Robot-based sorting and decoupling cells

In addition to drilling, Zimmer Systems creates applications for sorting furniture parts. These cells are either integrated into the overall process or, as an alternative, they can also be used as stand-alone applications. Modern sorting concepts make it possible to control material flow with high performance and flexibility. The systems are designed for throughput rates of 2.0 to 25.0 parts per minute and ensure efficient sorting. Storage and retrieval take place via separate conveyor levels, which ensures a smooth material flow. Robot-based cells can handle several parts at the same time, which increases process speed and reduces downtime. The storage volume of the system can be flexibly adapted to the respective requirements in order meet requirements in the best possible way.

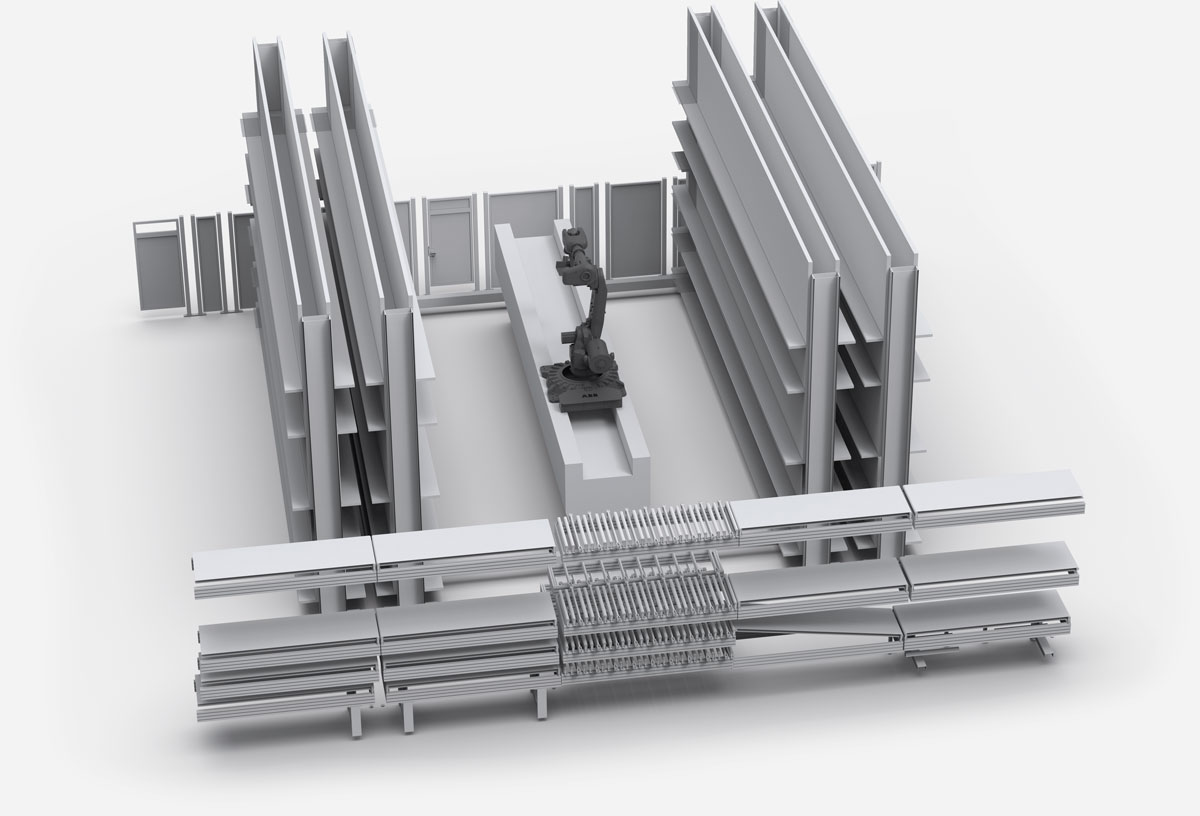

Traveling axle sorting version

Component sorting in the cell with traveling axis is particularly suitable for solutions with medium dynamics and high volume. The minimum output with one cell is 4-5 cycles per minute, whereby a higher output requirement can be achieved with several cells next to each other.

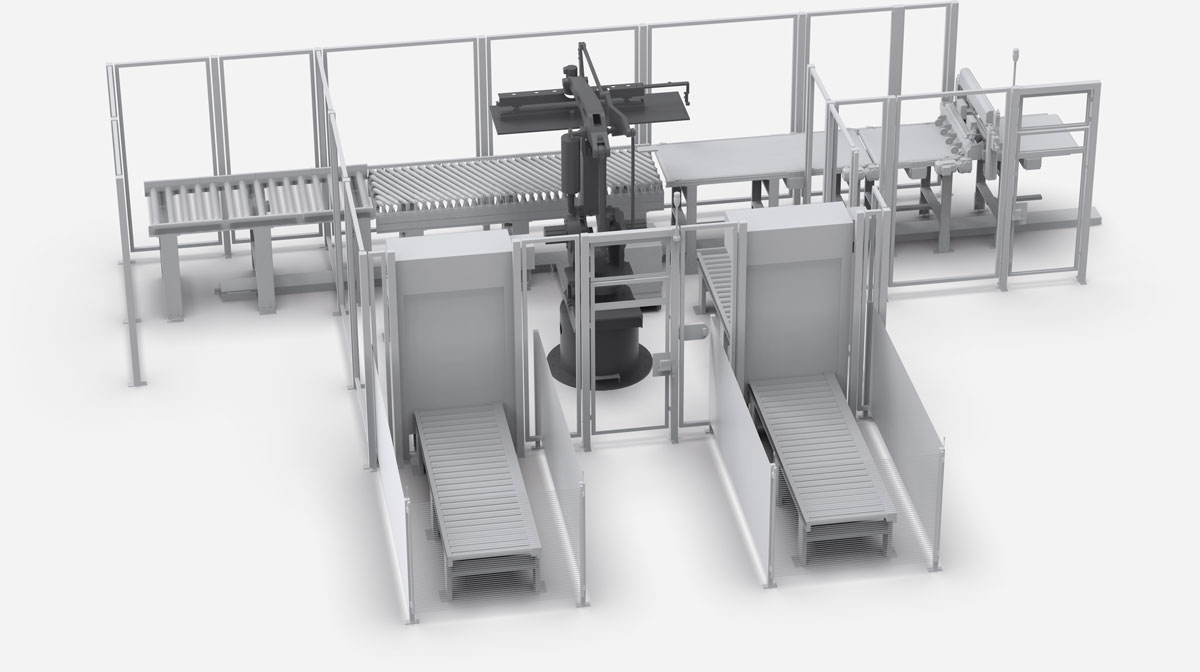

Loading / unloading

The loading and unloading units ensure the automatic feeding of parts. The sorting cells can be loaded and unloaded in various configurations (from the stack, from carriages, connected to conveyor systems, etc.). The following picture shows feeding from the stack.

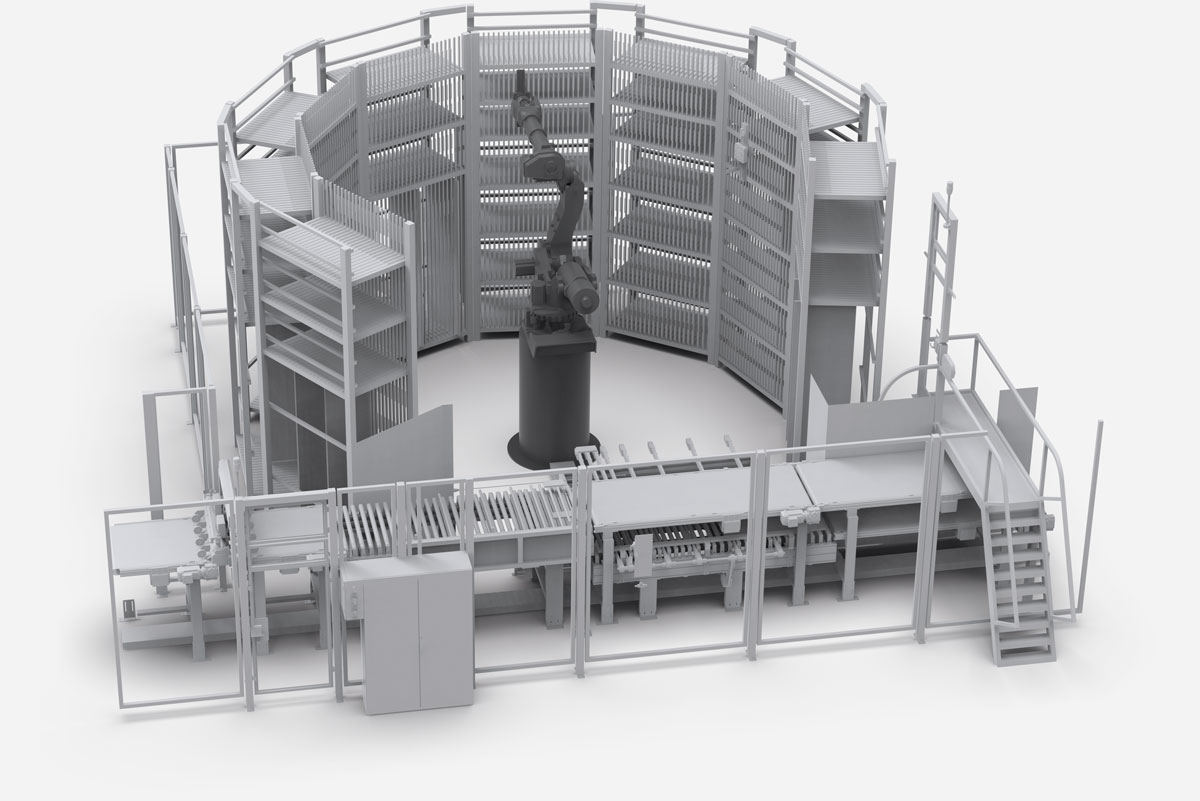

Round cell sorting version

The round cell enables efficient, automated component sorting. The sorting cells are seamlessly integrated into the material flow. The round cell is ideal for solutions with high dynamics and limited volume. The minimum output of a cell is 5-5.5 cycles per minute, whereby a higher output requirement is covered by using several cells next to each other.