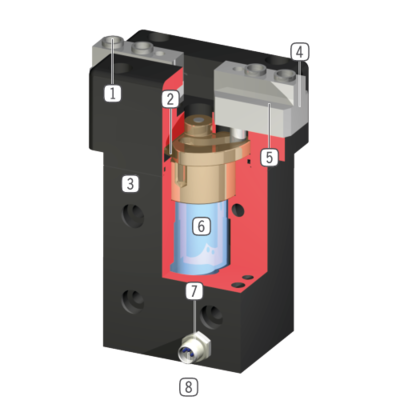

2-Jaw Parallel Grippers

Series GEP1400

"The robust"

- Proven T slot guide

This established and proven guiding technology stands for the highest process reliability like no other - Integrated position sensing

You can detect the gripper status safely via the motor current using your control system - The simplest activation

The included control unit is controlled easily via plus and minus buttons, while you can optionally adjust the gripping force using the potentiometer

Series features

5 million maintenance-free cycles (max.)

5 million maintenance-free cycles (max.) IP64

IP64 External gripping

External gripping Internal gripping

Internal gripping Digital I/O

Digital I/O Gripping force safety device for pressure maintenance

Gripping force safety device for pressure maintenance Gripping force safety device for spring

Gripping force safety device for spring

- Removable centering sleeves

quick and economical positioning of the gripper fingers - Positively driven curve disc

synchronized the movement of the gripper jaws high force transfer rapid stroke and force stroke (version with 6 mm stroke per jaw) - Robust, lightweight housing

Hard-coated aluminum alloy - Gripper jaw

hardened steel individual gripper finger mounting - Guide

precise T-Slot guide for high forces and moments capacity - Drive

electric drive by 24 VDC step motor - Position sensing

measured at the end of stroke via power increase on the motor - Energy supply

standardized interface M8 round plug signal control line (use only cable without diode)