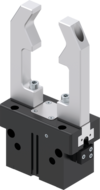

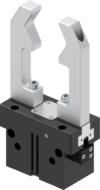

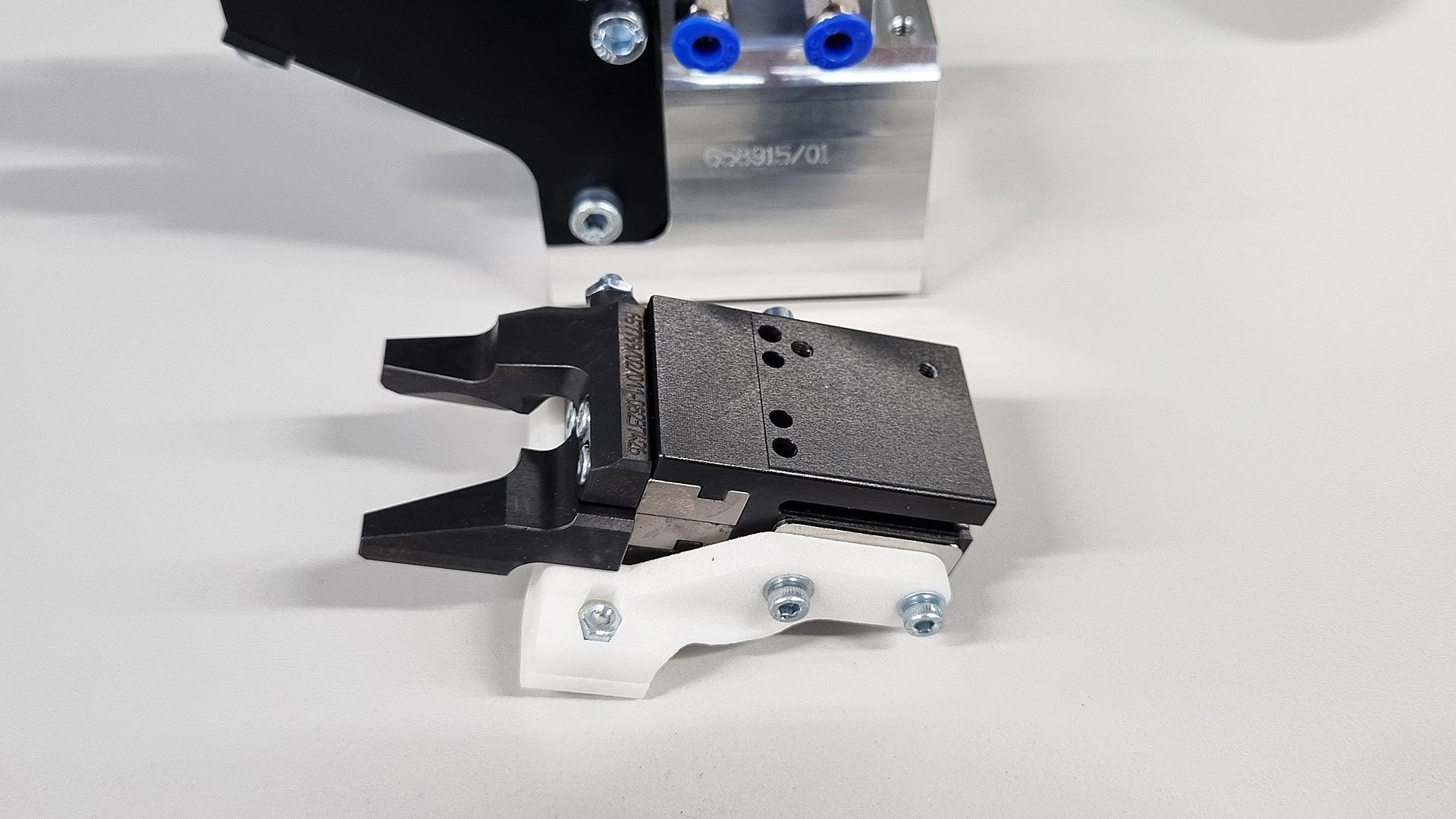

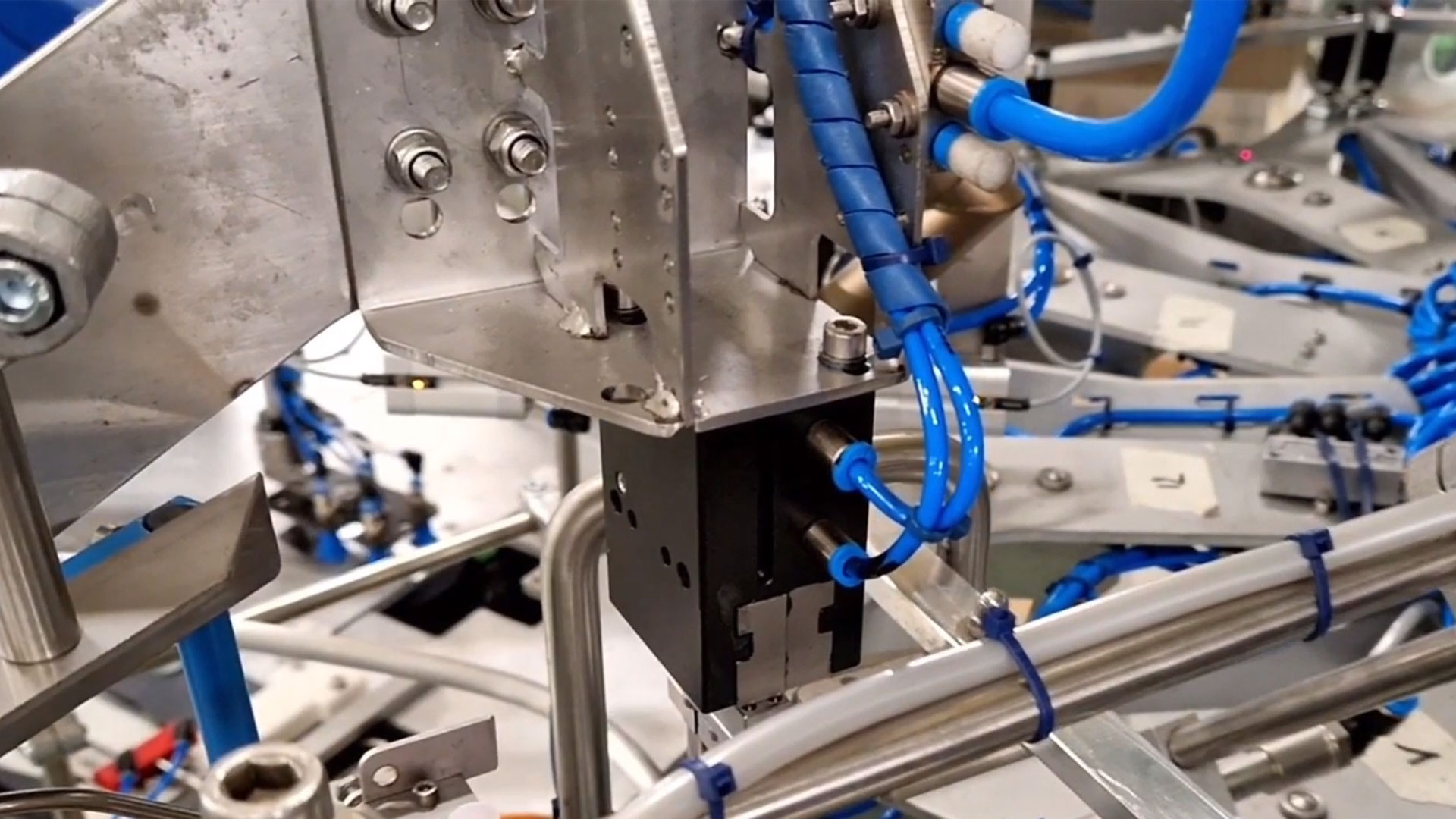

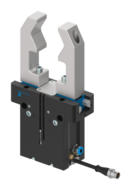

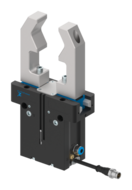

2-JAW PARALLEL GRIPPERS

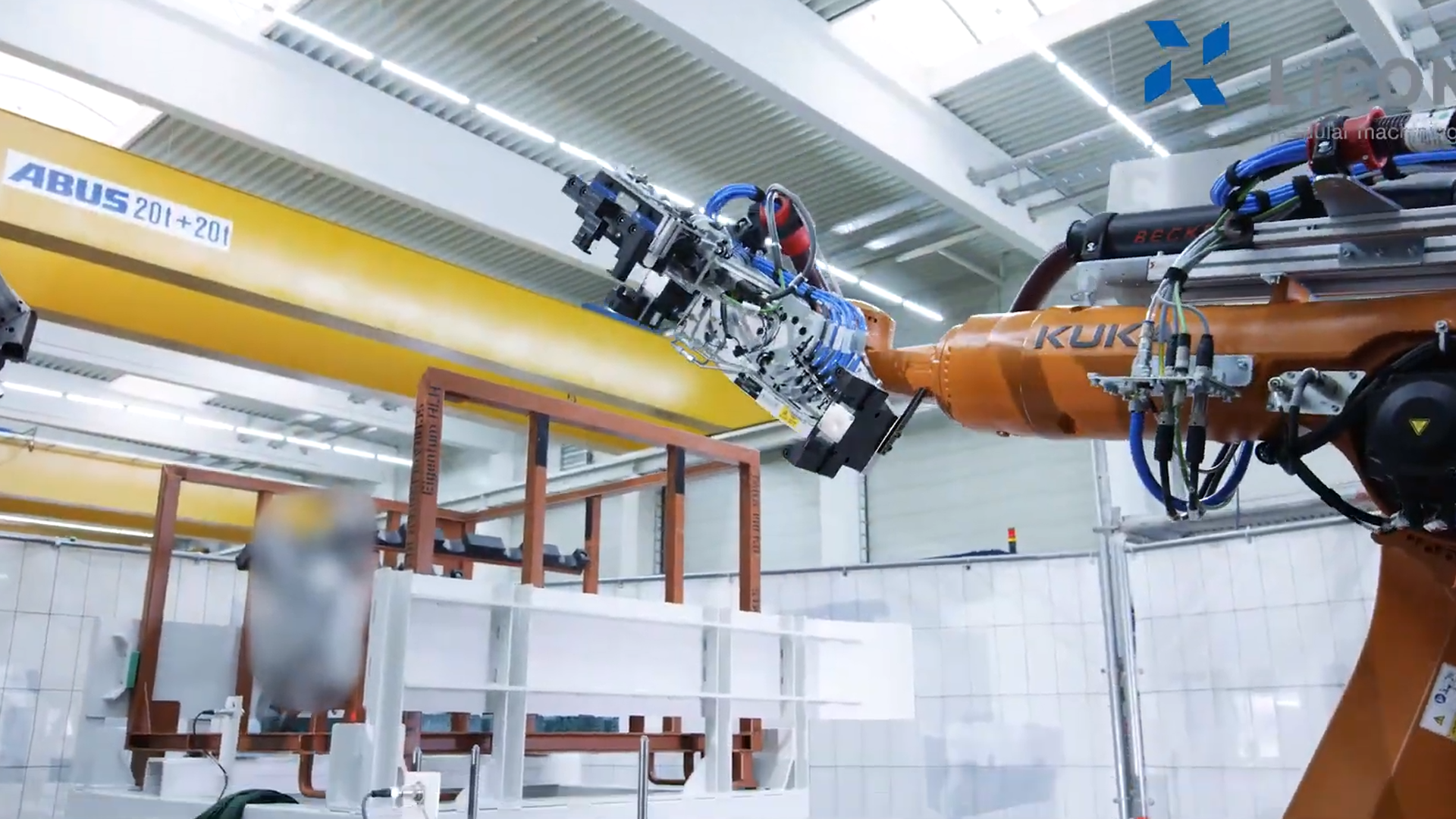

The 2-jaw parallel gripper is a versatile gripping solution for automation and handling technology. With its two gripper jaws, it enables precise gripping, holding and positioning of workpieces of different shapes and sizes. Discover our high-quality 2-jaw parallel grippers and find the right solution for your requirements.

2-Jaw Parallel Grippers with Long Stroke

Series GEH6000IL

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

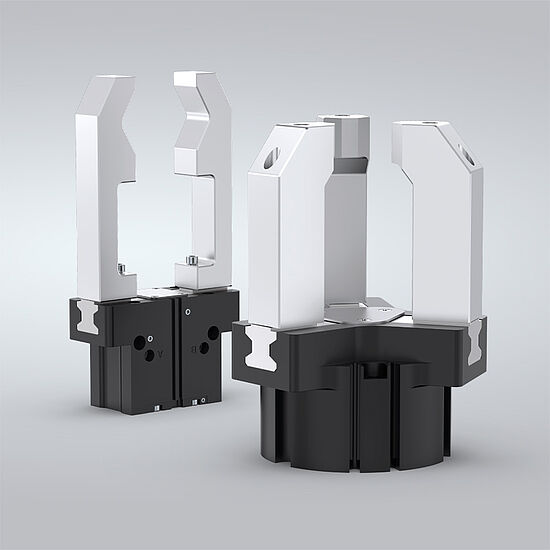

2-Jaw Parallel Grippers with Long Stroke

Series GH6000

2-Jaw Parallel Grippers with Long Stroke

Series GEH6000IL

2-Jaw Parallel Grippers

Series GEP2000

2-Jaw Parallel Grippers

Series GEP2000

2-Jaw Parallel Grippers

Series GP400

- High gripping force as a result of optimal direction change of driving force into gripping force

- High gripping force as a result of optimal direction change of driving force into gripping force

2-Jaw Parallel Grippers

Series GEP2000

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GEP5000

- Approximately the same gripping force as a comparable pneumatic gripper

- Self locking mechanism in case of power drop

- Same connection hole patterns as a comparable pneumatic gripper

- Approximately the same gripping force as a comparable pneumatic gripper

- Self locking mechanism in case of power drop

- Same connection hole patterns as a comparable pneumatic gripper

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GEP2000

2-Jaw Parallel Grippers

Series GEP2000

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

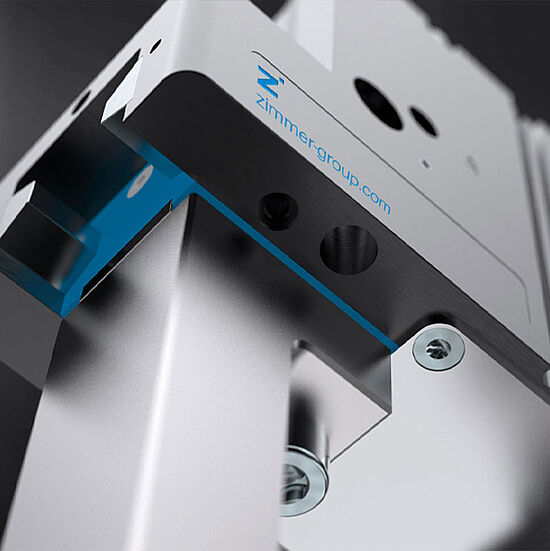

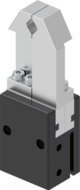

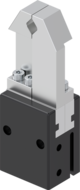

2-Jaw Parallel Grippers

Series MGP800

- Integrated position sensing for compact design and to minimized the interfering contour

- Gripper jaws made of ground surfaced and hardened steel ensure precision and a long durability

- Integrated position sensing for compact design and to minimized the interfering contour

- Gripper jaws made of ground surfaced and hardened steel ensure precision and a long durability

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GEP2000

2-Jaw Parallel Grippers

Series MGP800

- Integrated position sensing for compact design and to minimized the interfering contour

- Gripper jaws made of ground surfaced and hardened steel ensure precision and a long durability

- Integrated position sensing for compact design and to minimized the interfering contour

- Gripper jaws made of ground surfaced and hardened steel ensure precision and a long durability

2-Jaw Parallel Grippers with Long Stroke

Series GEH6000IL

2-Jaw Parallel Grippers

Series GP

- Dual round guide rods

- Double acting pneumatic cylinder with integrated mechanical gripping force safety device

- Dual round guide rods

- Double acting pneumatic cylinder with integrated mechanical gripping force safety device

2-Jaw Parallel Grippers with Long Stroke

Series GEH6000IL

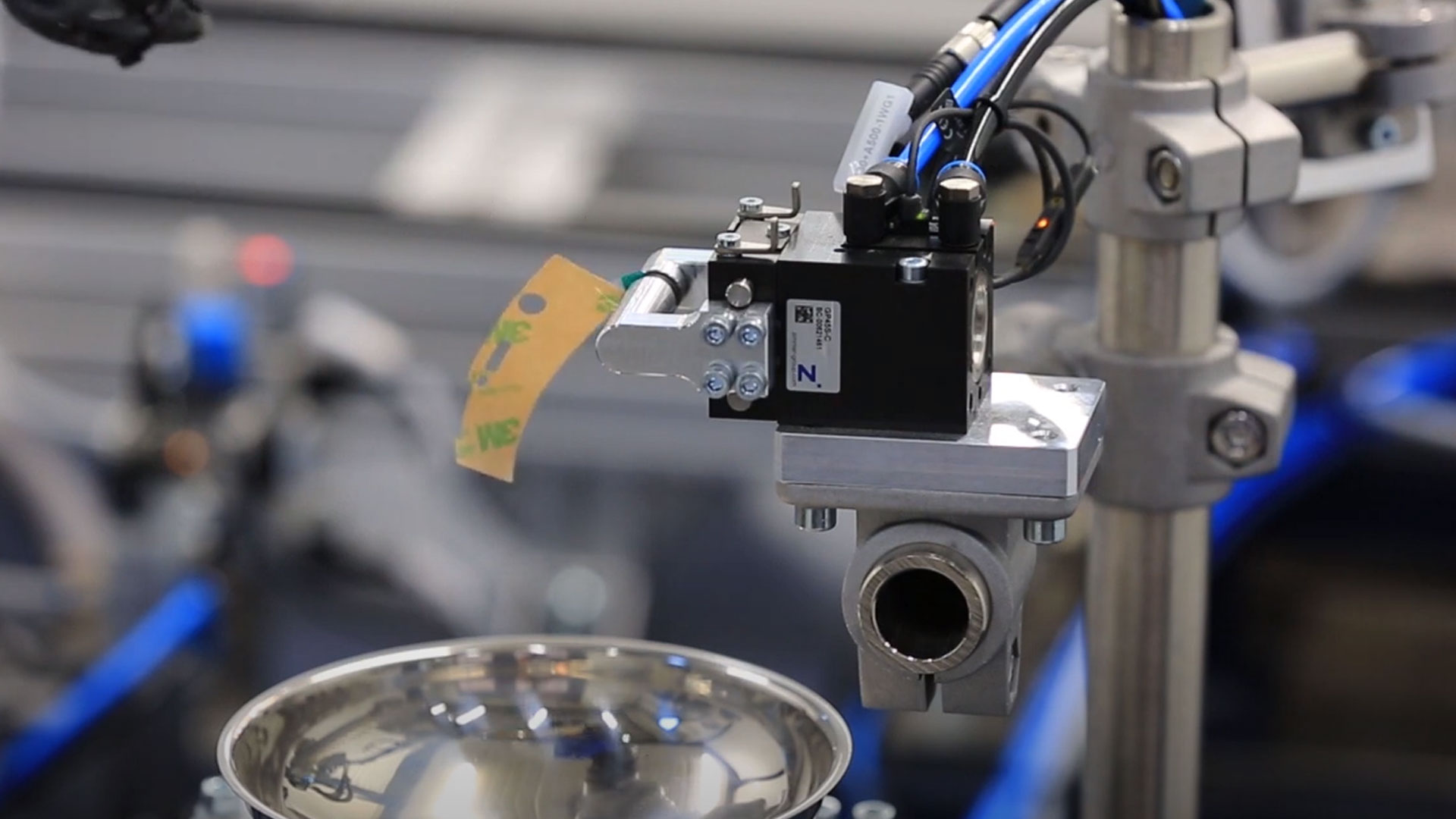

2-Jaw Parallel Grippers

Series GPP5000IL

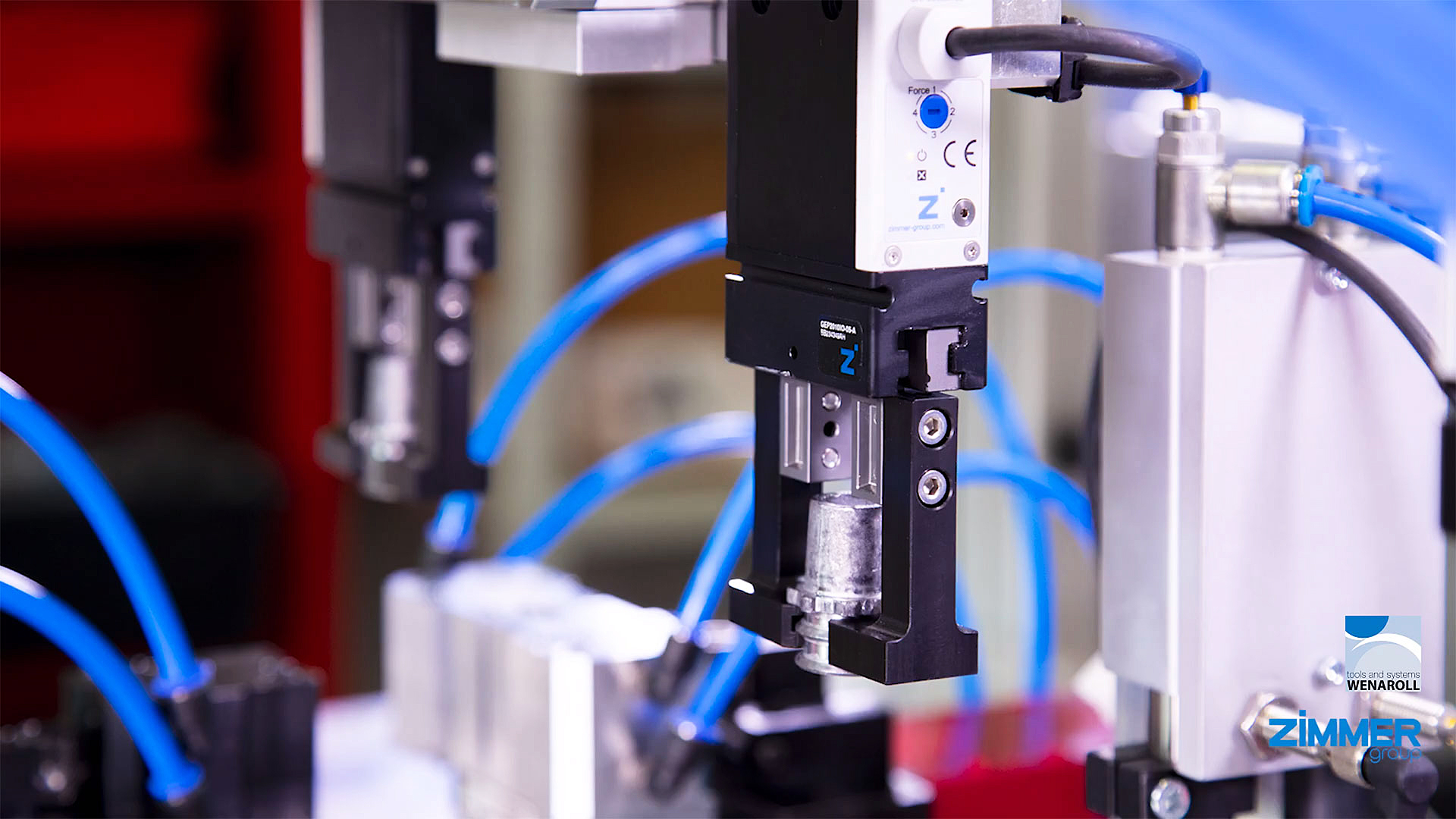

- Pneumatic drive combined with IO-Link technology

- Up to 50% cycle time reduction and up to 90% compressed air savings

- Connection via just one pneumatic line and IO-Link cable

- Pneumatic drive combined with IO-Link technology

- Up to 50% cycle time reduction and up to 90% compressed air savings

- Connection via just one pneumatic line and IO-Link cable

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GP400

- High gripping force as a result of optimal direction change of driving force into gripping force

- High gripping force as a result of optimal direction change of driving force into gripping force

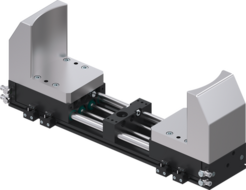

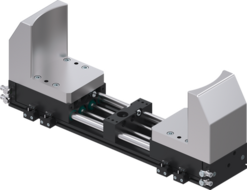

2-Jaw Parallel Grippers with Long Stroke

Series GPH8000

- Extremely long and heavy gripper fingers possible

- Synchronous, asynchronous and securing the workpiece

- Dirt protection

- Extremely long and heavy gripper fingers possible

- Synchronous, asynchronous and securing the workpiece

- Dirt protection

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GPP5000AL

- Aluminum Linear Guide – The alternative

- Only here – larger stroke, reduced costs

- The value promise – Consistent and without fine print

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Aluminum Linear Guide – The alternative

- Only here – larger stroke, reduced costs

- The value promise – Consistent and without fine print

2-Jaw Parallel Grippers

Series MGP800

- Integrated position sensing for compact design and to minimized the interfering contour

- Gripper jaws made of ground surfaced and hardened steel ensure precision and a long durability

- Integrated position sensing for compact design and to minimized the interfering contour

- Gripper jaws made of ground surfaced and hardened steel ensure precision and a long durability

FAQ – Questions and answers ON THE TOPIC OF 2-jaw parallel grippers

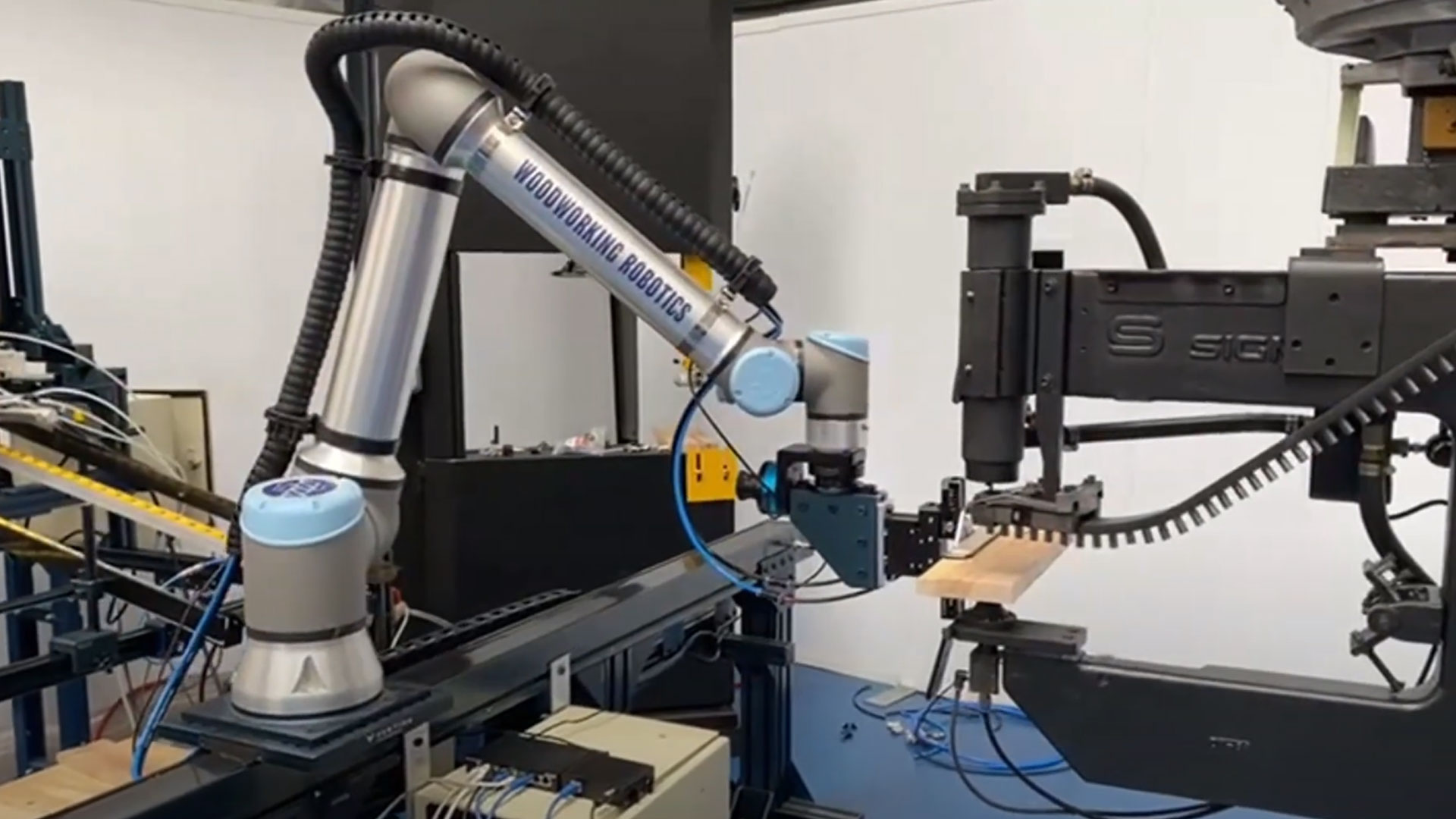

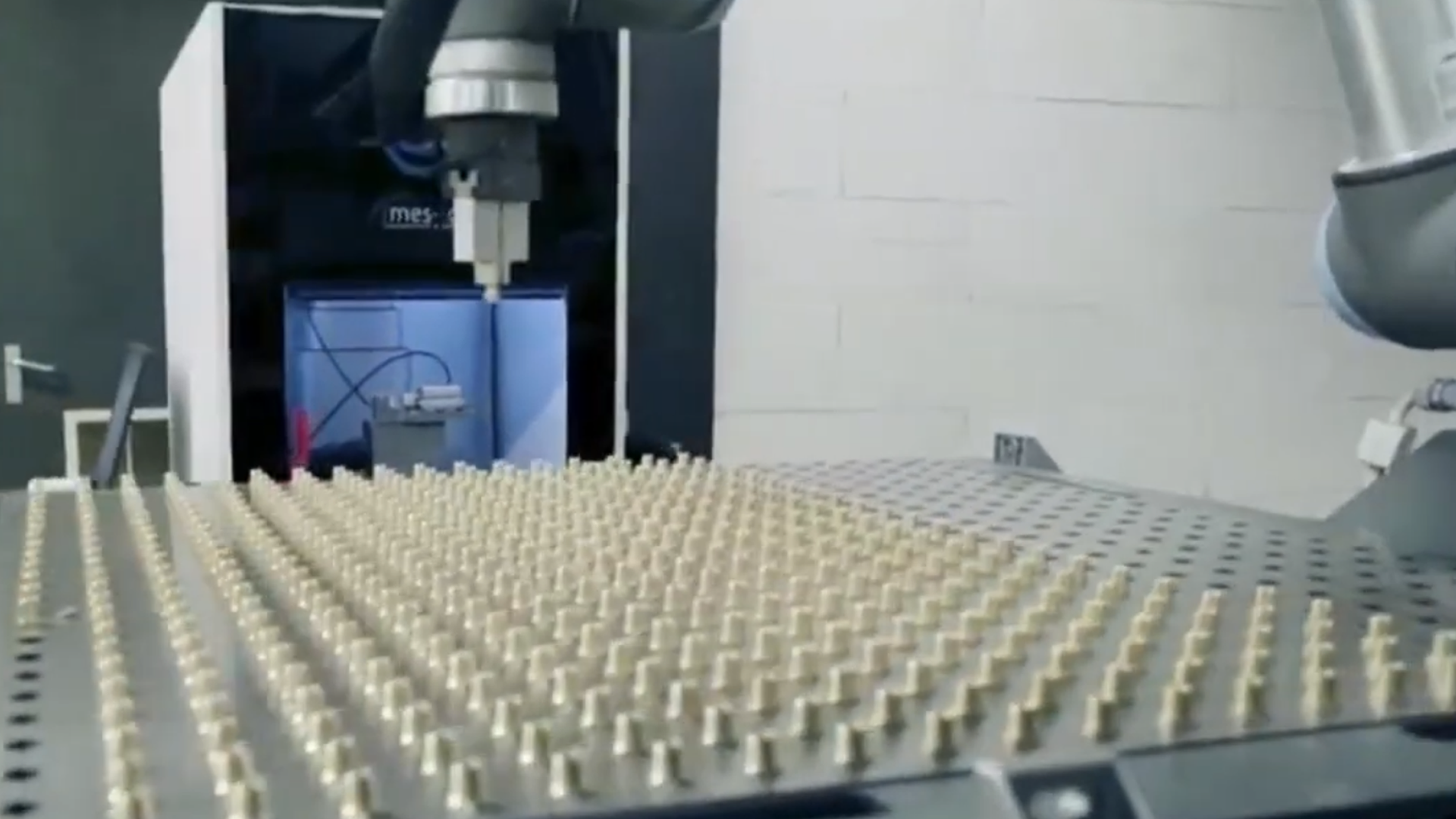

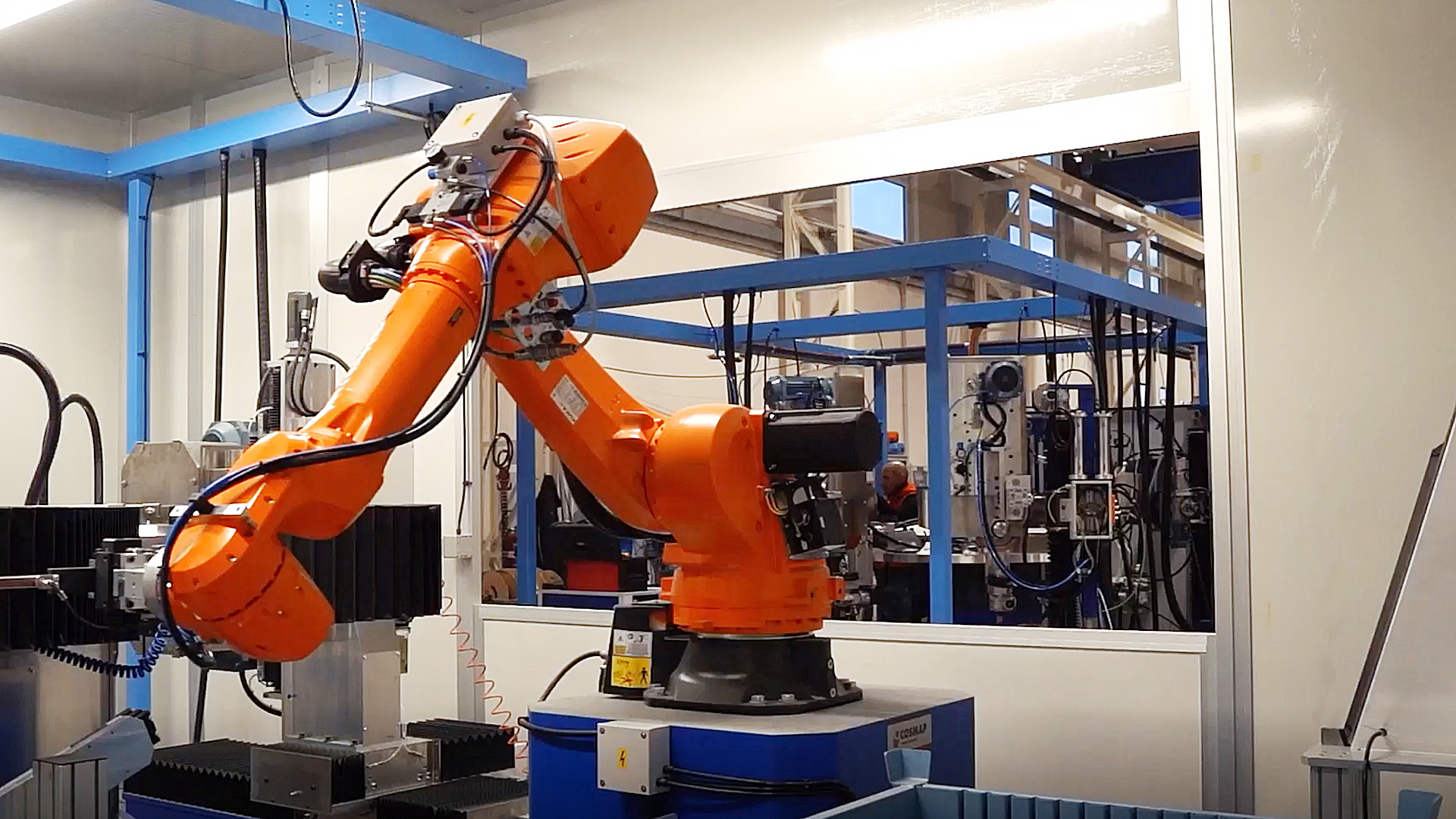

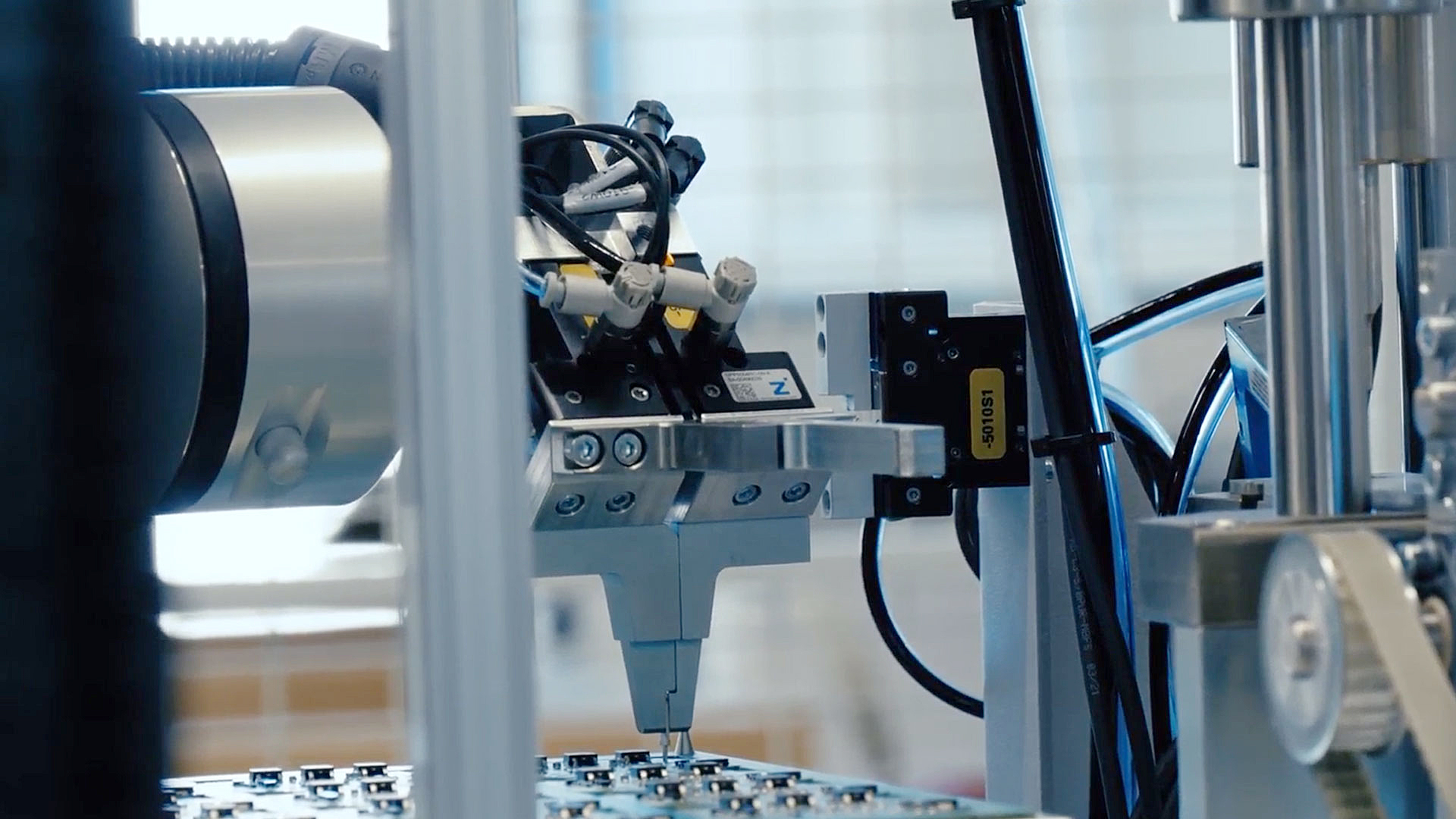

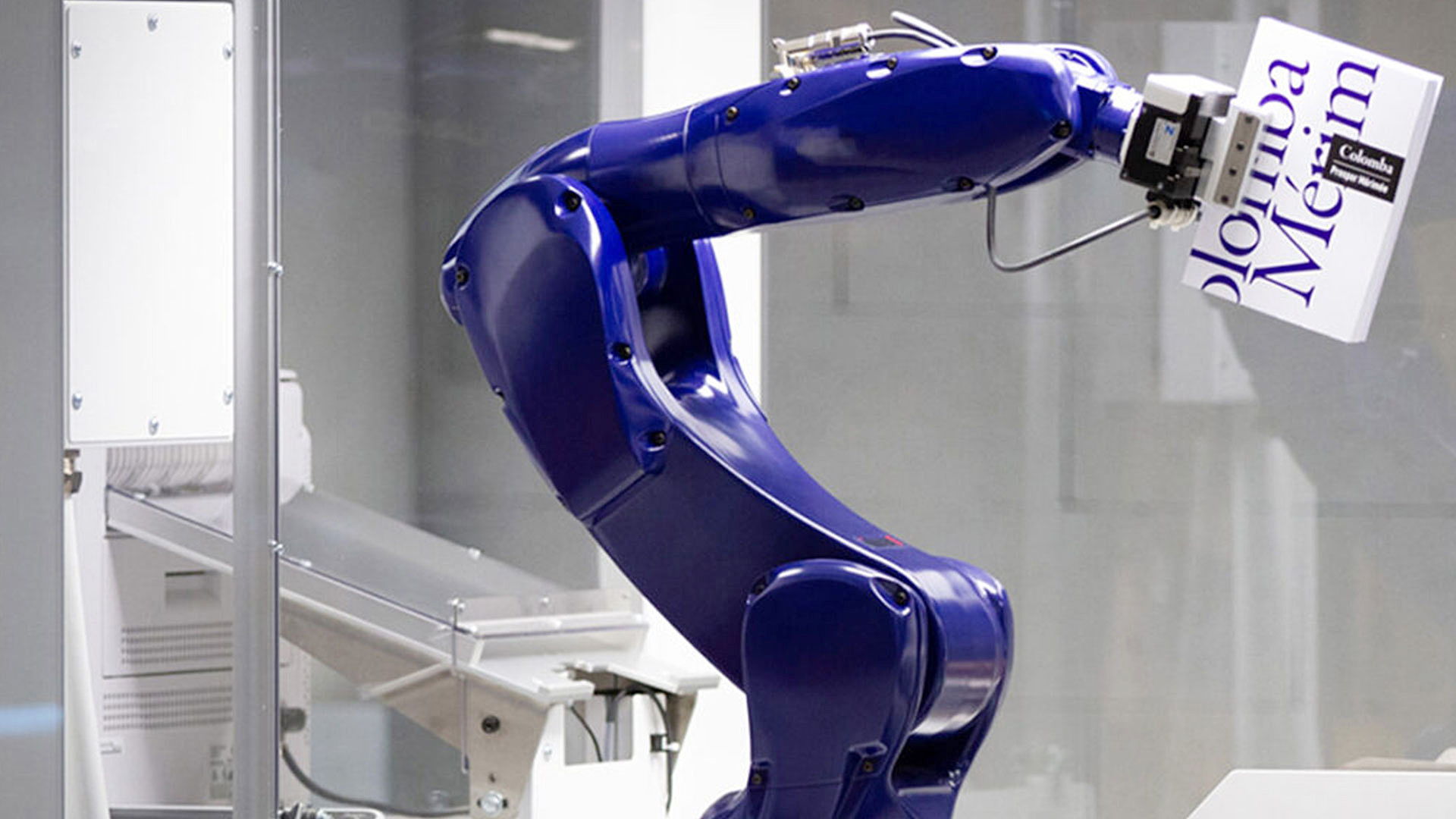

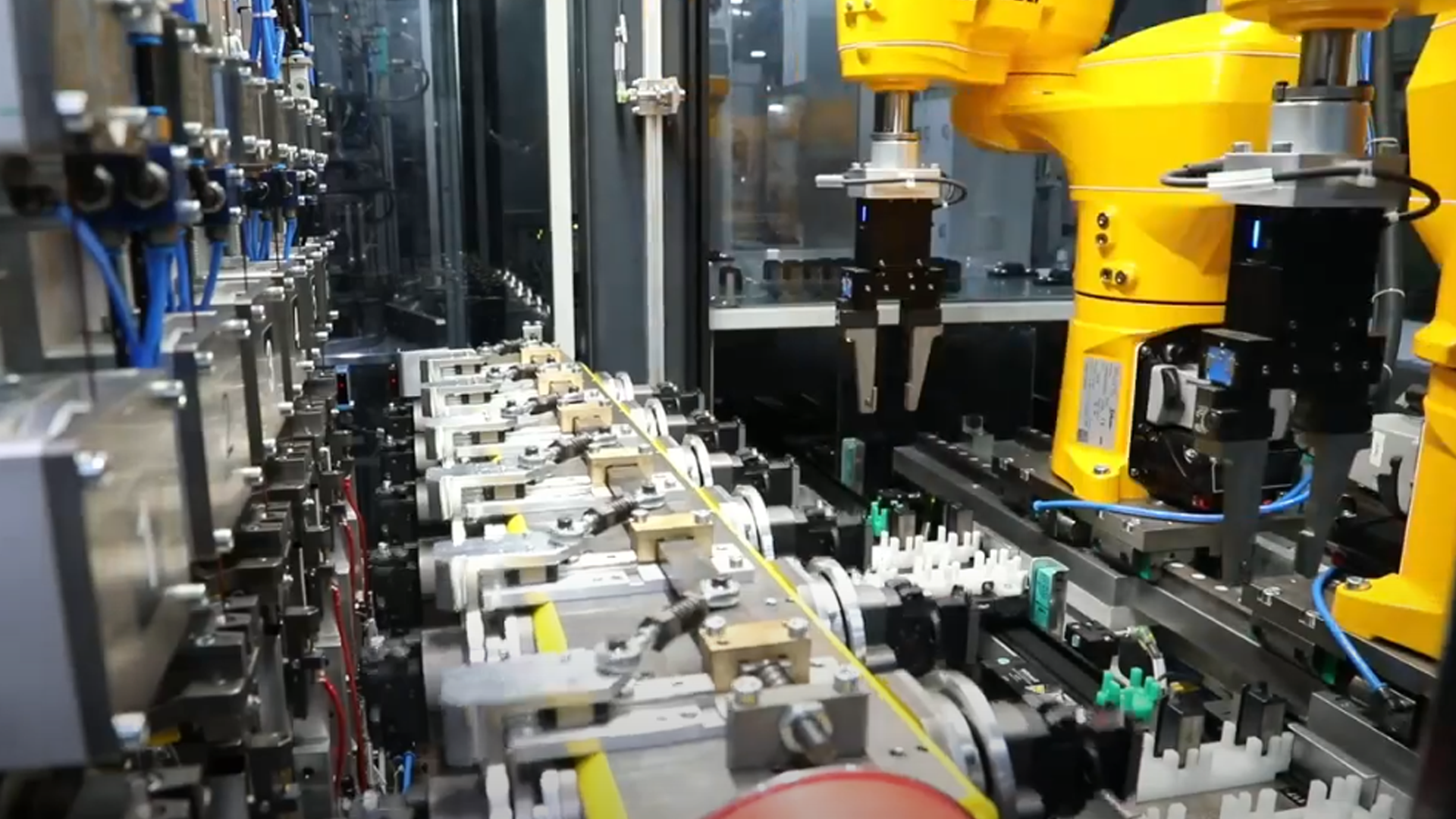

A 2-jaw parallel gripper is a mechanical device used in automated systems to grip and move objects. It consists of two parallel gripper jaws that move synchronously to grip an object. 2-jaw parallel grippers are often used in the manufacturing and assembly industry, for example for gripping and positioning workpieces, loading machines or packaging products. You can find further applications for 2-jaw parallel grippers in our showroom.

The Zimmer Group offers pneumatic, electric and pneumatic-intelligent 2-jaw parallel grippers, each with specific advantages and areas of application. Pneumatic grippers are widely used due to their simplicity and cost-effectiveness, but require a compressed air supply, which is not available in every plant. If you are unsure which drive type is the right one for your application, we will be happy to advise you.

Typical materials are aluminum, steel and plastics, depending on the requirements of the specific application, such as weight, corrosion resistance and load capacity. Customized adaptations are also possible depending on the area of application.