E-mobility

Zimmer Group offers handling solutions for all areas of e-mobility

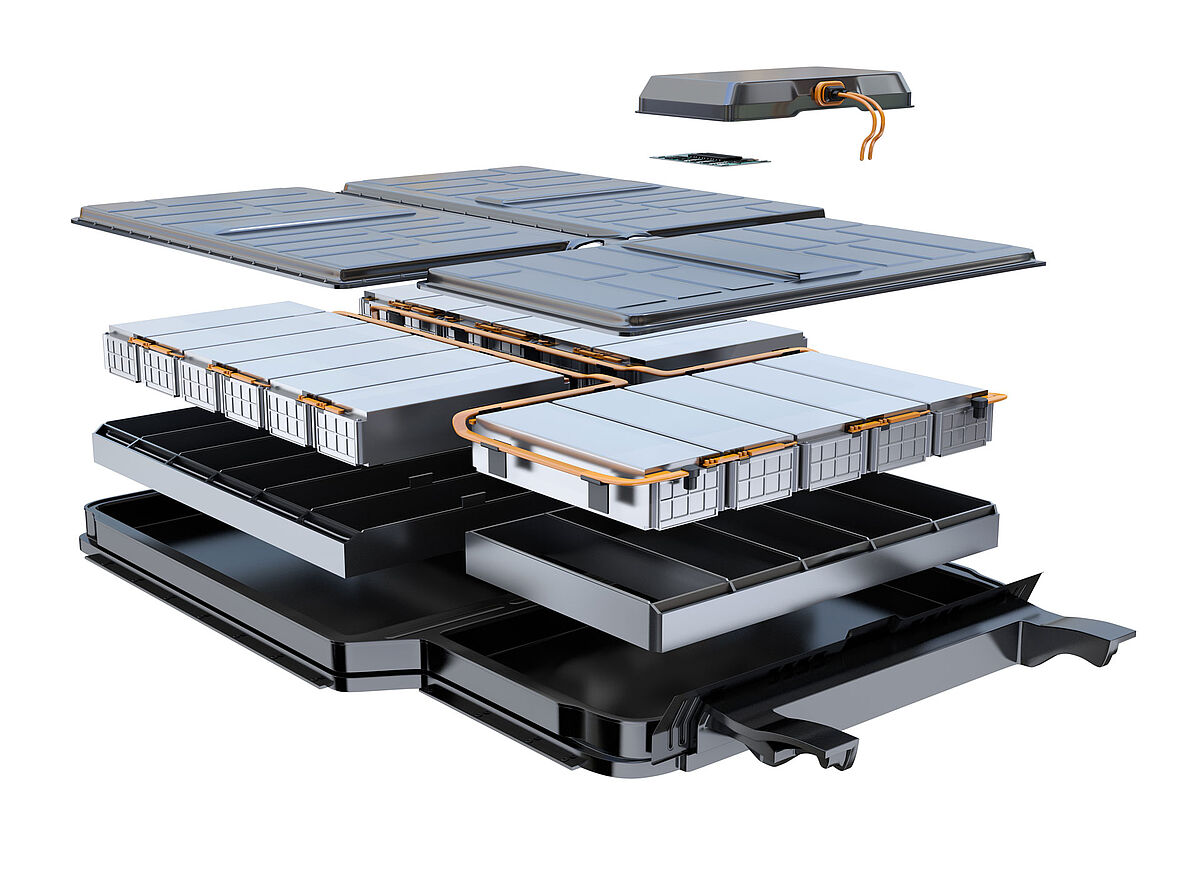

The manufacture of electric vehicles places new demands on production technology. Economical production of battery cells and packs is an important factor in ensuring that this market can grow successfully. The Zimmer Group is a development and system partner to many well-known premium manufacturers and system builders for battery production, module assembly and electric motor production.

- Projects completed:

100 projects, 800 grippers, 2000 devices - E-mobility solutions since 2014

- Engineering expertise:

More than 500,000 hours of engineering - Highlights:

Development partner of premium automotive, OEM and plant manufacturers

Gripper systems and EOAT for battery handling

Today, reducing CO2 emissions is more important ever. From electric scooters to electric trucks.The Zimmer Group offers solutions for all areas.