Zimmer Group at the LIGNA 2025

Visit us: Hall 12 | Stand B51

Customized solutions for woodworking. As a leading automation expert for the woodworking industry, we will be presenting tailor-made solutions – from individual components and systems to complete overall concepts comprising machines, software, and systems. Discover our trade fair highlights here!

AUDIO GUIDE

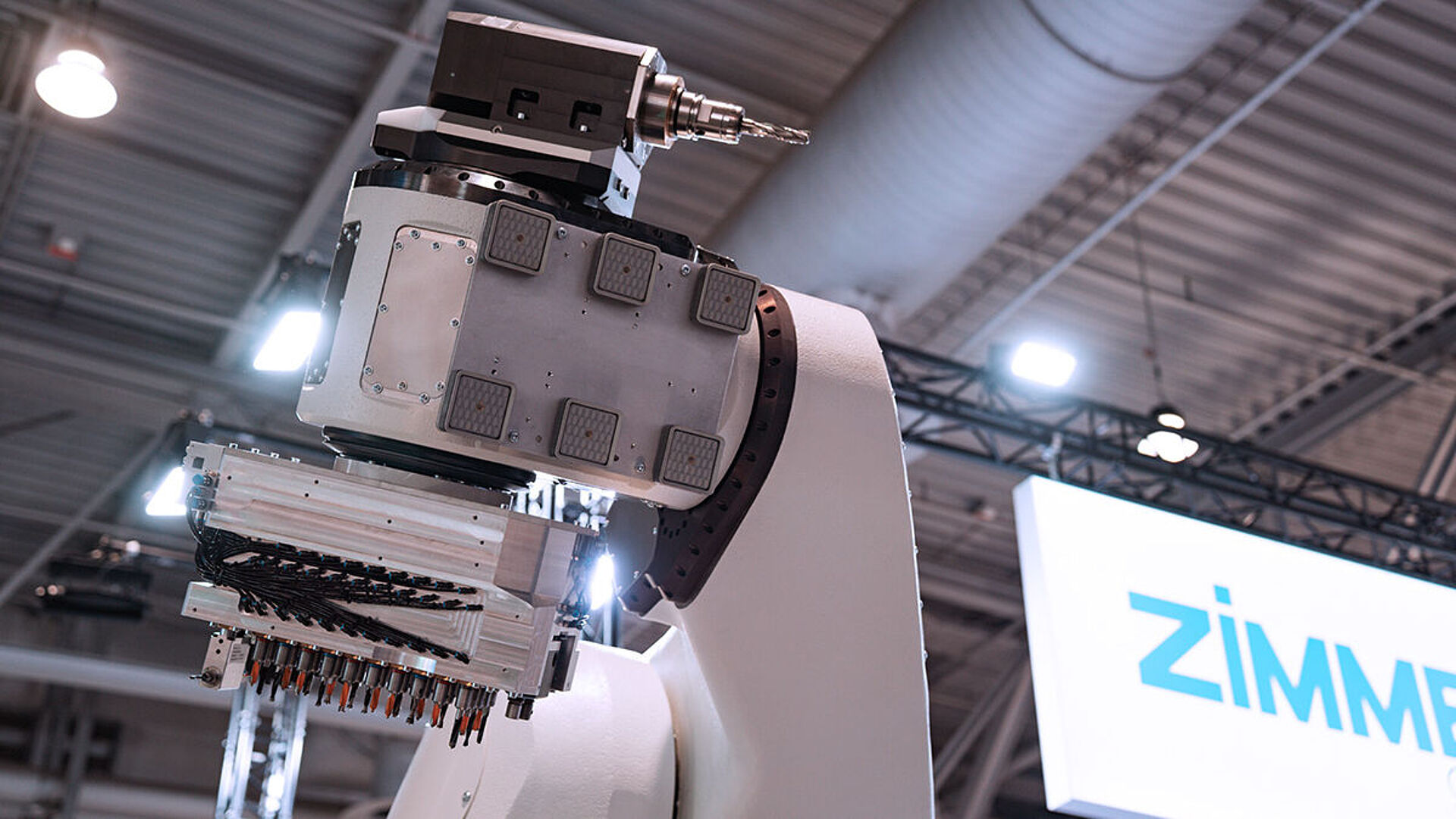

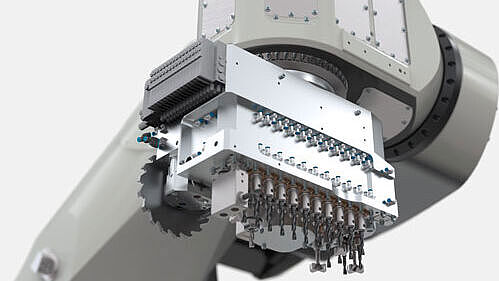

1. Processing with Raptor

Woodworking with precision

The woodworking robot Raptor was developed specifically for the woodworking industry and performs precise cutting, shaping, grinding, and painting tasks. Its use helps increase efficiency and reduce costs, as it performs complex tasks quickly, precisely, and in a more space-saving manner than gantry machines. Raptor has a multifunctional head with 2 flanges, a quick-change interface for fast tool changes, and features impressive internal energy guidance.

Audio guide

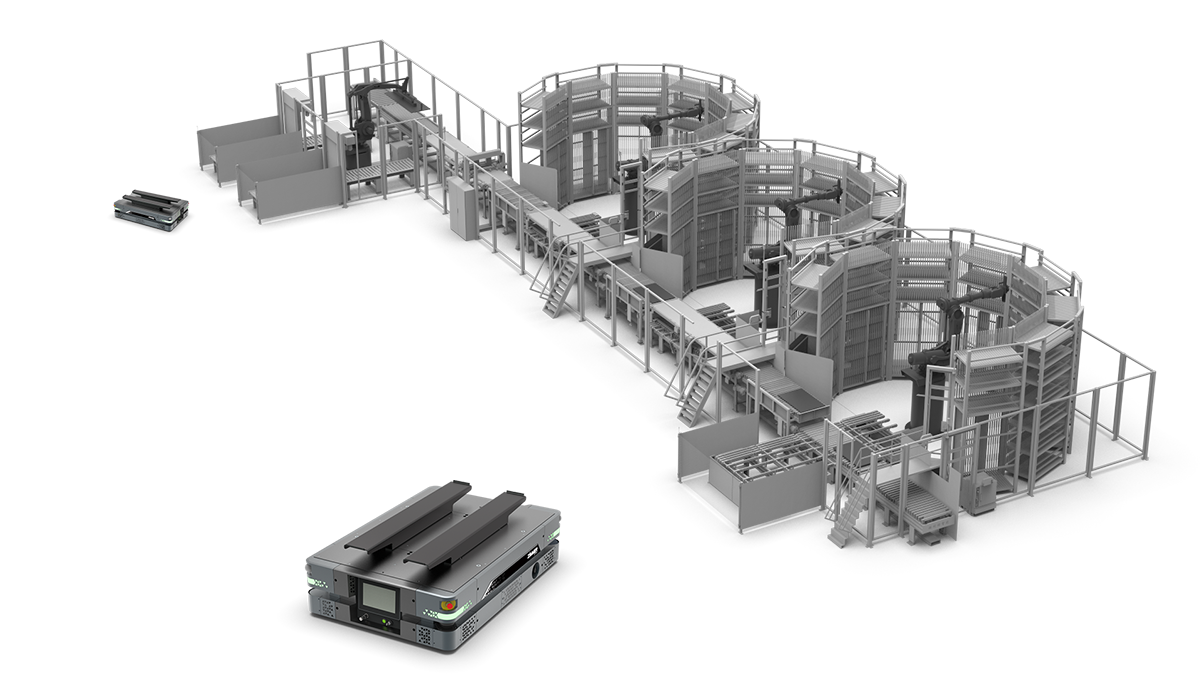

2. Transport with AMRs

Autonomous mobile robot Miles

Autonomous mobile robots (AMRs) are revolutionizing woodworking and increasing efficiency in numerous areas. The autonomous mobile robot Miles from Zimmer Group optimizes your intralogistics and makes the transport of goods and materials more efficient than ever before. Miles with a lifting unit offers a wide range of customer-specific customization options that can handle almost any challenge. The parts to be transported can be flexibly adapted. Despite its small size and compact design, the system, equipped with a lift, can transport loads of up to 3,500 kg.

Audio guide

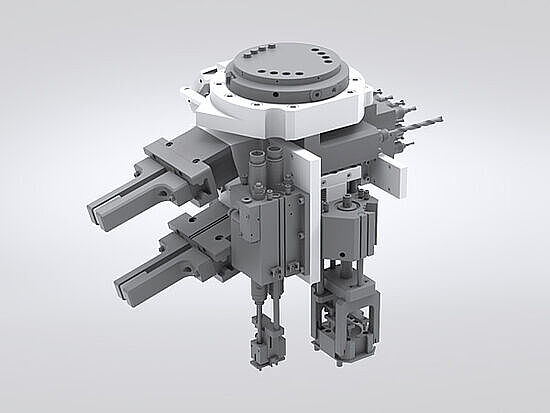

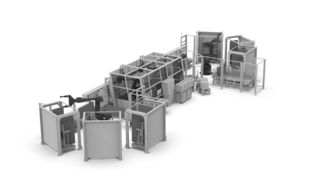

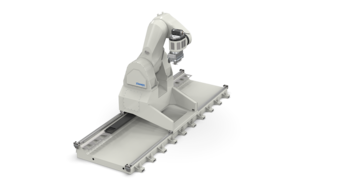

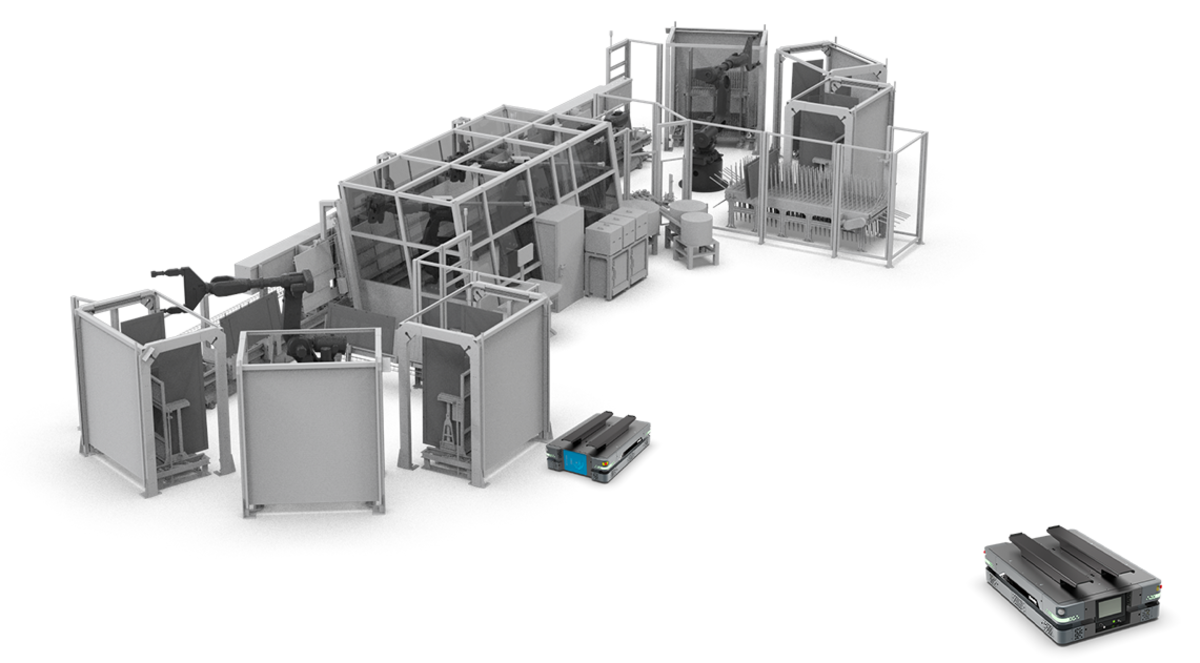

3. System for drilling work

Robot-based machining center

The highly flexible, innovative production line for machining furniture fronts in batch size 1 combines a highly flexible shuttle system with precision-compensated industrial robots. The shuttle system serves as an efficient workpiece transport and clamping system and enables precise and smooth machining. Precision-compensated industrial robots perform the drilling and ensure maximum accuracy.

Audio guide

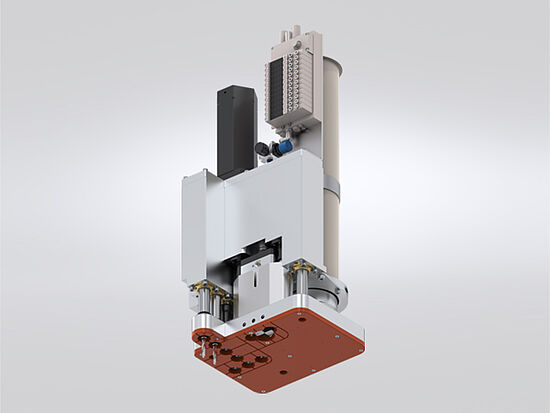

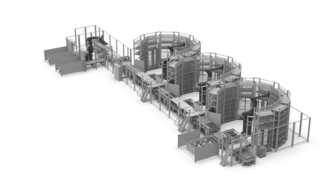

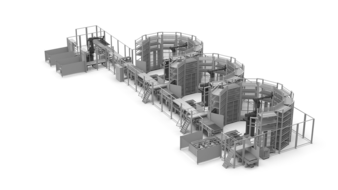

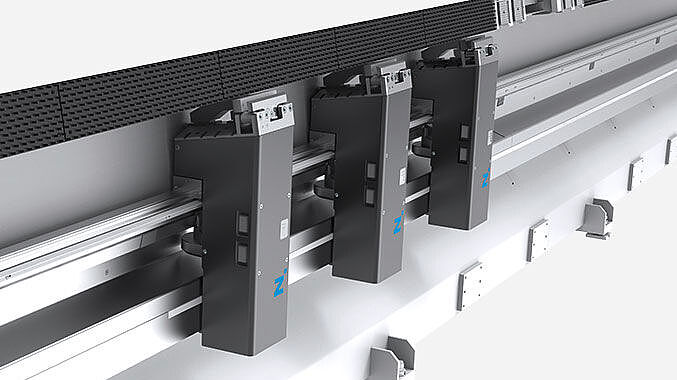

4. Transport with shuttle system

The Modular Transport System is a modular, flexible, fully scalable transport and handling system with a master/slave and recuperation function that combines transport, processing, and quality assurance functions in an almost ideal way. Depending on the requirements profile, the actual transport route can be flexibly enhanced with loading robots, measuring and plausibility checking stations, processing robots, transfer devices, and assembly stations. The high degree of flexibility is due in no small part to the reconfigurability of the overall system and the independently operating functional units.

Audio guide

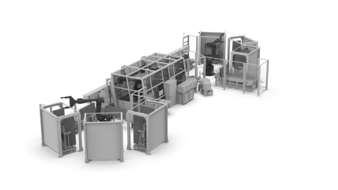

5. System for sorting workpieces

Robot-based sorting machine

In addition to drilling work, Zimmer Systems implements applications for sorting furniture parts. These cells are integrated into an overall process, or can also be used as stand-alone applications. Modern sorting concepts enable powerful and adaptable material flow control. The systems are designed for throughput rates of 2.0 to 25.0 parts per minute and ensure efficient sorting.

Audio guide

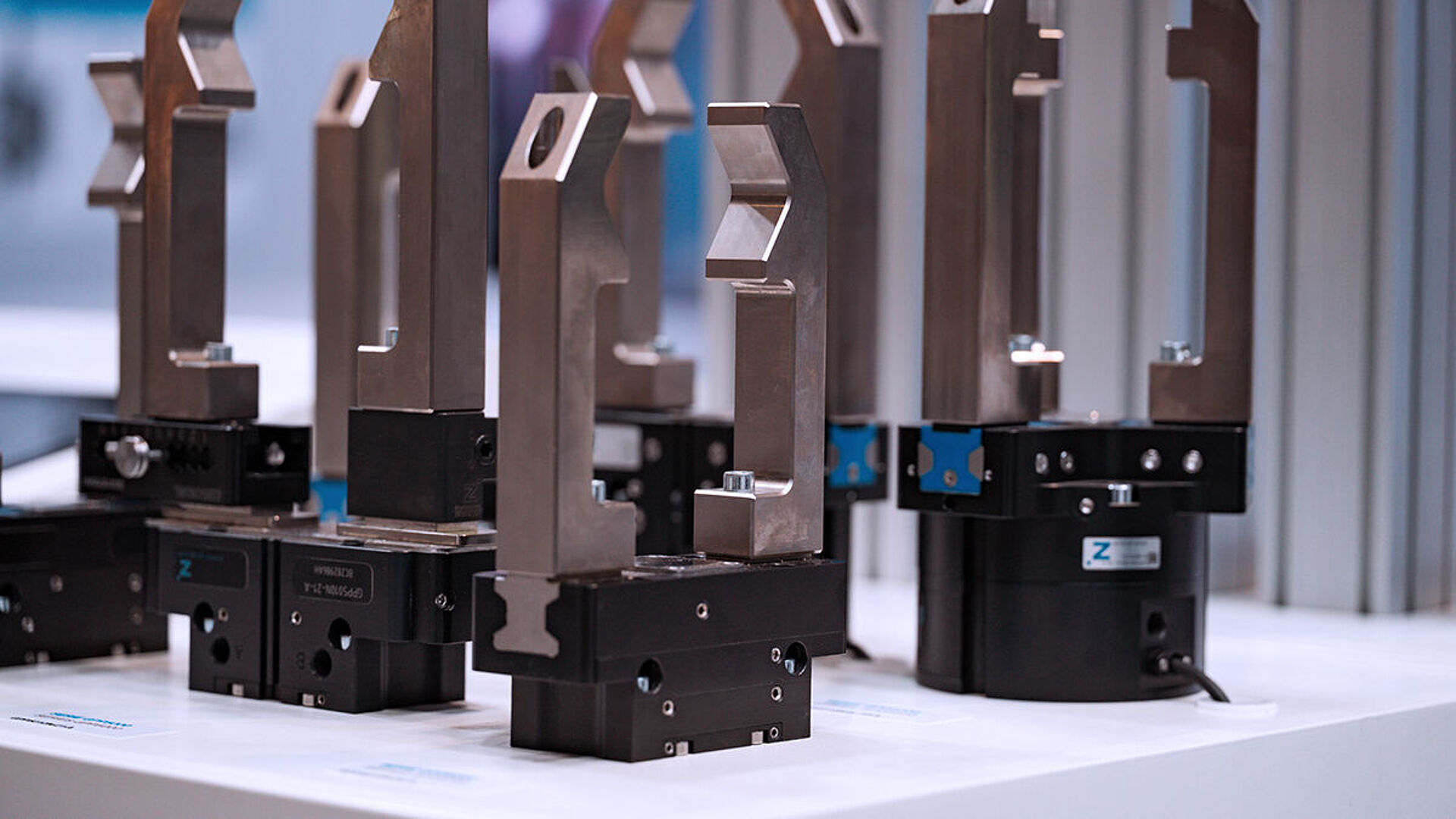

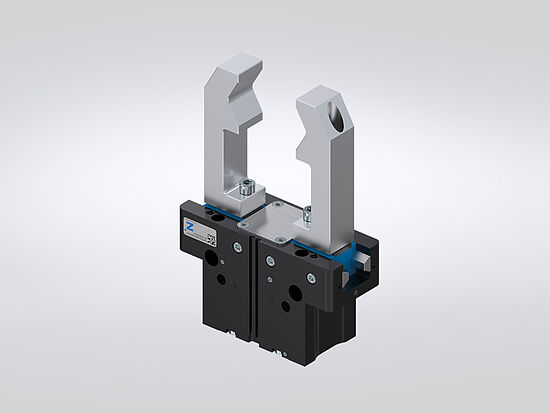

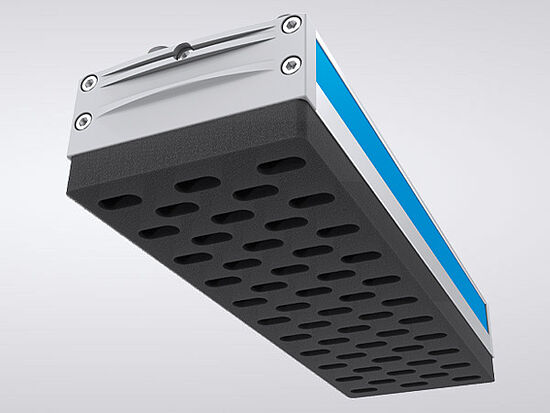

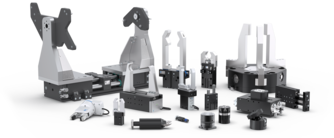

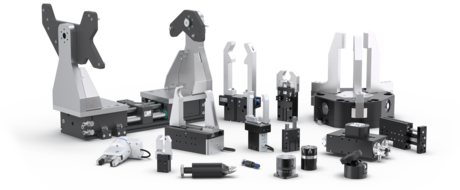

6. End-of-arm tools for woodworking

Modular, flexible, customized

For the increasing use of robots for processing wood, wood-like materials, and composite materials, we offer innovative, application-optimized end-of-arm products for implementing a wide variety of functions on the processing module. We deliver sophisticated high-tech solutions for the process chain with a focus on maximum flexibility, scalability, and productivity, relying on state-of-the-art development technologies and simulation methods such as digital twins. The possibilities are endless.

Audio guide

Components for Woodworking

More than 4 decades of experience

For 45 years, Zimmer Group has been providing excellent solutions in automation technology, including handling and vacuum technology, robotics, clamping and braking elements, damping and machine technology. As a leading manufacturer and supplier of hydraulic, pneumatic, and electrical components, we have in-depth industry knowledge to support you as a long-term, reliable, and competent partner. Safety and quality are core elements of our corporate philosophy.