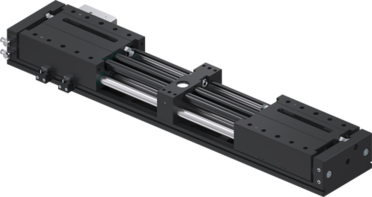

GPH84220N-00-A

2-Jaw Parallel Grippers with Long Stroke

Series GPH8000

"The powerful"

- Extremely long and heavy gripper fingers possible

Despite their flat structural design, one of the features of the gripper fingers is that there are virtually no limitations where it comes to loading the machine with engine blocks or rims. - Synchronous, asynchronous and securing the workpiece

Select between synchronous or asynchronous gripper finger movement and increase process safety by using the integrated clamping element to secure the workpiece in the event of a drop in pressure - Dirt protection

Using the scrapers on the guides, you can reliably use the gripper even under the harshest conditions

Technical Data

| Stroke per jaw | 220 [mm] |

| Gripping force in closing / opening | 3300 / 3300 [N] |

| Gripper jaws are synchronized | Yes |

| Closing time | 2.5 [s] |

| Opening time | 2.5 [s] |

| Dead weight of mounted gripper finger max. | 45 [kg] |

| Length of the gripper fingers max. | 900 [mm] |

| Repetition accuracy +/- | 0.05 [mm] |

| Operating pressure | 4 ... 8 [bar] |

| Nominal operating pressure | 6 [bar] |

| Operating temperature | +5 ... +80 [°C] |

| Air volume per cycle | 3500 [cm³] |

| Protection to IEC 60529 | IP54 |

| Weight | 48 [kg] |

Accessory

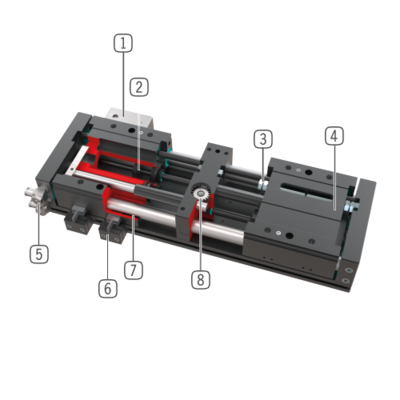

Benefits in detail

- Clamping element

Workpiece secured in the event of a drop in pressure - Drive

two double-acting pneumatic cylinders - Stroke adjustment

possible on both sides via stroke adjustment screws - Gripper jaw

individual gripper finger mounting - Energy supply

possible from several sides CAUTION: always operate long stroke gripper with supplied exhaust air flow control valve (speed regulation) - Mounting block

mounting for inductive proximity switch - Roller slide

sealed round guide for harsh environmental conditions Maintenance-free plain bearing bushes - Synchronization

By means of gear and rack Encapsulated and protected against dirt Also available as an asynchronous variant