GG1140NC

Discontinued model

Note on the previous model

This product is one of our previous models and is still available here to provide you with technical information and support. If you have any questions about this previous model, please use the contact form—we will be happy to help you! For product inquiries, please use the link above to the further developed successor model.

2-Jaw Angular Grippers

Series GG1000

Equipment/Options

10 million maintenance-free cycles (max.)

10 million maintenance-free cycles (max.) Spring closing C

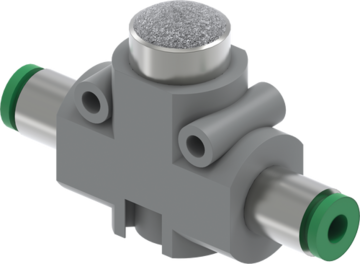

Spring closing C IP40

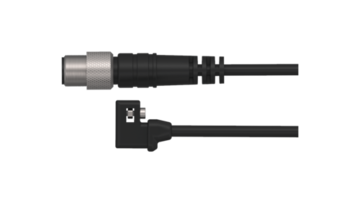

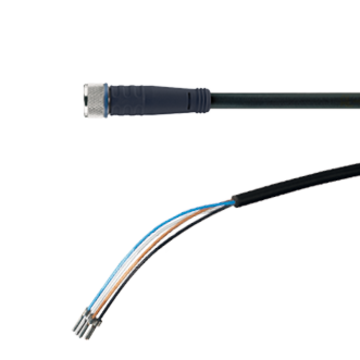

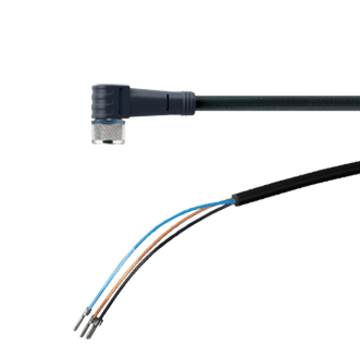

IP40 Magnetic field sensor

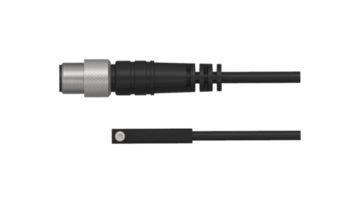

Magnetic field sensor Inductive sensor

Inductive sensor Purged air

Purged air Gripper jaws with mounting possibility on the side

Gripper jaws with mounting possibility on the side

Technical Data

| Stroke per jaw | 20 [°] |

| Gripping moment in closing max. | 725 [Nm] |

| Gripping moment secured by spring min. | 143 [Nm] |

| Gripping force in closing at 0° | 29110 [N] |

| Gripping force in closing max. (at 20°) | 36470 [N] |

| Gripping force secured by spring (at 0°) | 5740 [N] |

| Gripping force secured by spring (at 20°) | 13110 [N] |

| Closing time | 0.25 [s] |

| Opening time | 0.5 [s] |

| Repetition accuracy +/- | 0.05 [mm] |

| Operating pressure min. | 4 [bar] |

| Operating pressure max. | 8 [bar] |

| Nominal operating pressure | 6 [bar] |

| Operating temperature min. | 5 [°C] |

| Operating temperature max. | +80 [°C] |

| Air volume per cycle | 760 [cm³] |

| Weight | 12.4 [kg] |

Benefits in detail

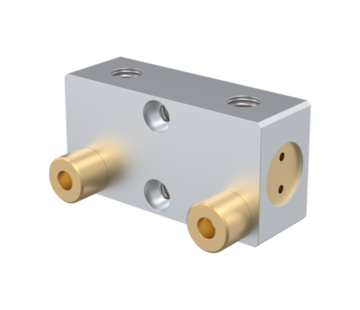

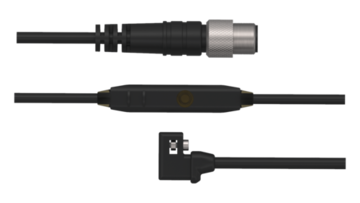

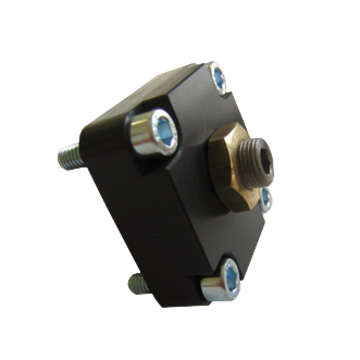

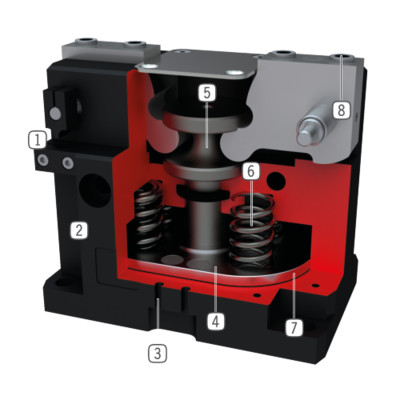

- Cam-switch and mounting block

for position sensing - Robust, lightweight housing

Hard-coated aluminum alloy - Sensing slot

groove for positioning of the magnetic field sensor - Permanent magnet

sensing of the piston setting position via magnetic field sensors - Positively driven lever mechanism

synchronized the movement of the gripper jaws - Integrated gripping force safety device

spring integrated into cylinder as energy storage - Drive

double-acting pneumatic cylinder - Removable centering sleeves

quick and economical positioning of the gripper fingers