GSI206

Vorgängermodell

Hinweis zum Vorgängermodell

Dieses Produkt gehört zu unseren Vorgängermodellen und ist weiterhin hier zu finden, um Ihnen technische Informationen und Support bereitzustellen. Falls Sie Fragen zu diesem Vorgängermodell haben, nutzen Sie bitte das Kontaktformular – wir helfen Ihnen gerne weiter!

Für Produktanfragen nutzen Sie bitte den Link oben zum weiterentwickelten Nachfolgemodell.

O-Ring Montagegreifer Innen

Serie GSI

Ausstattung/Optionen

5 Mio. wartungsfreie Zyklen (max.)

5 Mio. wartungsfreie Zyklen (max.) IP30

IP30 Magnetfeldsensor

Magnetfeldsensor

Technische Daten

| Aufnahmehub pro Backe einstellbar min. | 6 [mm] |

| Aufnahmehub pro Backe einstellbar max. | 20 [mm] |

| Spreizhub pro Backe einstellbar min. | 1 [mm] |

| Spreizhub pro Backe einstellbar max. | 6 [mm] |

| Abstreifhub | 5 [mm] |

| Spreizkraft | 240 [N] |

| Möglicher O-Ring Ø bei Schnurstärke 1 | 45 [mm] |

| Möglicher O-Ring Ø bei Schnurstärke 2 | 130 [mm] |

| Möglicher O-Ring Ø bei Schnurstärke 3 | 130 [mm] |

| Möglicher O-Ring Ø bei Schnurstärke 4 | 110 [mm] |

| Anzahl der Greifbacken | 6 [Anzahl] |

| Betriebsdruck min. | 3 [bar] |

| Betriebsdruck max. | 8 [bar] |

| Nennbetriebsdruck | 6 [bar] |

| Betriebstemperatur min. | 5 [°C] |

| Betriebstemperatur max. | +80 [°C] |

| Schutzart nach IEC 60529 | IP30 |

| Gewicht | 1.1 [kg] |

Zubehör

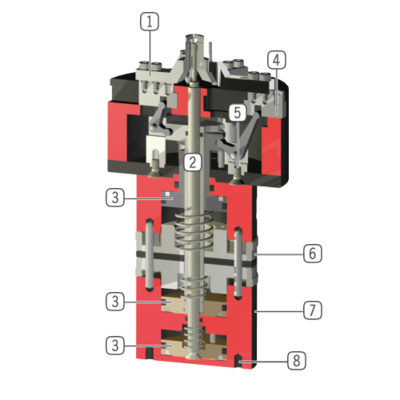

Aufbau im Schnitt

- Spreizbacken

zum Positionieren des O-Rings in der Nut des Werkstücks - Auswerfer (Kolbenstange)

zum Abstreifen des O-Rings - Antrieb über 3 einfachwirkende Pneumatikzylinder

Antrieb Aufnehmerbacken Antrieb Spreizbacken Antrieb Auswerfer - Aufnehmerbacken

zur Aufnahme des O-Rings - Kraftübertragung

über Hebel und Kulisse - Hubeinstellung Aufnehmerbacken

verhindert das Überdehnen des O-Rings bei der Montage - Hubeinstellung Spreizbacken

zum Anpassen an den Bohrungsdurchmesser des Werkstücks - Befestigung und Positionierung

axial, am Greiferboden