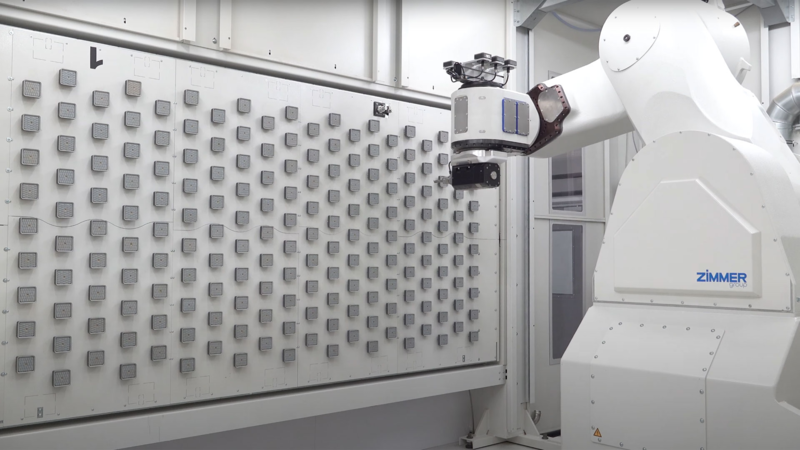

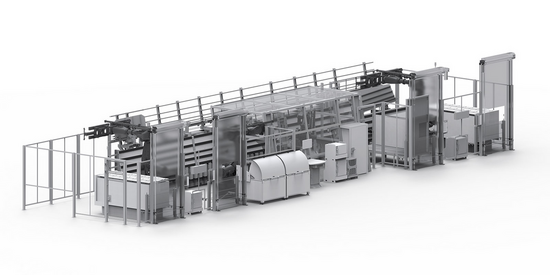

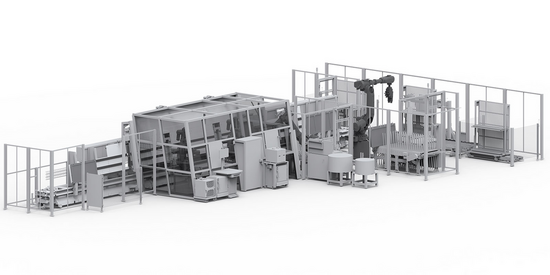

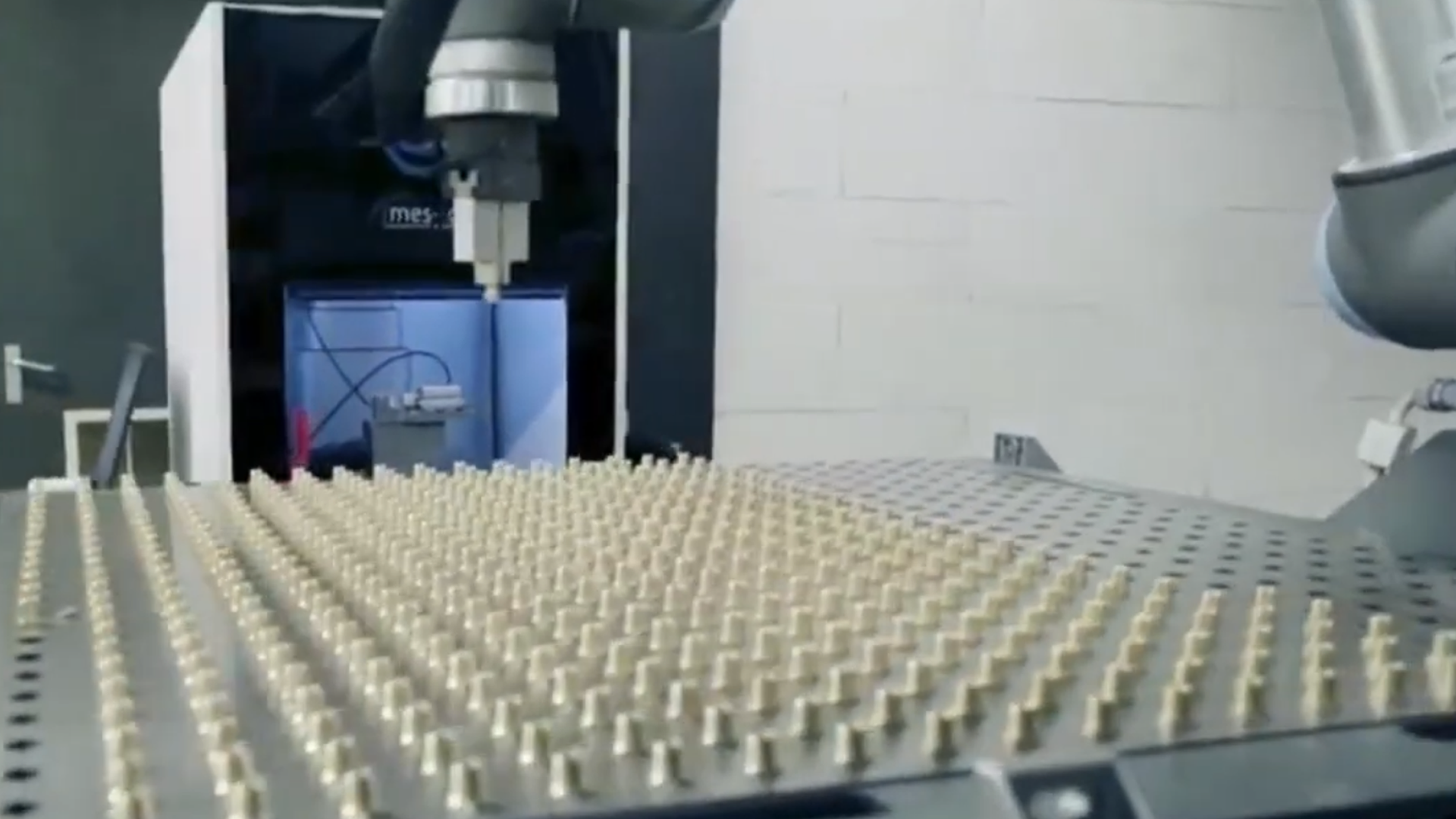

Limitless manufacturing

Your production, smarter than ever!

#THEKNOWHOWFACTORY

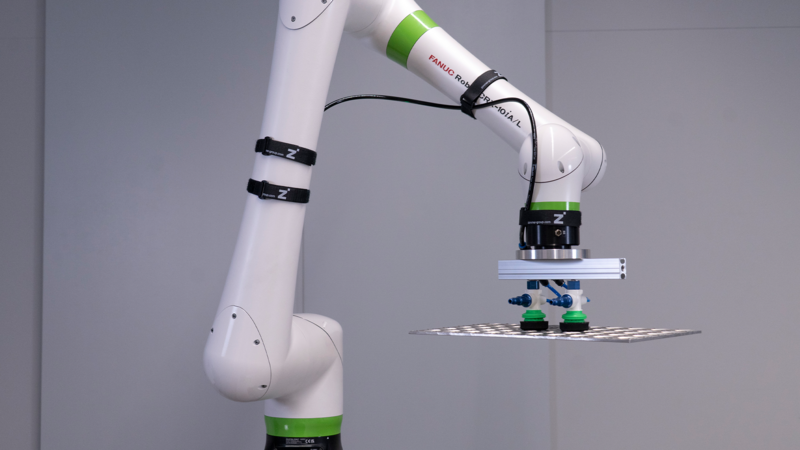

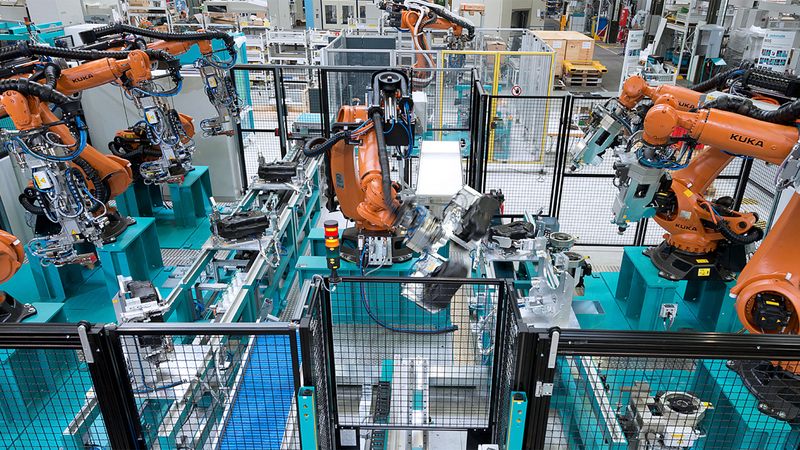

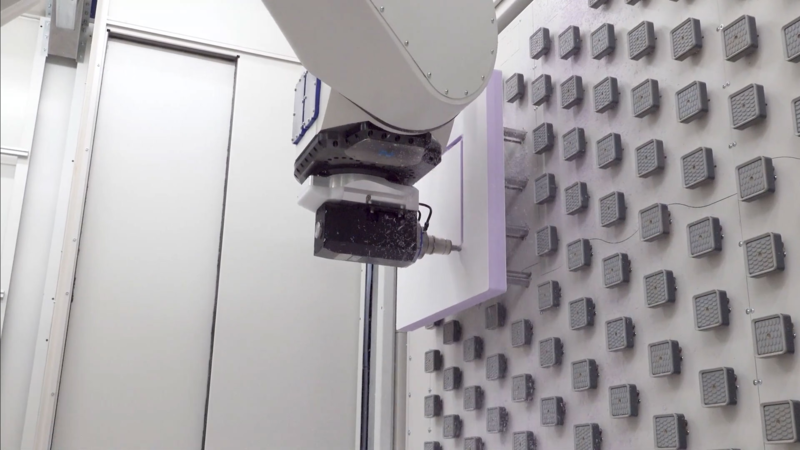

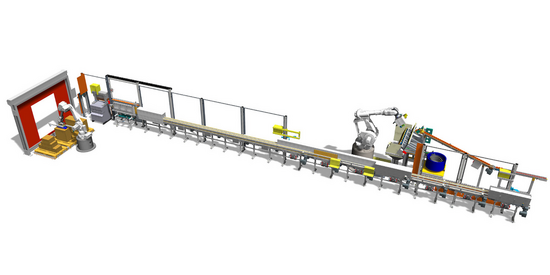

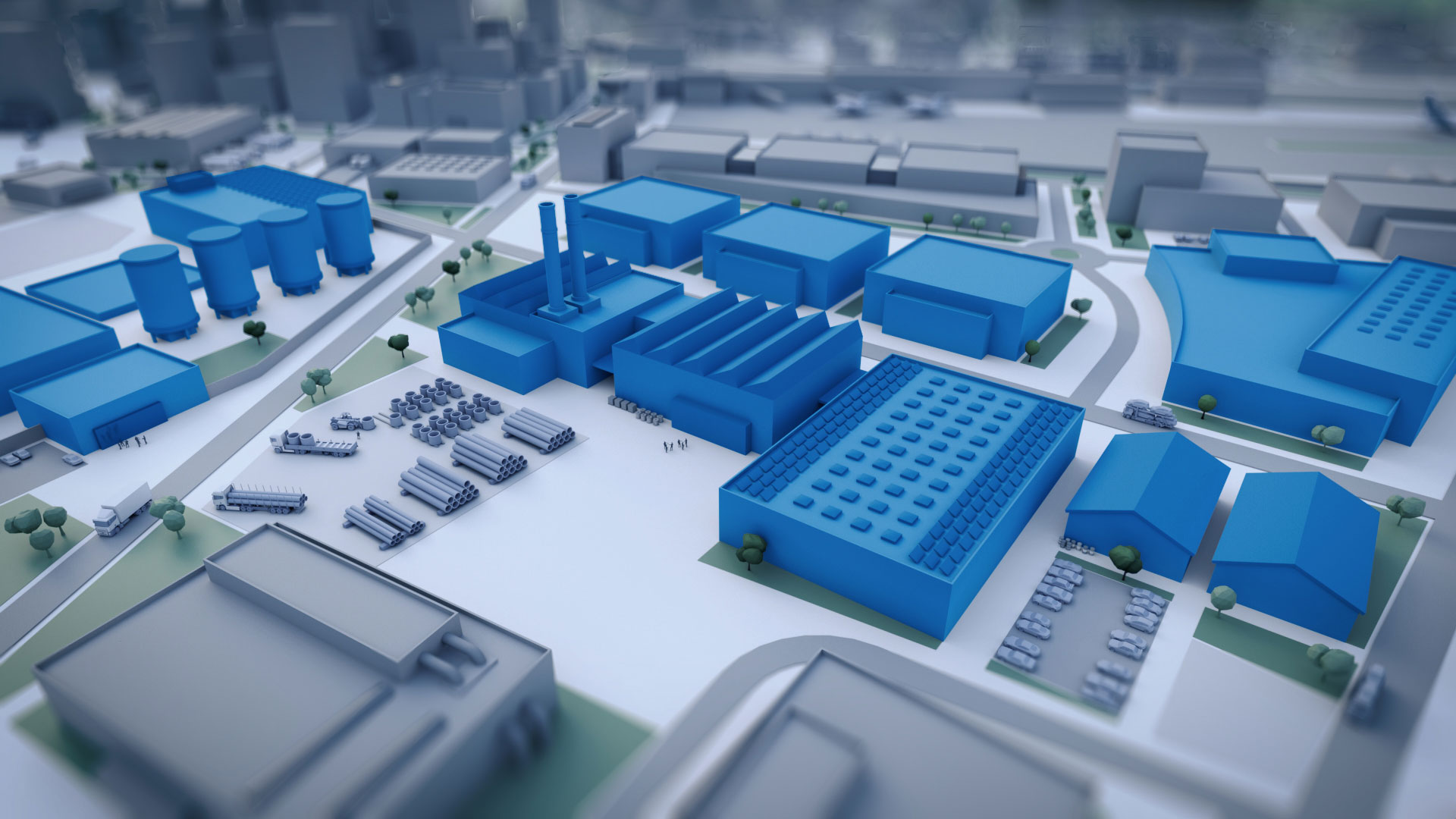

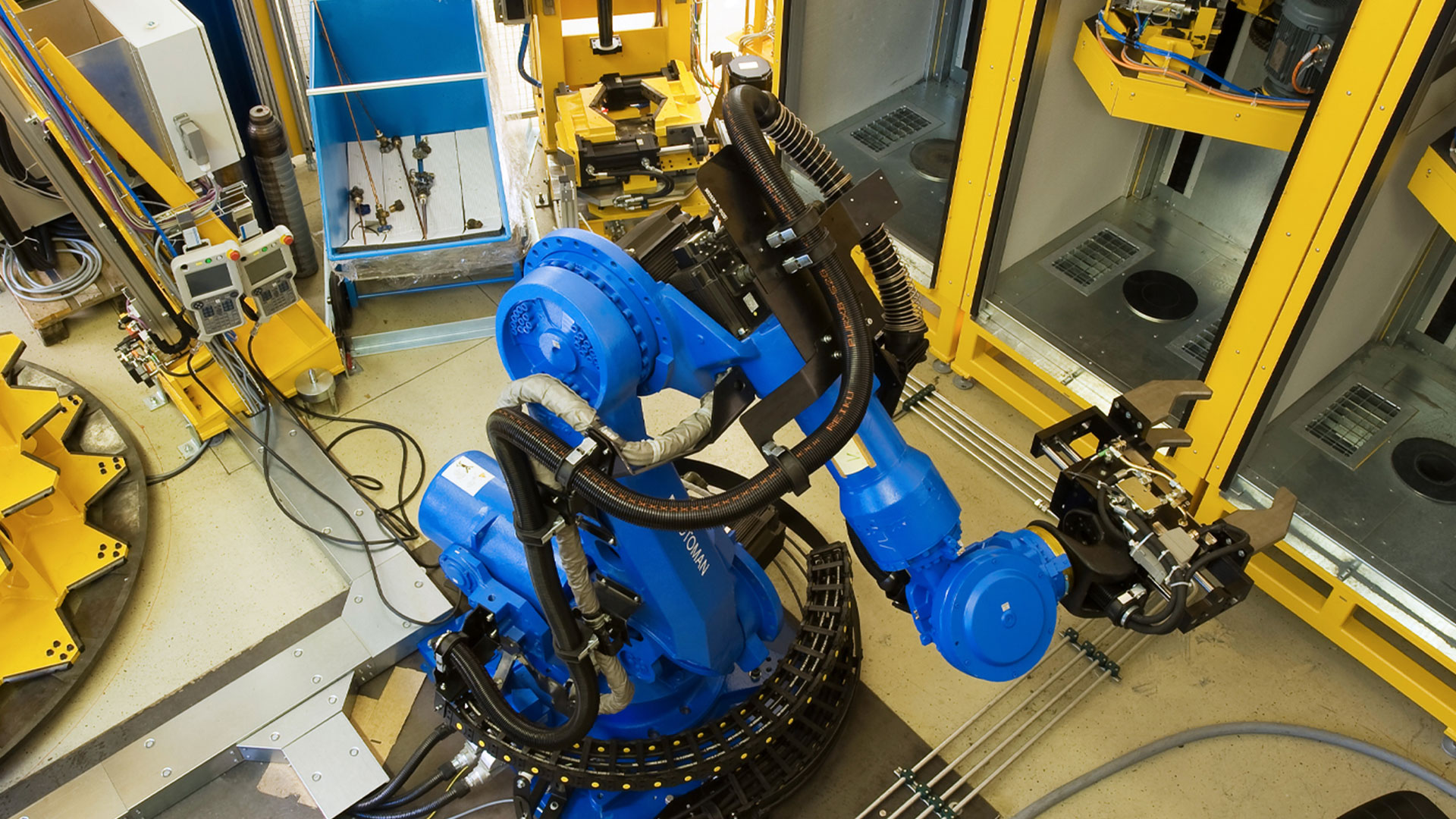

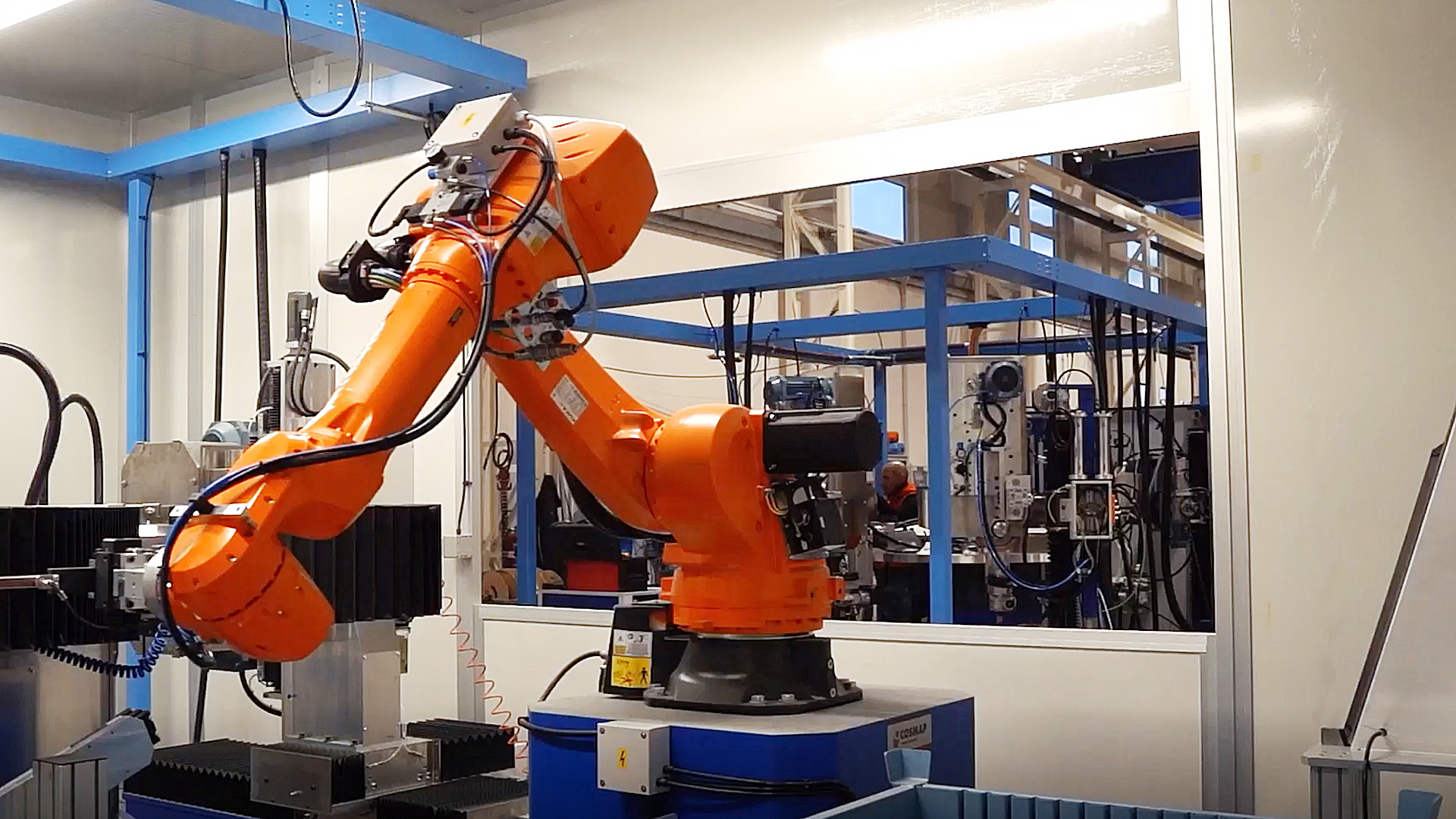

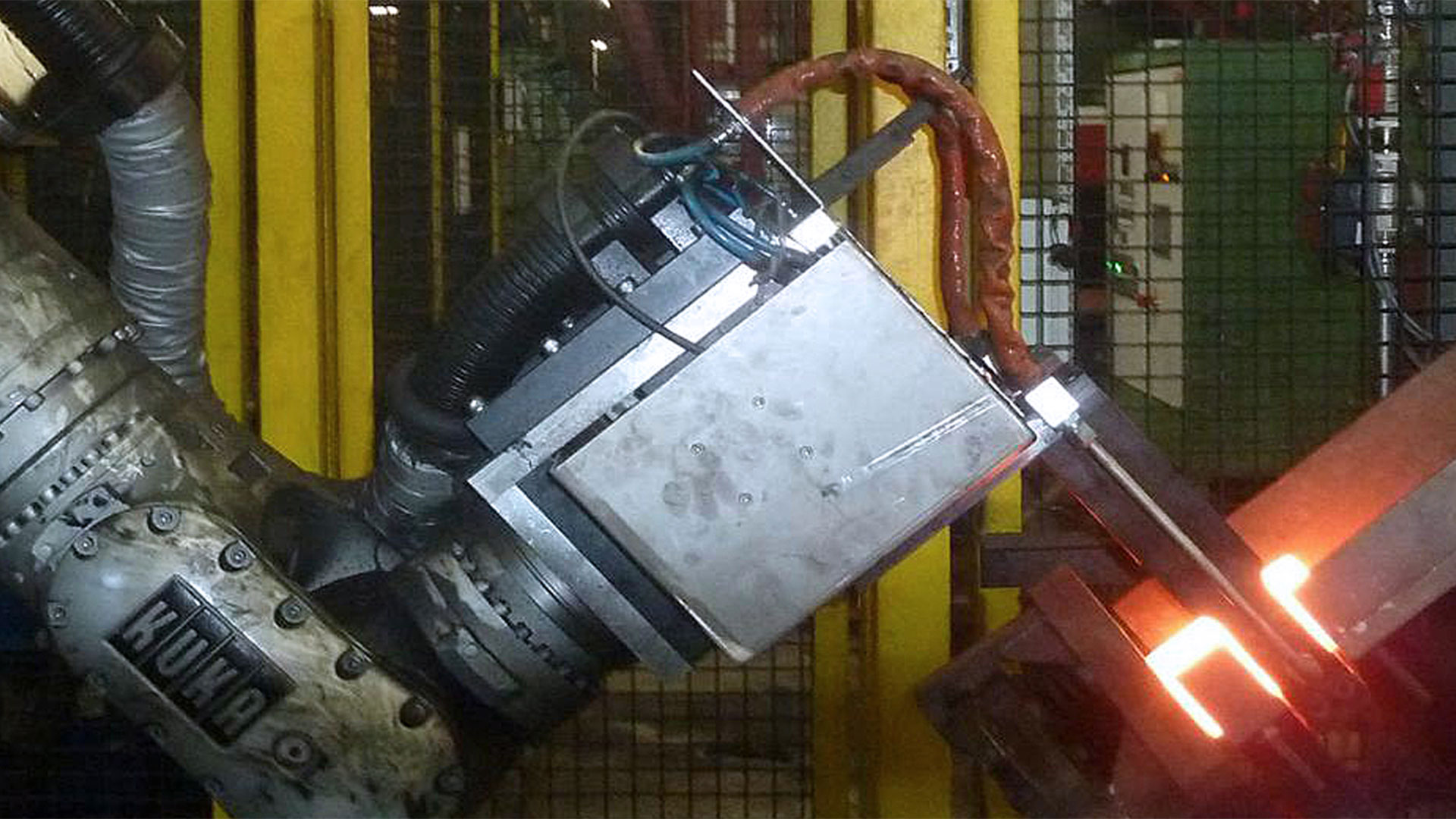

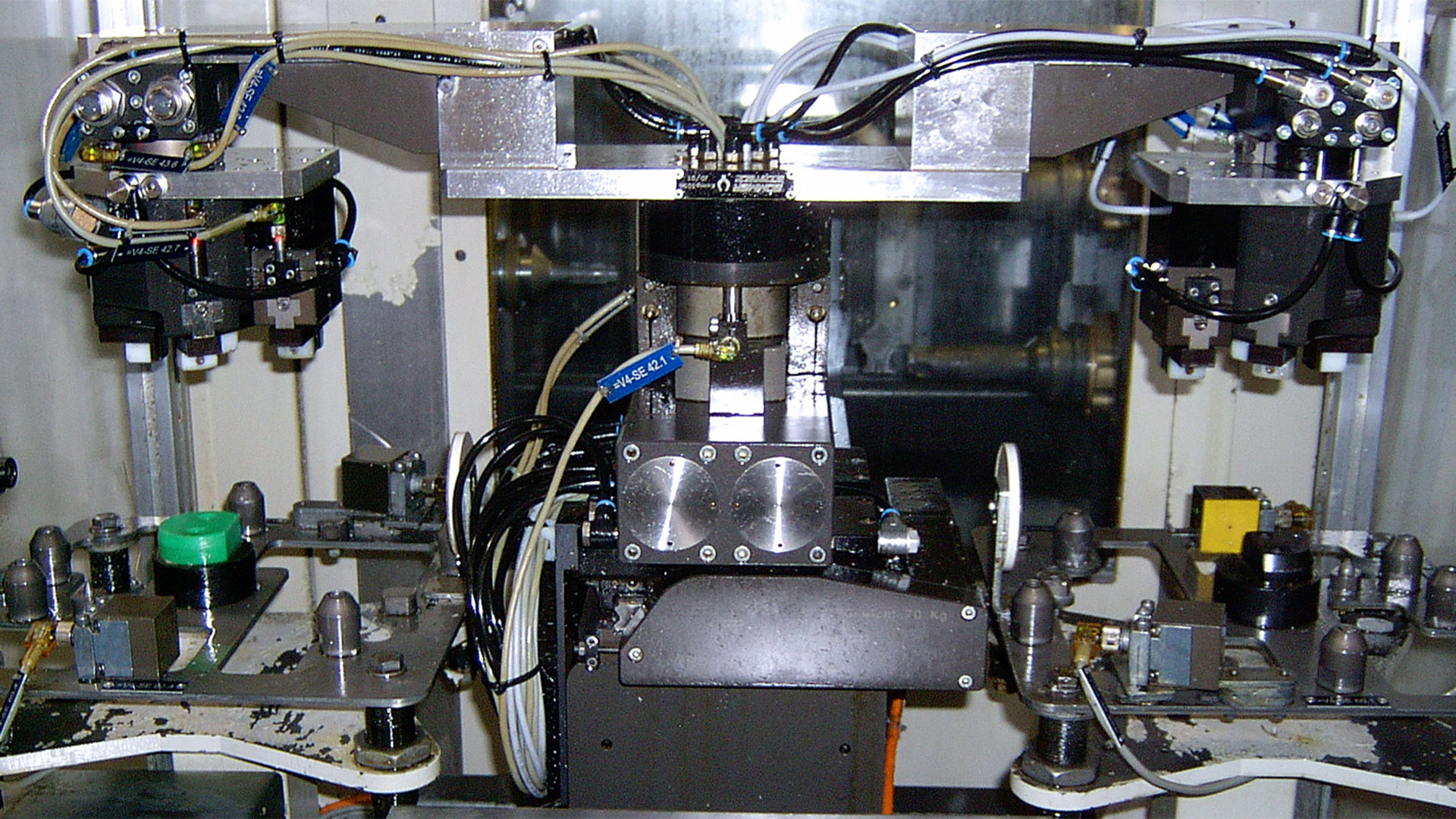

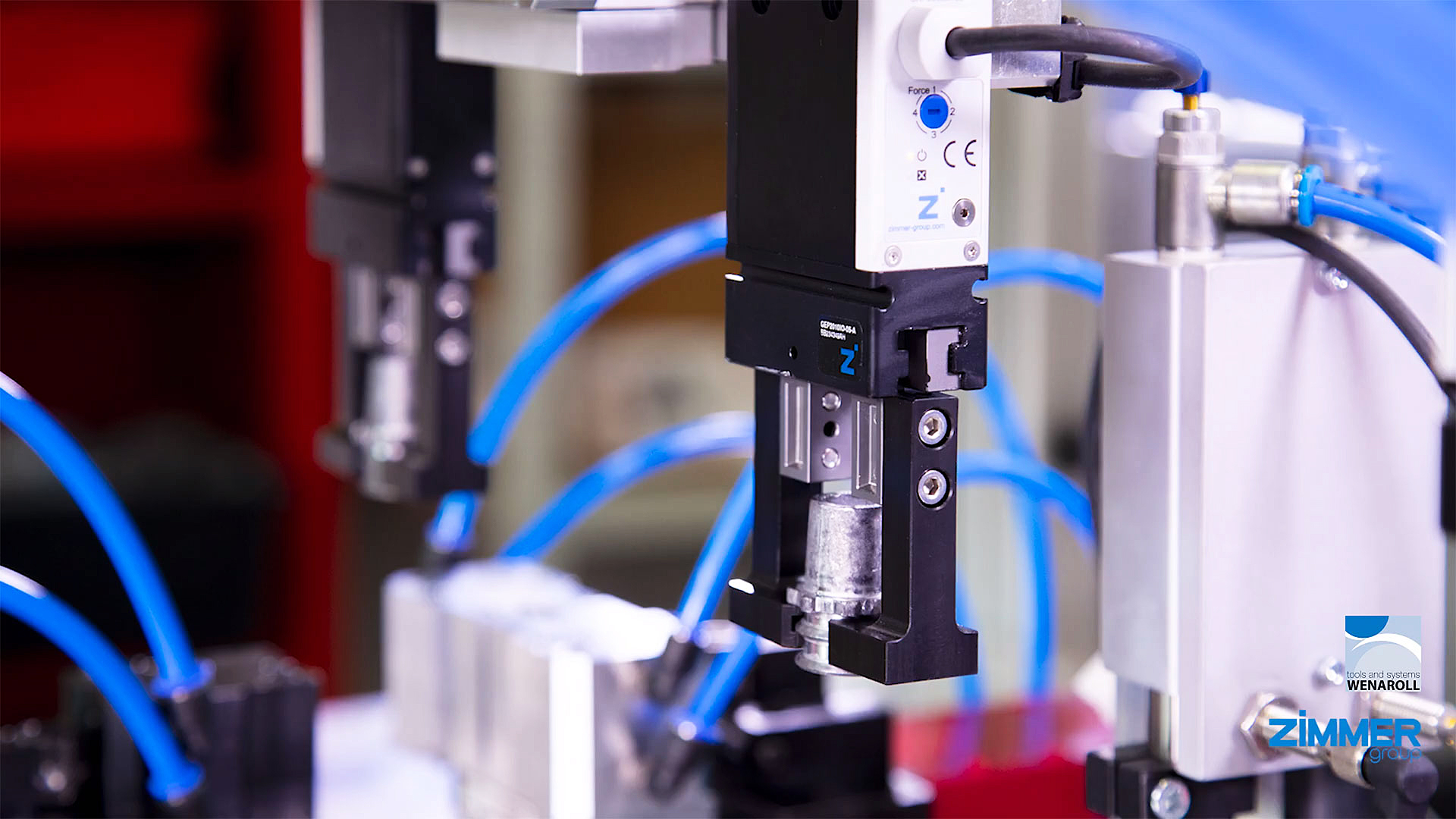

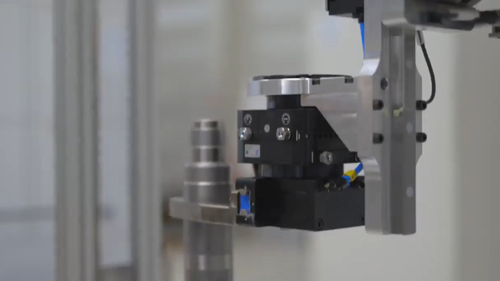

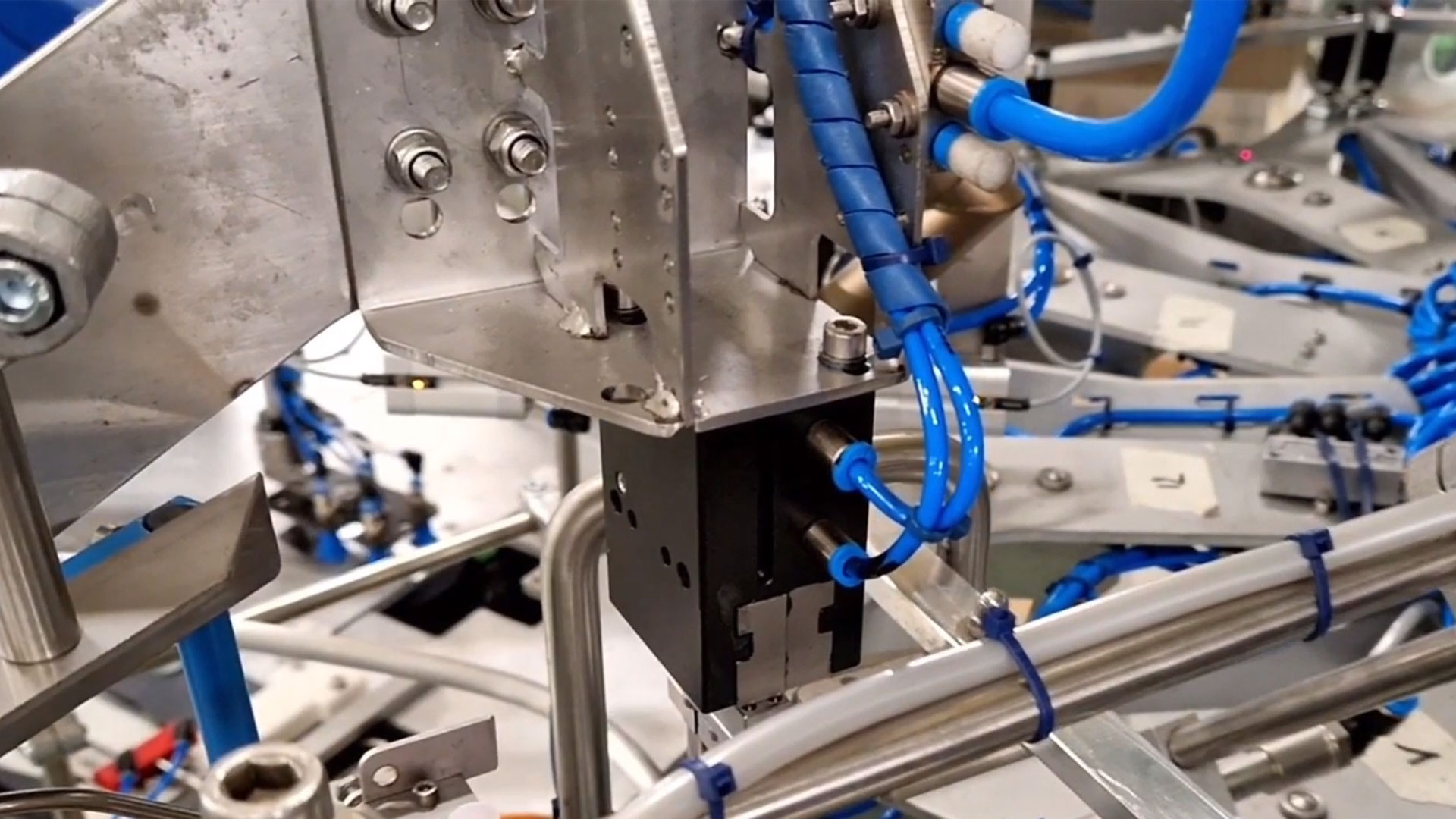

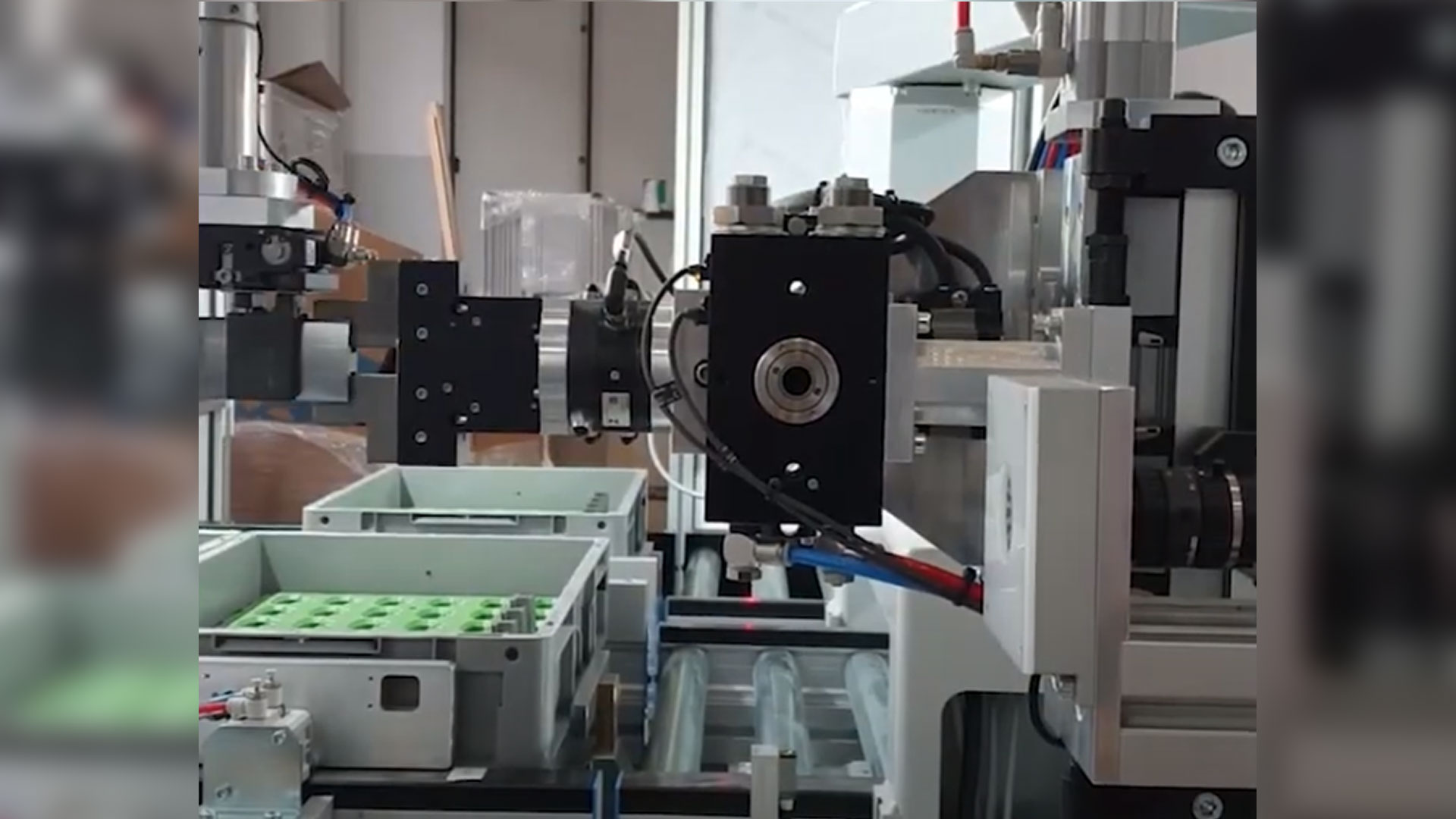

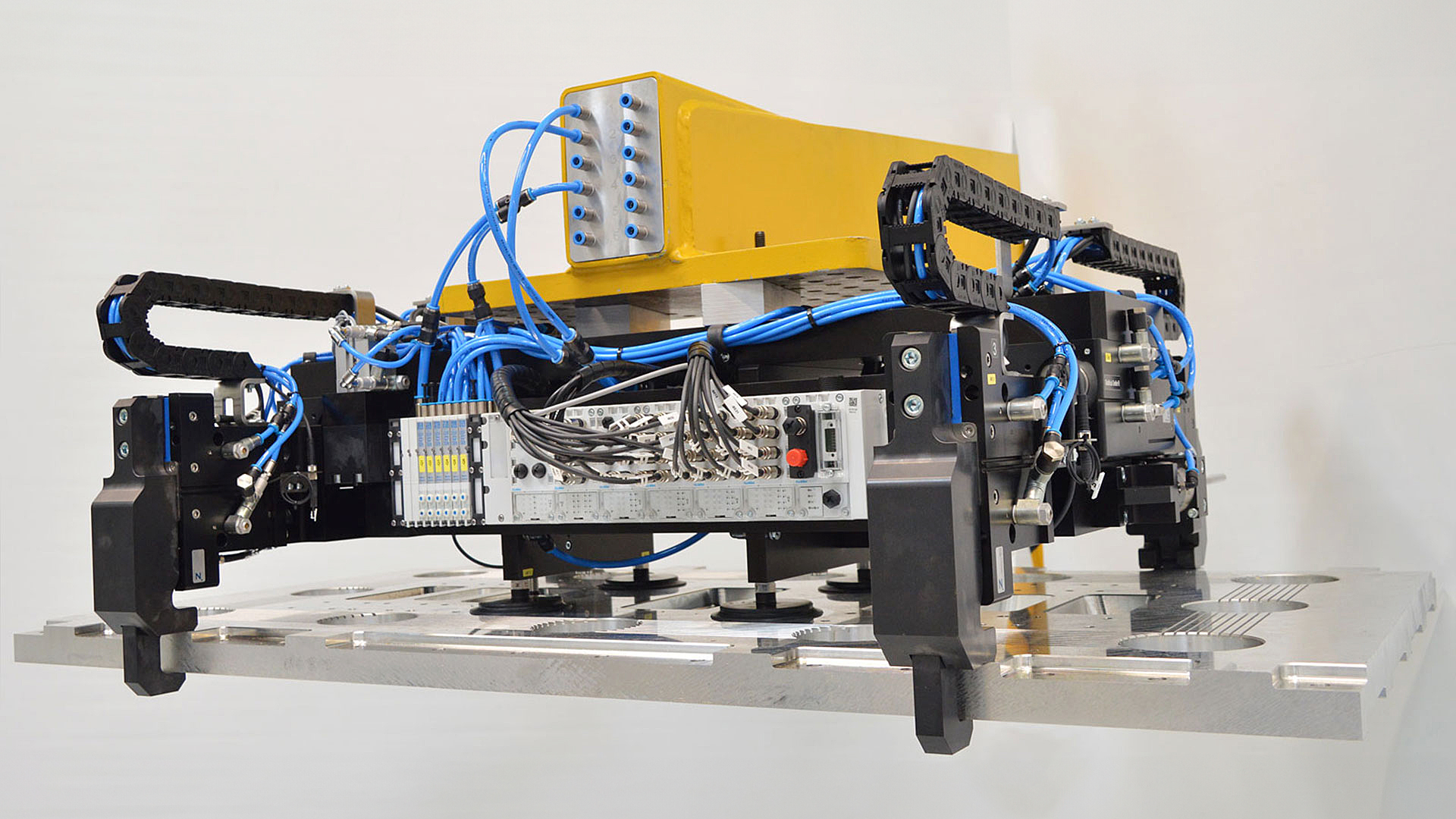

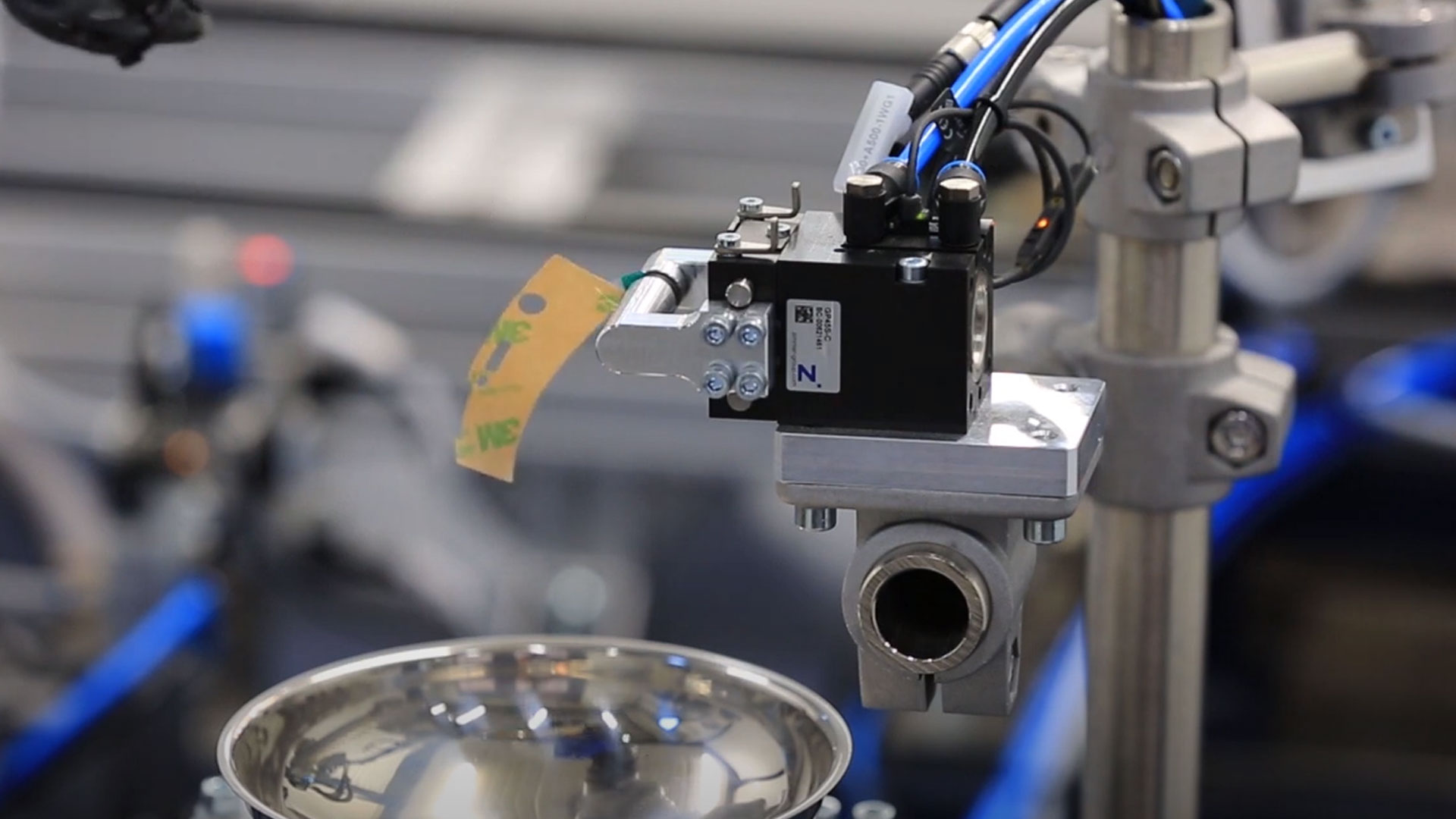

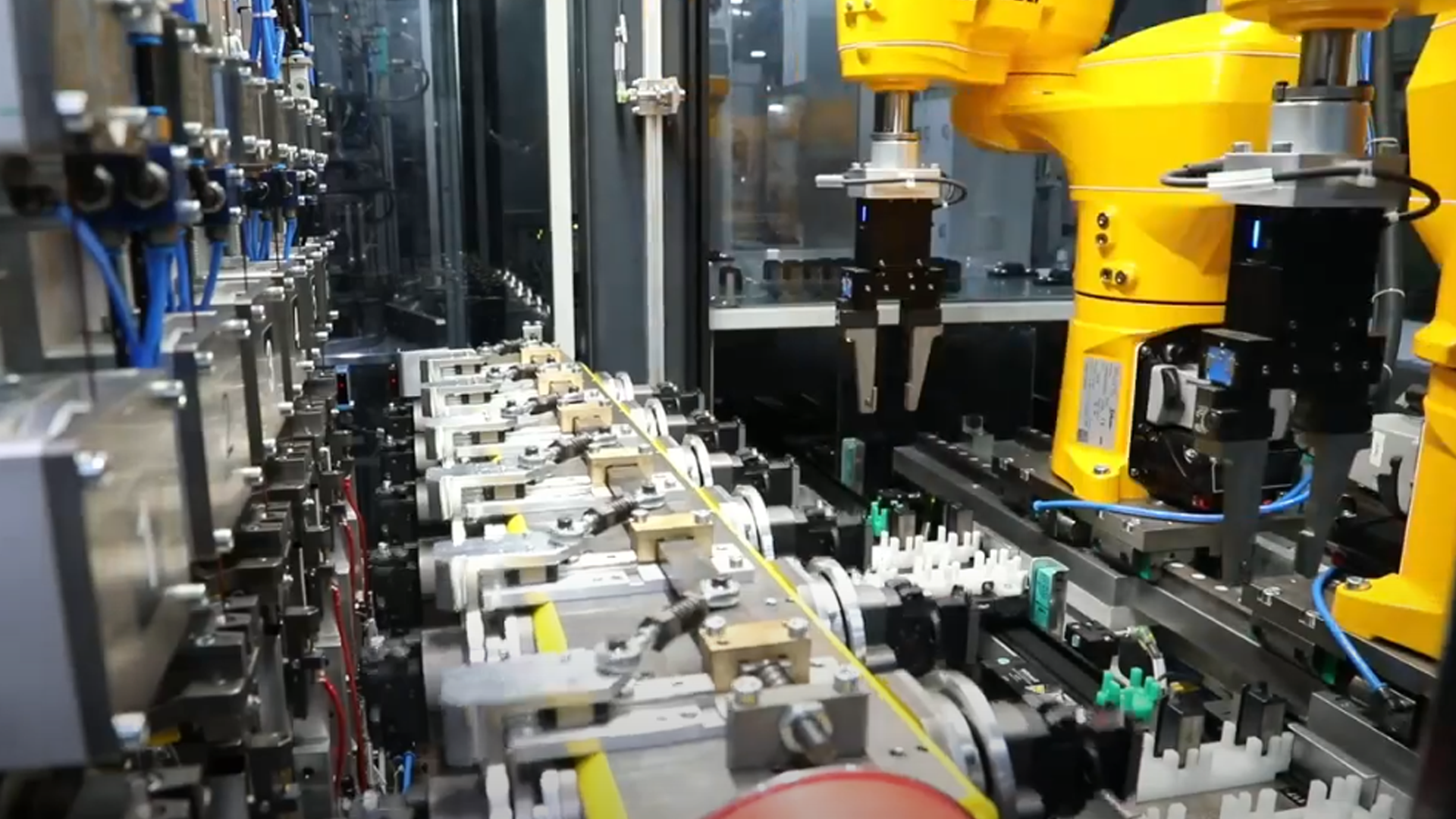

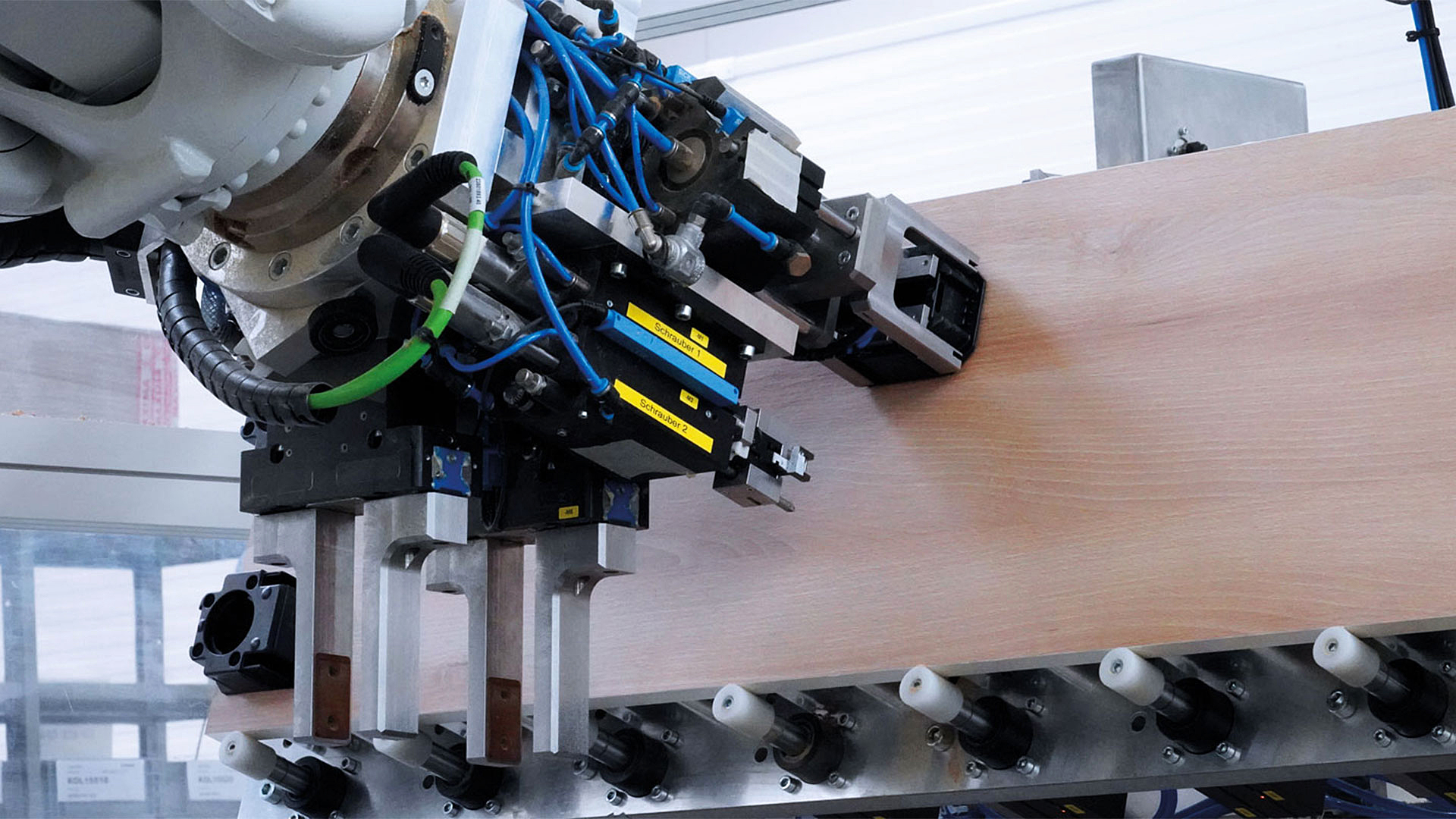

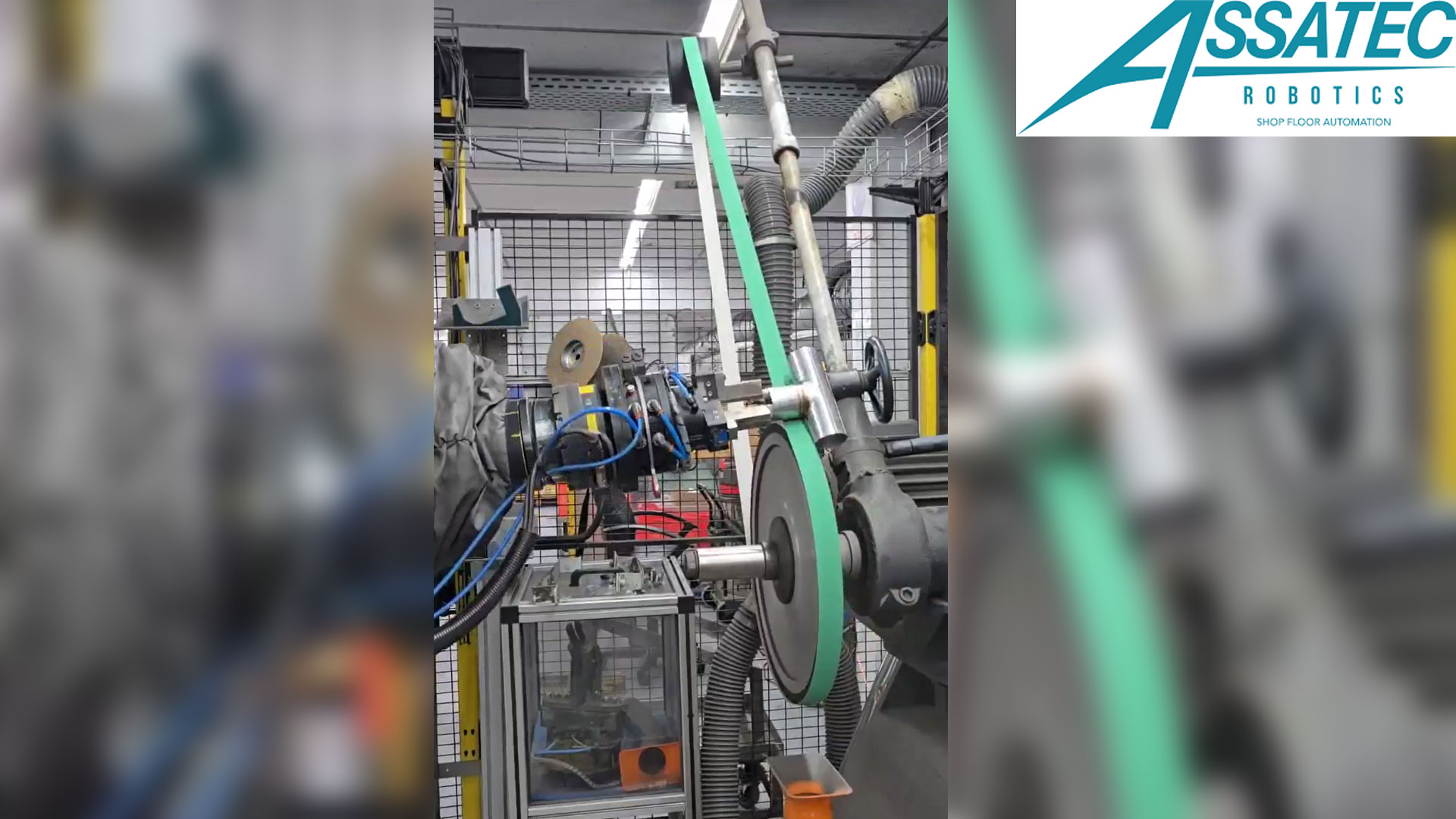

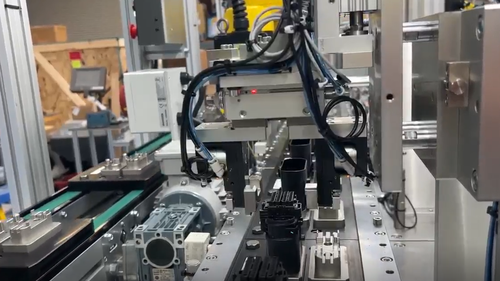

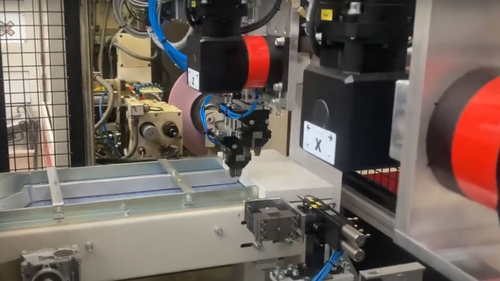

Automation in mechanical and plant engineering

Individual customer requirements, international competition, a shortage of skilled workers – the mechanical and plant engineering industry is facing numerous challenges. With our wide range of technologically leading solutions, we support you in mastering these challenges, offering tailor-made customer solutions and helping you remain globally competitive. Our commitment to energy efficiency and sustainable production demonstrates that we are already keeping an eye on the requirements of the future in the industry. We understand the complexity of automation and offer you both the right technologies and the necessary specialized expertise.

Would you like to find out more about how we can support you with your challenges? We look forward to continued successful collaboration with you!

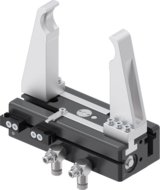

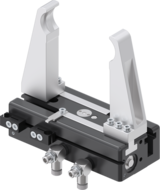

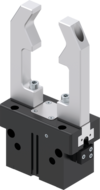

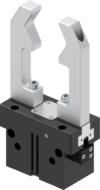

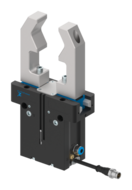

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

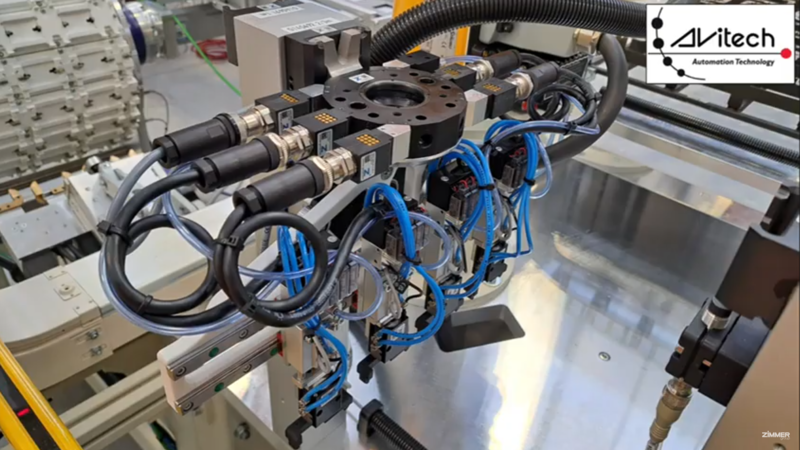

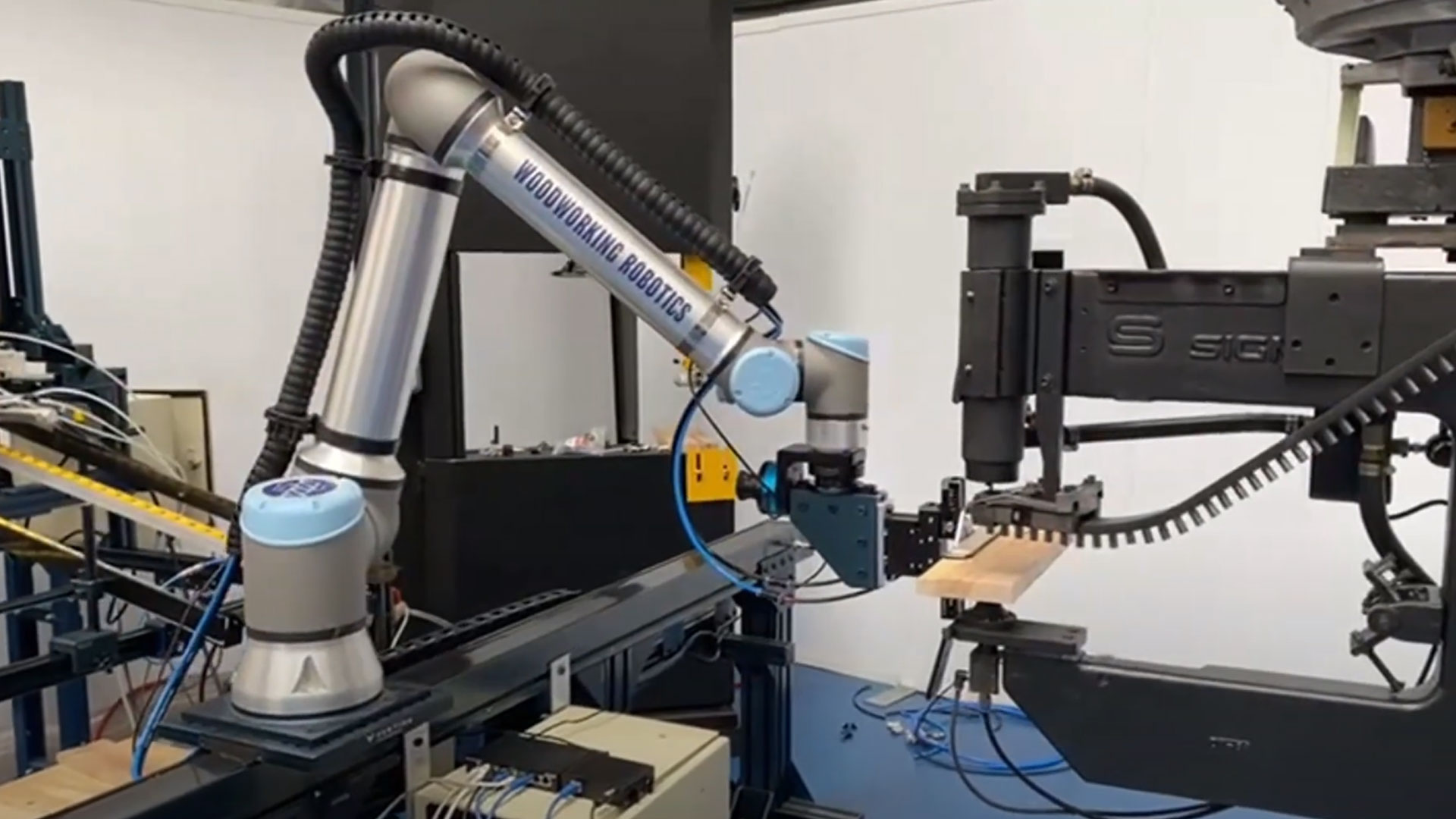

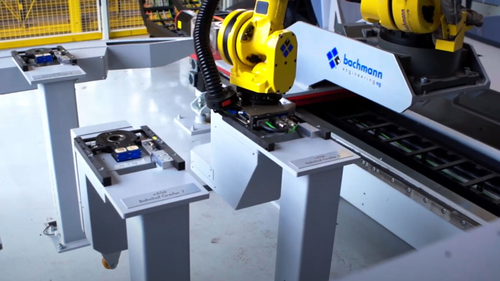

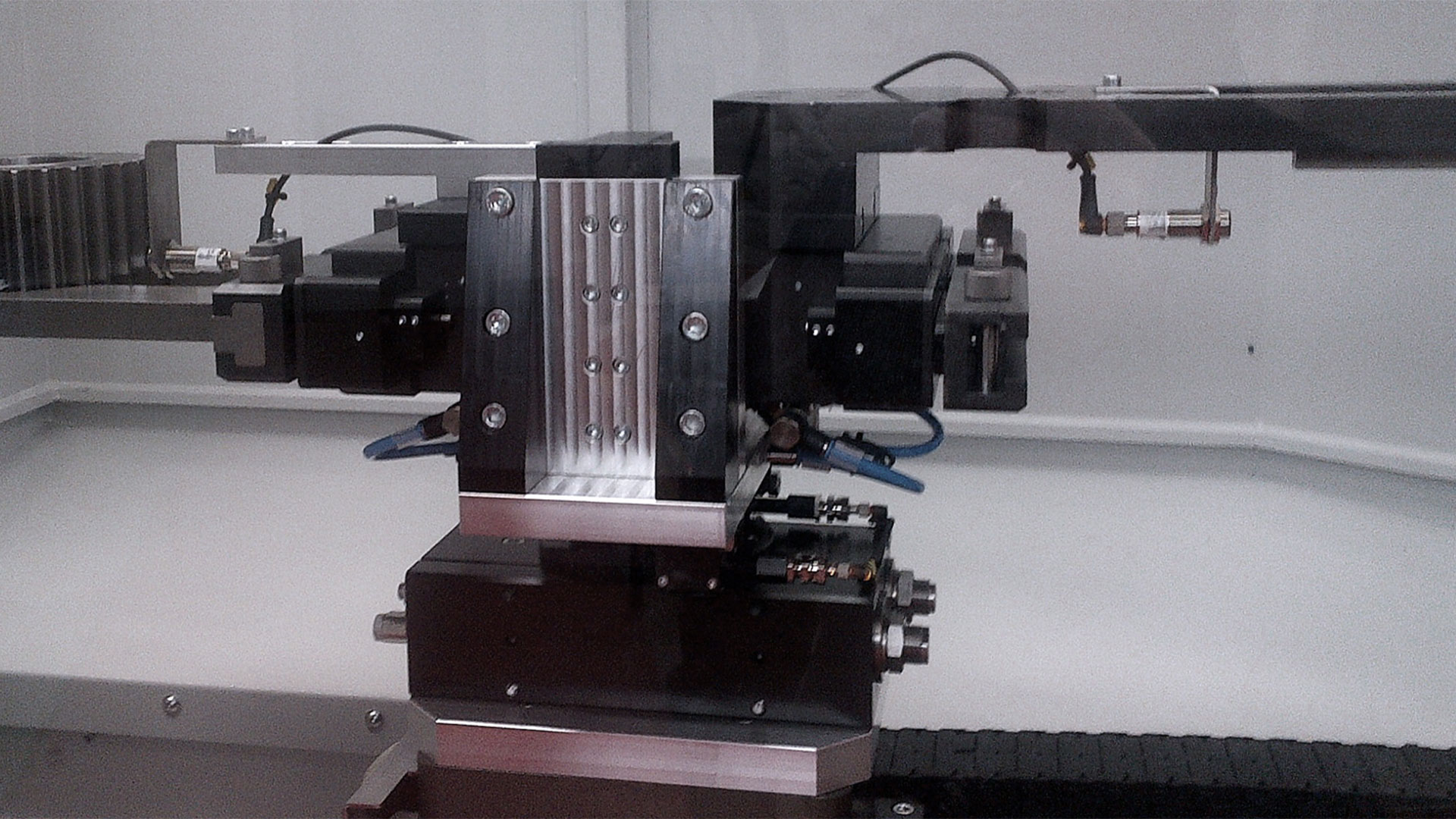

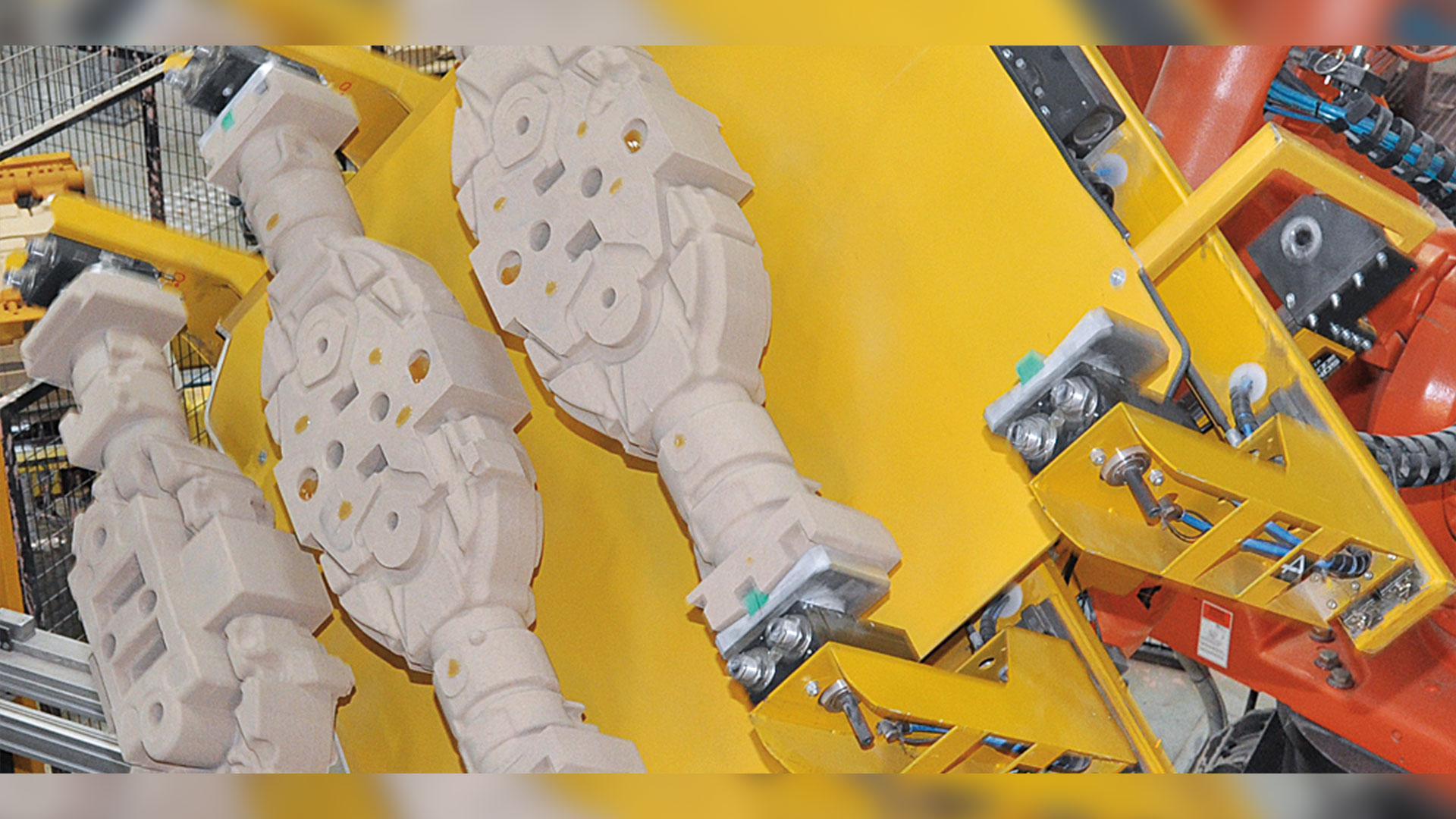

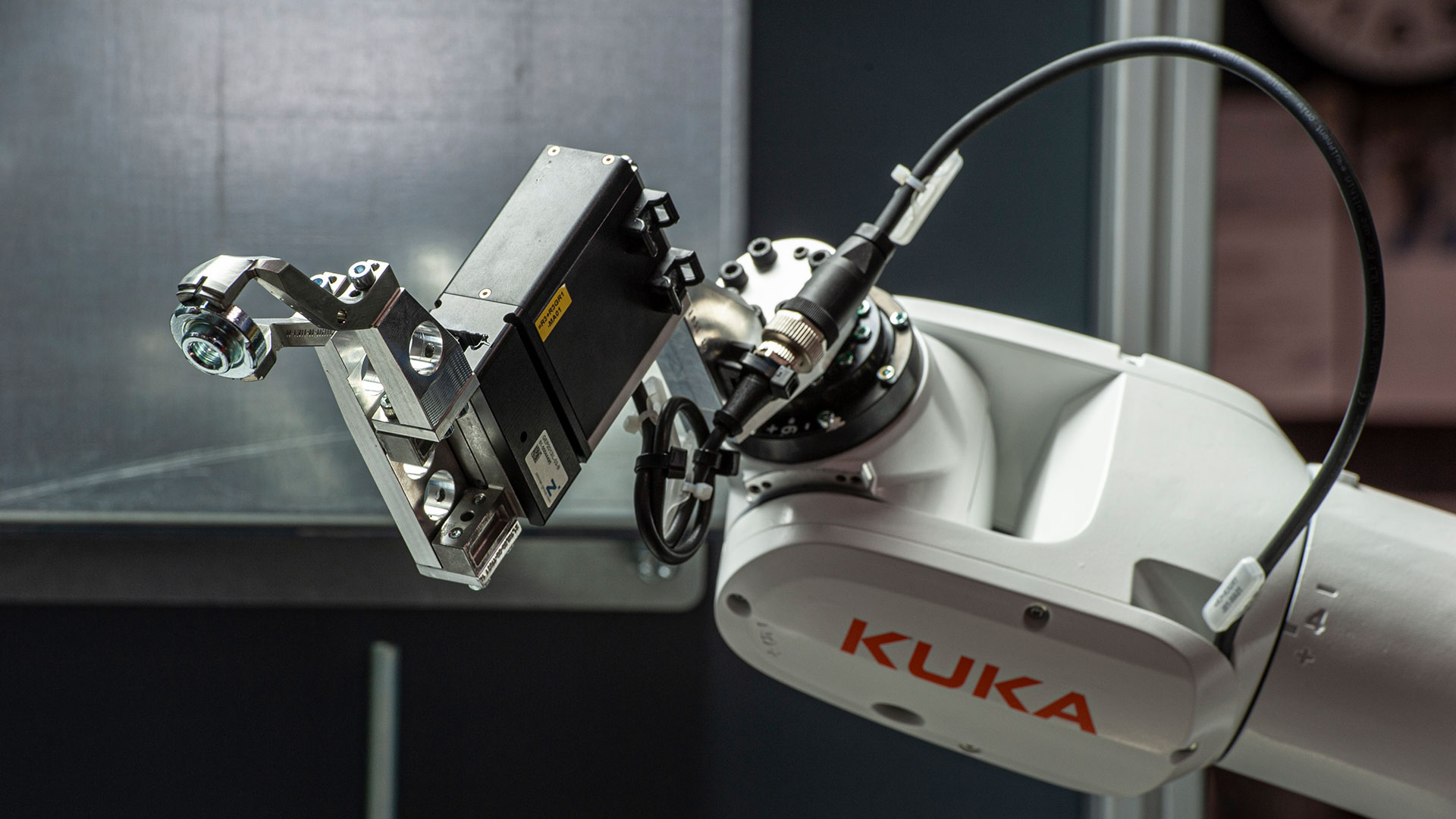

Tool Changers

Series WWR1000

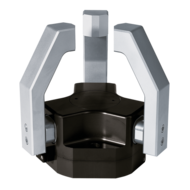

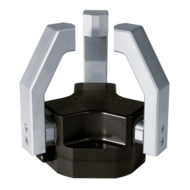

3-Jaw Concentric Grippers

Series GD300

- Extremely robust T-Slot guide for maximum forces and moments capacity

- Available with optional dust cover for use at extreme conditions

- Extremely robust T-Slot guide for maximum forces and moments capacity

- Available with optional dust cover for use at extreme conditions

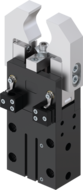

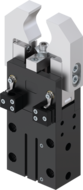

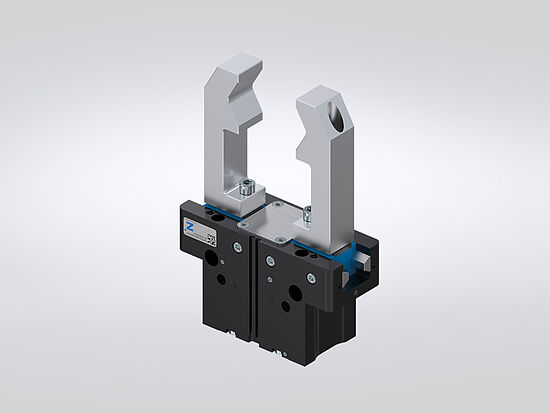

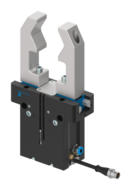

2-Jaw Parallel Grippers

Series GP400

- High gripping force as a result of optimal direction change of driving force into gripping force

- High gripping force as a result of optimal direction change of driving force into gripping force

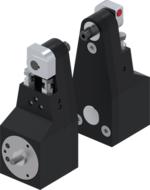

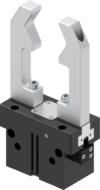

Tool Changers

Series WWR

- Robot flange with partial mounting circle in accordance with EN ISO 9409-1

- Very high handling weight up to 300 kg

- Robot flange with partial mounting circle in accordance with EN ISO 9409-1

- Very high handling weight up to 300 kg

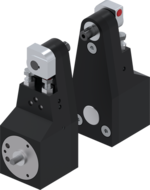

Flat Swivel Units

Series SF-C

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

2-Jaw Parallel Grippers

Series GP400

- High gripping force as a result of optimal direction change of driving force into gripping force

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

- High gripping force as a result of optimal direction change of driving force into gripping force

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

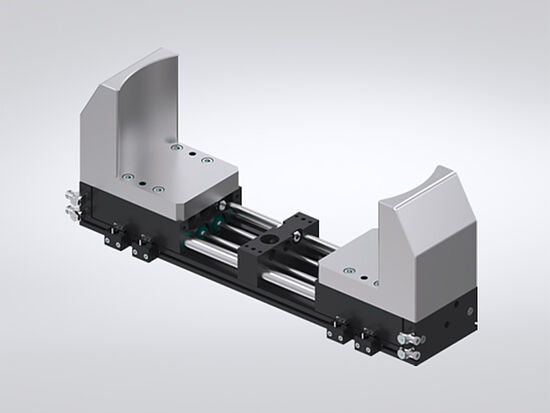

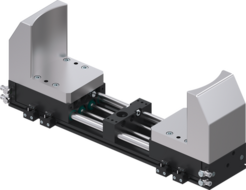

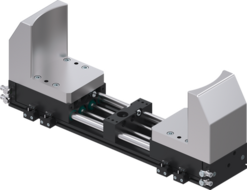

2-Jaw Parallel Grippers with Long Stroke

Series GH7000

- Heavy load linear guide for use under extreme conditions

- Ideal for highest transverse forces and moments capacity

- Heavy load linear guide for use under extreme conditions

- Ideal for highest transverse forces and moments capacity

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers with Long Stroke

Series GH7000

- Heavy load linear guide for use under extreme conditions

- Ideal for highest transverse forces and moments capacity

- Heavy load linear guide for use under extreme conditions

- Ideal for highest transverse forces and moments capacity

Flat Swivel Units

Series SF-C

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

3-Jaw Concentric Grippers

Series GD300

- Extremely robust T-Slot guide for maximum forces and moments capacity

- Available with optional dust cover for use at extreme conditions

2-Jaw Parallel Grippers

Series GP400

- High gripping force as a result of optimal direction change of driving force into gripping force

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

- Extremely robust T-Slot guide for maximum forces and moments capacity

- Available with optional dust cover for use at extreme conditions

- High gripping force as a result of optimal direction change of driving force into gripping force

2-jaw radial gripper

Series GK

Flat Swivel Units

Series SF-C

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

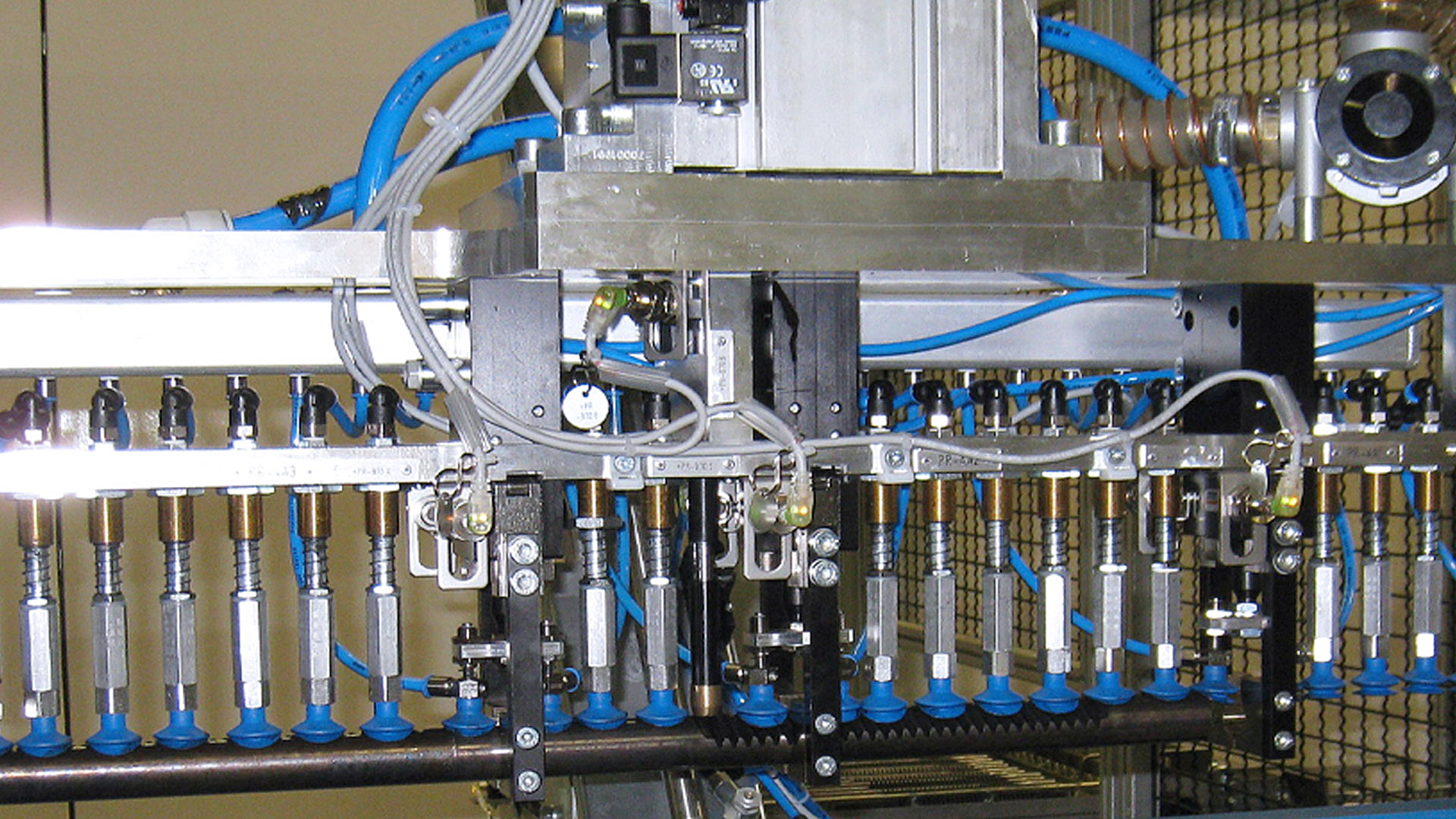

Suction cups

Series NS

2-Jaw Parallel Grippers

Series GP400

- High gripping force as a result of optimal direction change of driving force into gripping force

- High gripping force as a result of optimal direction change of driving force into gripping force

3-Jaw Concentric Grippers

Series GD300

- Extremely robust T-Slot guide for maximum forces and moments capacity

- Available with optional dust cover for use at extreme conditions

- Extremely robust T-Slot guide for maximum forces and moments capacity

- Available with optional dust cover for use at extreme conditions

Angle Pivot Units

Series SW

- Up to 100% more performance than the benchmark

- Includes two angle flanges

- More than 100% higher radial bearing load than the benchmark

3-Jaw Concentric Grippers

Series GD1700

- Up to 100% more performance than the benchmark

- Includes two angle flanges

- More than 100% higher radial bearing load than the benchmark

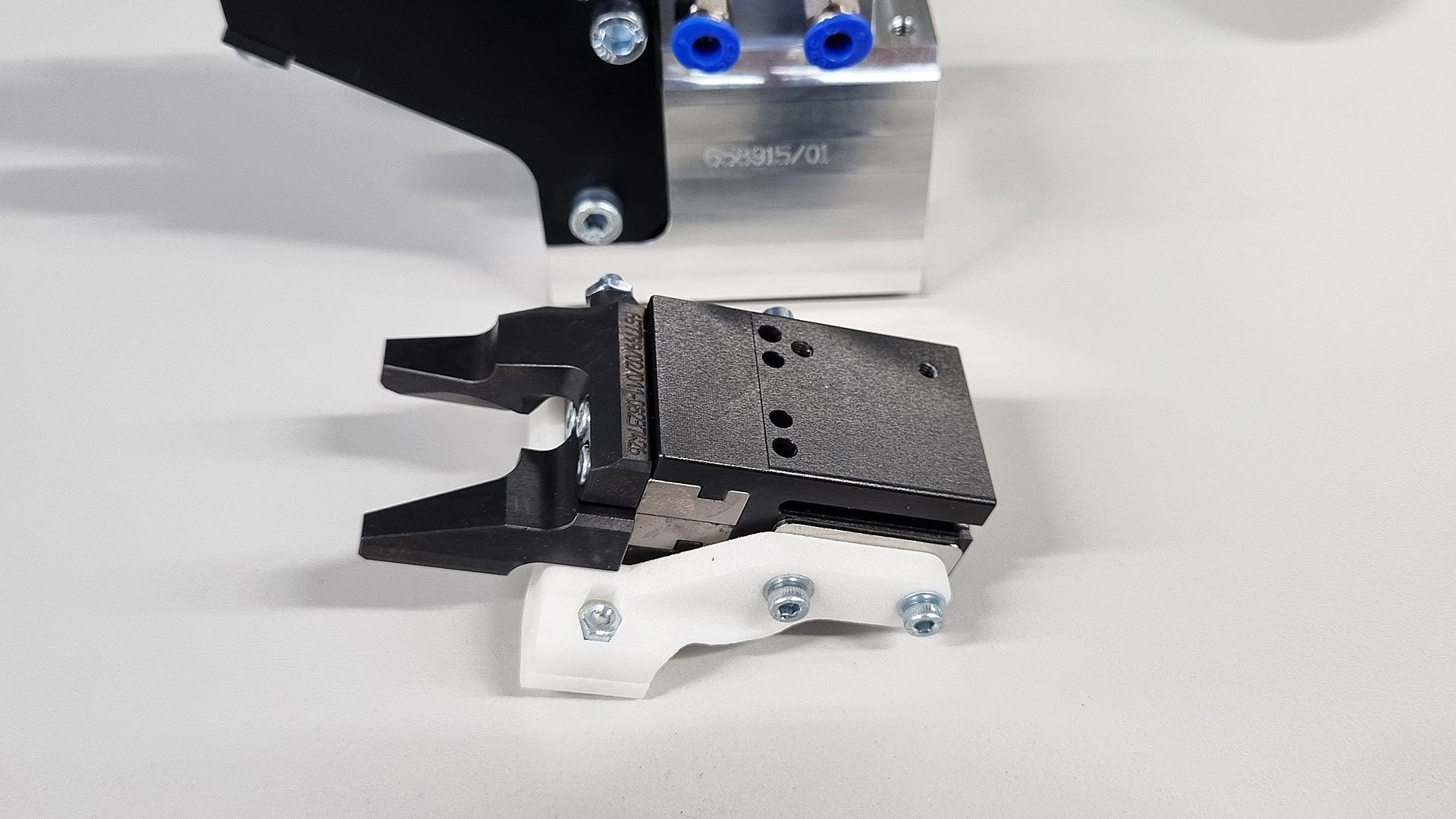

2-Jaw Parallel Grippers

Series MGP800

- Integrated position sensing for compact design and to minimized the interfering contour

- Gripper jaws made of ground surfaced and hardened steel ensure precision and a long durability

- Integrated position sensing for compact design and to minimized the interfering contour

- Gripper jaws made of ground surfaced and hardened steel ensure precision and a long durability

2-Jaw Angular Rotary Grippers

Series DGK

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GEP2000

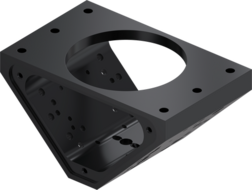

Axis Compensation Modules

Series XYR1000

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK 40 ... TK 200

- Axis compensation in the X-Y plane

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK 40 ... TK 200

- Axis compensation in the X-Y plane

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series MGP800

- Integrated position sensing for compact design and to minimized the interfering contour

- Gripper jaws made of ground surfaced and hardened steel ensure precision and a long durability

- Integrated position sensing for compact design and to minimized the interfering contour

- Gripper jaws made of ground surfaced and hardened steel ensure precision and a long durability

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

Flat Swivel Units

Series SF-C

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

Rotary Distributors

Series DVR

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK40... TK160

- With 4...8 pneumatic feedthroughs

- With 4...12 electrical feedthroughs

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK40... TK160

- With 4...8 pneumatic feedthroughs

- With 4...12 electrical feedthroughs

2-Jaw Parallel Grippers with Long Stroke

Series GH6000

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

3-Jaw Concentric Grippers

Series GPD5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GP

- Dual round guide rods

- Double acting pneumatic cylinder with integrated mechanical gripping force safety device

- Dual round guide rods

- Double acting pneumatic cylinder with integrated mechanical gripping force safety device

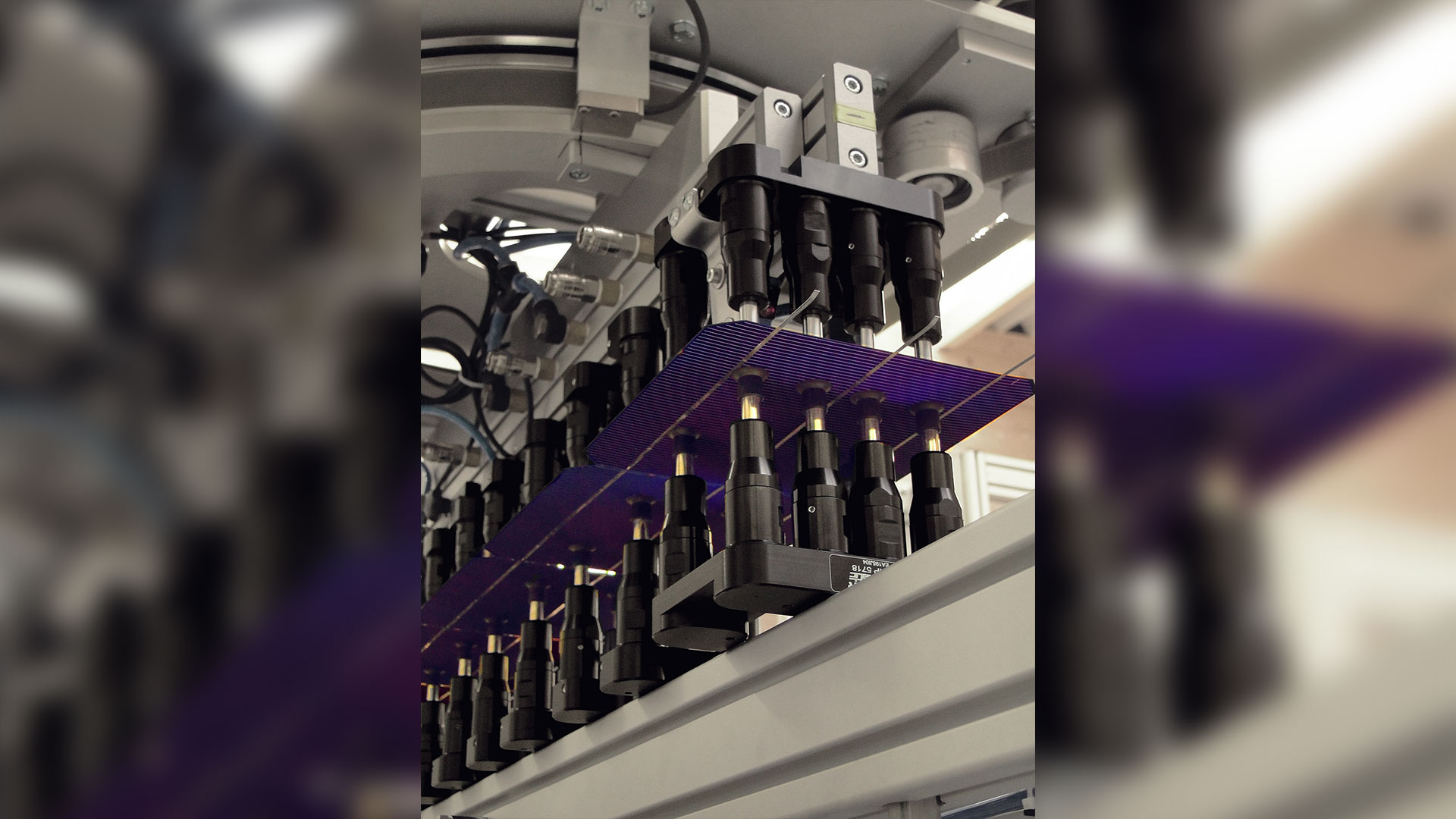

2-Jaw Parallel Grippers

Series GPP5000IL

- Pneumatic drive combined with IO-Link technology

- Up to 50% cycle time reduction and up to 90% compressed air savings

- Connection via just one pneumatic line and IO-Link cable

- Pneumatic drive combined with IO-Link technology

- Up to 50% cycle time reduction and up to 90% compressed air savings

- Connection via just one pneumatic line and IO-Link cable

3-Jaw Concentric Grippers

Series GPD5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

O-ring assembly grippers, outer

Series GS

- Expanding stroke adjustable from outside via adusting ring

- T-Slot guide for high forces and moments capacity

- Expanding stroke adjustable from outside via adusting ring

- T-Slot guide for high forces and moments capacity

3-Jaw Concentric Grippers

Series GPD5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

Swivel Jaws

Series SB

2-Jaw Parallel Grippers with Long Stroke

Series GPH8000

- Extremely long and heavy gripper fingers possible

- Synchronous, asynchronous and securing the workpiece

- Dirt protection

- Extremely long and heavy gripper fingers possible

- Synchronous, asynchronous and securing the workpiece

- Dirt protection

2-Jaw Parallel Grippers

Series GEP2000

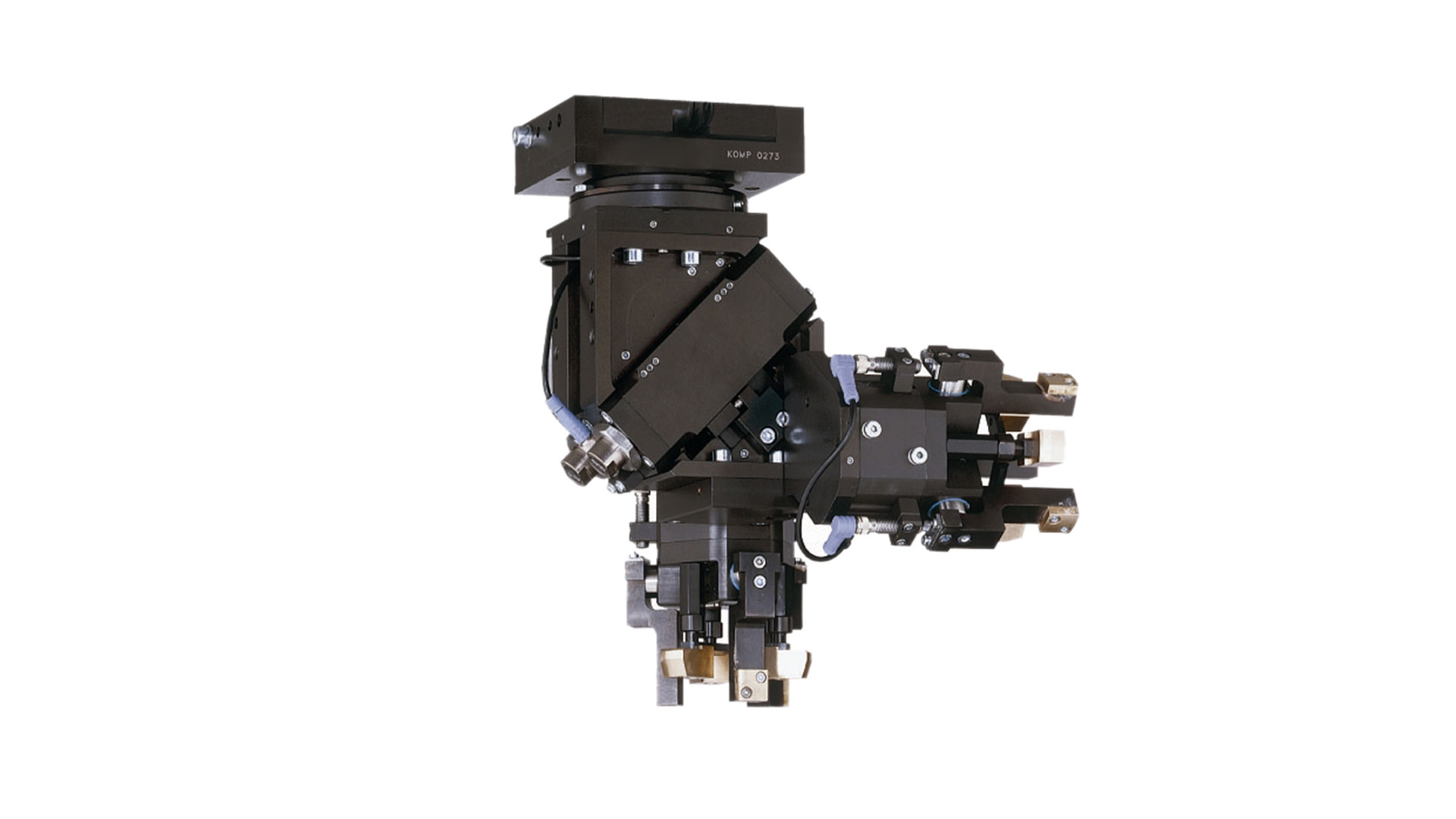

Tool Changers

Series WWR

- Robot flange with partial mounting circle in accordance with EN ISO 9409-1

- Very high handling weight up to 300 kg

- Robot flange with partial mounting circle in accordance with EN ISO 9409-1

- Very high handling weight up to 300 kg

Flat Swivel Units

Series SF-C

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

2-Jaw Parallel Grippers

Series GP

- Dual round guide rods

- Double acting pneumatic cylinder with integrated mechanical gripping force safety device

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

- Dual round guide rods

- Double acting pneumatic cylinder with integrated mechanical gripping force safety device

3-Jaw Concentric Grippers

Series GD300

- Extremely robust T-Slot guide for maximum forces and moments capacity

- Available with optional dust cover for use at extreme conditions

Rotary Distributors

Series DVR

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK40... TK160

- With 4...8 pneumatic feedthroughs

- With 4...12 electrical feedthroughs

- Extremely robust T-Slot guide for maximum forces and moments capacity

- Available with optional dust cover for use at extreme conditions

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK40... TK160

- With 4...8 pneumatic feedthroughs

- With 4...12 electrical feedthroughs

Rotary Distributors

Series DVR

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK40... TK160

- With 4...8 pneumatic feedthroughs

- With 4...12 electrical feedthroughs

Angle flange

Series WFR

3-Jaw Concentric Grippers

Series GPD5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK40... TK160

- With 4...8 pneumatic feedthroughs

- With 4...12 electrical feedthroughs

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

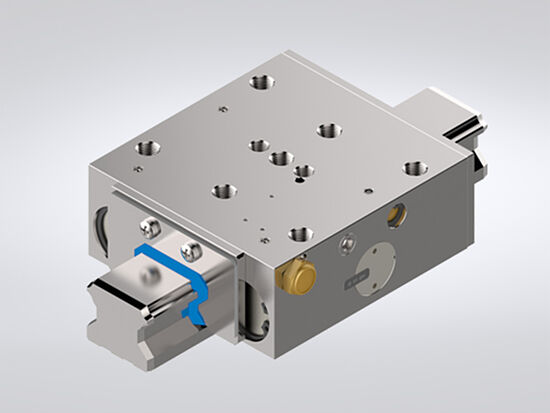

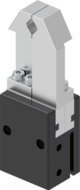

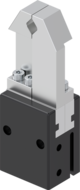

Clamping element

Series MBPS

Axis Compensation Modules

Series XYR1000

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK 40 ... TK 200

- Axis compensation in the X-Y plane

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK 40 ... TK 200

- Axis compensation in the X-Y plane