Zimmer Group: Efficient automation solutions

Success through innovation: Your partner for customized automation, components and systems for future-oriented solutions.

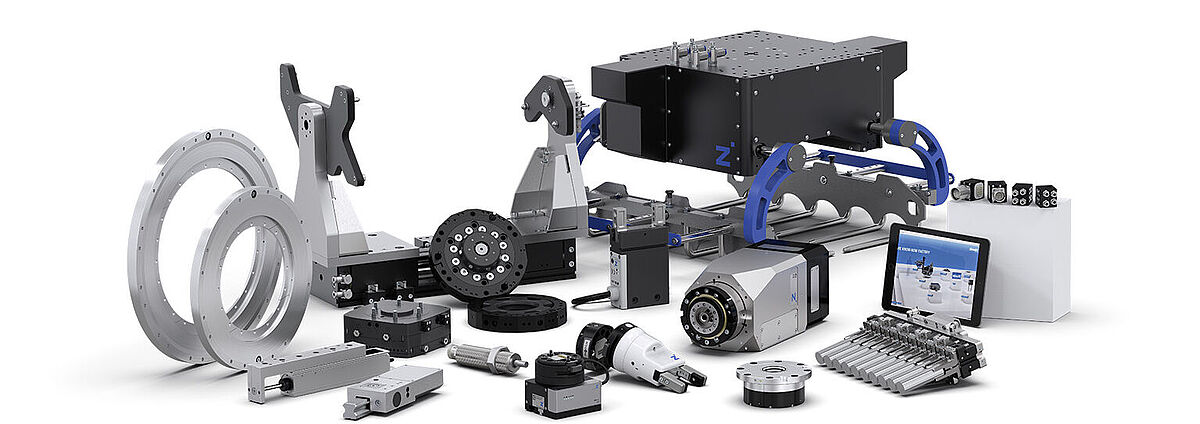

Everything from a single source

from the component to the complete system

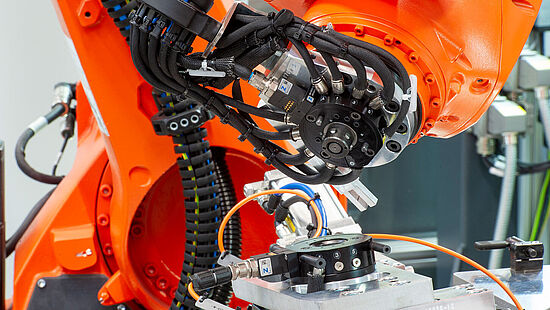

As one of the world’s leading manufacturers of automation solutions, we have stood for pioneering spirit, flexibility and sustainable quality for more than four decades. This is also reflected in our wide-ranging and highly innovative product portfolio. As an expert partner, we support and advise you with our know-how, including product development, prototype construction, the design of customer-specific solutions and integration into your production and commissioning – and beyond.

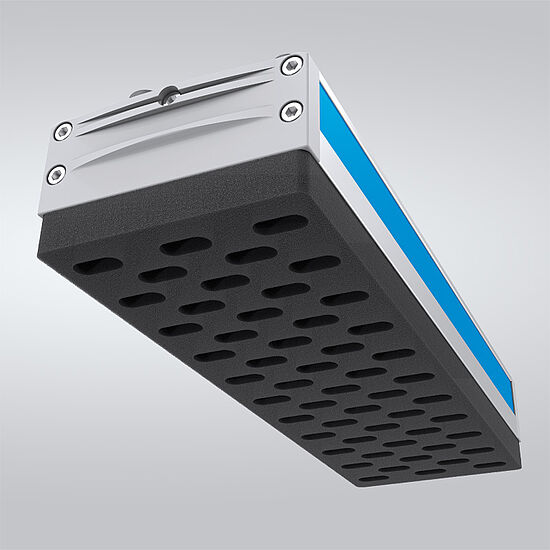

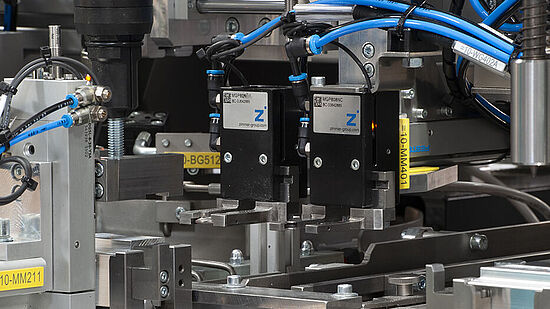

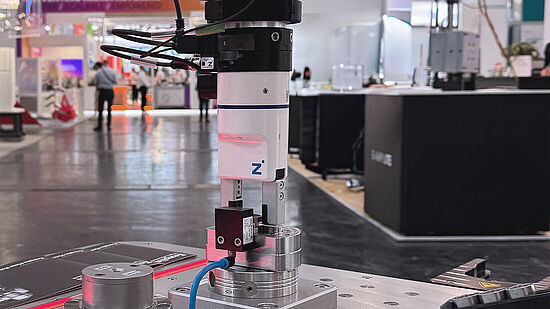

SERIAL PRODUCTION OF COMPLEX COMPONENTS

State-of-the-art manufacturing technologies and precise production processes

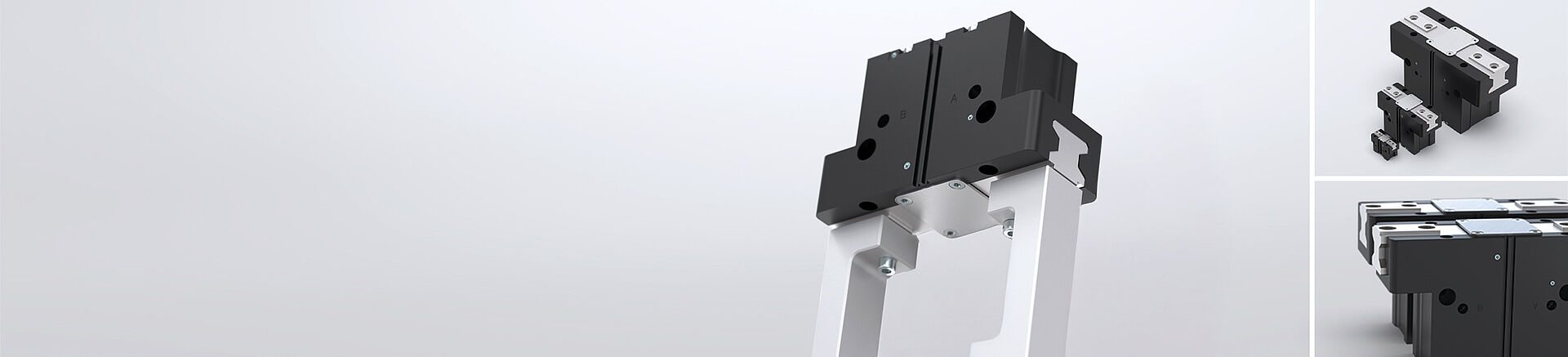

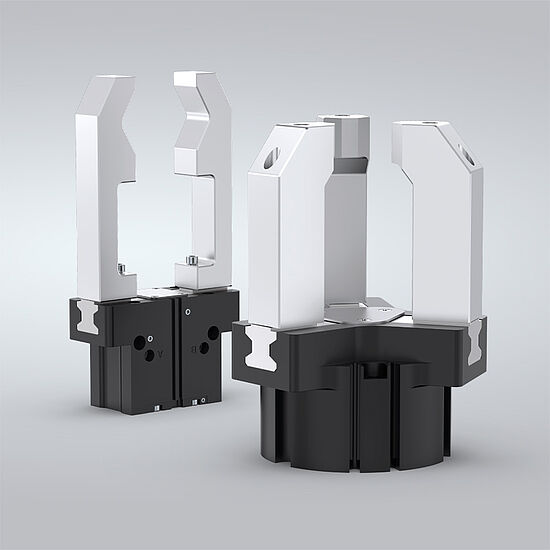

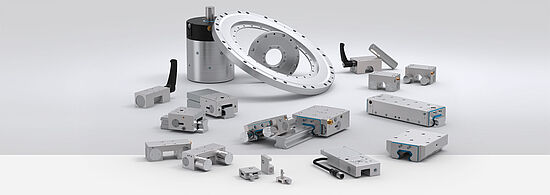

COMPONENTS FOR AUTOMATION

Powerful, efficient, reliable

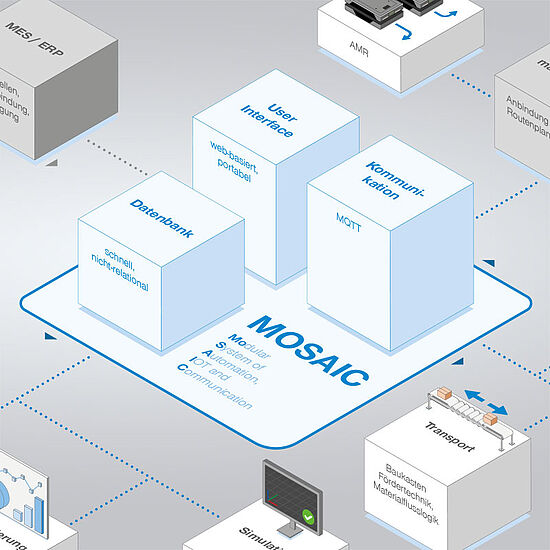

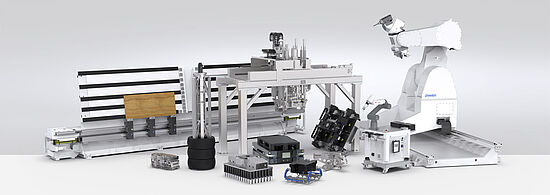

AUTOMATION SOLUTIONS AS A SYSTEM

Individual, process-optimizing system solutions

Innovations from the Zimmer Group

Innovations from our technology areas

OUR PORTFOLIO

Innovations in all areas

The best solution for every industry

Technological advantages in all markets and industries

WHAT’S NEW AT ZIMMER GROUP

News and success stories

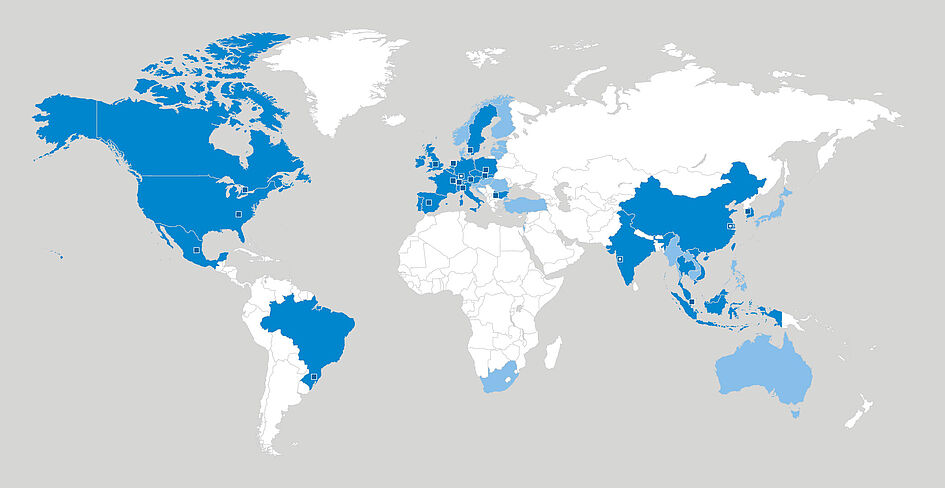

Head office

Germany

Production locations

Germany (3x), Bulgaria, China, India

Sales branches

Benelux, Brazil, Bulgaria, China, France, India, Italy, Canada, Mexico, Austria, Poland, Switzerland, Singapore, Slovakia, Scandinavia, Spain, South Korea, United Kingdom, USA

Dealers and partners

worldwide