Efficient disassembly of traction motors

Autonomous milling processes for sustainable electric mobility

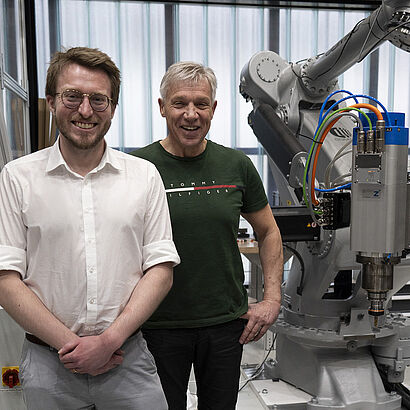

Electric mobility in Germany is currently facing a challenging phase. Following strong growth in recent years, new registrations of electric vehicles are declining due to the elimination of government purchase subsidies and economic uncertainties. Nevertheless, efforts are continuing to make the production and recycling of traction motors more efficient and sustainable. The wbk Institute for Production Technology at the Karlsruhe Institute of Technology (KIT) is breaking new ground with the AgiloDrive2 research project to make the dismantling of traction motors more economical and resource-efficient. The air-cooled motor spindle from Zimmer Group plays a special role here, enabling completely new dismantling sequences to be carried out. For example, worn screw heads can be milled off or openings can be created for the direct dismantling of critical components.

A new paradigm in disassembly automation

Until now, the disassembly of electric motors has been a complex, often manual process. As part of AgiloDrive2, KIT is developing an autonomous, robot-assisted solution that not only automates classic disassembly steps but also intelligently integrates destructive processes. The combination of digital process planning, sensory status detection, and adaptive milling processes results in a robust and flexible disassembly strategy.

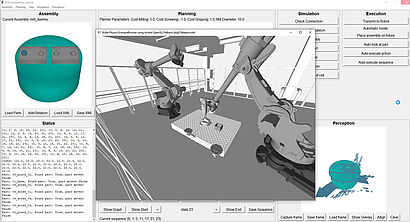

The process begins with a 3D mesh model of the motor, which is generated either from CAD data or scanned geometries. In addition, the system must be provided with information about connections that cannot be derived from the geometry alone. These are primarily adhesive or welded connections, but also screw connections, as threads are not usually modeled explicitly. From this model, the system can independently derive possible disassembly sequences for a given disassembly target and plan the corresponding disassembly processes. A simulation of the robotic disassembly cell is used to transfer the planned processes into the context of the robot cell and generate the corresponding control code.

A 3D camera system monitors the actual disassembly process and compares the actual state of the assembly with the expected state of the planned sequence. It detects deviations such as components that have not been removed or have been moved, as well as process failures. If screw heads can no longer be gripped due to wear or if a connection cannot be loosened, the system can calculate alternative disassembly strategies.

In such cases, the robot system uses an air-cooled milling spindle to remove problematic connections in a targeted manner. Based on the recorded geometry data, the system can generate precise milling paths, for example to remove screw heads. This enables continuous, adaptive adjustment of the disassembly process, ensuring that the motor can be successfully dismantled even if unforeseen obstacles arise.

However, milling is not simply a backup for non-destructive processes, but rather an equivalent alternative that opens up completely new possibilities. The strategy chosen depends on the disassembly goal and the individual constraints of the motors. For example, a solution generated autonomously by the system may be not to attempt to loosen a screw connection at all, but instead to mill an opening in the motor housing so that the rotor can be pulled out directly.

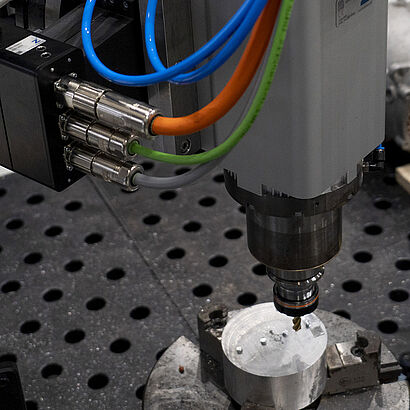

Air-cooled in use: motor spindle from Zimmer Group

The motor spindle from the HF145-001 series from the Zimmer Group plays a key role in this concept. This air-cooled, high-precision spindle allows destructive dismantling techniques to be carried out with maximum accuracy. Since critical components can be accessed directly by targeted milling work on the motor, dismantling processes are accelerated, material resources are conserved, and recycling processes are optimized.

The motor spindle is particularly characterized by its high performance and reliability, making it ideal for industrial automation solutions. Since it is suitable for both plastic and metal processing and is cooled by an electric fan, it was the ideal choice for this research project. In addition, it is characterized by a long service life even under demanding operating conditions.

Practical relevance and future potential

The technology developed by KIT could soon play a key role in the industrial recycling of traction motors. Companies in the automotive industry, but also recycling companies, could benefit from such a system by reducing expensive manual processes and improving the recyclability of electric motors. In addition to traditional recycling, the technology also offers potential in the field of refurbishing, i.e., the reconditioning and reuse of components. Within production, the system could also help reduce waste by specifically dismantling faulty or damaged components and preparing them for reuse. For example, manufacturing defects in engine blocks or rotors could be specifically reworked instead of disposing of the entire assembly.

In view of the current challenges on the market, but also the long-term need for sustainable production and recycling processes, autonomous disassembly offers a promising approach. The integration of destructive processes as a regular tool within the disassembly sequence is an innovative step that not only promises efficiency gains but also opens up new possibilities in resource-saving production and recycling.

With projects such as AgiloDrive2, KIT is impressively demonstrating how the challenges of electromobility can be mastered through the use of state-of-the-art robotics and intelligent process planning. Such research could lay the foundation for long-term change in the automotive industry, even if – or precisely because – the market is currently in flux.

You can find out more about our motor spindles here: