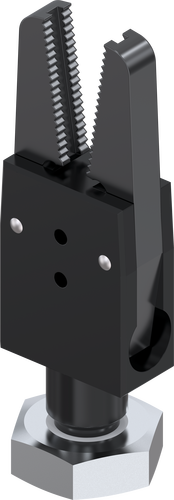

2-Jaw Angular Grippers

Series GZ1000

"The top of the line"

- Unique quality meets functionality

This is one of the best angular grippers on the market, enabling you to make your application more cost-effective and functional - Variable attachment

Decide for yourself whether you want use screws, locknuts or a toolkit clamping system for fastening - Sensing with process reliability

Unlike many other established products on the market, you can even differentiate between "Component present" and "Component not present"

Series features

2 million maintenance-free cycles (max.)

2 million maintenance-free cycles (max.) IP30

IP30 Inductive sensor

Inductive sensor Saw tooth jaw without query

Saw tooth jaw without query Saw tooth jaw with query

Saw tooth jaw with query Version for attaching customer-specific gripper fingers

Version for attaching customer-specific gripper fingers

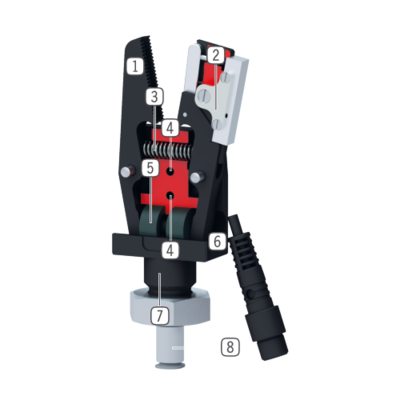

- Gripper jaw

available in different versions - Position sensing

Via inductive proximity switch - Return spring

to open the gripper jaws - Mounting and positioning

via thread / through-hole - Drive

single-acting pneumatic cylinder - Housing

hard coated surface for increased durability - Mounting and positioning

via fit, thread and lock nut - Energy supply