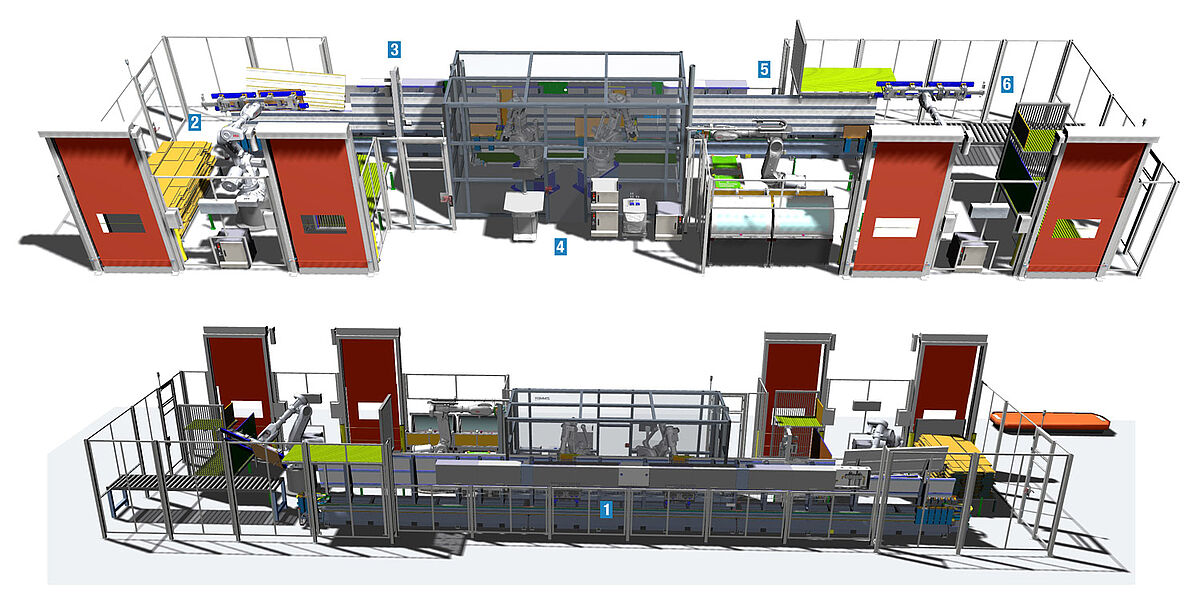

Body processing / lot size 1

Product advantages:

- Highly flexible single-quantity system for machining furniture parts

- Machining of coated chipboards and MDF boards with dimensions from 240 mm x 120 mm up to 2800 mm x 1300 mm

- Output requirement of more than 600 parts per shift

- Highly flexible shuttle circulation as workpiece transport and clamping system

- Precision-compensated industrial robots for drilling machining and metal fitting

- Direct integration into the customer's machining control system for flexible processing of the production lot

- Automatic loading and unloading with direct connection of customer-side AGV

1 Base machine with modular transport system

2 Loading module

3 Measurement module

4 Machining module

5 Metal fitting module

6 Unloading module

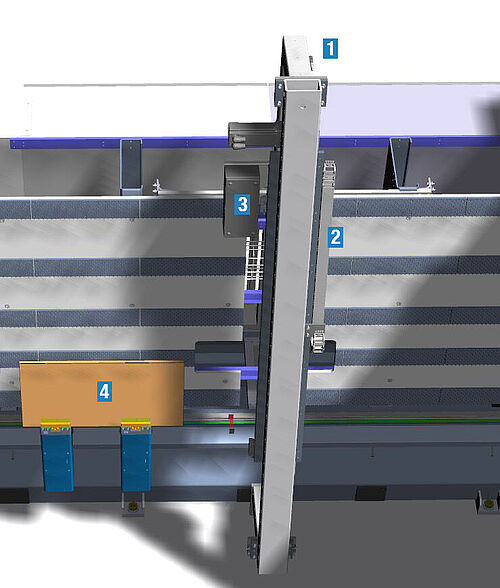

Modular transport system

Product advantages:

- Flexible transport system consisting of a machine bed with linear guides and toothed racks, rotational transfer units, intelligent movement units (shuttles), control system and user interface

- High positioning accuracy and high load and load carrying capacity in the direction of movement

- Scalable system in terms of the length of circulation and the number of shuttles

- Shuttle position, speed and acceleration can be programmed independently

- Dynamic configuration of groups with flexible control of all shuttles as master or slave

1 Linear guides for absorbing weight and machining forces

2 Optimized rack-and-pinion drive for the highest requirements on linear drive systems

3 Transfer of electrical energy and information (CAN bus) via sliding contacts

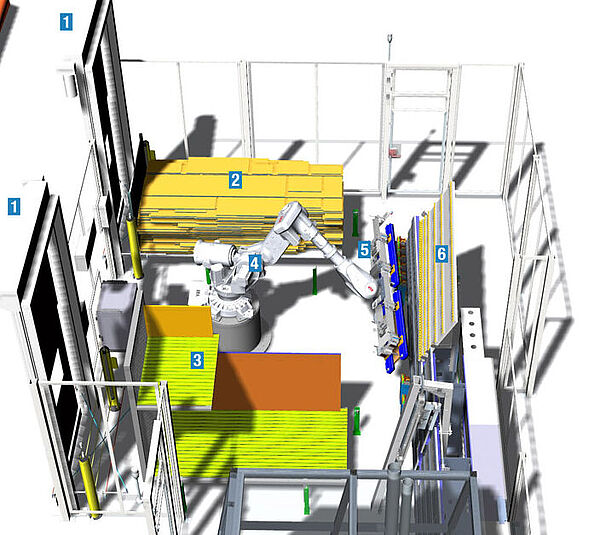

Loading module

Product advantages:

- Main time parallel feed of two independent storage positions via AGV with muting function

- 6-arm robot with independently activated 4x suction traverse

- Lane-by-lane loading from the new parts stack and individual loading from the tray trolley

- Reading in the stack data without labels directly via the customer's machining control system

- Alignment and separation via an alignment station with a plausibility check

- Supply and positioning of the shuttles depending on the part size

1 High-speed doors with muting function for automatic feed via an AGV

2 Workpiece supply as a stack

3 Workpiece supply as a stack in the tray trolley for rear side machining

4 Loading robot

5 Suction traverse for lane-by-lane loading

6 Alignment station

Measurement module

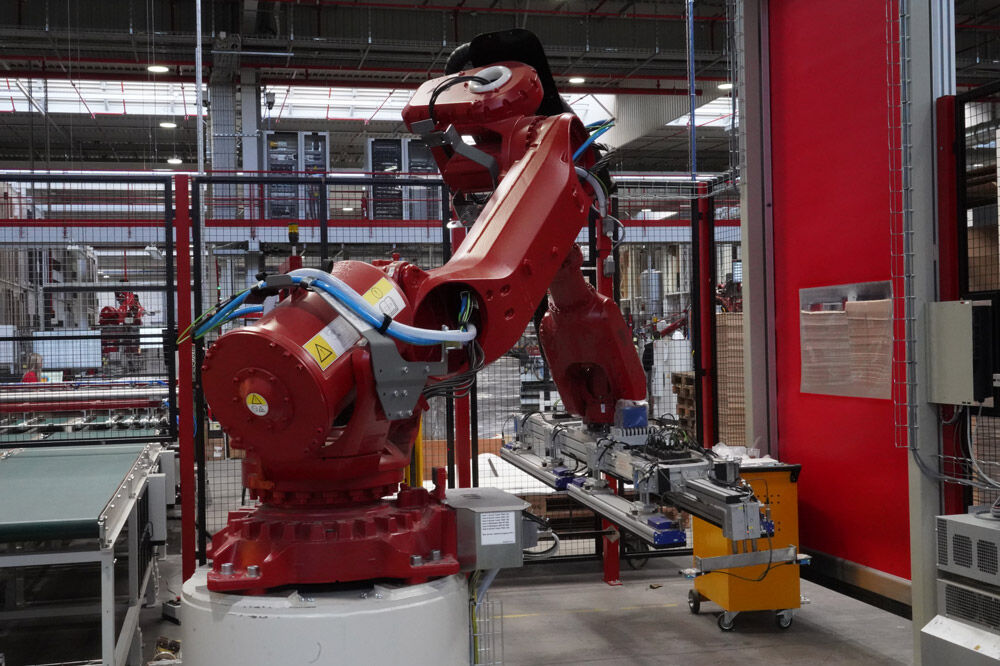

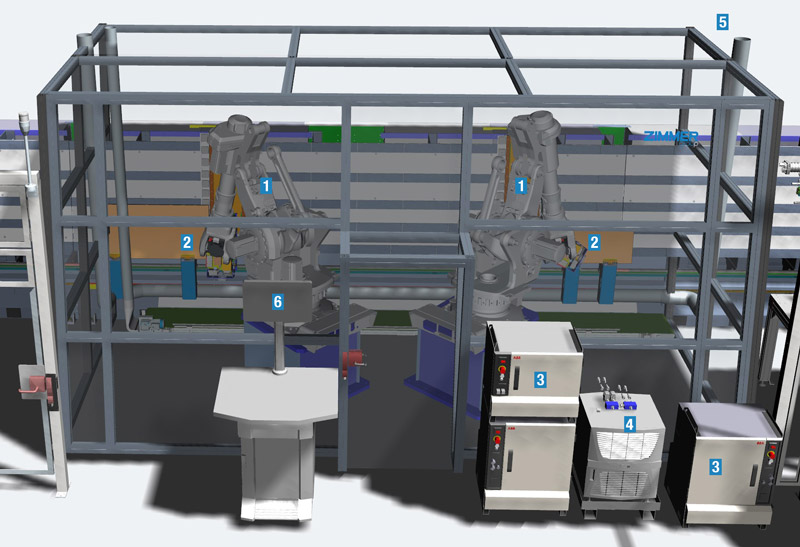

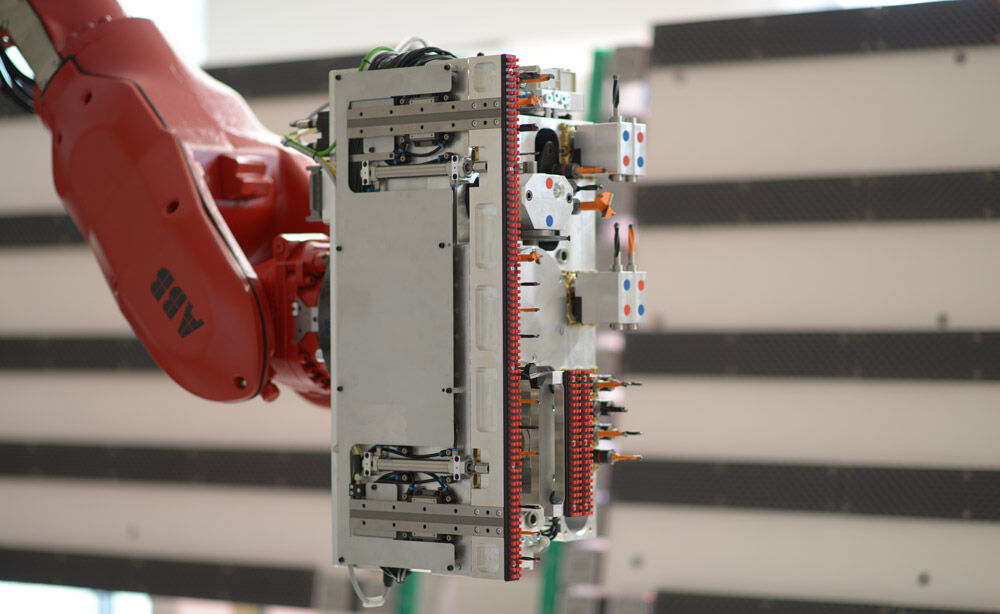

Machining module

Product advantages:

- Machining by two accuracy-compensated ABB machining robots and multi-function heads with individually extensible machining units

- Execution of all necessary machining functions: Grooving, milling, Clamex milling, horizontal and vertical drilling machining, drilling rows of holes

- Dynamic split of machining to both machining robots by upstream drilling optimization unit to optimize performance

1 ABB machining robot

2 Machining head

3 Robot control system

4 Spindle cooling system

5 Protective cabinet with suction system

6 Control terminal

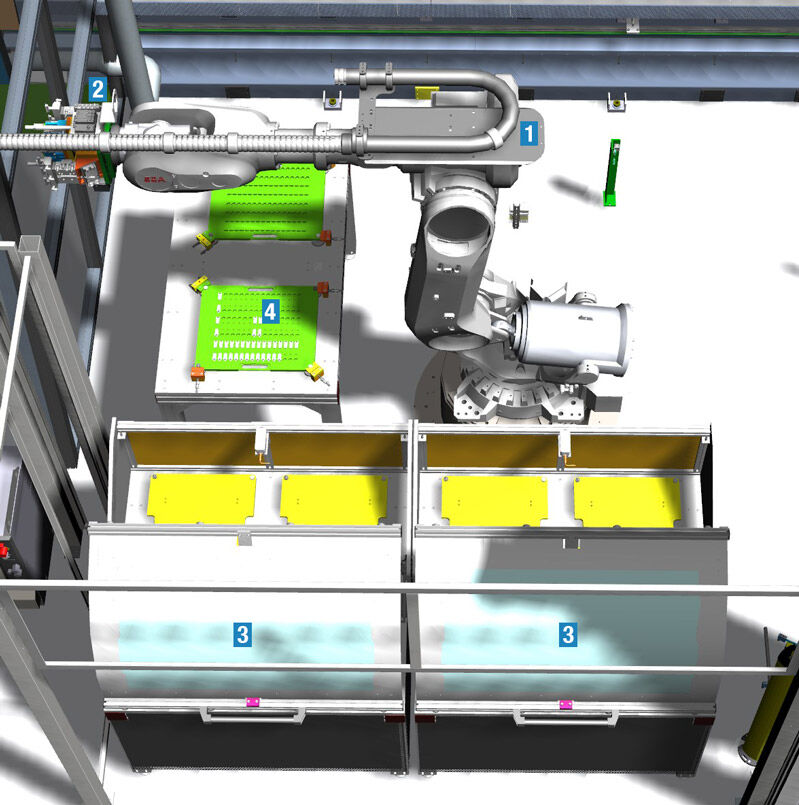

Metal fitting module

Product advantages:

- Program-controlled setting of various fitting types by a robot with multiple metal fitting head

- Manual feeding of fittings on stackable trays in transfer station

- Fittings supplied by the robot by positioning the trays in an alignment station

1 Machining robot

2 Metal fitting head

3 Feeding station for fittings

4 Alignment and supply station

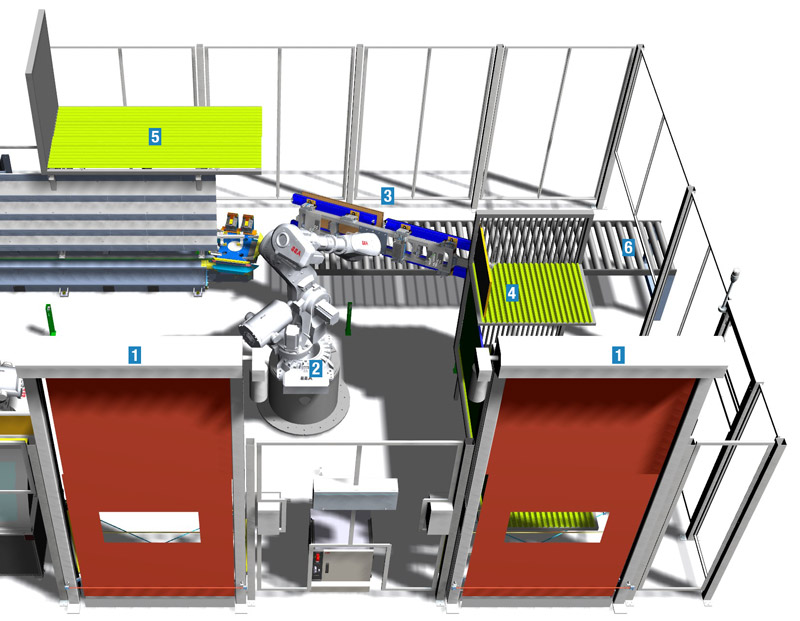

Unloading module

Product advantages:

- Fully automated unloading by 6-arm robot with independently activated 4x suction traverse

- Dynamic prioritization of workpiece placement on the conveyor line, tray trolley or buffer store

- Main time parallel collection of the tray trolleys via AGV with muting function

1 High-speed doors with muting function for automatic workpiece transport via an AGV

2 Unloading robot

3 Suction traverse

4 Tray trolley for storing parts for rear side machining

5 Intermediate buffer

6 Roller conveyor for workpiece transport

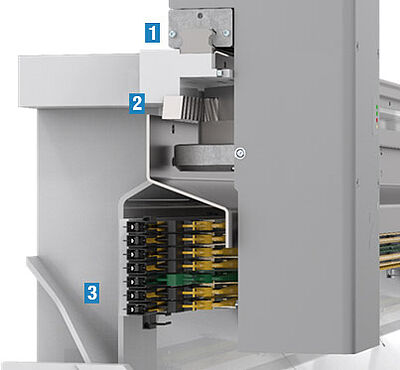

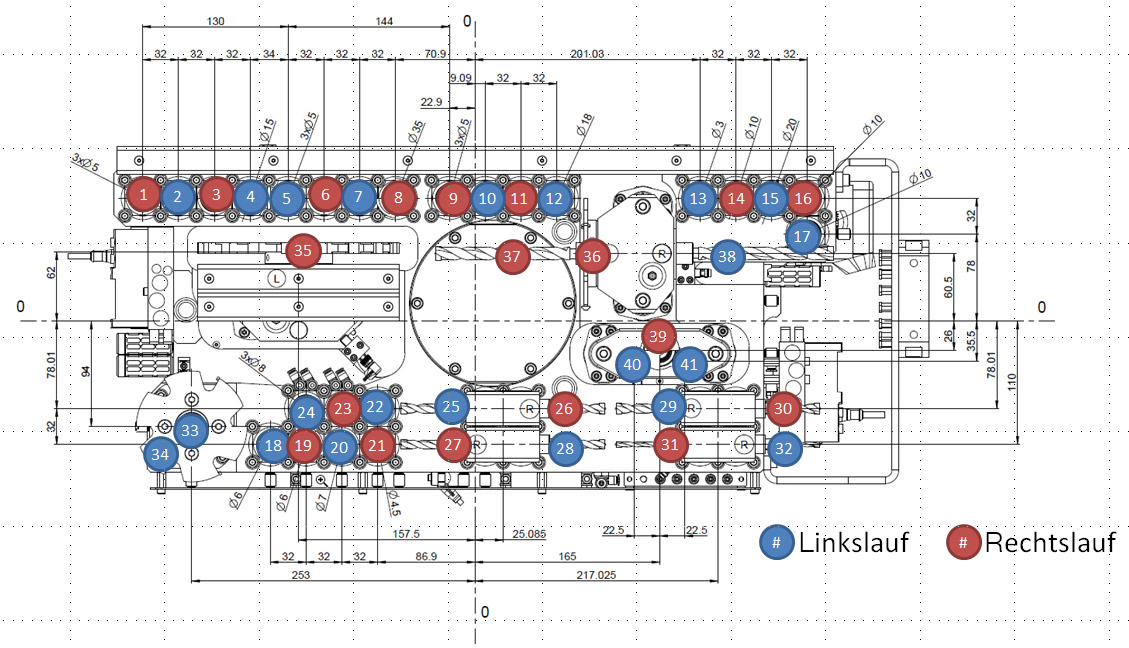

Machining head

Product advantages:

- Modular multi-function head for implementing the various functions on the machining module

- Project-specific design of the multi-function head for minimum space requirement and tool exchange effort

- Drill gears for individual/series drilling

1-24 Vertical drill spindles with quick-action chuck

25-31 Horizontal drill spindles with Weldon tool holder

33 End mill

34 Clamex, vertical

35 Grooving saw

36 Clamex, horizontal

37-38 Foot drill

39-41 Hinge drilling unit