METAL PROCESSING AT THE HIGHEST LEVEL

TEQQ relies on Zimmer Group grippers

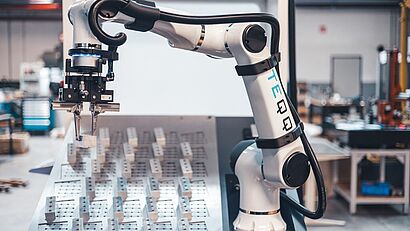

This is exactly what the Dutch company TEQQ International promises with its latest cobot. Alex Evers (son of founder Hans Evers) recently became the owner of TEQQ. Here, everything revolves around the complete relief of the customer through automation. When it comes to metalworking, TEQQ has the solution. An interview with Alex Evers about the advantages of TEQQ's cobots and the role played by Zimmer Group grippers.

Mr. Evers, could you start by telling us something about TEQQ and what your mission is?

There are about 10 of us here. What I like best is that we work with people who have a lot of expertise in-house. So we work with engineers, with different people for the software, we have someone for printing and a designer. We also have regular exchanges with my father, even though he's officially retired! To put it briefly, we make automation for the machining industry. Normally, there is a CNC machine and then there is also staff in front of the machine to switch the product on and off. We use a robot or one of our automation systems to ensure that this is done fully automatically. As a result, more spindle hours can be worked and production can also take place in the evening, for example. We actually ensure that employees can be deployed more effectively and that production can run for longer.

You have now developed two cobots. Can you tell us a little about them?

Our two cobots are almost identical. The biggest difference is actually the gripper and the housing. One cobot is ideal for milling lathes. Square products are usually processed here, so there is a parallel gripper. Our other cobot is for round products in lathes, with a three-point gripper. Both grippers are of course from the Zimmer Group.

What makes TEQQ's cobots so special?

We mainly focus on relieving the customer. If special or complicated products need to be processed or just a little more care is required, we can help and think along with them. That's also what makes our work so interesting, it's really about technology. This allows us to customize the cobot for the customer.

When people read this and think: "I want to do something with it too." Why should people contact you?

We are very versatile and specialists when it comes to almost all automation in CNC machine factories. We have a lot of expertise in-house, so we can really take the pressure off our customers. As a result, the customer can achieve more, more spindle hours can be run and therefore much more can be produced!

Do you have an application or product that you are particularly proud of?

Well, of course I am very proud of the Cobot as it is. Proud of what it can do, but also really proud of how it looks. And I'm also really proud of some of the customized solutions. Especially when they come up with a difficult product and we succeed and we think during the project: Yes, this will work!

The Zimmer Group and TEQQ have been working together for a long time, for around 15 years. Do you have a particular reason for this?

I have grown into it, so to speak. I took over the company from my father, who had been working for the Zimmer Group for over 10 years. I took a critical look at what I wanted and what I didn't want and why I would do business with the Zimmer Group. Again, there were competitors at the table, but we are simply very happy with our collaboration! I am a mechanical engineer and simply see the differences to the competition. For example, in the design, with the steel-on-steel guide, as the Zimmer Group has with the parallel and three-point grippers of the 5000 series. I think it's simply groundbreakingly different. It's a smart design, it looks very nice, the specifications are good and the weight is good too. Then there's the high force per kilogram. I also really like the color, this deep black, which together with the white and the color of the stainless steel looks great on our robot.

What do you like about working with the Zimmer Group?

The speed and the fact that our contact person Jeroen is always easy to reach. I call him, explain the problem and he solves it immediately. Sometimes even within a day. That is very valuable for us.

Would you recommend Zimmer to others?

Definitely! Actually for two reasons: high-quality products and a very pleasant working relationship. These are very important points. To say it in Brabantian: 't is mooi! (It's wonderful!)

-------------------------------------------

The grippers in the 5000 series impress with their extremely robust design with hard-coated steel-in-steel groove guidance. Their high speed, gripping force and long gripper jaw length make them suitable for universal use. You can find more information about the gripper series here.