Woodworking tools

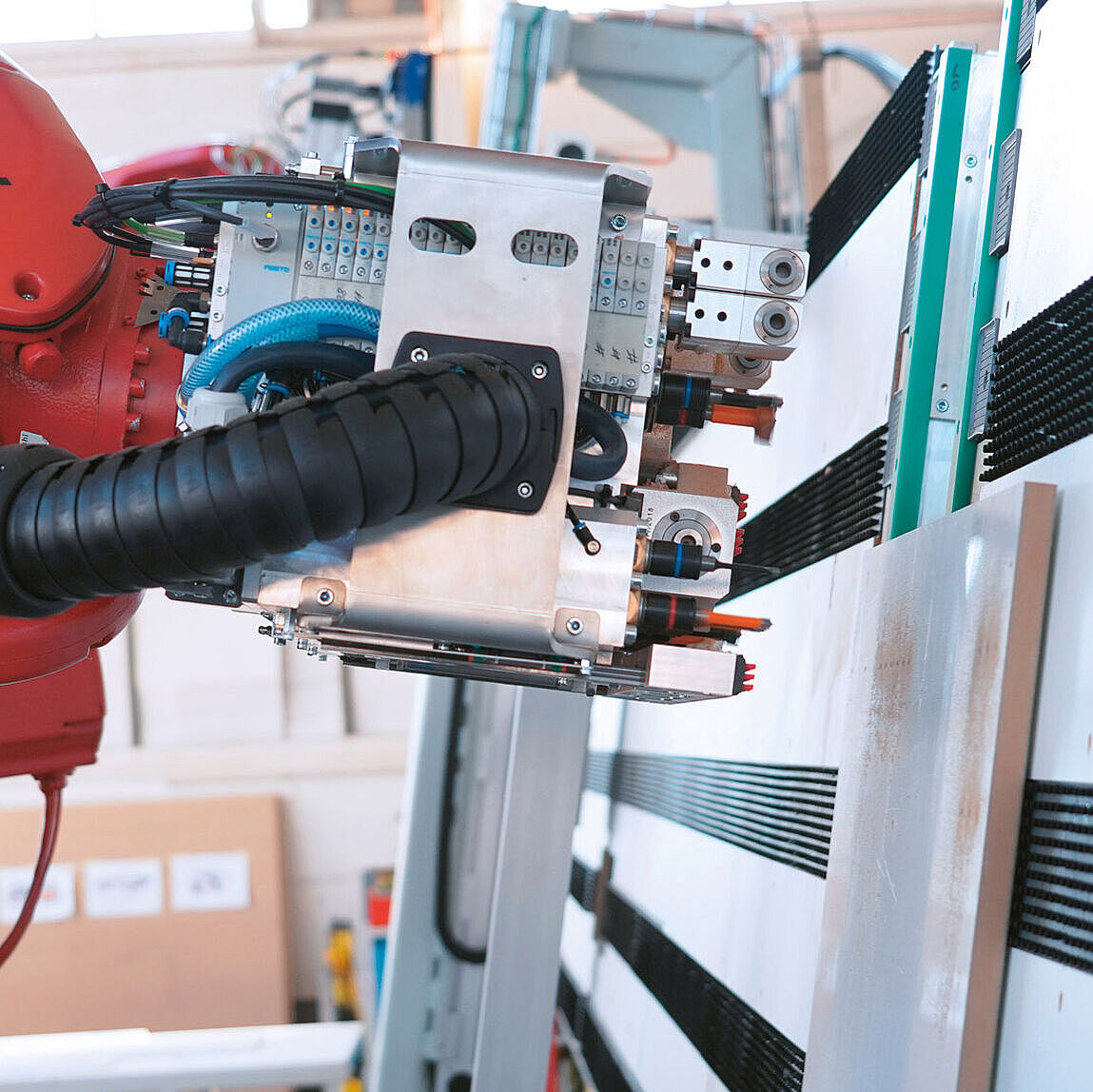

Zimmer Group has been one of the most innovative companies in the woodworking sector for over 30 years. In the 1990s and 2000s, we revolutionized the market with pioneering solutions, such as the world's first e-interface on the machining head, primarily as a think tank and OEM supplier. Today we deliver sophisticated high-tech products in the process chain with a focus on highest flexibility, scalability and productivity. To this end, we rely on the latest development technologies and simulation methods, such as the digital twin. Zimmer Group offers innovative end-of-arm products that are optimized for the application for the increasing use of robot technology in the machining of wood, materials similar to wood and composite materials. There are no limits to their flexibility.

- Modular end-of-arm tools for implementing a wide range of functions on the machining module

- Drilling units with fixed spindles

- Drilling units with extensible spindles

- Project-specific design for minimum space requirement and tool exchange effort

- Countless attachment options offer the greatest possible flexibility and freedom

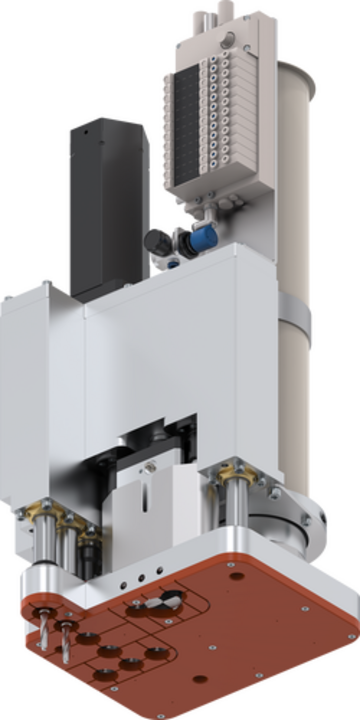

Drilling units with fixed spindles

We develop fixed drilling units for series drilling to maximize the performance of your drilling machine. The configuration and arrangement of the individual drill spindles can be freely selected. A central drive through all common machine interfaces drives all drill spindles at the same time via gear drives.

OUR EXPERTISE – YOUR ADVANTAGE

- Customized, rigid drilling units in different variations

- Machining of wood, composite materials and plastics

- Repair and replacement drilling units for all common machine manufacturers

- Variable number and arrangement of spindles

Drill arrangement

Standardized modular system with variable number of spindles and arrangement

Tool interface

Weldon drill holder, speed up to 3,000 rpm

Interfaces

Various machine interfaces for attaching to existing drives

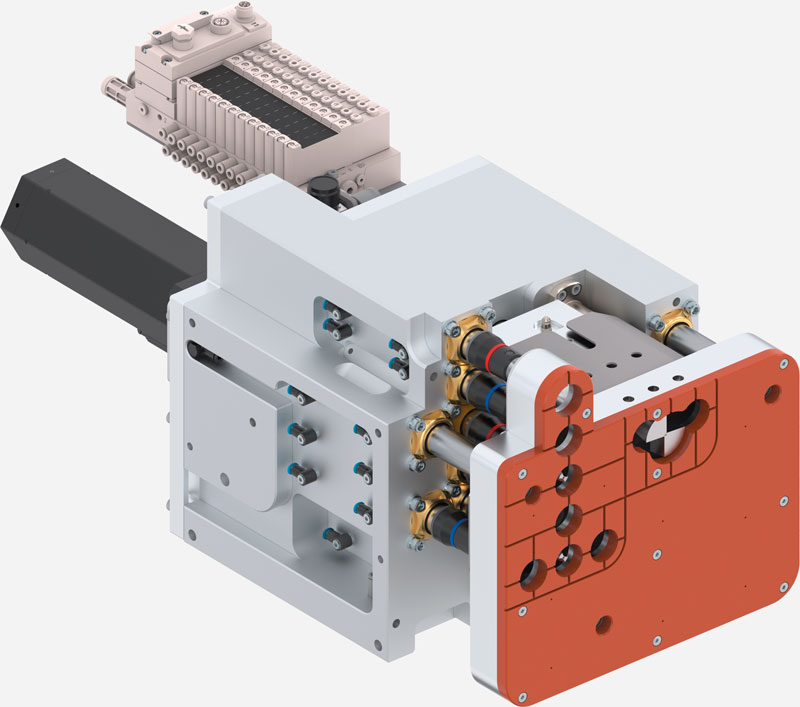

Drilling units with extensible spindles

Our high-quality drilling units with extensible spindles achieve maximum precision thanks to their monoblock design. The individually extensible drill sleeves have form-fit locking in the extended position to achieve maximum forces and machining speeds. In addition to the interchangeable installed drill sleeves, these spindles offer many other refined features in this product area.

OUR EXPERTISE – YOUR ADVANTAGE

- Customized, extensible drilling units in a wide range of variations

- Machining of wood, composite materials and plastics

- Various units for a wide range of machining operations (horizontal drilling unit, grooving saw, Clamex, cup conveyor)

- Variable number and arrangement of spindles

Design

The monobloc design guarantees maximum precision and easy replacement of the drill sleeves when mounted

Drill sleeves

Drill sleeves with Weldon mount, 32 mm pitch, speed up to 7,500 rpm

Drive

A drive motor controlled centrally by a frequency converter uses a gear drive to drive the drill sleeves and units

Extension stroke

Drill sleeves with 60 mm Extension stroke and locking in extended position

TECHNOLOGY CONSULTING

In the inquiry and early project phase, the main focus is on defining the key functional requirements, ensuring interfaces and connections to adjacent trades and defining a reliable cost framework.

Thanks to the expertise of our systems engineering team across all industries, we are the perfect partner for mechanical, mechatronic and software solutions in automation. The goal of getting your individual system up and running more quickly, making it easier to use and operating it more efficiently and reliably is our greatest motivation!

Customer engineering system solutions

With 30 years of development experience and more than 80 experts, Zimmer Group has the crucial industry expertise to analyze your task quickly and precisely, to develop technically innovative and cost-effective solutions and to implement them reliably and on schedule.

Our team in the semi-component area and in system development is able to develop these solutions for you.

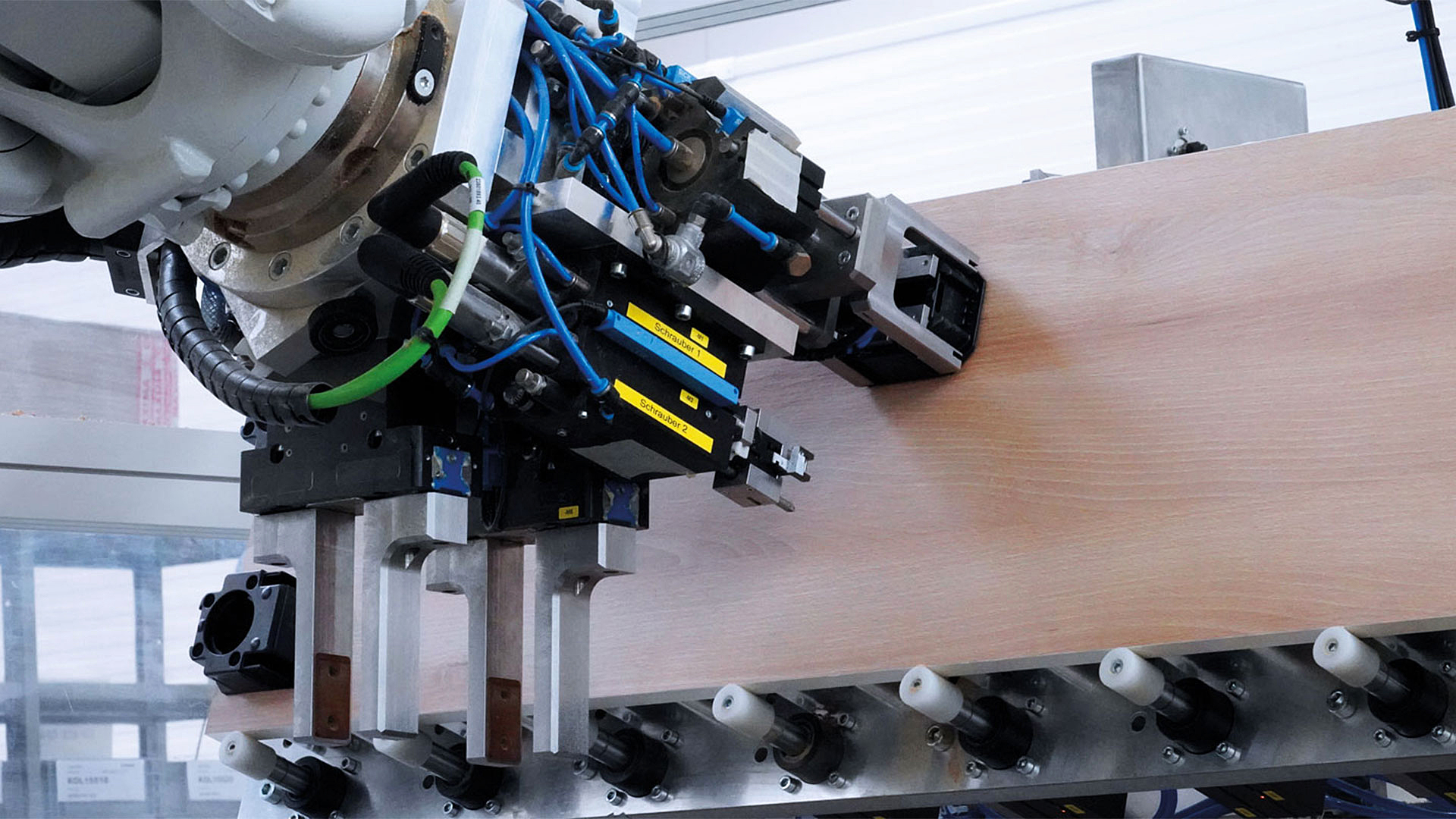

Use in the production environment

- The use of industrial robots is a crucial productivity factor in machine woodworking

- Zimmer Group offers innovative end-of-arm products optimized for the application for the increasing use of robot technology

- Our intelligent solutions for end-of-arm tooling make crucial contributions to increases in productivity

- Especially in the age of Industry 4.0, our mechatronic solutions and the complete range of accompanying digital services open up outstanding opportunities for differentiation