the tool changer is not available.