IO-Link meets digital I/O

The Smart Communication Module (SCM) is a master gateway that is suitable for all IO-Link components. With its two channels, the SCM can control two devices and on a functional level, offers the direct implementation of IO-Link to digital I/O. The module thus makes it possible to integrate IO-Link devices into a digital infrastructure and utilize almost the full extended range of functions of the IO-Link device.

YOUR benefits

- Translates IO-Link to digital inputs and outputs (digital I/O) and from digital I/O to IO-Link

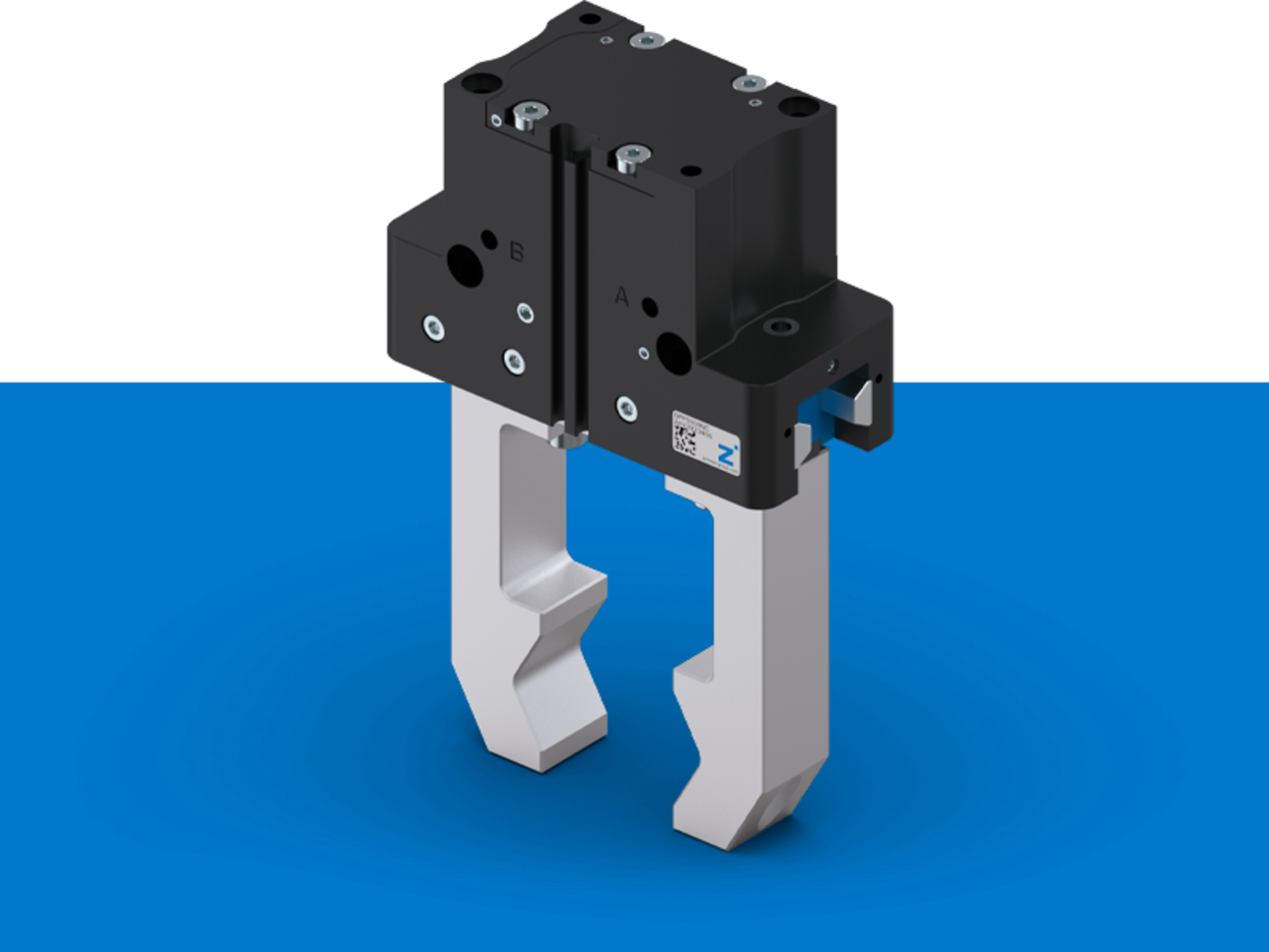

- Easy control of intelligent IO-Link grippers via 24 V digital I/O

- Configuration and training take place using the corresponding intuitive guideZ software

- Can be used with one or two grippers depending on the flexibility required

- Up to 15 different workpieces can be trained for one gripper

COMPLETE SOLUTION MATCH OR COMPLETE SOLUTION CONVENTIONAL

Whether MATCH end-of-arm ecosystem or conventional - the ready-to-connect communication modules from the Zimmer Group

enable a complete solution tailored to your needs. Thanks to the direct integration of a digital infrastructure

and interference-free communication from gripper to machine is guaranteed.

Complete solution MATCH

Complete solution with standardized

MATCH robot interface. Including SCM,

operating software and tooling.

Includes:

+ Smart Communication Module

+ Software package guideZ, expertZ

monitorZ

+ ComfortApp

+ Robot-specific

Connecting elements

+ MATCH-Robot module

+ MATCH-Gripper

Complete solution Conventional

Conventional complete solution from gripper,

SCM including intuitive operating software

up to the tool.

Includes:

+ Smart Communication Module

+ Software package guideZ, expertZ

monitorZ

+ ComfortApp

+ Robot-specific

Connection elements

+ Conventional gripper

SCM + COMFORT READY TO CONNECT

Simple connection of the SCM placed in the

SCM placed in the robot module by means of a ready-to-connect cable and controller.

Includes:

+ Smart Communication Module

+ Software package guideZ, expertZ

monitorZ

+ ComfortApp

+ Robot-specific

Connection elements

SCM + Comfort

Convenient control and operation of the gripper thanks to Comfort App directly via the respective robot operating unit.

Includes:

+ Smart Communication Module

+ Software package guideZ, expertZ

monitorZ

+ ComfortApp

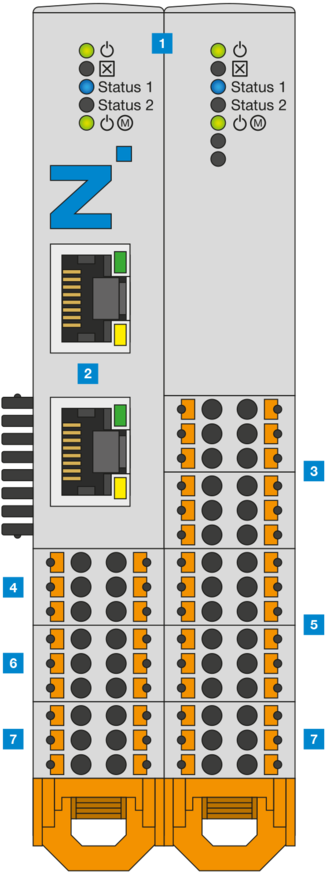

SCM

The intelligent gateway between gripper and robot controller translates IO-Link to digital inputs and outputs.

Includes:

+ Smart Communication Module

+ Software package guideZ, expertZ

monitorZ

1 Status

Status display of SCM and IO-Link device

2 Ethernet / RJ45

Temporary connection for gripper configuration

3 Digital input

Digital inputs for controlling the gripper actuators

4 IO-Link / Device 1

Gripper module 1 connection

5 Digital output

Digital outputs for monitoring the gripper sensors

6 IO-Link / Device 2

Gripper module 2 connection

7 Power supply

Voltage supply SCM and gripper

| Technical data | ||||

|---|---|---|---|---|

| Order No. | SCM-C-00-00-A | |||

| Voltage [V] | 24 V ± 10 % | |||

| Current draw [A]* | SCM without gripper typ. 0.075 A SCM with gripper GEH6040IL without gripping movement typ. 0.215 A SCM with gripper GEP2010IL without gripping movement typ. 0.1 A | |||

| Protection class in accordance with IEC 60529 | IP20 | |||

| Operating temperature [°C] | +5 ... +50 | |||

| Configuration | Ethernet with RJ45 | |||

| Control of the gripper | 2 channels with IO-Link port class B | |||

| Interface to higher-level control system | 12 digital inputs 24 V PNP logic, 12 digital outputs 24 V PNP logic | |||

* For the load current consumption of the gripper, refer to the respective gripper documentation

Application example

The SCM is installed in the robot control cabinet, where it communicates directly with the robot control system using its digital I/O. On the gripper side, the 5 pins of the IO-Link are connected directly to the SCM, using an external or (where available) internal line.