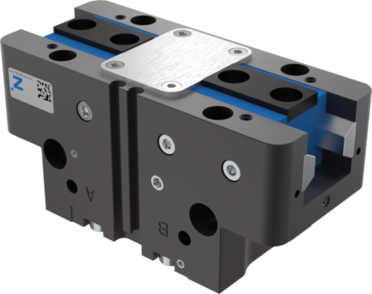

GPP5008N-20-A

2-Jaw Parallel Grippers

Series GPP5000

"The best"

- Steel Linear Guide –

The superior guidance system concept

The steel / steel guide stands for lasting precision, durability and a long service life—featuring maintenance intervals of up to 30 million gripping cycles. Benefit from these features and increase the profitability and process reliability of your machine. - Leakproof and corrosion protected – The universal gripper

Suitable for virtually all ambient conditions, with a sealed guide up to IP67 and corrosion protection as standard, you are able to use this gripper universally. As a result, the range of models in your production is reduced, along with a reduction in associated storage and process costs. - The value promise – Consistent and without fine print

Rely on the Zimmer Group and benefit from an exclusive 24-month warranty for your GPP and GPD5000 grippers – without restrictions, even for parts that come into contact with the workpiece and wear parts. Maximum reliability, maximum productivity – 24/7!

Equipment/Options

30 million maintenance-free cycles (max.)

30 million maintenance-free cycles (max.) IP64

IP64 Protected against corrosion

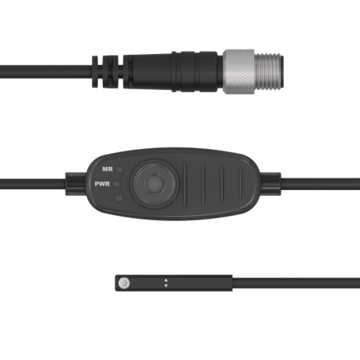

Protected against corrosion Magnetic field sensor

Magnetic field sensor Inductive sensor

Inductive sensor Purged air

Purged air Temperature-resistant

Temperature-resistant Long stroke

Long stroke Steel Linear Guide

Steel Linear Guide

Technical Data

| Stroke per jaw | 8 [mm] |

| Gripping force in closing | 520 [N] |

| Gripping force in opening | 560 [N] |

| Closing time | 0.035 [s] |

| Opening time | 0.035 [s] |

| Dead weight of mounted gripper finger max. | 0.7 [kg] |

| Length of the gripper fingers max. | 125 [mm] |

| Repetition accuracy +/- | 0.01 [mm] |

| Operating pressure | 3 ... 8 [bar] |

| Nominal operating pressure | 6 [bar] |

| Operating temperature | -10 ... +130 [°C] |

| Air volume per cycle | 22 [cm³] |

| Certifications | LABS / REACH / RoHS |

| Protection to IEC 60529 | IP64 |

| Protected against corrosion | Yes |

| Weight | 0.53 [kg] |

Benefits in detail

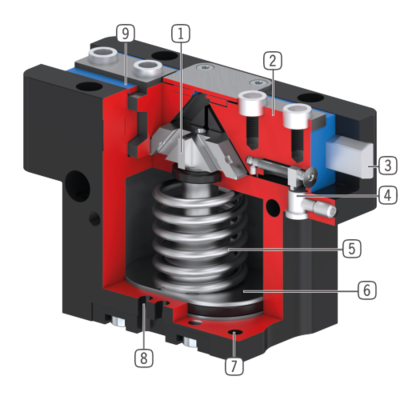

- Wedge hook mechanism

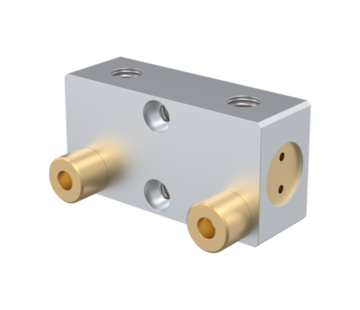

Supports to absorb high forces and moments Synchronized gripper jaw movement - Gripper jaw

Gripper fingers mounted using removable centering sleeves Lubricated for life via incorporated lubrication slots - Steel Linear Guide

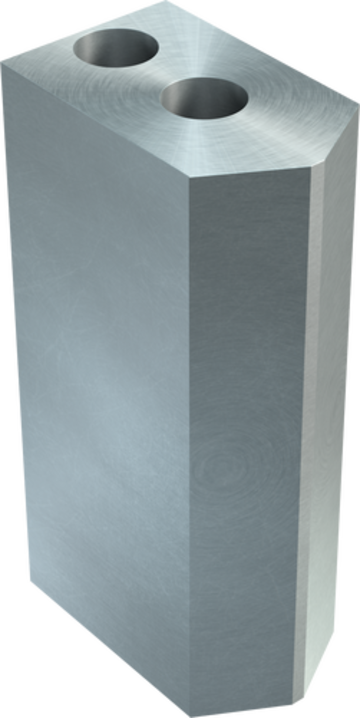

Steel in steel guide Enables use of extremely long gripper fingers - Mounting block

mounting for inductive proximity switch - Integrated gripping force safety device

Spring built into cylinder chamber as an energy store - Drive

Double-acting pneumatic rotor cylinder - Mounting and positioning

Alternatively, on several sides for customized mounting Pneumatic and electrical versions identical apart from height - Sensing slot

mounting and positioning of magnetic field sensors - Dual lip seal

IP64 and up to IP67 (with purged air) for Protector version Prevents grease from being squeezed out, increasing service life

Certificates clean room suitability

SERIES GPP5000 00-VERSIONS*

SERIES GPP5000 21-VERSIONS*

SERIES GPP5000 AL-VERSIONS*

*Certifications are valid for all versions only up to installation size GPP5016