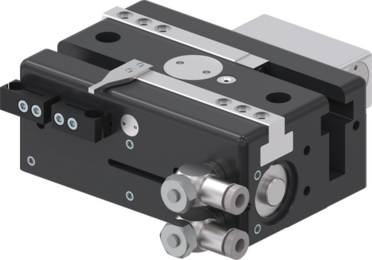

GHK6360

2-Backen-Parallelgreifer mit großem Hub

Serie GHK6000

"Der Robuste"

- Werkstücksicherung bei Druckabfall über Klemmelement unter Voraussetzung einer formschlüssigen Greifbackengestaltung

- Abmaße basieren auf den Standardgreifer der GH6000-Serie

- Langer Hub, bis zu 200 mm pro Backe

- Stabile T-Nutenführung, komplett über die gesamte Gehäuselänge geführt

- Für Greifbacken mit einer Länge von bis zu 600 mm

- Kompakte Bauform, durch übereinander angeordneten Zylinder und Führung

Ausstattung/Optionen

10 Mio. wartungsfreie Zyklen (max.)

10 Mio. wartungsfreie Zyklen (max.) IP40

IP40 Magnetfeldsensor

Magnetfeldsensor Induktiver Sensor

Induktiver Sensor Positionserhalt über Klemmelement

Positionserhalt über Klemmelement

Technische Daten

| Hub pro Backe | 60 [mm] |

| Greifkraft beim Schließen | 1840 [N] |

| Greifkraft beim Öffnen | 1520 [N] |

| Schließzeit | 0.4 [s] |

| Öffnungszeit | 0.4 [s] |

| Eigengewicht montierte Greifbacke max. | 3.5 [kg] |

| Länge Greifbacken max. | 300 [mm] |

| Wiederholgenauigkeit +/- | 0.05 [mm] |

| Betriebsdruck min. | 3 [bar] |

| Betriebsdruck max. | 8 [bar] |

| Nennbetriebsdruck | 6 [bar] |

| Betriebstemperatur min. | +5 [°C] |

| Betriebstemperatur max. | +80 [°C] |

| Zylindervolumen pro Zyklus | 486 [cm³] |

| Schutzart nach IEC 60529 | IP40 |

| Gewicht | 7.5 [kg] |

Zubehör

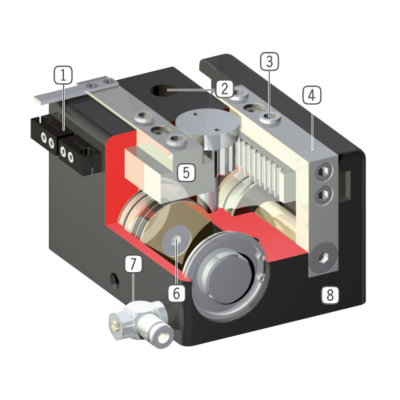

Aufbau im Schnitt

- Klemmbock

Aufnahme für induktiven Näherungsschalter - Befestigung und Positionierung

alternativ an mehreren Seiten für eine individuelle Montage - Abnehmbare Zentrierhülse

schnelle und kostengünstige Positionierung der Greifbacken - Greiferbacke

Aufnahme der individuellen Greifbacke - präzise, lange T-Nutenführung

Hohe Kräfte- und Momentenaufnahme - Antrieb

zwei doppelwirkende Pneumatikzylinder über Zahnrad synchronisiert - Energiezuführung

von mehreren Seiten möglich VORSICHT: Großhubgreifer immer mit mitgelieferter Abluftdrossel betreiben (Geschwindigkeitsregulierung) - Robustes, leichtes Gehäuse

hartbeschichtete Aluminiumlegierung