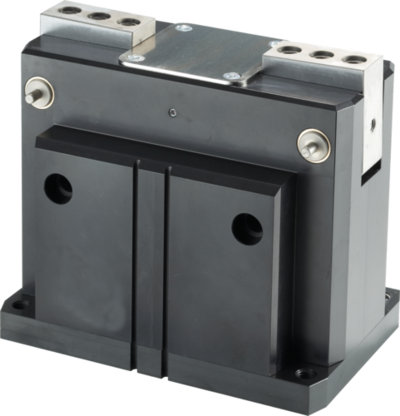

2-Jaw Angular Grippers

Series GG1000

"The strong"

- High gripping force

Using the high gripping force, you can safely handle even the heaviest workpieces - High moment load

The generously scaled angular gear box provides the highest possible durability for your application - Failure-free continuous operation

Our uncompromising "Made in Germany" quality guarantees up to 10 million maintenance-free cycles

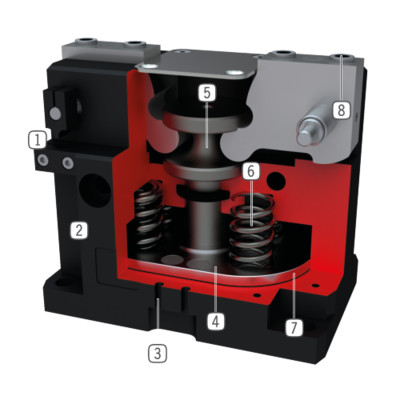

- Cam-switch and mounting block

for position sensing - Robust, lightweight housing

Hard-coated aluminum alloy - Sensing slot

groove for positioning of the magnetic field sensor - Permanent magnet

sensing of the piston setting position via magnetic field sensors - Positively driven lever mechanism

synchronized the movement of the gripper jaws - Integrated gripping force safety device

spring integrated into cylinder as energy storage - Drive

double-acting pneumatic cylinder - Removable centering sleeves

quick and economical positioning of the gripper fingers