System reference

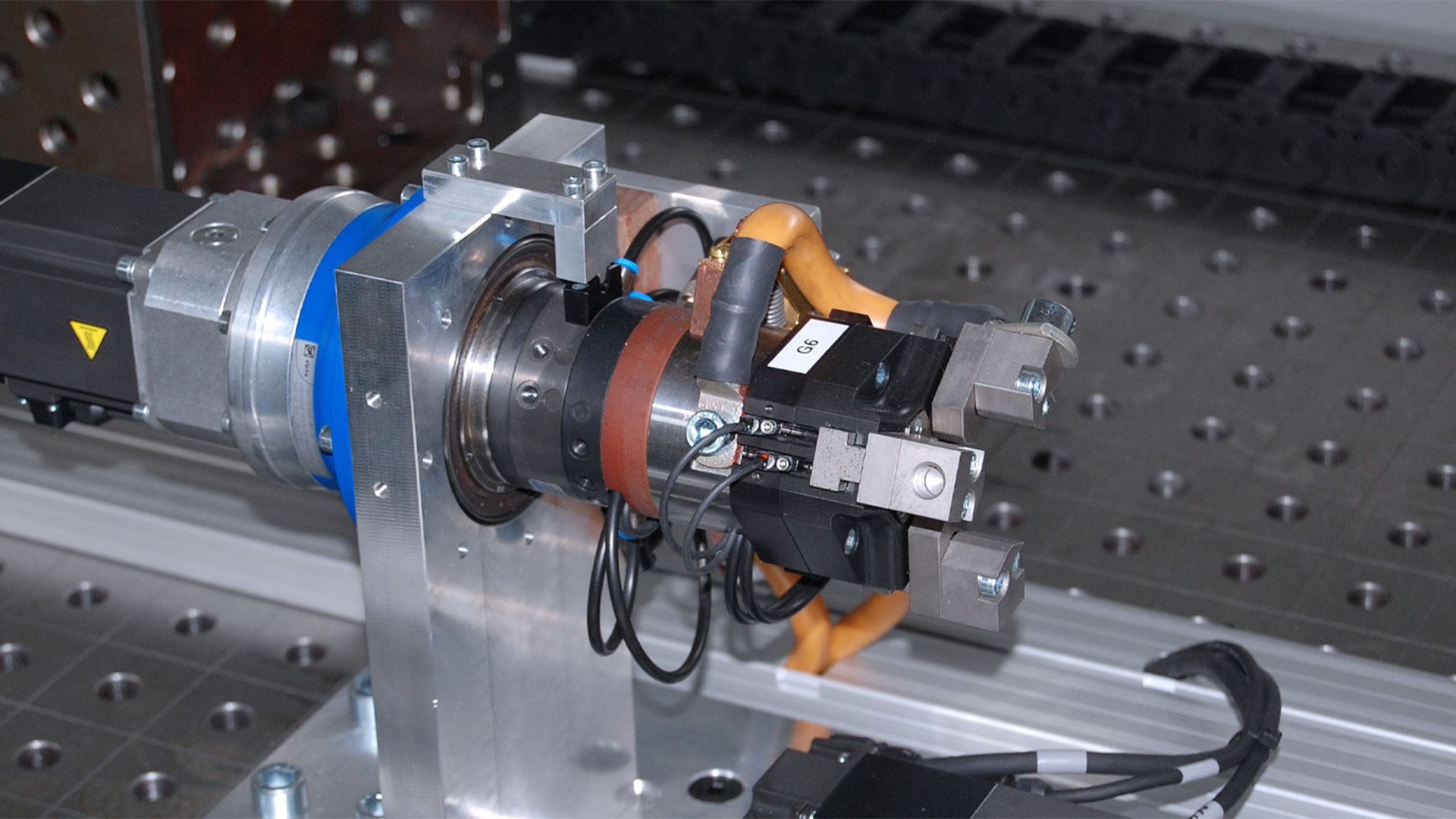

Turning station for welding

Gripper | System solutions | Mechanical and plant engineering | Metal | Welding and cutting

3-Jaw Concentric Grippers

Series GD300

- Extremely robust T-Slot guide for maximum forces and moments capacity

- Available with optional dust cover for use at extreme conditions

Rotary Distributors

Series DVR

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK40... TK160

- With 4...8 pneumatic feedthroughs

- With 4...12 electrical feedthroughs

1. 3-jaw concentric grippers

- Extremely robust T-Slot guide for maximum forces and moments capacity

- Available with optional dust cover for use at extreme conditions

2. Rotary distributor

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK40... TK160

- With 4...8 pneumatic feedthroughs

- With 4...12 electrical feedthroughs

Challenge

In the production of garage doors by Europe's largest garage door manufacturer, steel shafts needed to be lathed so that they could be welded by a MAG welding robot. Harsh ambient conditions and ground discharging (welding current) were the challenges here.

Solution

A servo rotary axis, in combination with a Zimmer rotary distributor and three-jaw gripper, was the solution here. The components were held securely by the three-jaw gripper. In the gripped state, the components were turned by the servo motor and the ground discharged via the rotary distributor.

Highlights and technical data

IP40

IP40 Pneumatic

Pneumatic External gripping

External gripping Gripping force safety device for pressure maintenance

Gripping force safety device for pressure maintenance

Technical Data

| Drive type | PNEU |

| Max. gripping force | 750 [N] |

| Gripping concept | KRAFT |

| Gripping safety device | DRUCKSICHER |

| Max. stroke | 12 [mm] |

| IP class | IP40 |

| System weight | 5 [kg] |

| Max. workpiece weight | 0.3 [kg] |

| Max. workpiece temperature | 130 [°C] |

Built-in standard components