Tool changers

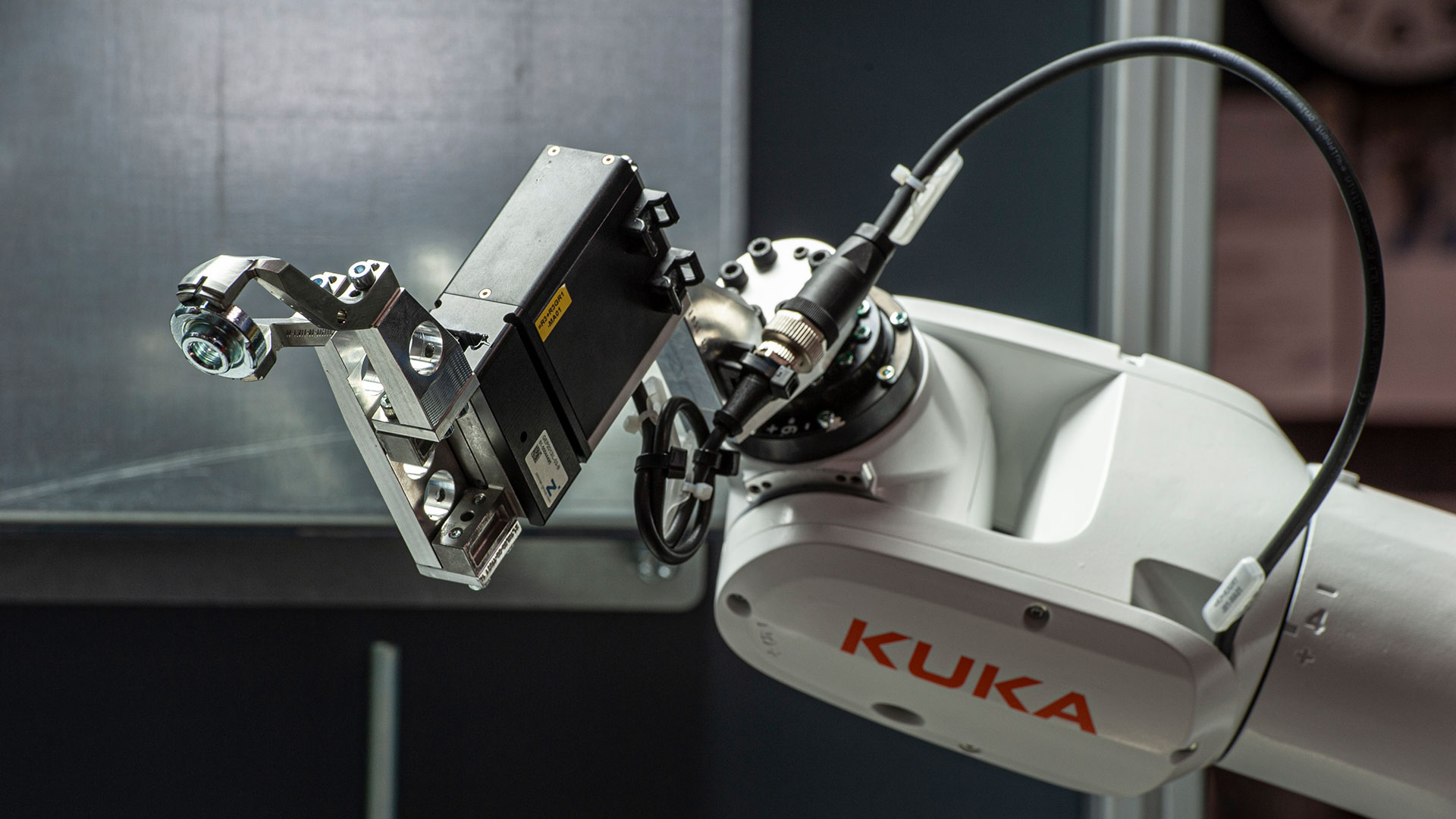

Our tool changers offer you the perfect solution to maximize the flexibility and productivity of your manufacturing processes. Designed for maximum precision and durability, they allow you to change between different tools quickly and safely. From compact systems to highly complex models for industrial applications – we have the right tool changer specifically for your requirements. Browse through our selection and discover the variety of our innovative products that will make your production processes more efficient and increase your competitive edge.

Technology highlight: Tool changers

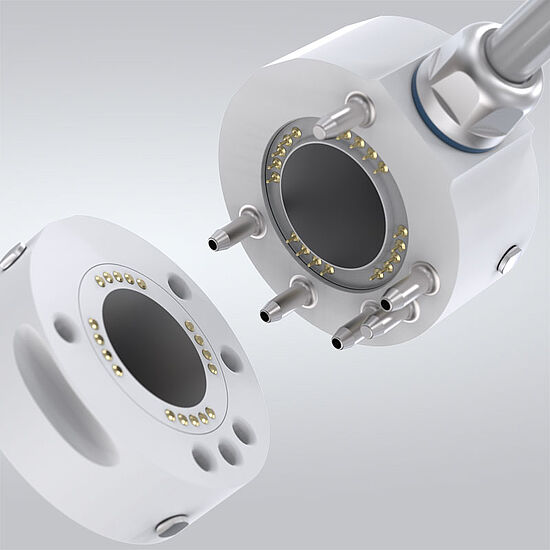

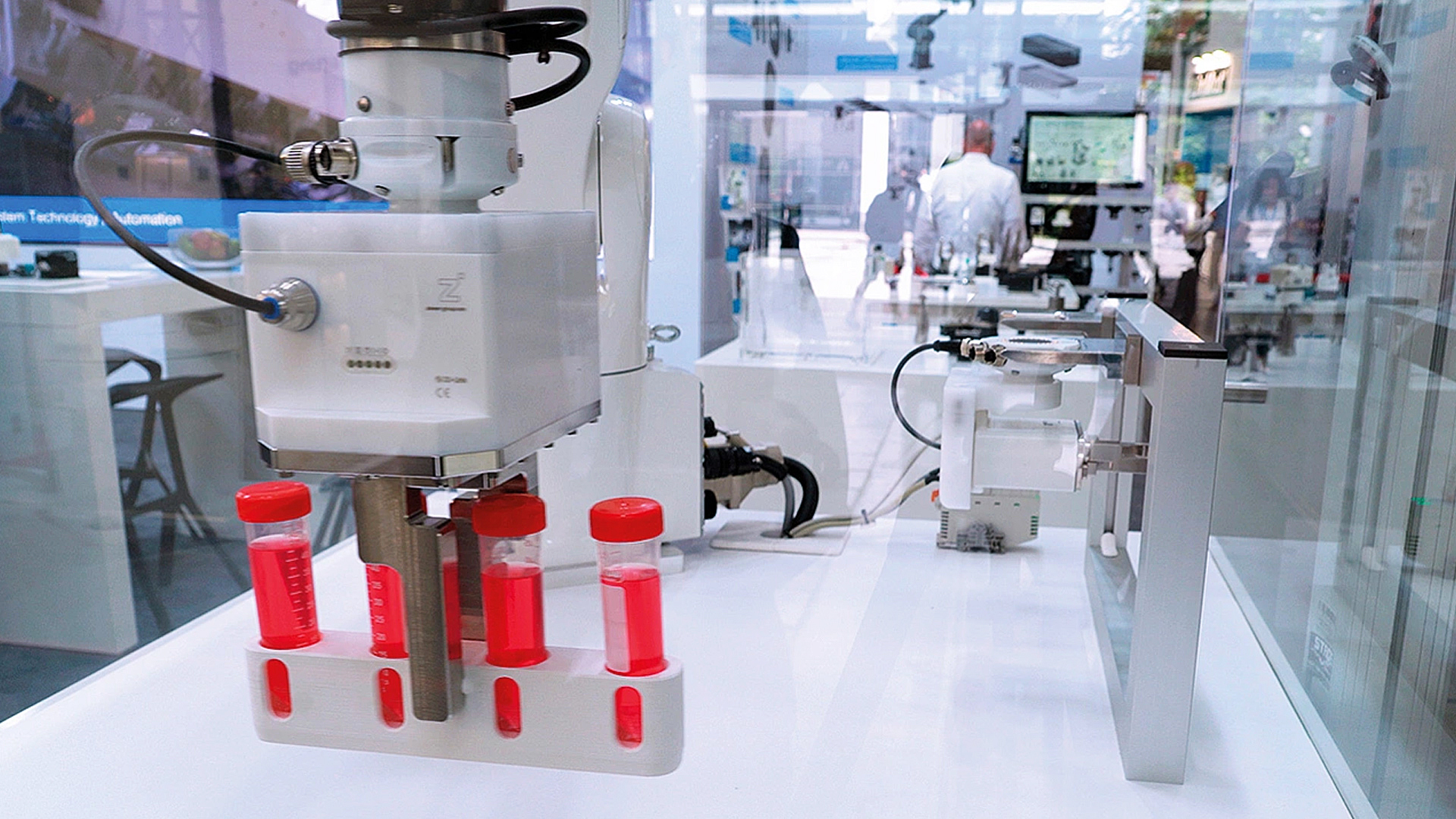

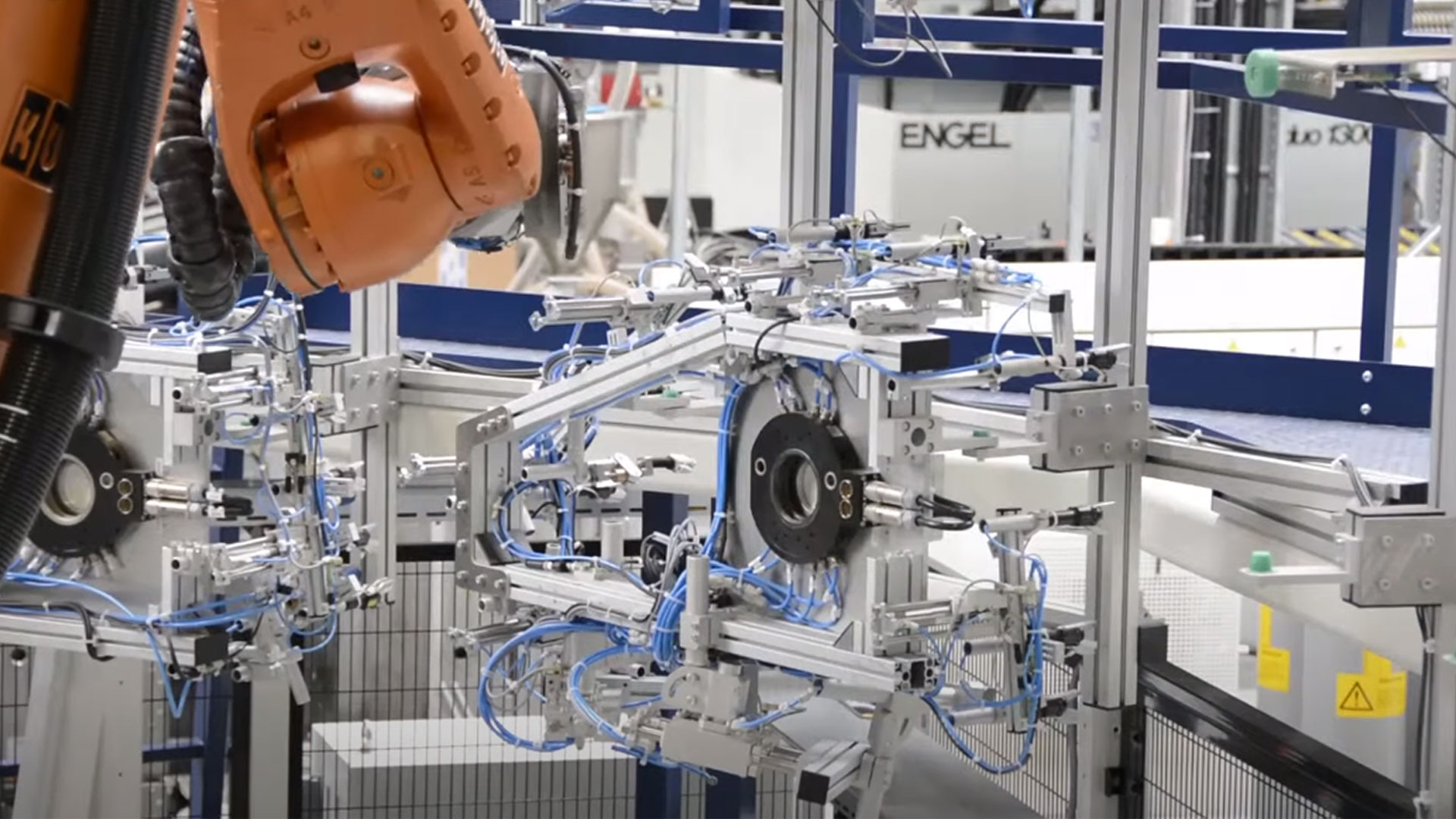

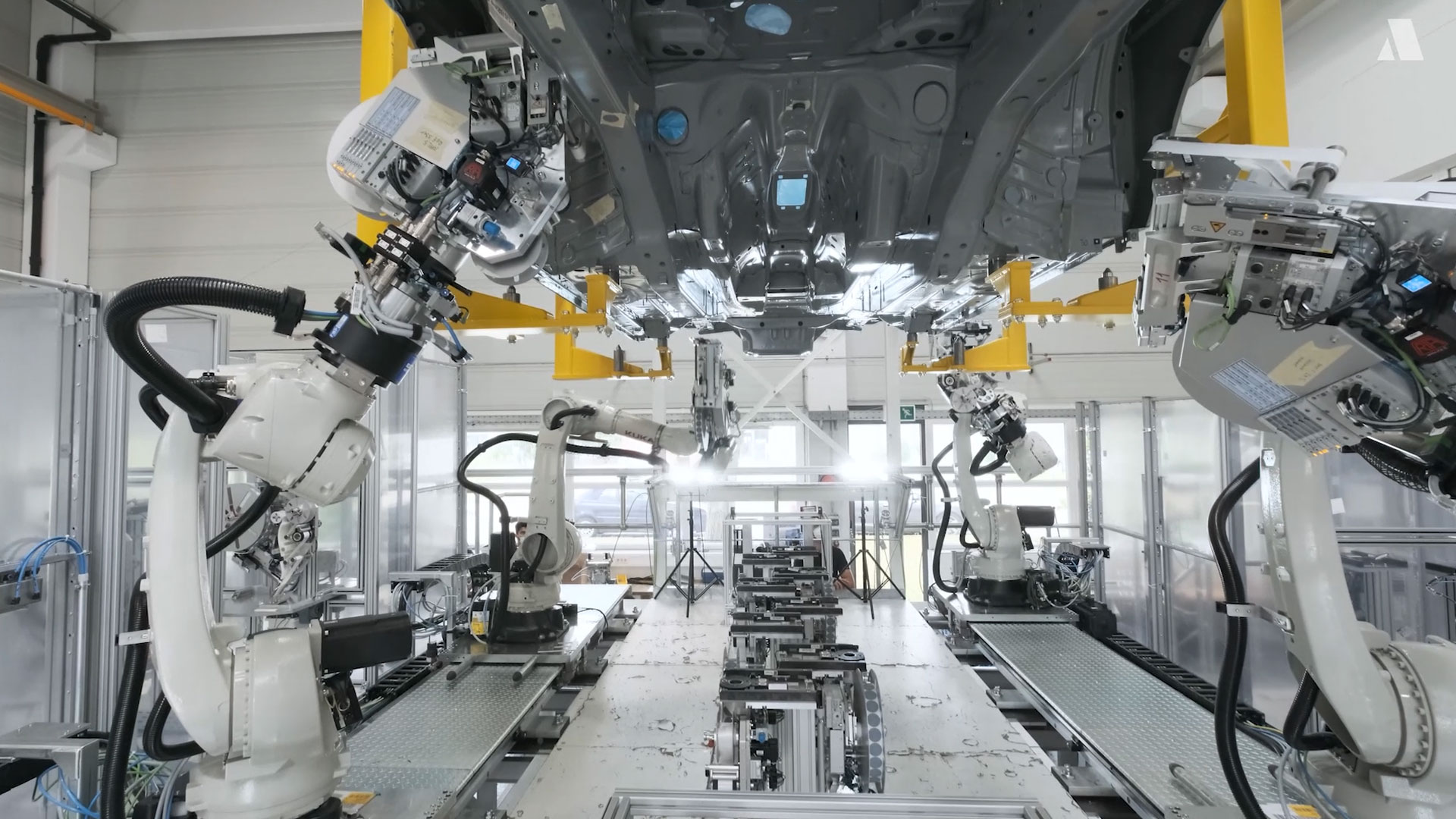

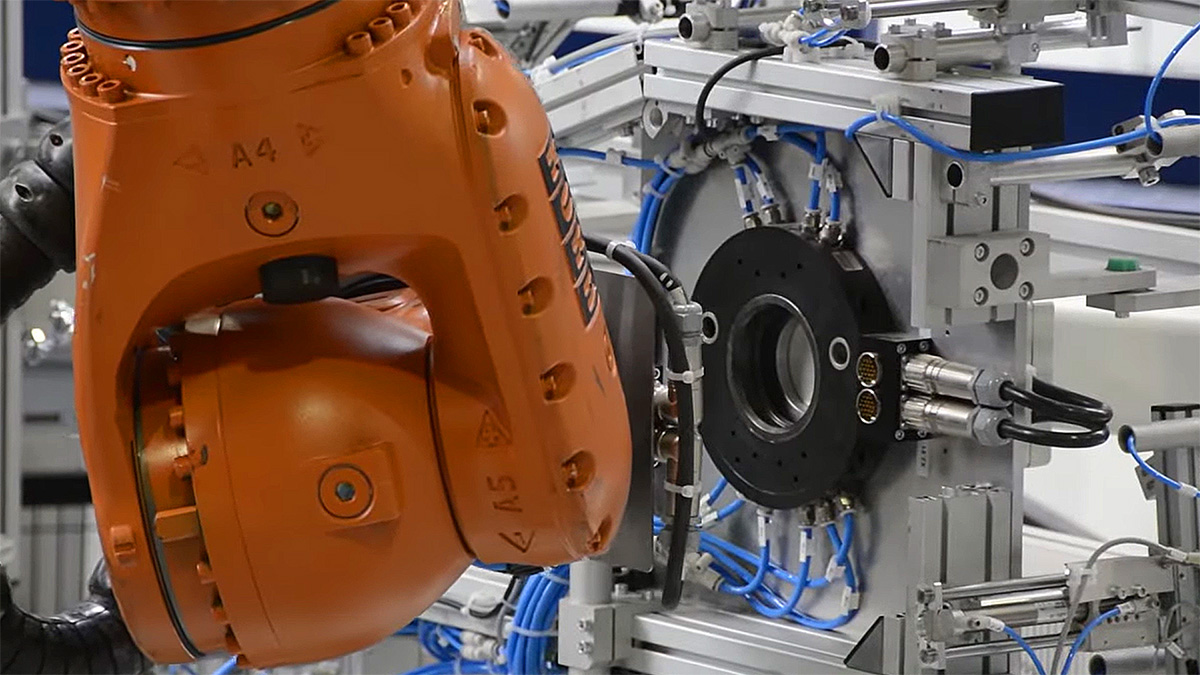

Tool changers are used to change tools in automated and manual processes safely. They consist of two main components: the stationary part, which is permanently attached to the robot or portal, and the loose part, which is attached to the tool. Both parts work together precisely to ensure that changeovers are efficient and reliable.

Manual or automatic change

The choice is up to you!

Manual

HWR2000 and HWR series

- Tools are changed manually by employees, e.g. with an integrated locking lever or an Allen key

- Change possible within seconds

- Ideal for applications with less frequent changes

Magnetic

WMR2000 series

- Permanent electromagnet for a secure hold

- Specially developed, sealed spring pins for secure signal transmission

- Thanks to cleanroom certification, particularly suitable for clean applications and cleanroom applications

Automatic

FWR series

- Manual and automatic change possible

- Manual change using side operating elements, without additional aids such as an Allen key

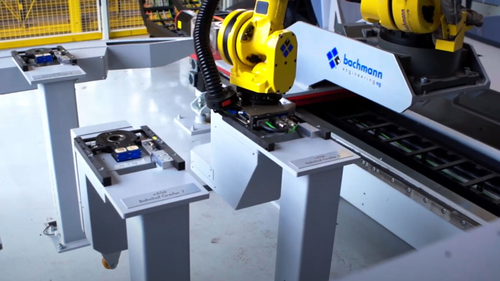

- Can be used passively, e.g. with storage stations

- No additional actuator required

Pneumatic

WPR5000 and WWR1000 series

- Fully automated changeover process

- Uses double-acting, spring-loaded pneumatic pistons for higher forces and handling weights

- Particularly suitable for fast changes and demanding applications

- Maximum safety thanks to mechanical self-locking

TIP: Use our product filter to find the right tool changer for your requirements!

TOOL CHANGERS FROM THE ZIMMER GROUP

Our expertise – your advantages:

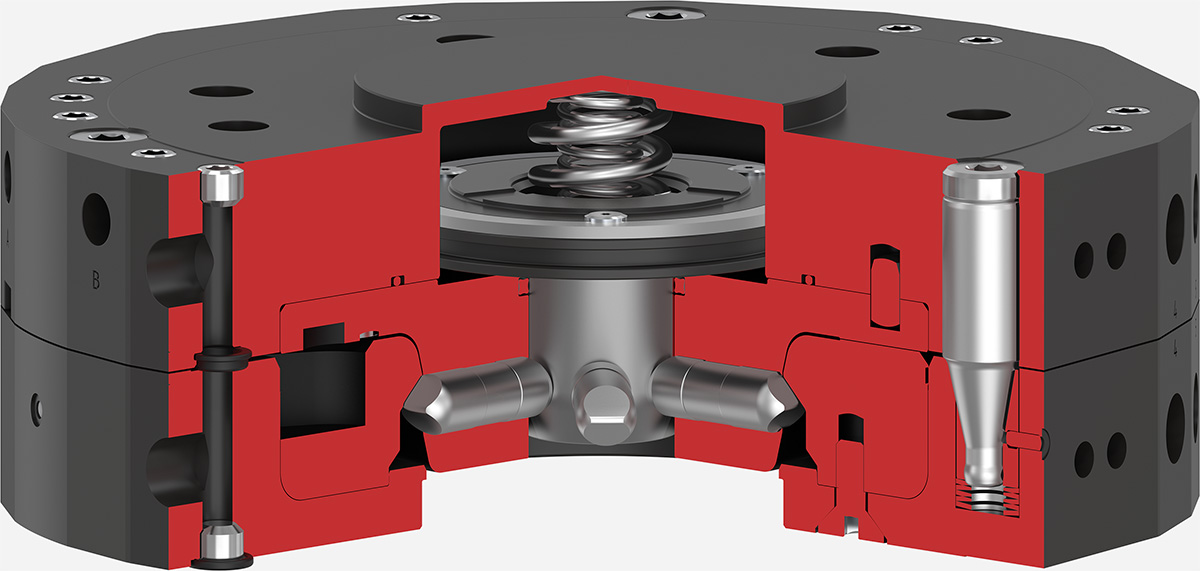

- Secure hold during a pressure drop: A redundant system, created by the combination of a spring accumulator and a self-locking mechanism, guarantees you maximum safety

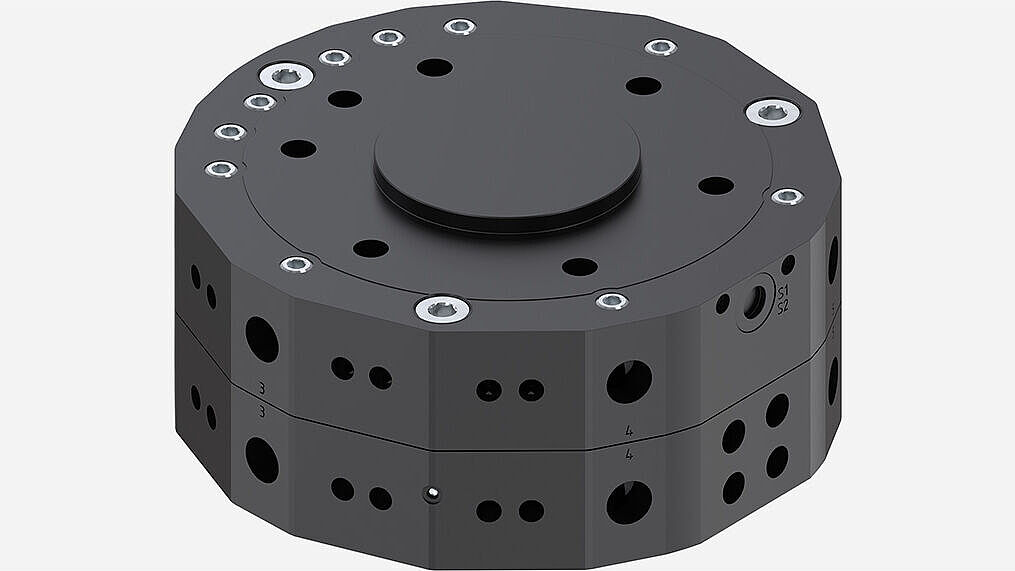

- Extremely flat design: This structure reduces the torque load for your robot to a minimum and makes it possible to use smaller and more affordable sizes.

- Endless variety of media transmitters: No matter which medium you would like to transmit, we will draw from our wealth of experience in implementing projects and find a solution to suit your needs

Standardized

The overall height reduces the load capacity of your robot. That is why our robot components are extremely flat and can be combined with each other without extra adapter plates. Direct mounting onto the robot is done with the mounting flange in accordance with EN ISO 9409-1.

Safe

Production reliability is our top priority, which is why our tool changers offer you maximum reliability. The optionally available piston position monitoring and optional loose part monitoring contribute to this, as do the springs installed to maintain force in emergency stop situations and the extremely robust locking bolts with line contact.

Focus: The importance of tool changers

Tool changers play a decisive role in robot technology. Find out more here about the background and why tool changers should not be underestimated as a key element in full automation.

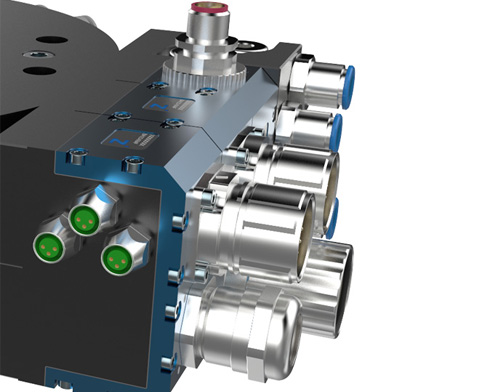

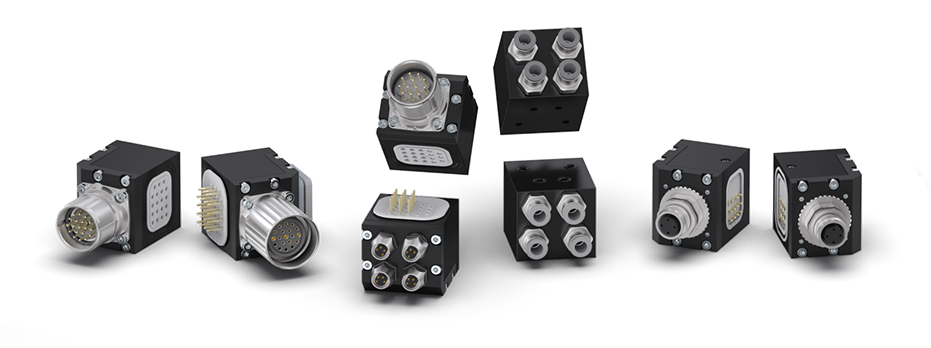

Suitable for every tool changer: Our energy elements

Tool changers are highly complex systems that create more than just a mechanical connection. Our energy elements enable the reliable transmission of pneumatics, vacuum, signal and load current, communication, fluidics and much more, allowing us to implement any application.

Discover our comprehensive selection and find the perfect solution for your application.

Versatile

Do you want to custom-build your system and have freedom in media transmission? Working with us allows you to select from a wide variety of standardized energy elements. We would also be happy to develop a customized solution for you.

FAQ – Questions and answers on the topic of tool changers

A tool changer allows tools to be changed automatically or manually on robots, portals or systems. It significantly increases flexibility and efficiency in automated production processes.

The Zimmer Group offers various series:

- Manual tool changers (e.g. HWR series and HWR2000 series)

- Pneumatic tool changers (e.g. WPR5000 series and WWR1000 series)

- Automatic tool changers (e.g. FWR series)

- Magnetic tool changers (e.g. WMR2000 series)

The Zimmer Group offers a wide range of standardized energy elements for:

- Pneumatics/vacuum

- Electrical signals and load

- Hydraulics, coolants or other fluids

- Communication such as IO-Link, bus systems

- As well as many others on request or customized

Yes, the Zimmer Group also offers standardized storage stations for automated changeovers. The matching storage station is listed as an accessory with the respective tool changer.

As with all robot technology components, installation is carried out directly with the standardized robot flange in accordance with EN ISO 9409-1.