ZK1036

Schneidzangen

Serie ZK1000

- Extrem Leicht

Dieses Leichtgewicht ermöglicht Ihnen oftmals den Einsatz einer kleineren Verfahrachse und reduziert somit die Gesamtkosten der Anwendung - Magnetfeldsensorabfrage integriert

Eine der wenigen Schneidzangen auf dem Markt, deren Stellungen prozesssicher abgefragt und an die Steuerung übertragen werden können - Hier entscheiden Sie selbst!

Ob Anguss oder Stahldraht: Durch die Vielzahl an Schneidengeometrien und -materialien finden Sie immer die richtigen Schneiden

Ausstattung/Optionen

5 Mio. wartungsfreie Zyklen (max.)

5 Mio. wartungsfreie Zyklen (max.) Feder öffnend O

Feder öffnend O IP30

IP30 Magnetfeldsensor

Magnetfeldsensor

Technische Daten

| Hub pro Backe | 2.5 [°] |

| Greifmoment beim Schließen | 40 [Nm] |

| Schließzeit | 0.04 [s] |

| Öffnungszeit | 0.15 [s] |

| Betriebsdruck min. | 2 [bar] |

| Betriebsdruck max. | 6 [bar] |

| Nennbetriebsdruck | 6 [bar] |

| Betriebstemperatur min. | 5 [°C] |

| Betriebstemperatur max. | +80 [°C] |

| Zylindervolumen pro Zyklus | 9.2 [cm³] |

| Schutzart nach IEC 60529 | IP30 |

| Gewicht | 0.31 [kg] |

| möglicher Schneid-Ø max. Kunststoff | 4 [mm] |

| möglicher Schneid-Ø max. Hartkunststoff | 2.6 [mm] |

| möglicher Schneid-Ø max. Kupfer | 1.6 [mm] |

| möglicher Schneid-Ø max. Stahl | 1 [mm] |

| möglicher Schneid-Ø max. Klavierdraht | 0.5 [mm] |

Zubehör

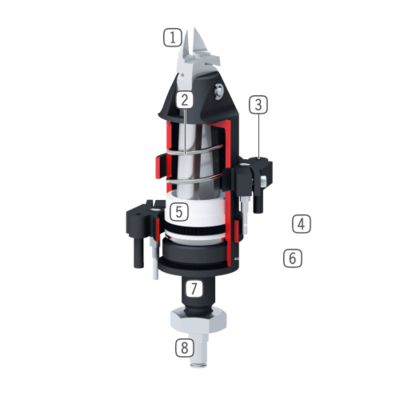

Aufbau im Schnitt

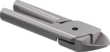

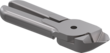

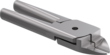

- Schneideinsatz

flexibel Einsetzbar durch applikationsspezifische Schneidengeometrien - Rückstellfeder

zum Öffnen der Schneiden - Befestigungsschelle

Aufnahme für die Magnetfeldsensorik - Magnetfeldsensor

zur Positionsabfrage - Antrieb

einfachwirkender Pneumatikzylinder - Gehäuse

hartbeschichtete Aluminiumlegierung - Befestigung und Positionierung

über Passung, Gewinde und Kontermutter - Energiezuführung