Everything from a single source

How vertical integration and innovation lead to leaner production

The series production of complex components places the highest demands on technology, efficiency, and quality. The Zimmer Group, known as THE KNOW-HOW FACTORY, is demonstrating its expertise in a current project by mapping the entire process for manufacturing a sensor component for level measurement using a vibration limit switch (vibration sensor) in-house. With a comprehensive “everything from a single source” approach, the company impressively demonstrates how interdisciplinary expertise leads to outstanding results.

Series production of delicate metal components

The customer's specific requirements were the focus from the outset: The tuning fork had to be manufactured in series with high precision and cost-efficiency. At the same time, the complex geometry of the component required solutions that went beyond conventional manufacturing processes. Traditional machining processes quickly reached their limits – whether due to high costs, long production times or the limited possibilities for realizing complex geometries and tight tolerances.

The decision was made in favor of the innovative metal injection molding (MIM) technology. This process allows metal components with complex geometries and tight tolerances to be manufactured economically in large quantities. But that was not the end of the challenge: precisely coordinated process steps, state-of-the-art technology, and interdisciplinary expertise were required to implement the entire process efficiently and seamlessly.

The solution: an interdisciplinary process

The customer order is fulfilled based on a seamless process chain that combines all steps of production - from design to the final product - under one roof. The project began with the development and design of the injection mold. Zimmer Group's many years of experience in toolmaking ensured that the precision requirements were met, even for complex geometries. As with all injection molding processes, these tools form the basis of the MIM process. The feedstock, a mixture of the finest metal powders and a plastic component, is plasticized in an injection molding machine and injected into the mold. This creates the so-called “green part,” which already determines the final shape of the component. The green part is a larger preform of the component, which is held together by the binder.

Automated workpiece removal

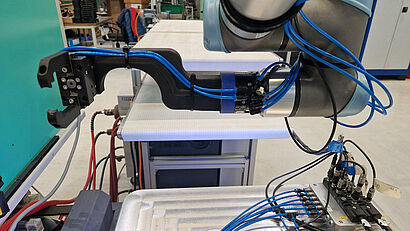

In complex processes such as MIM, the focus is on automated process steps in order to make overall production as efficient as possible. For the Zimmer Group, it is clear that repetitive tasks such as removing the green parts from the injection molding machine must be fully automated. This is where the in-house developed mobile robot cell ZiMo comes into play. ZiMo is characterized by its compact design, which is based on a modular frame with rollers. This allows for extremely flexible use on different machines, as it can be quickly and easily converted. The particularly short changeover times make it an ideal solution for highly dynamic production environments.

ZiMo is equipped with a Zimmer Group standard gripper from the GP series. To optimize removal, parts of the robot arm and the gripper jaws were designed for this application and quickly printed in-house using a 3D printer. Equipped in this way—with connecting pieces and gripper jaws made of temperature-stable, glass-fiber-reinforced polyamides—ZiMo proved to be the perfect solution for safely gripping the still-hot green parts without damaging their sensitive structure. The standard GP gripper used was optimized with these custom-made components, enabling the workpiece to be gripped and removed simultaneously. This significantly increased the efficiency of the process while reducing the incidence of errors.

Catalytic debinding and sintering

The next step is to remove the binder from the green part. In catalytic debinding, the still sensitive tuning forks are exposed to fuming nitric acid in a special furnace. The acid reacts with the plastic component of the feedstock, which is then burned without leaving any residue. What remains is the so-called brown part, which now has a porous structure.

In the sintering furnace, the brown parts are first thermally debonded at temperatures of up to approx. 500°C. Put simply, the residual binder that holds the fine metal powder particles together is thermally decomposed. At these temperatures, the metal powder particles begin to bond and form so-called sinter necks, which give the component stability. The parts are then heated to approx. 1,350°C. During this process, the metal particles compact, the pores close, and the component achieves a density of over 97% of the theoretical material density. The tuning fork shrinks by about 17% during this process, giving it its exact dimensions. The result: a component with almost complete density that impresses with its mechanical properties.

Perfection through post-processing

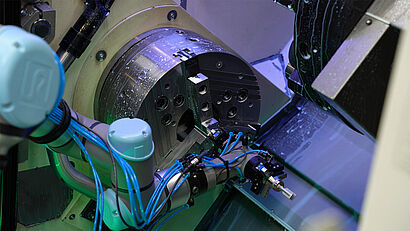

After the sintering process is complete, the components are post-processed in a machining center. ZiMo was also used here to automatically load and unload the workpieces. Thanks to the modular design of the robot cell, it can be converted within a few minutes, allowing the same ZiMo that previously removed the green parts from the injection molding machine to now assist at the machining center. This once again demonstrated the versatility of the robot cell, which easily met the high mechanical and thermal requirements thanks to the use of specially adapted components. Glass fiber-reinforced 3D-printed components are also used for this step. Parts of the robot arm were additively manufactured to optimize the process. Two 3-jaw centric grippers from the GPD5000 series precisely grip the tuning forks for machining. The sealed guides and standard corrosion protection prove to be decisive advantages in a difficult working environment.

Results and advantages

The result of the project is high-precision tuning forks that meet all of the customer's requirements and also impress with their quality and cost efficiency. Thanks to the seamless integration of all process steps in-house, the Zimmer Group was not only able to significantly shorten development time, but also reduce production costs. Particularly noteworthy is the vertical range of manufacture, which makes it possible to combine all relevant technologies under one roof.

The advantages of this approach are obvious:

- A single point of contact for all process steps: Customers benefit from centralized communication and smooth processing.

- Innovative solutions: The Zimmer Group's interdisciplinary approach allows challenges to be viewed and solved from different perspectives.

- Time and cost efficiency: Complete in-house production not only saves time, but also minimizes the risk of errors caused by external interfaces.

Conclusion and outlook

The project to manufacture the tuning fork impressively demonstrates how the Zimmer Group uses its vertical range of manufacture and comprehensive expertise to successfully implement even the most demanding projects. The combination of innovative technologies such as MIM and 3D printing, flexible automation solutions, and the ability to carry out all process steps in-house makes the Zimmer Group an indispensable partner in industrial manufacturing.

In addition to MIM and 3D printing technologies, the Zimmer Group has extensive expertise in elastomer technology and plastic injection molding, as well as decades of know-how in the component areas of handling, vacuum, robot, machine, damping, clamping, and brake technology, right through to complex systems. This enables tailor-made solutions for a wide range of industries, such as the automotive industry, pharmaceutical and laboratory companies, and highly specialized logistics solutions. The ability to draw on this broad technological base not only guarantees a high level of vertical integration, but also maximum flexibility and innovative strength in the realization of demanding projects.

Future potential is particularly evident in the field of additive manufacturing. In addition to standard and glass-fiber-reinforced plastics, the metal extrusion process (MEX) can also be used to manufacture metal components using 3D printing, for example. Numerous new applications are conceivable here, including in the areas of prototype production, assembly optimization, and small-batch production, which could further revolutionize process engineering. The Zimmer Group is ready to continue along this path and support its customers with innovative solutions. This is a clear advantage for anyone looking for a partner who combines expertise, innovation, and quality.