WWR125L-B

Legacy Product

Note on the predecessor model

This product belongs to an earlier product generation, but is still available. For new designs, we recommend using the enhanced successor model of the WPR5000 series. You can access it via the link above. Technical information and support for this product is of course still available. If you have any questions, please use our contact form - we will be happy to help you!

Tool Changers

Series WWR

Technical Data

| Connecting flange according EN ISO 9409-1 | TK 125 |

| Type of drive | pneumatic |

| Pneumatic energy transfer | 10 [Quantity] |

| Electrical energy transfer | optional |

| Hydraulic energy transfer | optional |

| Flow per connector | 500 [l/min] |

| Self locking mechanism when locking | mechanical |

| Repetition accuracy in Z | 0.01 [mm] |

| Repetition accuracy in X, Y | 0,02 [mm] |

| Offset at coupling max. in X,Y | 2.85 [mm] |

| Operating pressure | 4 ... 10 [bar] |

| Nominal operating pressure | 6 [bar] |

| Operating temperature | 5 ... +80 [°C] |

| Moment of inertia | 42 [kgcm²] |

| Certifications | LABS / REACH / RoHS |

| Weight | 1.5 [kg] |

Suitable loose part

| Legacy Product | Details |

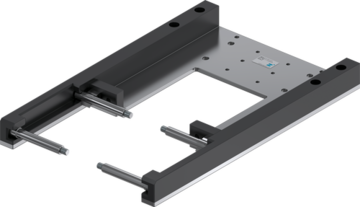

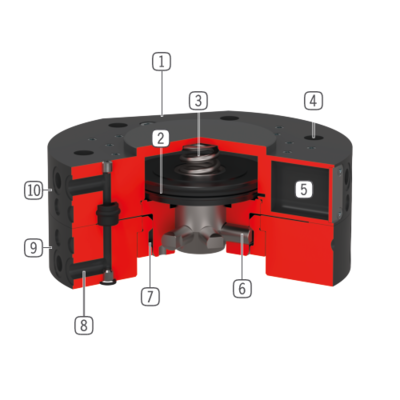

Benefits in detail

- Mounting for energy element

- Drive

double-acting pneumatic cylinder - Integrated spring

energy storage in case of drop in pressure - Robot flange

partial mounting circle in accordance with EN ISO 9409-1 - Piston position sensing

via magnetic field sensor - Locking bolt

adapted to the clamping sleeve - Locking sleeve

high moment capacity - Integrated air feed-through

Air / vaccum transfer Hoseless control possible - Loose part

For tool side assembly - Fix part

For robot side assembly