Linear Cylinders

Series LI

- Large locating flange

The large mounting surface simplifies your design and allows secure attachment of follow-on tools - Dampened end position

By using PowerStop shock absorbers, you can gently move up to the end positions, increasing the process reliability and durability of your application - Failure-free continuous operation

Our uncompromising "Made in Germany" quality guarantees up to 10 million maintenance-free cycles

Series features

10 million maintenance-free cycles (max.)

10 million maintenance-free cycles (max.) Elastomer end position damping

Elastomer end position damping Powerstop end position damping

Powerstop end position damping IP54

IP54 Inductive sensor

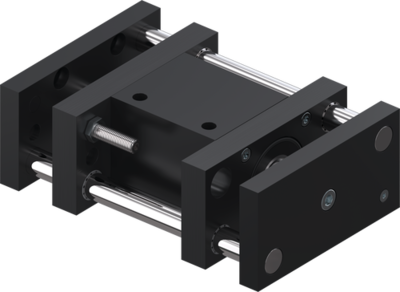

Inductive sensor- Continuous piston rod

- 2 way guiding

- 3 way guiding

- Guide rod

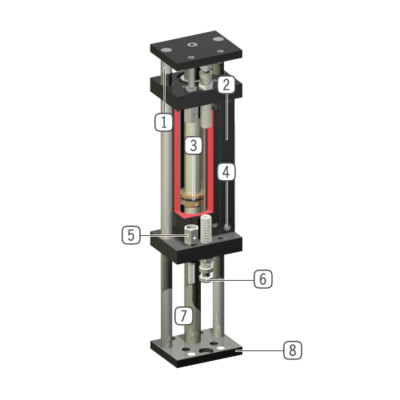

hardened, polished steel shaft - Mounting block

mounting for inductive proximity switch - Drive

double-acting pneumatic cylinder - Energy supply

reducing exhaust air is recommended - End stop confirmation screw

direct flange position sensing included in scope of delivery - End position damping

with elastomer absorber or patented hydraulic shock absorber - Piston rod

polished, hard chrome plated steel continuous in design D - Intake flange

for connection to application-specific adapter plate (to be supplied by the customer)