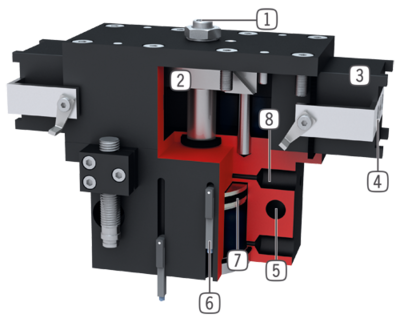

2-Jaw Parallel Grippers

Series GP200

"The variable"

- Smooth stroke configuration

An adjusting screw allows you to adjust the stroke to your specific application - Proven technology

We have more than 20 years of proven reliability, which ensures uninterrupted production for you - Dirt protection

Using the scrapers on the guides, you can reliably use the gripper even under the harshest conditions

Series features

10 million maintenance-free cycles (max.)

10 million maintenance-free cycles (max.) Spring closing C

Spring closing C High-strength S

High-strength S IP40

IP40 Magnetic field sensor

Magnetic field sensor Inductive sensor

Inductive sensor Purged air

Purged air

- Stroke adjustment

infinitely adjustable in „open“ movement adjusting screw in delivery - Wedge hook mechanism

synchronized the movement of the gripper jaws high force transfer - Square guide

high forces and moments capacity - Gripper jaw

individual gripper finger mounting - Mounting and positioning

mounting possible from several sides for versatile positioning - Sensing slot

mounting and positioning of magnetic field sensors - Drive

double-acting pneumatic cylinder - Energy supply

possible from several sides