WWR80F-B

Legacy Product

Tool Changers

Series WWR

Technical Data

| Connecting flange according EN ISO 9409-1 | TK 80 |

| Pneumatic energy transfer | 6 [Quantity] |

| Flow per connector | 170 [l/min] |

| Electrical energy transfer | optional |

| Self locking mechanism when locking | mechanical |

| Locking stroke | 1 [mm] |

| Repetition accuracy in Z | 0.01 [mm] |

| Repetition accuracy in X, Y | 0,02 [mm] |

| Joining force | 100 [N] |

| Release force | 60 [N] |

| Offset at coupling max. in X,Y | 1.65 [mm] |

| Operating pressure | 4 ... 10 [bar] |

| Nominal operating pressure | 6 [bar] |

| Operating temperature | 5 ... +80 [°C] |

| Air volume per cycle | 16 [cm³] |

| Moment of inertia | 5.6 [kgcm²] |

| Weight | 0.6 [kg] |

| Recommended handling weight | 70 [kg] |

Accessory

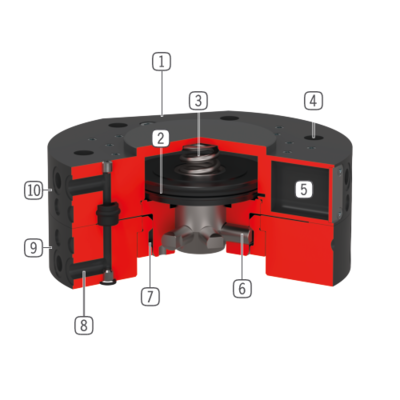

Benefits in detail

- Mounting for energy element

- Drive

double-acting pneumatic cylinder - Integrated spring

energy storage in case of drop in pressure - Robot flange

partial mounting circle in accordance with EN ISO 9409-1 - Piston position sensing

via magnetic field sensor - Locking bolt

adapted to the clamping sleeve - Locking sleeve

high moment capacity - Integrated air feed-through

Air / vaccum transfer Hoseless control possible - Loose part

For tool side assembly - Fix part

For robot side assembly

Energy Elements

Transmission mode Communication

| Fixing thread | Number of fluid couplings | No. of contacts | ||

|---|---|---|---|---|

| WER1000FIL01-00-B |  | M12 | 5 | |

| WER1000FIL01-19-B |  | M12 | 5 |

Transmission mode electrical

| Fixing thread | Number of fluid couplings | No. of contacts | ||

|---|---|---|---|---|

| WER1000FSI04-00-B |  | M8 | 4 | |

| WER1000FSI08-00-B |  | M12 | 8 | |

| WER1000FSI08-10-B |  | M8 | 8 | |

| WER1000FSI12-00-B |  | M12 | 12 | |

| WER1000FSI20-05-B |  | 20 | ||

| WER2000FSI32-05-B |  | 32 | ||

| WER1000FSI04-19-B |  | M8 | 4 | |

| WER1000FSI08-19-B |  | M8 | 8 |

Transmission mode pneumatic

| Fixing thread | Number of fluid couplings | No. of contacts | ||

|---|---|---|---|---|

| WER1000FPL02-12-B |  | M5 | 2 | |

| WER1000FPL04-12-B |  | M5 | 4 | |

| WER2000FPL01-03-B |  | G1/4" | 1 | |

| WER2000FPL02-06-B |  | G1/8" | 2 | |

| WER2000FPL06-12-B |  | M5 | 6 |