WMR2063L-00-A

Tool Changers

Series WMR2000

- Permanent electromagnet

The permanent electromagnet in the NC version ensures a secure hold, even if there is a power failure. - Integrated media transmission

Up to four integrated compressed air/vacuum transmitters possible. In addition, secure signal transmission is ensured by specially developed and sealed spring pin contacts. - Resistant materials

The tool changer was designed in accordance with GMP (Good Manufacturing Practice) and ISO 14644 and relies exclusively on FDA-compliant materials to ensure reduced particle emissions. Durable surfaces and materials guarantee resistance to aggressive cleaning agents such as hydrogen peroxide (H2O2) and many others.

Equipment/Options

Protected against corrosion

Protected against corrosion IO-Link

IO-Link Digital I/O

Digital I/O Cleanroom-certified

Cleanroom-certified FDA-compliant materials

FDA-compliant materials H2O2 resistant materials

H2O2 resistant materials IP68

IP68

Technical Data

| Connecting flange according EN ISO 9409-1 | TK 63 |

| Type of drive | Magnetic |

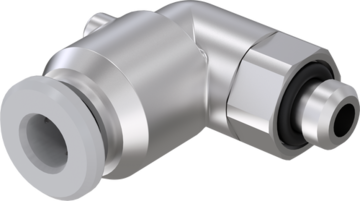

| Pneumatic energy transfer | 4 [Quantity] |

| Electrical energy transfer | 10 [Quantity] |

| Flow per connector | 360 [l/min] |

| Energy element operating voltage | 24 [V] |

| Energy element nominal current | 5 [A] |

| Data transmission | Digital I/O, IO-Link |

| Joining force | 60 [N] |

| Release force | 120 [N] |

| Repetition accuracy in Z | 0.1 [mm] |

| Repetition accuracy in X, Y | 0.1 [mm] |

| Offset at coupling max. in X,Y | 1 [mm] |

| Operating temperature | 5 ... +60 [°C] |

| Moment of inertia | 1.6 [kgcm²] |

| Clean room applications according to DIN EN ISO 14644-1 | 2 |

| Certifications | LABS / REACH / RoHS |

| Protection to IEC 60529 | IP68 |

| Weight | 0.21 [kg] |

Benefits in detail

- Certifications

Developed and constructed in accordance with GMP Class A H2O2-resistant materials TÜV-certified cleanroom class - Drive

Permanent electromagnet (NC version) Secure hold even in the event of a power failure - Robot flange

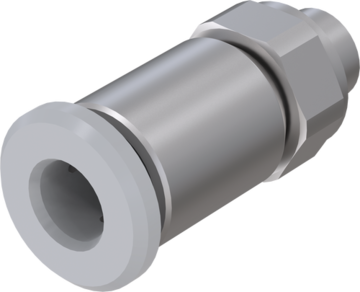

partial mounting circle in accordance with EN ISO 9409-1 - Integrated air feed-through

Air / vaccum transfer Hoseless control possible - Integrated current and signal transmission

Sealed FDA-compliant spring contacts Integrated loose part coding - Loose part

For tool side assembly Sealed flange - Fix part

For robot side assembly Sealed flange