PRECISION, DYNAMICS AND SPEED

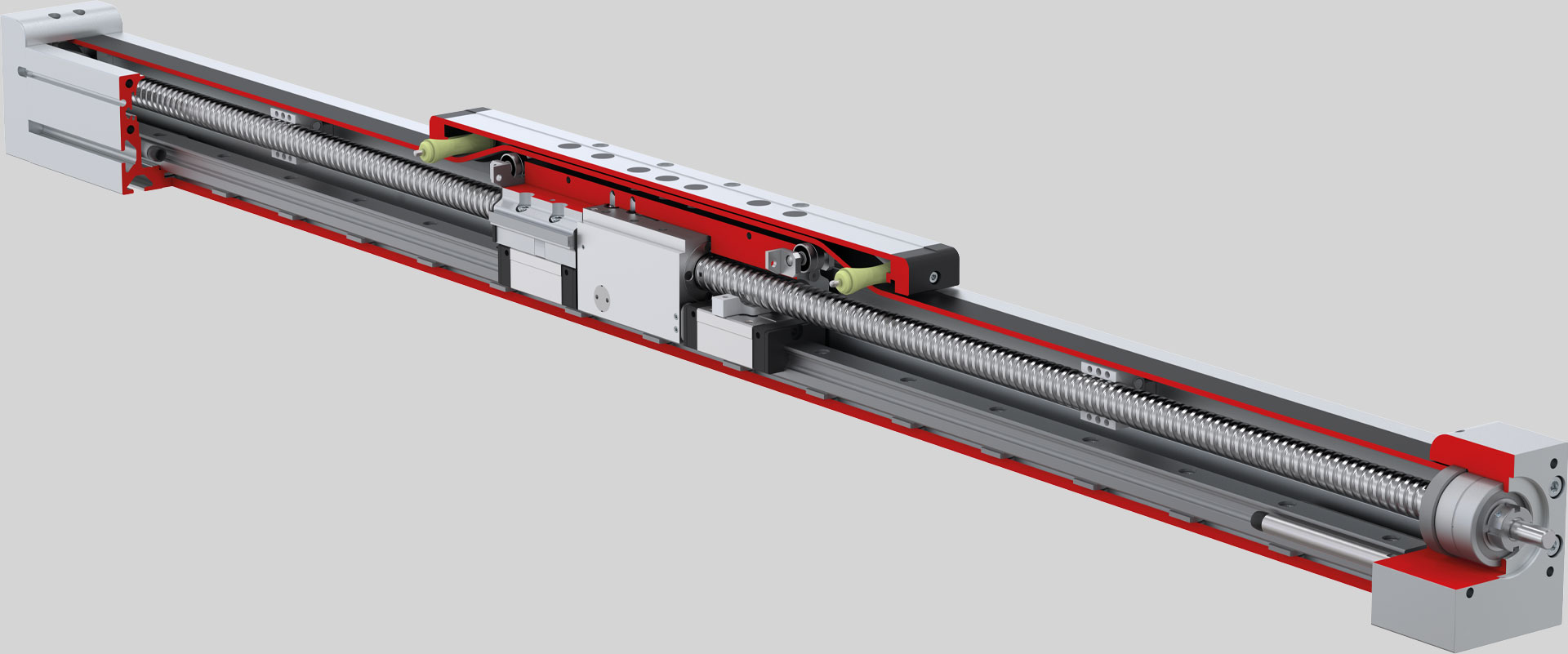

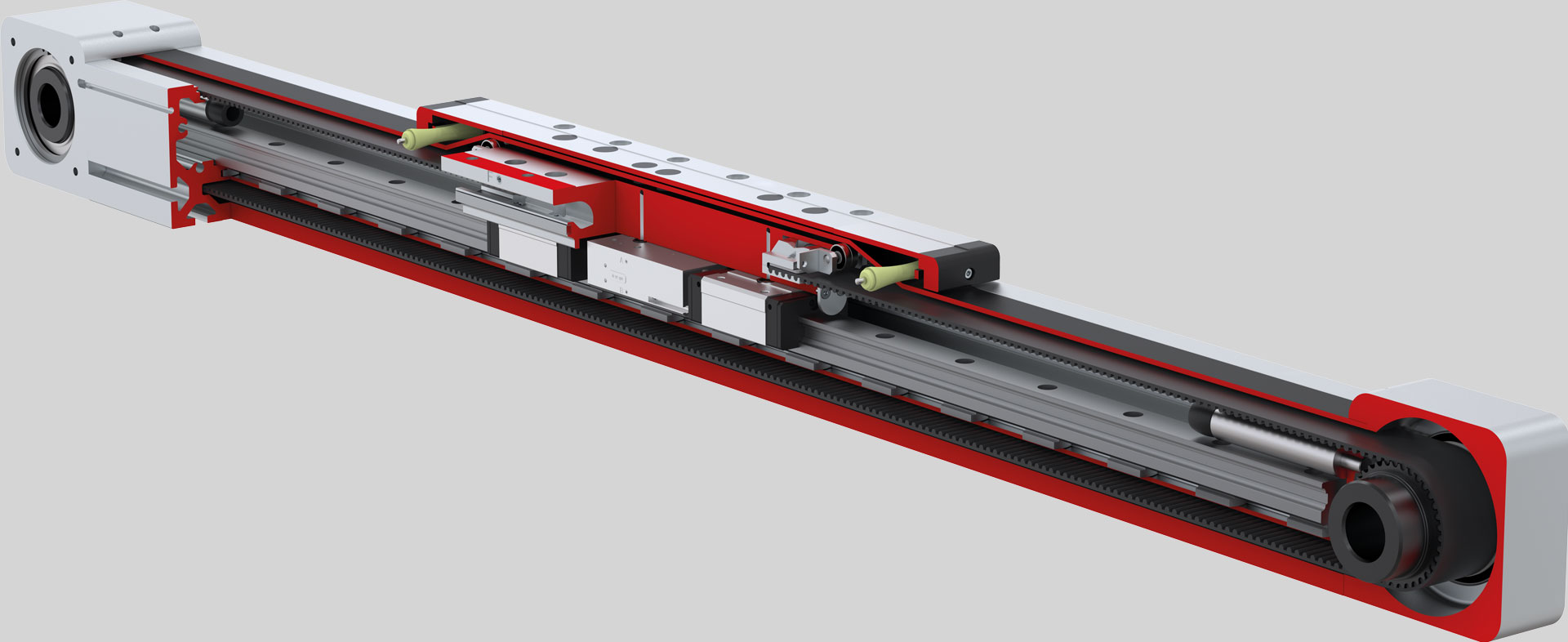

Linear axes are essential components in automation technology and offer reliable solutions for precise linear movements over long distances. Spindle axes and toothed belt axes in particular have proven themselves in this area. Spindle axes are characterized by their high precision and feed forces, ideal for applications that require accuracy and load capacity. Toothed belt axes, on the other hand, score points with their high dynamics and speed, making them perfect for fast motion sequences and large working areas. Discover the advantages of both axis types and find out how you can take your production efficiency to a new level with the AMS and AMB series.

OUR EXPERTISE – YOUR ADVANTAGES

High forces and torques

In combination with the integrated guide rail, the optimized axle profile enables maximum absorption of forces and torques.

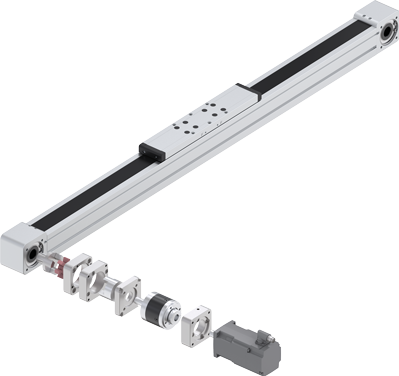

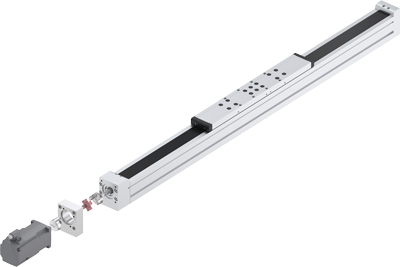

Optional drivetrain

The drivetrain, which consists of a clutch, gearbox, motor, drive control system and other accessories, is available upon request.

Maximum movement speeds

The optional spindle support enables high speeds even at long stroke, allowing for gentle high feed speeds.

Short cycle times

Maximum speeds of up to 5 m/s and acceleration of up to 50 m/s² are possible.

Integrated clamping element

The optional clamping element allows high clamping forces without interference contours or longer overall lengths.

Linear axes with toothed belt drive

THE TECHNICAL FEATURES IN DETAIL

Linear axes at a glance

THE AMS SERIES IN DETAIL