Individual, driverless transport systems for your production and logistics processes

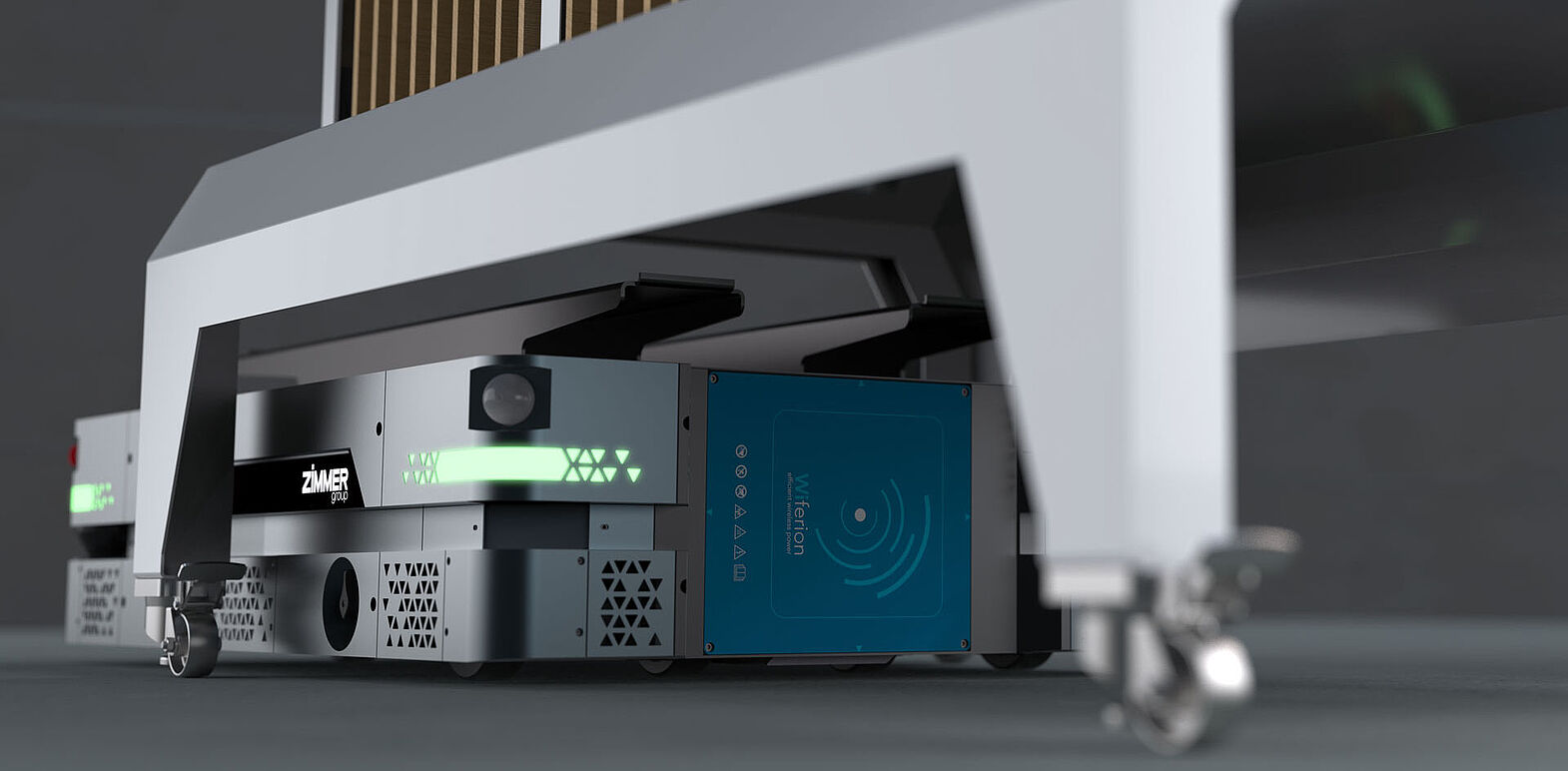

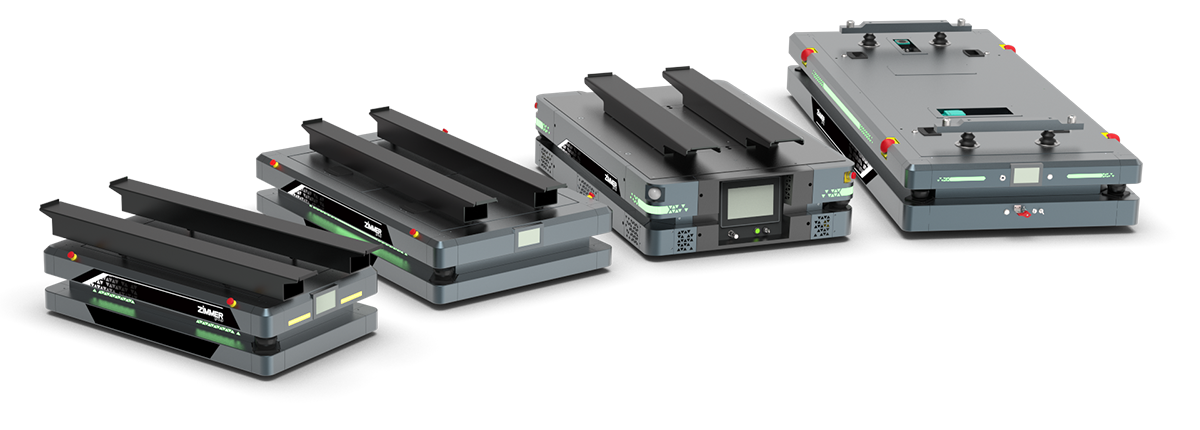

MILES – Autonomous Mobile Robot

Rely on autonomous mobile robots (AMRs) and incorporate dynamics into your material and storage management. The AMRs move autonomously in a defined area and support you in automating your intralogistics processes: from transport of various goods such as pallets, material containers or small parts through the automatic pickup and drop-off of load carriers all the way to fully automated fleet management, including connection to your ERP system. Use the advantages of an efficient and intelligent material flow solution with the flexible, modular Miles AMRs from the Zimmer Group!

YOUR ADVANTAGES WITH MILES

- A tailored complete system made up of hardware, software and service

- Customized concepts and setups

- Omnidirectional drive optionally available

- The ability to turn in the tightest of spaces

- Long battery lifespans and intelligent battery management

- Software for smart navigation and fleet management

ADJUSTED TO YOUR NEEDS

Total system made up of hardware, software and customer service

Simple integration into your processes

Highest safety standards for people and machines

Advice on tailored AMR setup solutions

Individual concept based on system layout

Flexible in the tightest of spaces

Turning possible in the tightest of spaces with omnidirectional drive

Natural navigation: autonomous navigation through detection and mapping of the environment

Driving speed of up to 6 km/h

Loads of up to 3,500 kg

In use 24/7

Long-lasting lithium ion battery with 48 V on-board voltage

Contactless and wear-free inductive charging technology

Fast charging times enable maximum flexibility in use

Unlimited use, day and night

Comprehensive software and service concept

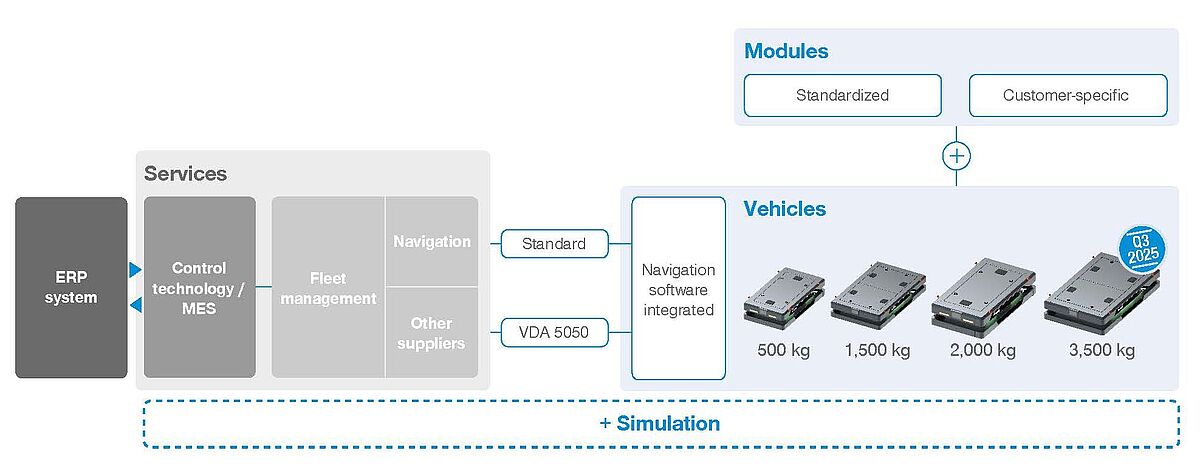

With the Zimmer Group AMR, you will receive a complete software package for navigating your transport system. Efficient route planning and fleet management become child’s play thanks to swarm intelligence and a simple teach-in and copy function via a user-friendly user interface.

In addition, we offer you a connection to your control technology and ERP system with suitable interfaces (VDA 5050). The integrated diagnostic system enables you to plan ahead and thus achieve high availability. Raise your Kanban processes to a new level and control a safe and intelligent fleet management with the right software.

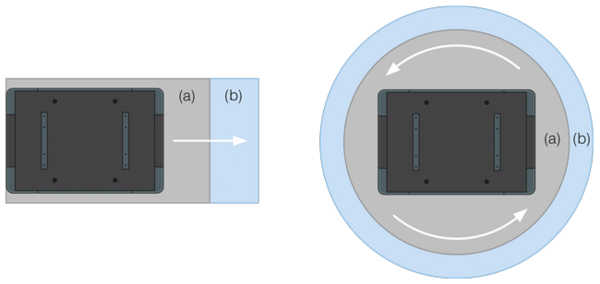

NAVIGATE SAFELY

With Miles, safety comes first. People scanners ensure a safe environment for people and the machine. When used in 360°, the scanners detect obstacles precisely, proactively and in real time and provide automatic speed adjustment up to and including an immediate stop to avoid potential collisions.

Safety areas when driving and when turning the vehicle

a) = Movement stop

b) = Speed reduction

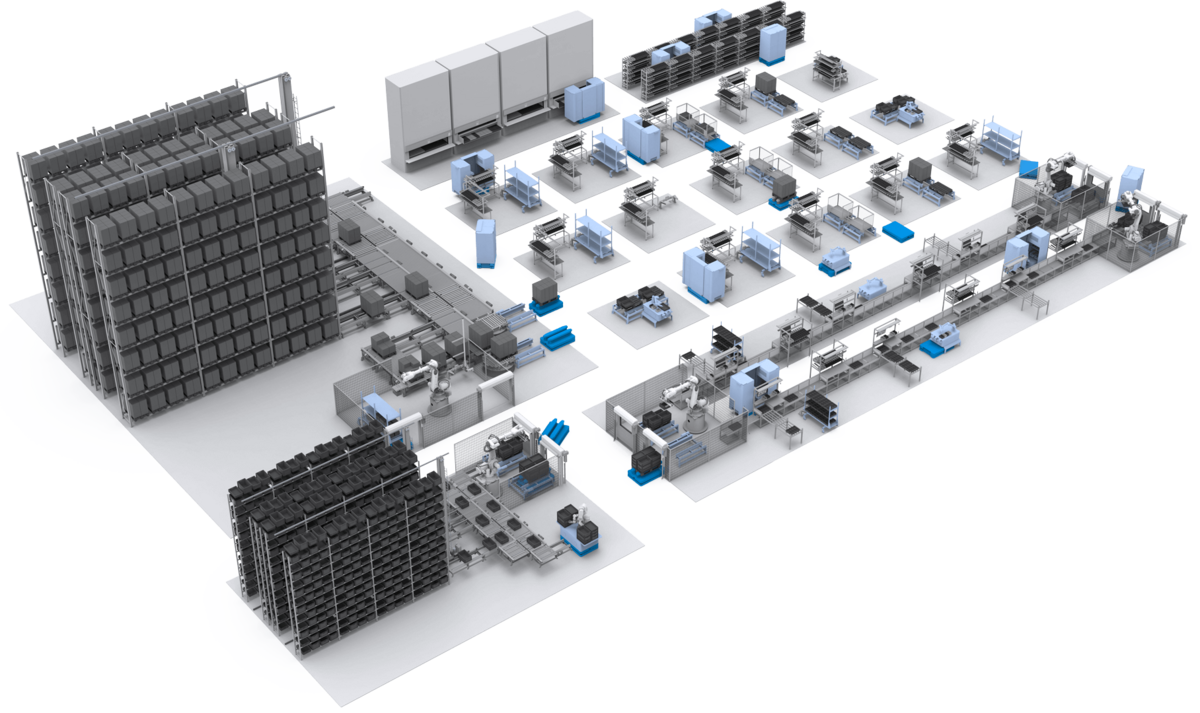

Your solution for automated transport

To meet the various requirements of intralogistics, flexible automation solutions are needed.

We support you with modular setup options for the AMR and will look at the individual needs of your company in the process.

DESIGNED TO WORK TOGETHER

Optimally coordinated, the ERP system, the control technology (or MES) and the fleet management system are crucial for the efficient control and monitoring of your fleet and operational processes. A complete system made up of hardware, software and customer service from the Zimmer Group enables:

- Customized concepts and superstructures

- Planning of the hall and the AMR fleet using simulation

- Fully automated process chain in various areas of logistics and production

- Commissioning by the Zimmer Group, including complete integration into the ERP system

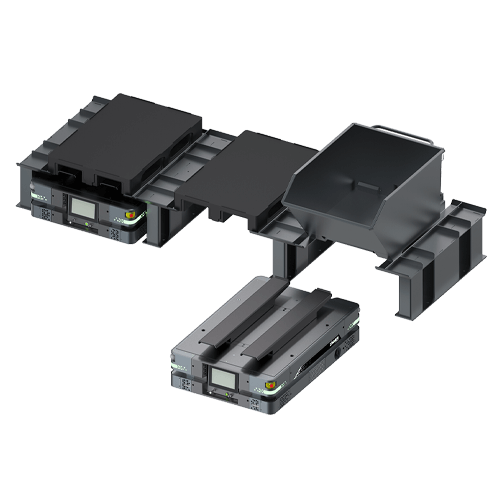

AMR with lifting unit

Zimmer Group’s AMRs with lifting unit offer a wide range of solutions for nearly every challenge in your warehouse. The parts to be transported can be adapted flexibly. Despite its small size and compactness, this universally implementable system that is equipped with a stroke of 80 mm can transport loads of up to 3500 kg.

Possible applications:

Transport of (euro) pallets, off-cuts, shopping carts, picking carts and much more.

- Up to 80 mm stroke for lifting the load carriers

- Up to 3,500 kg load capacity

- Various storage stations can be combined

- Customization of the superstructure at any time

- One system for many applications

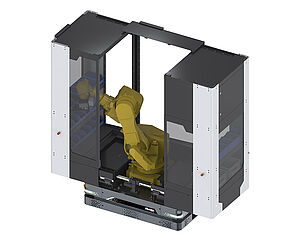

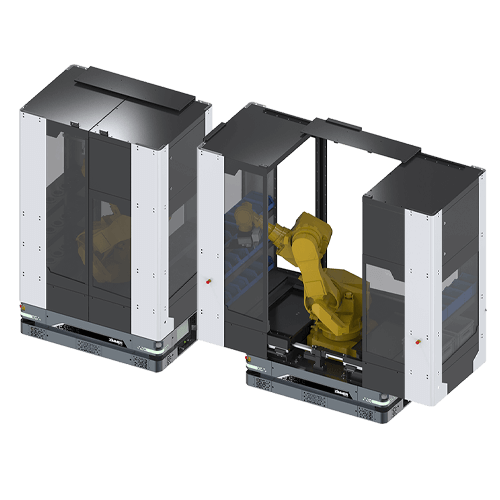

AMR with robot module

Compact design, maximum availability: Combine your AMR with a robot (up to 50 kg handling weight) and get maximum flexibility with the modular shelf concept for various workpieces. Automatic safety fence and a battery packet for longer runtimes are additional options.

Possible applications:

Handling and transport of Kanban containers and much more.

- Robot with a handling weight of up to 50 kg

- 400 V voltage source available

- Optionally with automatically opening safety fence

- Modular rack concept for different workpieces

- Optional battery pack for longer running times

- Compact design, no additional interfering contour during travel

- Positioning to the transfer point using a camera

AMR with ZiMo

In this setup, the AMR takes over collection, transport and positioning of the flexible ZiMo robot cell. Then, the AMR takes on other tasks such as pallet transport. Thanks to the modular setup and a voltage supply from batteries, the ZiMo can be used with versatility.

Possible applications:

parts removal, assembly work, quality control and much more.

- ZiMo is picked up, transported

- and set down by an AMR

- The AMR can then take on other tasks

- such as pallet transport

- Battery-operated

- Thanks to the variable design, many applications are possible

- Robot-neutral HMI

DOWNLOAD

You can find detailed information and all the advantages in the current brochure:

Step-by-step to automated storage

ANALYSIS and planning

Together, we will look at your needs and draft a solution that is tailored to your requirements.

Implementation

Starting with simulation, continuing through integration into your ERP system, all the way to go-live, we are by your side as your development partner during implementation.

Support

After successful implementation, we are also still at your side with specialized expertise, technical support, software updates and maintenance.

FAQ – frequently asked questions and answers

AGVs (automated guided vehicles) and AMRs (autonomous mobile robots) are used to automate both industrial transport and logistics processes. AGVs are driverless vehicles that usually move on specified paths or rails. Using sensors, magnets or other guide systems, they follow prescribed lanes or markings on the floor. In contrast, AMRs are autonomous robots that can move in dynamic and unstructured environments. Intelligent navigation systems allow AMRs to orient themselves in real time in their environment and to avoid obstacles. They can perform various tasks in different environments and therefore have very versatile applicability. Thanks to their flexibility, major structural adaptations are not required to use AMRs.

AMRs offer a variety of advantages that make them an attractive solution for various industries:

- Flexible use: AMRs are extremely flexible and adaptable. They can be used without issues in various environments, whether they be in production, in warehouses or in healthcare. Their navigability allows them to move in dynamic environments without fixed paths.

- Rigid transport equipment is not required: In contrast to conventional conveyor belts or fixed, anchored robots, AMRs do not need any fixed infrastructure. This means that they can be integrated easily into existing working environments without expensive conversions or adaptations being necessary.

- Quick amortization: Since they work efficiently and productively, companies can recoup their investment costs in a relatively short period of time through productivity and efficiency gains.

- Various degrees of automation can be realized: AMRs can be scaled to various degrees of automation. Companies can integrate them easily into existing workflows and extend them if needed. This allows step-by-step automation that meets the individual needs of a company.

- Low space requirements: Since AMRs do not require any fixed transport routes and can move in tight spaces, they only need a little space. This is particularly advantageous in environments with limited available space, such as warehouses or production facilities.

The possible applications for Zimmer Group AMRs are numerous thanks to their flexibility and modularity. They can perform a wide range of tasks in various industries (logistics, e-commerce, manufacturing, agriculture, healthcare, airports, etc.):

- Material transport: AMRs transport goods and materials efficiently between various locations.

- Shelf replenishment: They replenish shelves automatically, optimizing inventory management.

- Inspection: AMRs check products and systems for quality control or maintenance requirements.

- Storage management: They organize storage spaces and track inventory in real time.

- Delivery: AMRs deliver packages and orders in warehouses or retail environments.

- Document transport: They transport important documents in offices or facilities.

- Monitoring: AMRs monitor environments for safety or quality purposes.

AMRs make a significant contribution to efficient processes, ensure higher capacity utilization of your plants and thus lead to lower production costs with maximum output at the same time. This ensures a rapid return on investment. Which scope and model is right for you depends largely on your requirements and environmental parameters. We are happy to help you find the right package – contact us today!

The batteries supply 48 volts. However, we can also provide 12 and 24 volts for control components. There is an inverter for 230 volts or for 400 volts for the robot.

The batteries are designed for an 8-hour shift. Subsequently, the batteries are inductively charged. The battery modules of the vehicle and attachment are connected to each other and form a unit (for loading and unloading).