LI50-250S

Linear Cylinders

Series LI

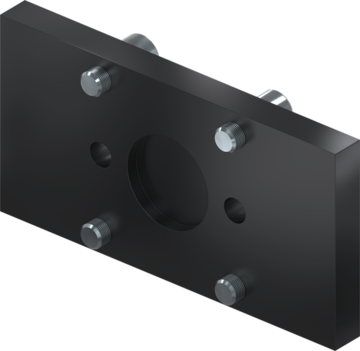

- Large locating flange

The large mounting surface simplifies your design and allows secure attachment of follow-on tools - Dampened end position

By using PowerStop shock absorbers, you can gently move up to the end positions, increasing the process reliability and durability of your application - Failure-free continuous operation

Our uncompromising "Made in Germany" quality guarantees up to 10 million maintenance-free cycles

Equipment/Options

10 million maintenance-free cycles (max.)

10 million maintenance-free cycles (max.) Elastomer end position damping

Elastomer end position damping Powerstop end position damping

Powerstop end position damping IP54

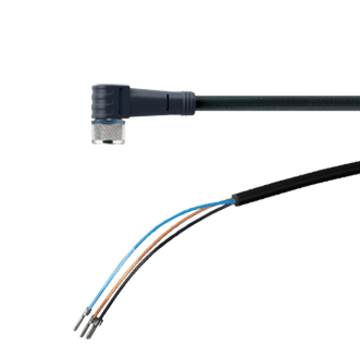

IP54 Inductive sensor

Inductive sensor- 2 way guiding

Technical Data

| Stroke | 250 [mm] |

| Pressure force max. | 950 [N] |

| Retraction force | 950 [N] |

| Travel time without external load | 0.63 [s] |

| Nominal operating pressure | 6 [bar] |

| Operating temperature | 5 ... +80 [°C] |

| Air volume per cycle | 833 [cm³] |

| Approvals | LABS / REACH / RoHS |

| Protection to IEC 60529 | IP54 |

| Weight | 7.2 [kg] |

| Load Fa max. | 75 [N] |

| Max. deflection A | 0.15 [mm] |

Benefits in detail

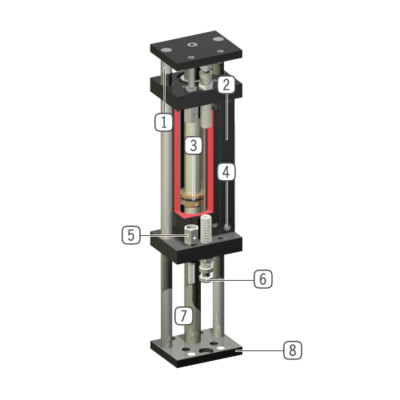

- Guide rod

hardened, polished steel shaft - Mounting block

mounting for inductive proximity switch - Drive

double-acting pneumatic cylinder - Energy supply

reducing exhaust air is recommended - End stop confirmation screw

direct flange position sensing included in scope of delivery - End position damping

with elastomer absorber or patented hydraulic shock absorber - Piston rod

polished, hard chrome plated steel continuous in design D - Intake flange

for connection to application-specific adapter plate (to be supplied by the customer)