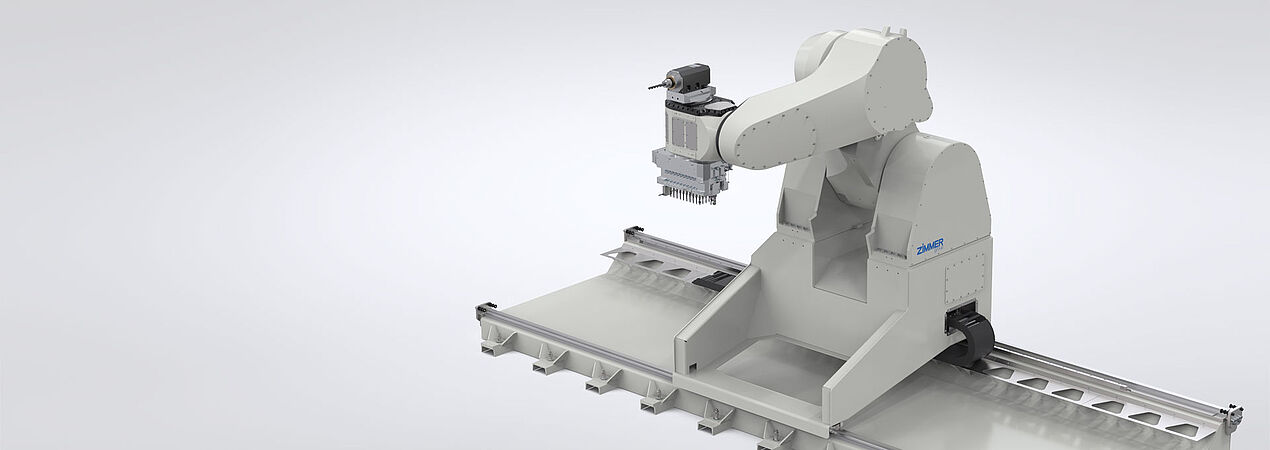

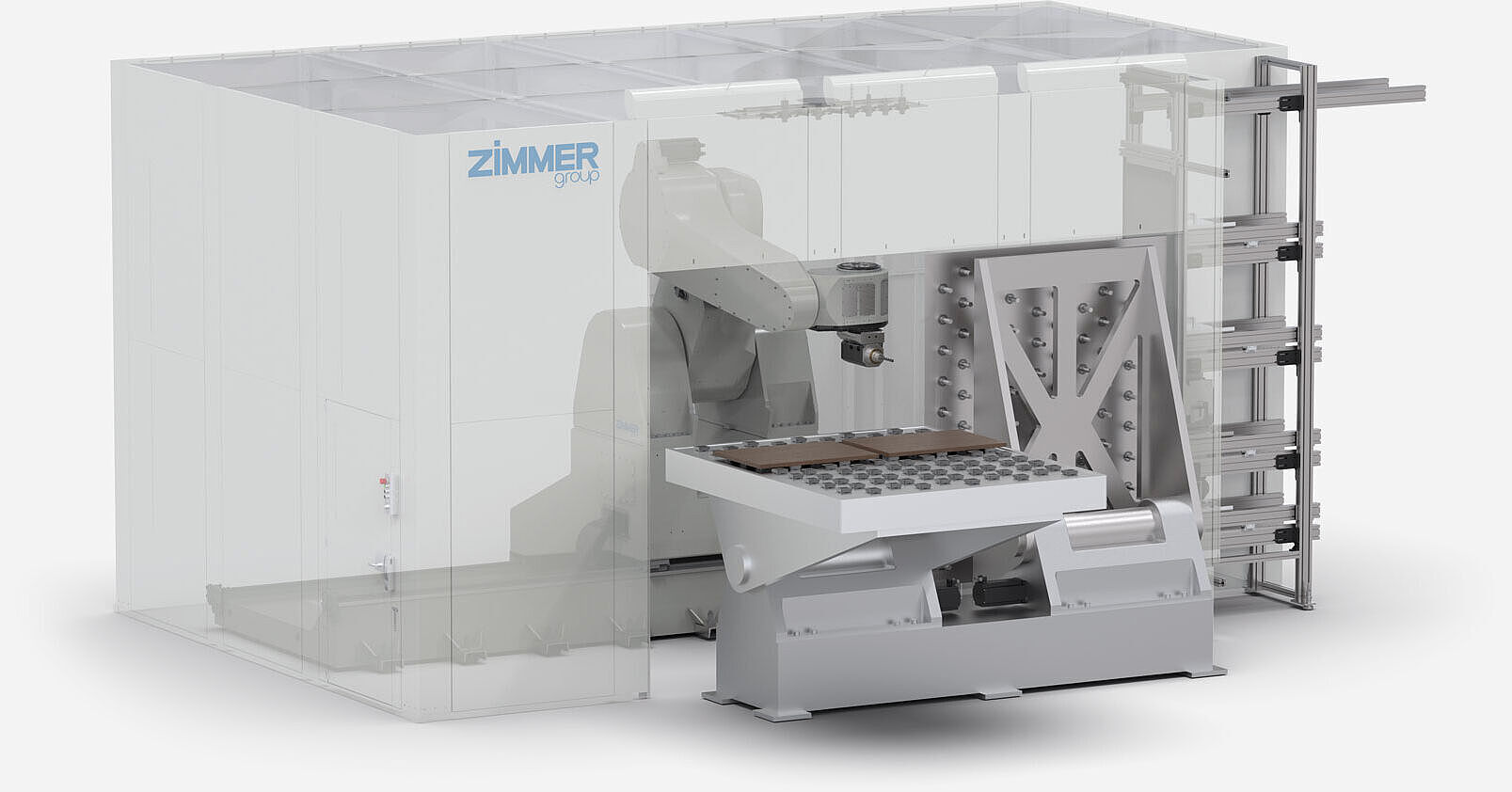

Discover Raptor – the robot-based manufacturing cell with a customized design to increase rigidity, dynamics and precision in the area of kinematics for high-quality machining quality. Raptor combines the advantages of modern industrial robot technology with the precision of CNC stationary technology and sets new standards in terms of efficiency and adaptability. The fully modular system enables flexible expansion and individual adaptation to a wide range of production requirements. State-of-the-art drive, gear and control technologies ensure maximum process reliability and performance. The fully encapsulated design reliably protects internal supply elements – such as cables and hoses – from chips, abrasion and collisions, thereby minimizing interfering contours. Raptor is controlled by an industry-standard CNC controller combined with a powerful CAM programming system that is well established in the industry.

The machining cell was specially developed for machining wood, lightweight construction materials, fiber composites, plastics and light metals for the precise machining of complex contours, appliqués and additive manufacturing processes. Its use helps to increase efficiency and reduce costs, as it completes complex tasks quickly, precisely and in a more space-saving manner than comparable portal machines. The machining robot has a multi-functional head with 2 flanges, a quick-change interface for quick tool changes, an impressive internal electrical, fluidic and pneumatic energy transmission as well as data and signal technology. Get to know the highlights of Raptor here!

Your benefits at a glance

- A wide variety of tasks in one machine: Nesting, milling, sawing, pre-assembly, handling parts

- Full encapsulation paired with intelligent workpiece arrangement increases performance

- Programming with a universal and powerful CAD-CAM system

- Flexible and efficient workpiece clamping systems (e.g.: PIN table with active PINs)

- Optimized extraction with low energy consumption (vertical arrangement of parts, chips fall downwards)

- Easy-to-maintain modular design, which ensures high availability during downtime/set-up/maintenance, etc.

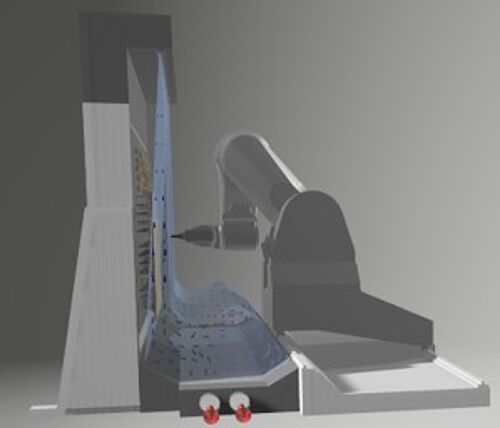

Maximum safety and cleanliness

Machining cell with enclosure

Raptor works in a fully enclosed machining cell that is equipped with an integrated room extraction system. This reduces exposure to dust and noise to a minimum – for an efficient and healthy work process. The enclosure meets all safety requirements, including access and splinter protection, ensuring reliable protection for both people and machines. For maintenance and operation, access to all supply units is available via a separate aggregate station outside the machining area – convenient, safe and sophisticated.

Integrated extraction

The segmented blower unit on the ceiling of the enclosure ensures a laminar air flow that acts as air curtain. The chips and dust emissions are thus directed into the corresponding floor-side extraction unit in the machining or workpiece clamping area with the help of specially designed aerodynamics. Extraction connections on both sides ensure the controlled removal of chips and particles at their point of origin. This means that the machining environment can be kept clean, which increases process reliability and the service life of the technology.

- Optimized extraction with low energy consumption

- Integrated guidance of the chips and dust emissions with the help of a specially designed laminar air flow into the corresponding floor-side extraction device in the area of the machining or workpiece clamping

- Minimized dust pollution and noise due to the closed system concept

- Machinability of materials with hazardous or air-polluting dust development (e.g. TRGS 905 and 906)

- Improved air quality in the hall

- Reduced contamination of workpieces, machine and surroundings

- Significant increase in performance level

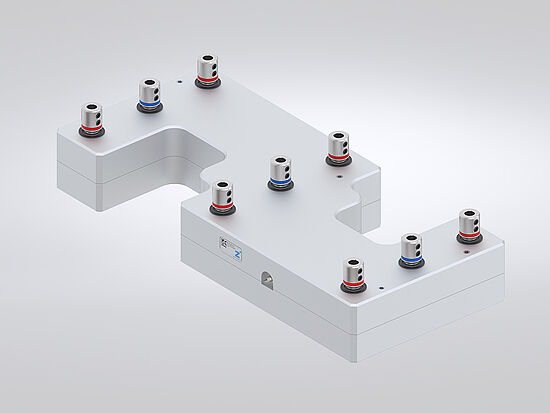

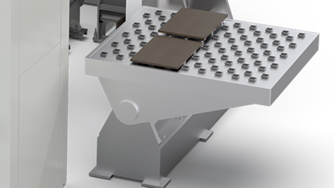

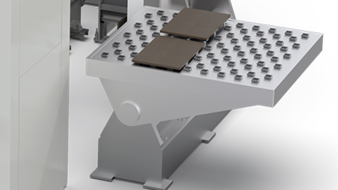

PIN table

The PIN table design is a universal and efficient concept for clamping plate-shaped or flat workpieces with vacuum pins. The design enables flexible clamping and positioning, which reduces retooling times. Individually extendable cylinders and table designs with different extension strokes (e.g. for nesting with a short extension stroke) ensure problem-free machining on the revolving side and horizontally.

- Turning table design (pendulum machining system) with individually controllable extension stroke and vacuum control for the respective suction pin.

- Universal workpiece loading manually by the user or automatically with robot handling as single or multiple loading.

- Automatically generated proposal for PIN activation depending on the part geometries to be machined or the machining operations to be carried out at the time the space is occupied.

- Individual selection and deselection of the vacuum and the extension stroke during ongoing machining or in the underlying machining program (e.g.: automatic removal of remaining parts, workpiece release, etc.)

- Constant clamping of the workpiece in the area of nested part machining (nesting system) with a reduced vacuum performance requirement, as no additional leakages occur during machining. Additional optimization through demand-oriented power consumption with frequency control in area of the vacuum generator.

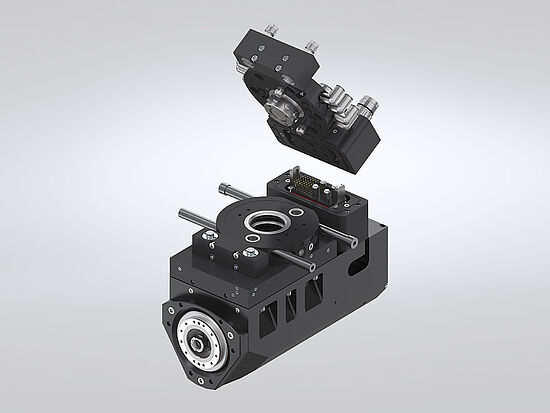

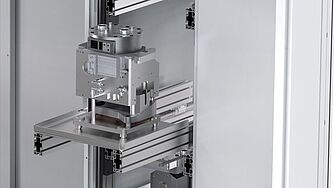

Quick-change interface

The quick-change interface is particularly advantageous for machining wood, plastic and fiber composites. With various end-of-arm tools, like for sawing or milling, the robot can perform different machining tasks. This increases productivity and makes it easier to manufacture individual workpieces.

- Holding by using zero-point clamping systems

- Electrical, fluid and pneumatic energy transmission

- Mounting position C1 or C2

- Free C-axis angle +/- 190°

- Orthogonal working direction

- Designed to automatically change modules up to 100 kg

- Power supply: 600V/400V/24V

- High power transmission (e.g.: supply for motor spindles, unit equipment, etc.) Data: EtherCAT

- Media: Liquid cooling / compressed air / working media

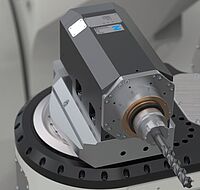

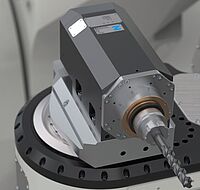

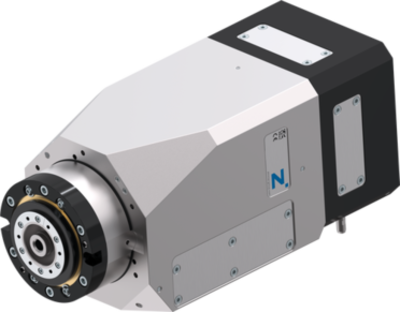

Swivel-mounted milling spindle

The swivel-mounted milling spindle can be used for a wide range of machining tasks and is impressive in many ways:

- Mounting position C1

- Orthogonal alignment to the machining contour

- Individual alignment in the machining area

- 5-sided machining of panels possible (3,600 x 2,100 x 80 mm)

- Choice of different milling spindles depending on the machining requirements (e.g.: Standard spindle with 15 kW water-cooled, optionally with compressed air through spindle, synchronous technology, etc.).

- Automatic tool change (e.g.: from ceiling-oriented comb or linear changer).

- Energy and media supply of change units possible

- Fast spindle and unit change from an independent aggregate station.

- Very low interfering contour

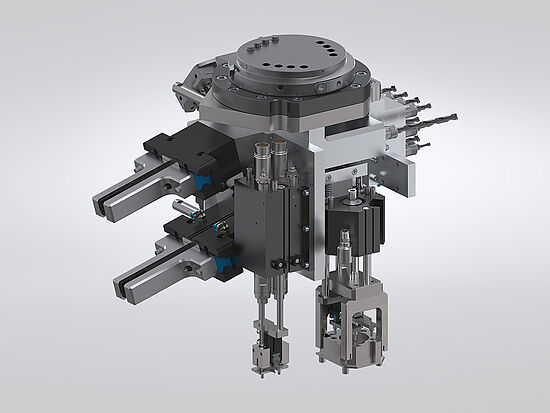

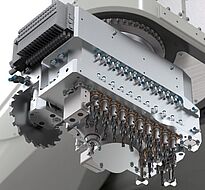

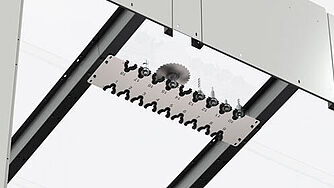

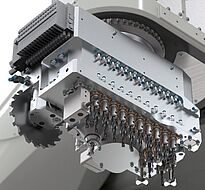

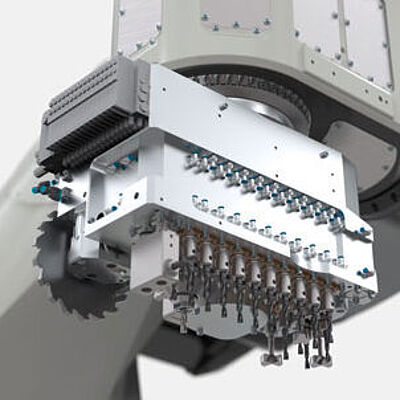

Swivel-mounted multi-spindle head / multi-function units

Combine several machining operations in one work step. The swivel-mounted multi-spindle head enables simultaneous multi-machining, which reduces your production times and increases efficiency.

- Orthogonal alignment on the machining surface or machining contour

- Individual alignment in the machining area

- Free C-axis angle +/- 190°

- Fitting drilling patterns in one drilling stroke

- Horizontal sawing / Clamex also possible

- Lock-case machining with shank tool up to 100 mm cutting depth

- Option to use own aggregate technology (given interface functionality)

Aggregate station

The aggregate station lets you store various interchangeable machining units (e.g.: from machining spindles, drilling units and individual machining units to handling equipment in the form of a suction spider).

- The machining units are located outside the machining area and are thus protected from soiling by chips and dust.

- They are accessible from the outside and can therefore be serviced accordingly during machining (e.g.: cleaning task, adjustments, refilling consumables, etc.) or removed.

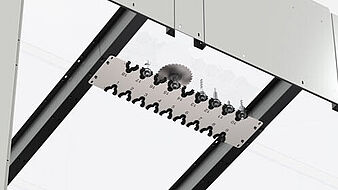

Tool magazine

The tool magazine of the robot-based manufacturing cell allows tools to be changed quickly and safely throughout the entire machining process. The ability to use a wide range of tools minimizes set-up times and greatly increases the output of the manufacturing cell.

- Quick and safe tool changes

- Minimized set-up times

- Increased efficiency by optimizing the manufacturing process

Motor spindle with rotary feed-through

The optional compressed air feed-through through the machining spindle offers two major advantages. On the one hand, it provides the help of chip removal in the area where grooves, pockets and bores are machined. It is also used for active tool cooling, which increases tool life, improves machining quality and increases process reliability.

- Possibility of feeding compressed air or MQL through the spindle and the tool

- Particularly suitable for machining wood and composite materials

- Tool cooling

- Chip removal

- HF150-005-004 with synchronous motor

- Power: 20 kW

- Speed: 10,300 rpm (max. 24,000 rpm)

- Torque: 18.5 Nm

- Tool interface: HSK-F63

Unit and spindle technology

The Zimmer Group is one of the most innovative companies in the field of complex components and modular end-of-arm products for implementing a wide range of functions on machining modules, drilling units with fixed and extendable spindles and multi-function units. However, it also offers project-specific designs for minimal installation space and tool change effort as well as numerous attachment options for maximum flexibility and freedom.