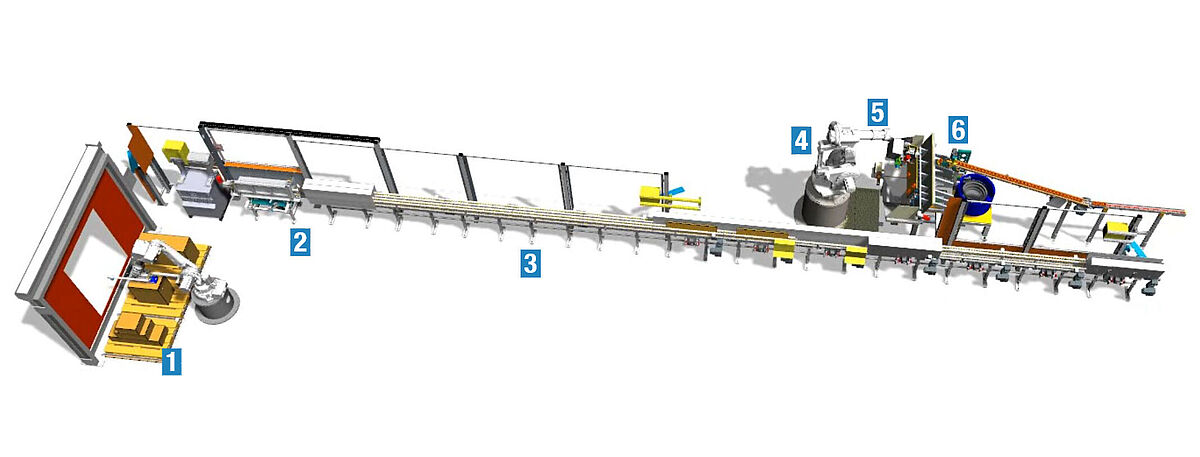

Body processing / lot size 1

Product advantages:

- Highly flexible single quantity system for robot-based machining of furniture bases

- Integration of drilling machining and metal fitting thanks to a project-specific multi-function head

- Machining of coated chipboards and MDF boards with dimensions from 200 mm x 200 mm up to 1200 mm x 368 mm

- Direct integration into the customer's machining control system for flexible processing of the production lot

- Minimal space requirement of the system due to two-lane vertical workpiece transport as an extension of an existing production environment

1 Feeding module

2 Alignment and measurement module

3 Transport module

4 ABB machining robot

5 Machining module for drilling

6 Machining module for metal fitting

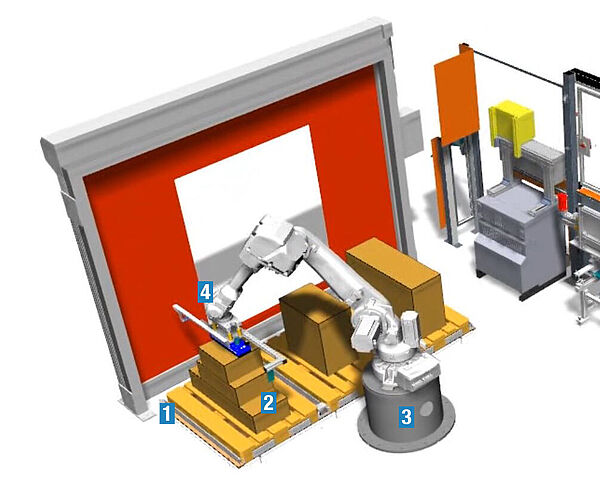

Feeding module

Product advantages:

- Pallet feed using a forklift

- Ability to give priority to special parts or rush jobs

- Reading in the stack and part data using the customer's machining control system

- Parts removal using a feeding robot with a suction traverse

1 High-speed door

2 Pallet locations

3 ABB feeding robot

4 Suction traverse

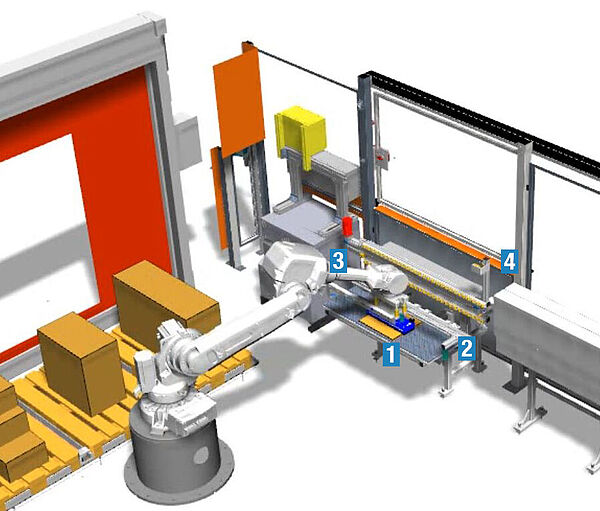

Alignment and measurement module

Product advantages:

- Aligning and setting up the components using a pneumatic setup table

- Control system-based track switch for selecting the required transport route

- Plausibility check of the programmed workpiece dimensions by height sensor and servo insertion axis

1 Setup table

2 Track switch

3 Insertion axis

4 Measurement sensor

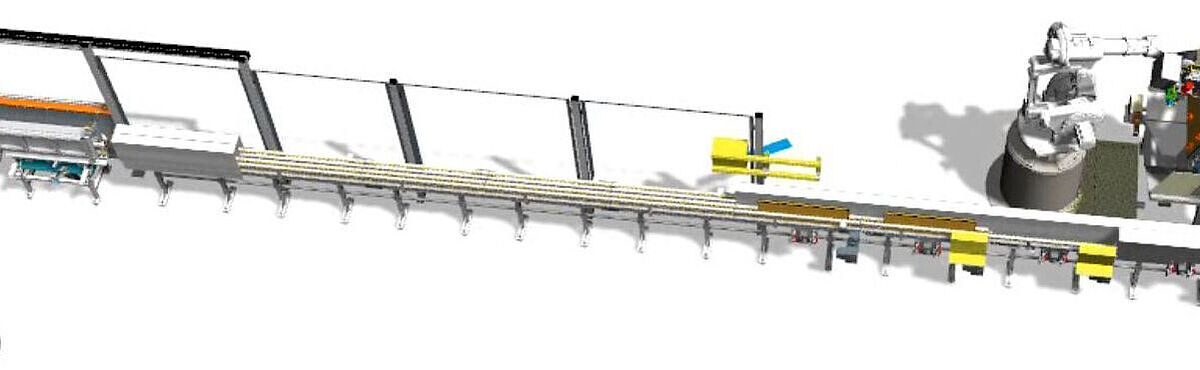

Transport module

Product advantages:

- Dual-lane vertical transport route for machined and unmachined components

- Integrated buffer stations on the transport route

- Provisioning the parts to be machined to the machining location

- Provisioning the bottoms to the removal position with a color-controlled interface for manual parts removal

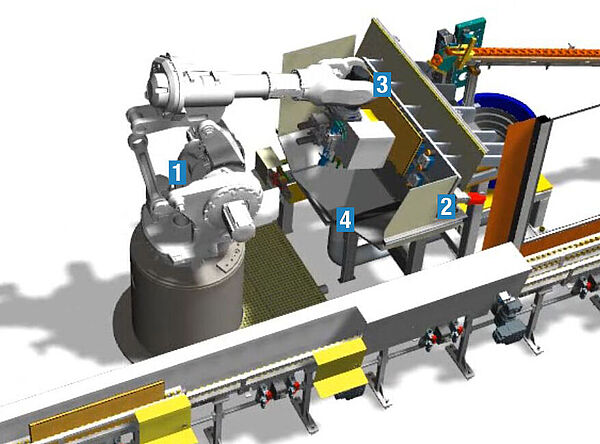

Machining module for drilling

Product advantages:

- Infeed of parts via the vertical transport route

- Program-controlled removal and reversal of the parts using handling grippers on the multi-function head

- Positioning and securing the components using an anvil with an integrated plausibility check

- Drilling machining by the ABB machining robot and the 10x drill gears with individually adjustable drill spindles

1 ABB machining robot

2 Anvil

3 Multi-function head

4 Chip suction

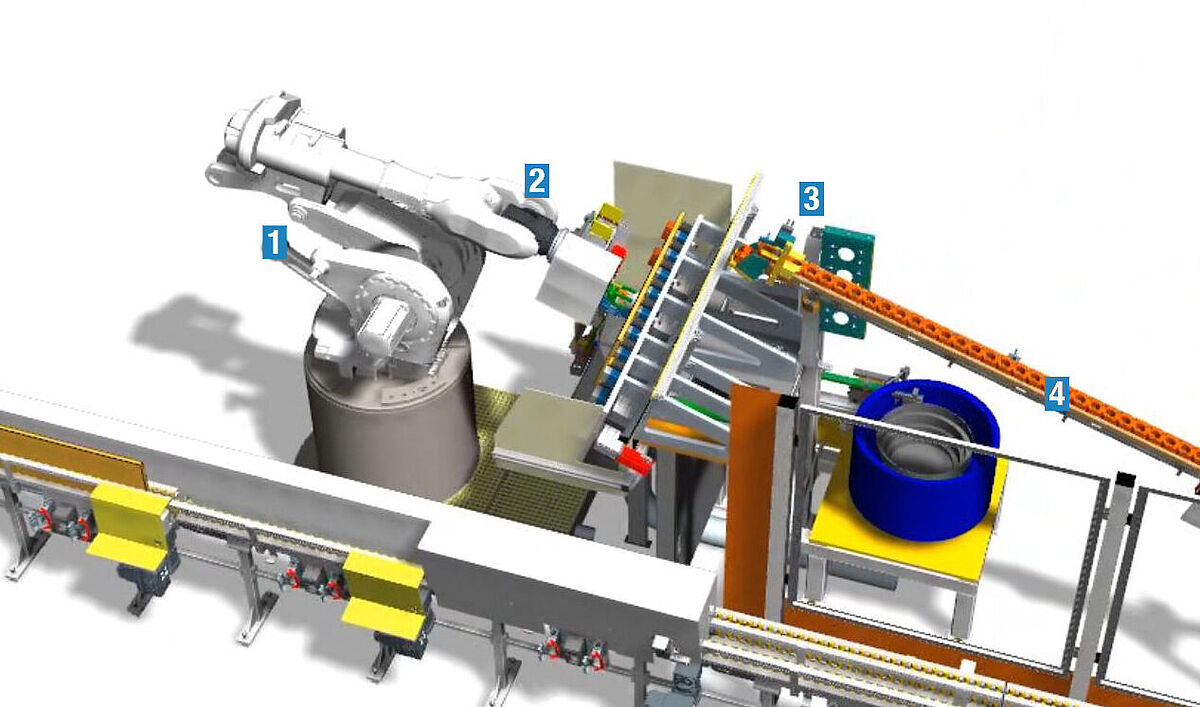

Machining module for metal fitting

Product advantages:

- Fully automated setting of base feet

- Fully automated setting and torque-controlled screwing of hinge mount plates

- Manually loaded feeding line for base feet

- Infeed of the hinge mount plates as bulk material by a separator and a supply device

1 Machining robot

2 Multi-function head

3 Infeed of base feet

4 Infeed of mount plates

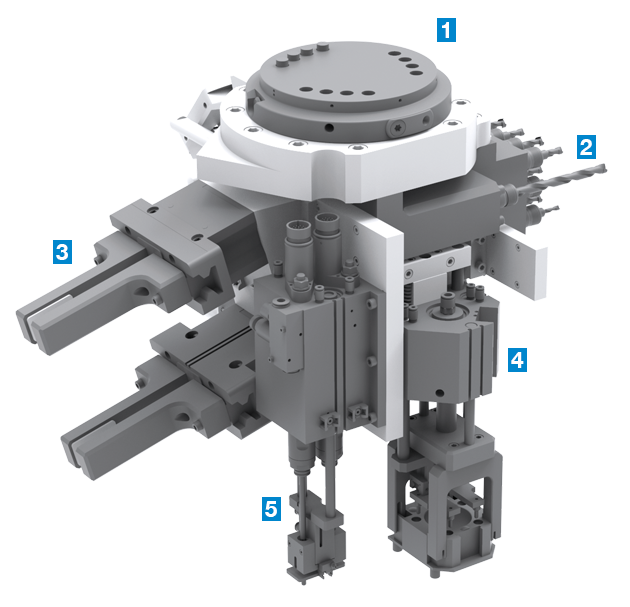

Multi-function head

Product advantages:

- Modular multi-function head for implementing the various functions on the machining module

- Project-specific design of the multi-function head for minimum space requirement and tool exchange effort

- Pneumatic two-jaw grippers for workpiece handling

- Drill gears for individual/series drilling

- Setting module for base feet

- Unit for setting and screwing in hinge mount plates

1 Drive motor

2 Workpiece gripper

3 10x drill gears

4 Setting module for base gripper

5 Setting module for mount plates

6 Screw module