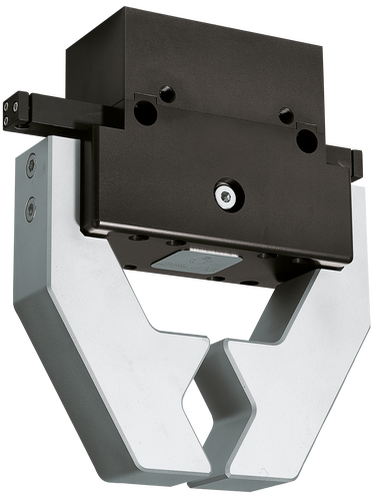

Series DAL

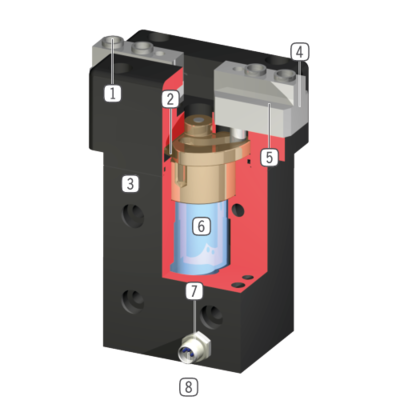

3-Jaw Concentric Grippers

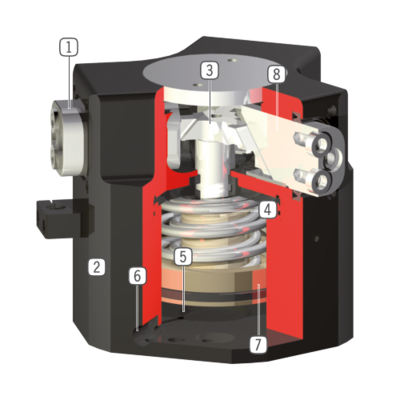

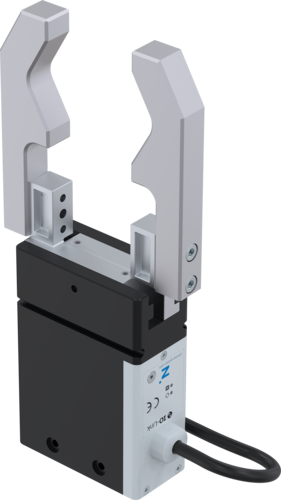

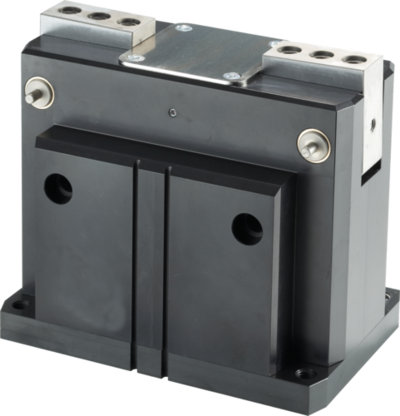

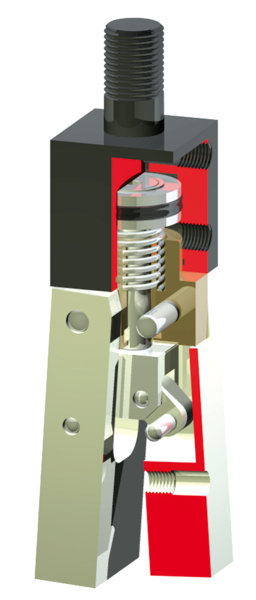

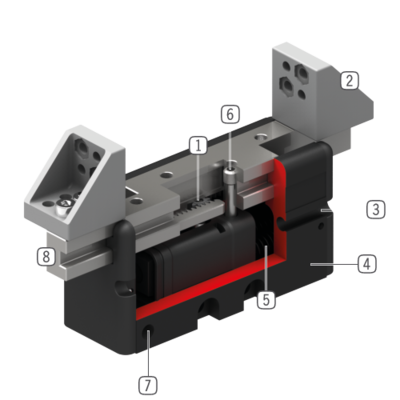

Series GD1700

"The sealed"

- Suitable for use under extreme conditions

The sealed square guide guarantees process reliability even under the harshest conditions - High moment load

The square guide provides the highest possible durability for your application - Variety in the versions

Corrosion-protected, temperature-resistant or cleanroom-compatible for flexible use

Installation Size: GD1704 | |

| Order-No. | |

|---|---|

| GD1704N-B | |

| GD1704NC-B | |

| GD1704NO-B | |

Installation Size: GD1706 | |

| Order-No. | |

| GD1706N-B | |

| GD1706NC-B | |

| GD1706NO-B | |

Installation Size: GD1708 | |

| Order-No. | |

| GD1708N-B | |

| GD1708NC-B | |

| GD1708NO-B | |

Installation Size: GD1710 | |

| Order-No. | |

| GD1710N-B | |

| GD1710NC-B | |

| GD1710NO-B | |

Installation Size: GD1712 | |

| Order-No. | |

| GD1712N-B | |

| GD1712NC-B | |

| GD1712NO-B | |

Installation Size: GD1716 | |

| Order-No. | |

| GD1716N-B | |

| GD1716NC-B | |

| GD1716NO-B | |

Installation Size: GD1720 | |

| Order-No. | |

| GD1720N-B | |

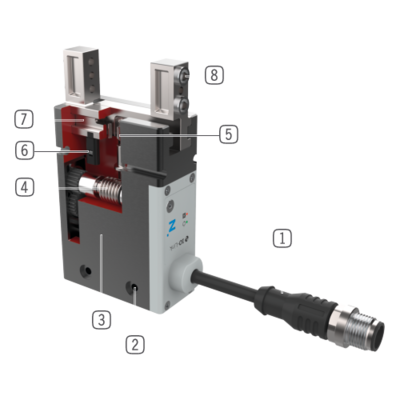

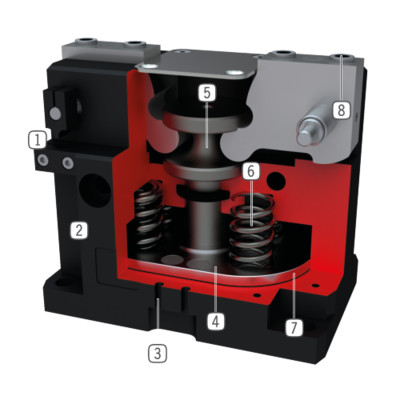

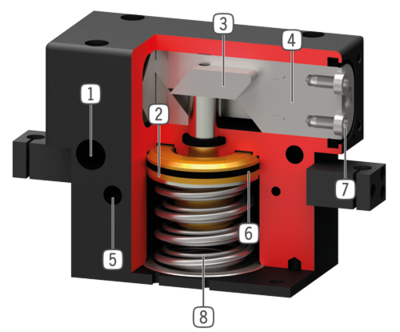

- Sealed and precise square guide for / harsh environmental conditions

high forces and moments capacity - Robust, lightweight housing

Hard-coated aluminum alloy - Wedge hook mechanism

synchronized the movement of the gripper jaws high force transfer - Integrated gripping force safety device

spring integrated into cylinder as energy storage optional in designs C and O - Permanent magnet

installed in piston chamber as indicator for magnetic field sensor (up to GD1708-B) - Energy supply

possible from several sides - Drive

double-acting pneumatic cylinder - Removable centering sleeves

quick and economical positioning of the gripper fingers

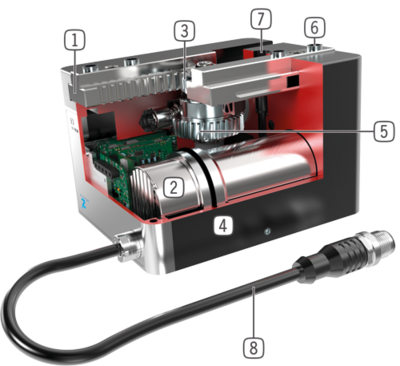

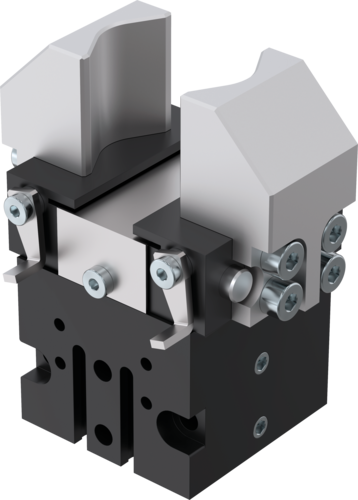

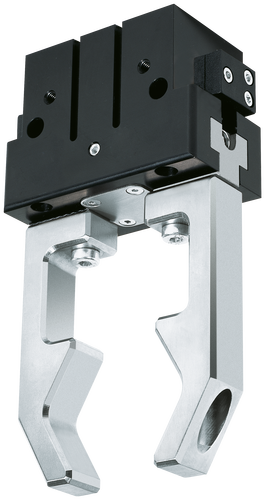

Series

3-Jaw Concentric Grippers

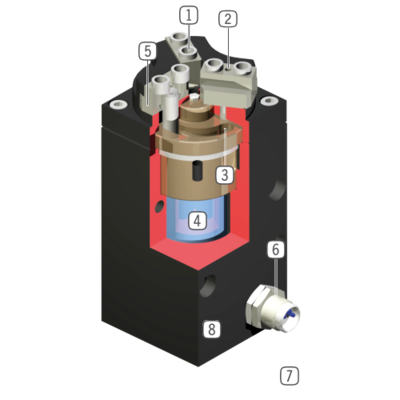

Series GED1300

"The robust"

- Proven T slot guide

This established and proven guiding technology stands for the highest process reliability like no other - Integrated position sensing

You can detect the gripper status safely via the motor current using your control system - The simplest activation

The included control unit is controlled easily via plus and minus buttons, while you can optionally adjust the gripping force using the potentiometer

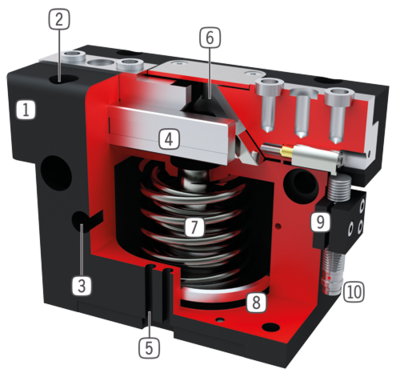

- Removable centering sleeves

quick and economical positioning of the gripper fingers - Gripper jaw

hardened steel individual gripper finger mounting - Positively driven curve disc

synchronized the movement of the gripper jaws high force transfer rapid stroke and force stroke (version with 6 mm stroke per jaw) - Drive

electric drive by 24 VDC step motor - Guide

precise T-Slot guide for high forces and moments capacity - Position sensing

measured at the end of stroke via power increase on the motor - Energy supply

standardized interface M8 round plug connection signal control line (use only cable without diode) - Robust, lightweight housing

Hard-coated aluminum alloy

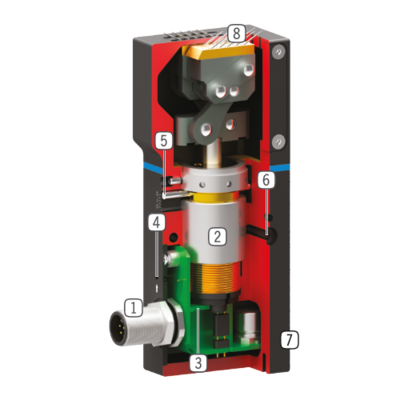

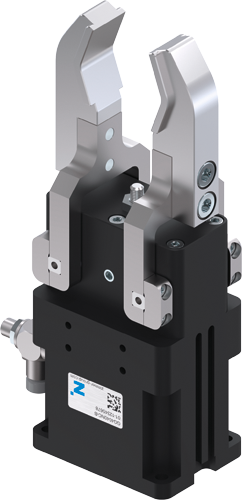

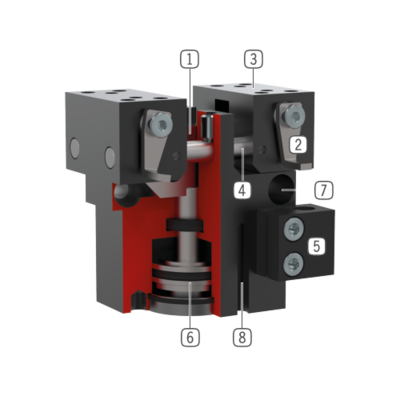

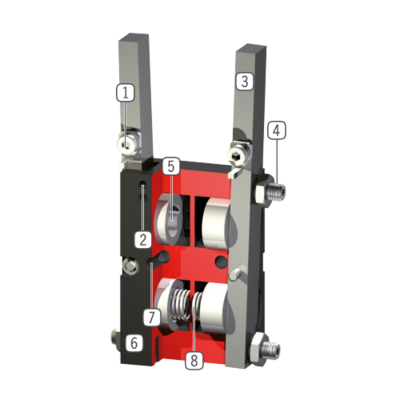

3-Jaw Concentric Grippers

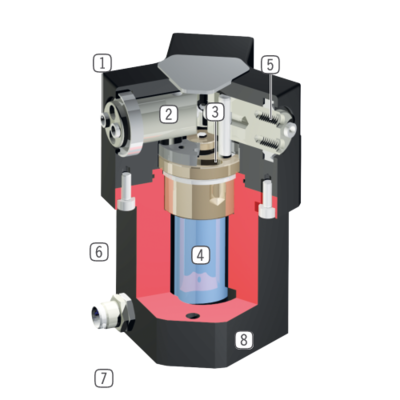

Series GED1500

"The sealed"

- IP64

The sealed circular guide guarantees process reliability even under the harshest conditions - Integrated position sensing

You can detect the gripper status safely via the motor current using your control system - The simplest activation

The included control unit is controlled easily via plus and minus buttons, while you can optionally adjust the gripping force using the potentiometer

- Removable centering sleeves

quick and economical positioning of the gripper fingers - Gripper jaw

hardened steel individual gripper finger mounting - Positively driven curve disc

synchronized the movement of the gripper jaws high force transfer rapid stroke and force stroke (version with 6 mm stroke per jaw) - Drive

electric drive by 24 VDC step motor - Guide

sealed round guide for harsh environmental conditions - Position sensing

measured at the end of stroke via power increase on the motor - Energy supply

standardized interface M8 round plug connection signal control line (use only cable without diode) - Robust, lightweight housing

Hard-coated aluminum alloy

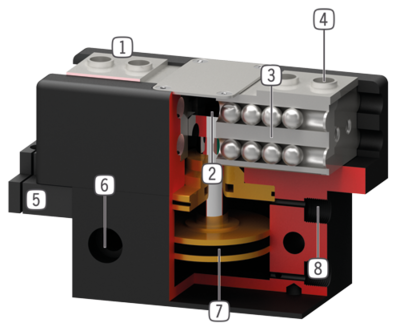

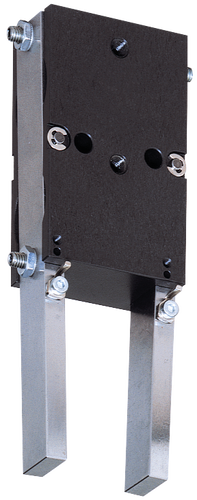

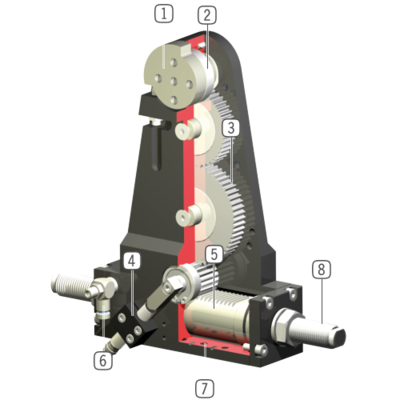

2-Jaw Parallel Grippers with Long Stroke

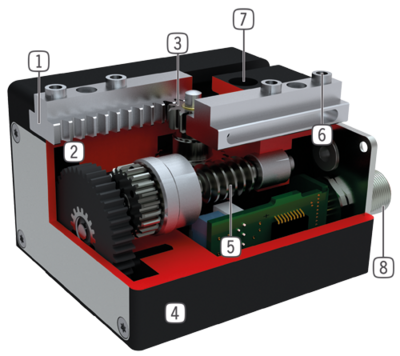

Series GEH6000

"The powerful"

- 60% more powerful than comparative products

Optimisation of weight and force reduces your application costs since all components can have a smaller scale - Servo drive

Position, speed or force control in combination with a self locking mechanism guarantee the highest functionality - Multibus

Be flexible: CANopen, DeviceNet or PROFIBUS - You decide what harmonises the best with your system

- Precise T-Slot guide

high forces and moments capacity - Drive

DC-Motor with encoder - Rack and pinion gear

synchronized the movement of the gripper jaws high force transfer - Robust, lightweight housing

Hard-coated aluminum alloy - Helical worm gear

self locking mechanism in case of power drop - Removable centering sleeves

quick and economical positioning of the gripper fingers - Mounting and positioning

mounting possible from several sides for versatile positioning - Energy supply

standardized connector

2-Jaw Parallel Grippers with Long Stroke

Series GEH6000IL

"Highest performance"

- 5 million maintenance-free cycles

- Integrated sensing via IO-Link

- Servo drive with integrated controller

Brushless drive technology, position, speed and force control guarantee the highest amount of functionality - IO-Link on board

In addition to the unshielded single-cable solution, the future-proof, hot-pluggable activation provides you with a wide variety of travel profiles for easy implementation into your control system - Gentle yet powerful

Power version -03 for handling heavy workpieces with mechanical self-locking and version -31 for gently gripping of delicate parts

Installation Size: GEH6060IL | |

| Order-No. | |

|---|---|

| GEH6060IL-03-A | |

Installation Size: GEH6140IL | |

| Order-No. | |

| GEH6140IL-03-A | |

Installation Size: GEH6180IL | |

| Order-No. | |

| GEH6180IL-03-A | |

- Precise T-Slot guide

high forces and moments capacity - Drive

Brushless DC servomotor - Rack and pinion gear

synchronized the movement of the gripper jaws high force transfer - Robust, lightweight housing

Hard-coated aluminum alloy - Helical worm gear

self locking mechanism in case of power drop (only version -03) - Removable centering sleeves

quick and economical positioning of the gripper fingers - Mounting and positioning

mounting possible from several sides for versatile positioning - Energy supply

standardized connector

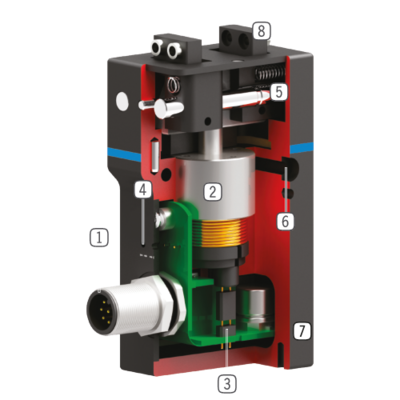

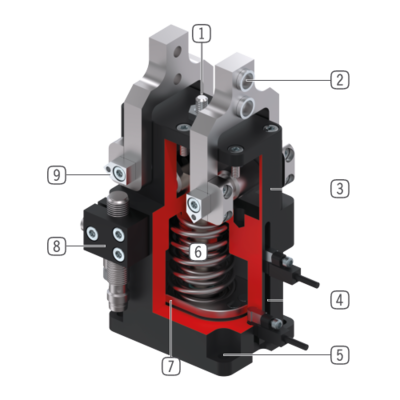

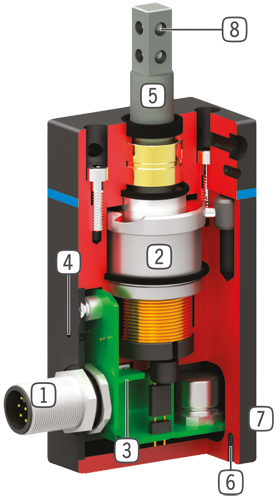

Needle gripper

Series GEN9100

- Plug and play

Reduce programming and assembly costs to a minimum with the integrated control system and the 2 position query - Saving energy with pulse control

You only have to supply current briefly when retracting and extending the needle; no energy is required when transporting the workpiece - Smooth stroke configuration

The needle stroke is displayed via a scale. You can smoothly adjust the needle stroke to fit your application

Installation Size: GEN9102 | |

| Order-No. | |

|---|---|

| GEN9102 | |

- Energy supply

standardized interface M12 round connector - Drive

via Pot magnet and coil bobbin according to the coil system principle energy consumption only at impulse <25 ms - Position sensing

integrated Hallsensor 2 positions monitorable - Status control

optical LED position display Needles retracted, needles extended - Stroke adjustment

infinitely variable Can be read off the scale - Mounting and positioning

mounting possible from several sides for versatile positioning - Robust, lightweight housing

Hard-coated aluminum alloy - Extending needles

gripping by penetration

2-Jaw Parallel Grippers

Series GEP1400

"The robust"

- Proven T slot guide

This established and proven guiding technology stands for the highest process reliability like no other - Integrated position sensing

You can detect the gripper status safely via the motor current using your control system - The simplest activation

The included control unit is controlled easily via plus and minus buttons, while you can optionally adjust the gripping force using the potentiometer

- Removable centering sleeves

quick and economical positioning of the gripper fingers - Positively driven curve disc

synchronized the movement of the gripper jaws high force transfer rapid stroke and force stroke (version with 6 mm stroke per jaw) - Robust, lightweight housing

Hard-coated aluminum alloy - Gripper jaw

hardened steel individual gripper finger mounting - Guide

precise T-Slot guide for high forces and moments capacity - Drive

electric drive by 24 VDC step motor - Position sensing

measured at the end of stroke via power increase on the motor - Energy supply

standardized interface M8 round plug signal control line (use only cable without diode)

2-Jaw Parallel Grippers

Series GEP1600

"The sealed"

- IP64

The sealed circular guide guarantees process reliability even under the harshest conditions - Integrated position sensing

You can detect the gripper status safely via the motor current using your control system - The simplest activation

The included control unit is controlled easily via plus and minus buttons, while you can optionally adjust the gripping force using the potentiometer

- Removable centering sleeves

quick and economical positioning of the gripper fingers - Positively driven curve disc

synchronized the movement of the gripper jaws high force transfer rapid stroke and force stroke (version with 6 mm stroke per jaw) - Robust, lightweight housing

Hard-coated aluminum alloy - Gripper jaw

hardened steel individual gripper finger mounting - Guide

sealed round guide for harsh environmental conditions - Drive

electric drive by 24 VDC step motor - Position sensing

measured at the end of stroke via power increase on the motor - Energy supply

standardized interface M8 round plug signal control line (use only cable without diode)

2-Jaw Parallel Grippers

Series GEP2000

"The electric compact one"

- Largest stroke in small installation space

Do you require a large stroke, due to the fact that you are operating either a form fit gripper or a large range of parts but the installation space and the load capacity of your application is limited? Then this gripper is perfect for you! - The simplest activation

It is your choice whether you want to control the gripper by means of I/O ports—like a valve—or if you prefer the version with IO-Link. Both have this in common: they are easy to integrate into your control system. - Positionability via IO-Link

Allows you to position the gripper jaws of the IL-03 and IL-43 variant. In this way, the stroke can be flexibly adapted to the workpiece, which saves time in the process and prevents interfering contours.

Installation Size: GEP2006 | |

| Order-No. | |

|---|---|

| GEP2006IL-00-A | |

| GEP2006IO-00-A | |

| GEP2006IO-05-A | |

Installation Size: GEP2010 | |

| Order-No. | |

| GEP2010IL-00-A | |

| GEP2010IO-00-A | |

| GEP2010IO-05-A | |

Installation Size: GEP2013 | |

| Order-No. | |

| GEP2013IL-00-A | |

| GEP2013IO-00-A | |

| GEP2013IO-05-A | |

Installation Size: GEP2016 | |

| Order-No. | |

| GEP2016IL-00-A | |

| GEP2016IO-00-A | |

| GEP2016IO-05-A | |

- Control

Via I/O ports (IO) or via IO-Link (IL) - Mounting and positioning

mounting possible from several sides for versatile positioning - BLDC motor

wear-resistant brushless DC motor - Helical worm gear

self locking mechanism in case of power drop - Synchronization

via rack and pinion - Position sensing

Permanent magnet for direct query of jaw movement via magnetic field sensors - Gripper jaw

individual gripper finger mounting - Removable centering sleeves

quick and economical positioning of the gripper fingers

2-Jaw Parallel Grippers

Series GEP9000

"The quickest"

- Plug and play

- 250 cycles per minute

- Failure-free continuous operation

Installation Size: GEP9002 | |

| Order-No. | |

|---|---|

| GEP9002NC-B | |

| GEP9002NO-B | |

Installation Size: GEP9004 | |

| Order-No. | |

| GEP9004NC-B | |

| GEP9004NO-B | |

- Energy supply

standardized interface M12 round connector - Drive

via Pot magnet and coil bobbin according to the coil system principle energy consumption only at opening and closing (<25ms) - Position sensing

integrated Hallsensor 3 positions monitorable - Status control

optical LED position display gripper opened, gripper closed, “workpiece available“ - Wedge hook mechanism

self locking mechanism at stop position - Mounting and positioning

mounting possible from several sides for versatile positioning - Robust, lightweight housing

Hard-coated aluminum alloy - Gripper jaw

from high-strength, hard-anodized aluminium removable centering sleeves for individual gripper finger mounting

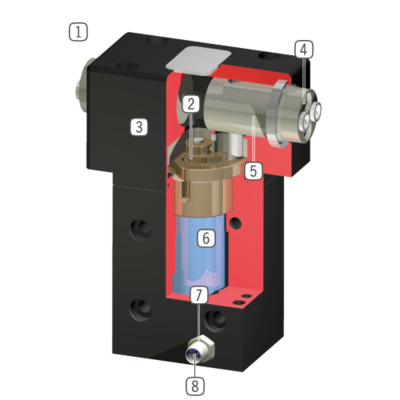

Grippers for Specific Tasks

Series GFP

Installation Size: GFP2012 | |

| Order-No. | |

|---|---|

| GFP2012NC-14 | |

| GFP2012NC-16 | |

| GFP2012NC-25 | |

| GFP2012NC-34 | |

- Sealed and precise square guide

high forces and moments capacity - Wedge hook mechanism

synchronized the movement of the gripper jaws high force transfer - Removable centering sleeves

quick and economical positioning of the gripper fingers - Adjustment ring

regulation of gripping force - Robust, lightweight housing

hard coated aluminium alloy - Drive

single-acting cylinder with spring return opening stroke via tool machine coolant supply closing stroke via integrated spring - Tool intake

standardized HSK-A, VDI, Capto - available upon request - Coolant feed

via tool machine

2-Jaw Angular Grippers

Series GG1000

"The strong"

- High gripping force

Using the high gripping force, you can safely handle even the heaviest workpieces - High moment load

The generously scaled angular gear box provides the highest possible durability for your application - Failure-free continuous operation

Our uncompromising "Made in Germany" quality guarantees up to 10 million maintenance-free cycles

- Cam-switch and mounting block

for position sensing - Robust, lightweight housing

Hard-coated aluminum alloy - Sensing slot

groove for positioning of the magnetic field sensor - Permanent magnet

sensing of the piston setting position via magnetic field sensors - Positively driven lever mechanism

synchronized the movement of the gripper jaws - Integrated gripping force safety device

spring integrated into cylinder as energy storage - Drive

double-acting pneumatic cylinder - Removable centering sleeves

quick and economical positioning of the gripper fingers

2-jaw radial gripper

Series GG4000

- Mounting for inductive proximity switch

Installation Size: GG4032 | |

| Order-No. | |

|---|---|

| GG4032NC | |

| GG4032SC | |

Installation Size: GG4040 | |

| Order-No. | |

| GG4040NC | |

| GG4040SC | |

Installation Size: GG4049 | |

| Order-No. | |

| GG4049NC | |

| GG4049SC | |

Installation Size: GG4058 | |

| Order-No. | |

| GG4058NC | |

| GG4058SC | |

Installation Size: GG4072 | |

| Order-No. | |

| GG4072NC | |

| GG4072SC | |

Installation Size: GG4084 | |

| Order-No. | |

| GG4084NC | |

| GG4084SC | |

- Stroke adjustment screw

Infinitely adjustable opening stroke - Removable centering sleeves

individual gripper finger mounting - Robust, lightweight housing

Hard-coated aluminum alloy - Sensing slot

mounting and positioning of magnetic field sensors - Mounting and positioning

mounting possible from several sides for versatile positioning - Integrated gripping force safety device

spring integrated into cylinder as energy storage - Position sensing

permanent magnet for direct monitoring of piston movement - Mounting block

mounting for inductive proximity switch - Sealed rotation point

for use under extreme conditions

2-Jaw Angular Grippers

Series GM

"Unique"

- Proven technology

We have more than 20 years of proven reliability, which ensures uninterrupted production for you - Fitted machinable gripper jaws

Quickly acquire customised gripper jaws thanks by machining while installed - Variable gripping direction

In just a few steps, you can convert the single-acting cylinder to an opener or closer as needed

- Mounting and positioning

- Robust, lightweight housing

hard coated aluminium alloy - Energy supply

- Drive

single or (depending on design) double-acting pneumatic cylinder - Integrated spring

integrated into piston chamber as energy storage (as reset in single acting cylinder version) - Positively driven lever mechanism

synchronized the movement of the gripper jaws - Gripper jaw

machinable - Sheet metal (GM10)

allows parallel position of the gripper jaws for machining

2-Jaw Parallel Grippers

Series GP

"The enduring"

- Proven technology

We have more than 20 years of proven reliability, which ensures uninterrupted production for you - Very short cycle times

Low-friction circular guides enable very short cycle times and, therefore, high component output for your machine - Failure-free continuous operation

Our uncompromising "Made in Germany" quality guarantees up to 10 million maintenance-free cycles

Installation Size: GP100 | |

| Order-No. | |

|---|---|

| GP100-B-99 | |

| GP100S-B | |

- Wedge hook mechanism

synchronized the movement of the gripper jaws high force transfer - Adjustable switch cam

for position sensing - Gripper jaw

individual gripper finger mounting - Roller slide

for low wear movement sequence - Mounting block

mounting for inductive proximity switch - Drive

double-acting pneumatic cylinder - Mounting and positioning

mounting possible from several sides for versatile positioning - Sensing slot

mounting and positioning of magnetic field sensors

2-Jaw Parallel Grippers

Series GP100

"The precise"

- Gripper jaws 20% longer than similar products

Low-backlash ball guide, guided into a steel housing, for maximum precision - Near constant gripping force for different gripper jaw lengths

Makes it possible to cover a high range of variants with only one gripper - Failure-free continuous operation

Our uncompromising "Made in Germany" quality guarantees up to 10 million maintenance-free cycles

- Gripper jaw

individual gripper finger mounting - Wedge hook mechanism

synchronized the movement of the gripper jaws high force transfer - Ball guide

smooth running guides via rolling friction near constant force in various gripping jaw lengths - Removable centering sleeves

quick and economical positioning of the gripper fingers - Mounting block

mounting for inductive proximity switch - Mounting and positioning

mounting possible from several sides for versatile positioning - Drive

double-acting pneumatic cylinder - Energy supply

possible from several sides

2-Jaw Parallel Grippers

Series GP1800

"The sealed"

- Suitable for use under extreme conditions

The sealed square guide guarantees process reliability even under the harshest conditions - High moment load

The overlapping square guide provides the highest possible durability for your application - Variety in the versions

Corrosion-protected, temperature-resistant or cleanroom-compatible for flexible use

Installation Size: GP1803 | |

| Order-No. | |

|---|---|

| GP1803N-B | |

| GP1803NC-B | |

| GP1803NO-B | |

Installation Size: GP1804 | |

| Order-No. | |

| GP1804N-B | |

| GP1804NC-B | |

| GP1804NO-B | |

Installation Size: GP1806 | |

| Order-No. | |

| GP1806N-B | |

| GP1806NC-B | |

| GP1806NO-B | |

Installation Size: GP1808 | |

| Order-No. | |

| GP1808N-B | |

| GP1808NC-B | |

| GP1808NO-B | |

Installation Size: GP1810 | |

| Order-No. | |

| GP1810N-B | |

| GP1810NC-B | |

| GP1810NO-B | |

Installation Size: GP1812 | |

| Order-No. | |

| GP1812N-B | |

| GP1812NC-B | |

| GP1812NO-B | |

Installation Size: GP1816 | |

| Order-No. | |

| GP1816N-B | |

| GP1816NC-B | |

| GP1816NO-B | |

Installation Size: GP1820 | |

| Order-No. | |

| GP1820N-B | |

| GP1820NC-B | |

| GP1820NO-B | |

Installation Size: GP1830 | |

| Order-No. | |

| GP1830N-B | |

| GP1830NC-B | |

| GP1830NO-B | |

- Mounting and positioning

mounting possible from several sides for versatile positioning - Permanent magnet

installed in piston area - Wedge hook mechanism

synchronized the movement of the gripper jaws high force transfer - Sealed and precise square guide

high forces and moments capacity - Energy supply

possible from several sides - Drive

double-acting pneumatic cylinder - Removable centering sleeves

quick and cost-effective gripper finger positioning - Integrated gripping force safety device

optional via intergrated spring (C and O Models)

2-Jaw Parallel Grippers

Series GP400X

"The robust"

- 30% more guidance than the GP400 series

Ingrained and overlapping gripper jaws mean optimal process reliability - 20% higher moment load than the GP400 series

FEM-optimised T-slotted guard rails provide the highest possible durability - Failure-free continuous operation

Our uncompromising "Made in Germany" quality guarantees up to 10 million maintenance-free cycles

Installation Size: GP403X | |

| Order-No. | |

|---|---|

| GP403XN-C | |

| GP403XNC-C | |

| GP403XNO-C | |

Installation Size: GP404X | |

| Order-No. | |

| GP404XN-C | |

| GP404XNC-C | |

| GP404XNO-C | |

| GP404XS-C | |

| GP404XSC-C | |

| GP404XSO-C | |

Installation Size: GP406X | |

| Order-No. | |

| GP406XN-C | |

| GP406XNC-C | |

| GP406XNO-C | |

| GP406XS-C | |

| GP406XSC-C | |

| GP406XSO-C | |

Installation Size: GP408X | |

| Order-No. | |

| GP408XN-C | |

| GP408XNC-C | |

| GP408XNO-C | |

| GP408XS-C | |

| GP408XSC-C | |

| GP408XSO-C | |

Installation Size: GP410X | |

| Order-No. | |

| GP410XN-C | |

| GP410XNC-C | |

| GP410XNO-C | |

| GP410XS-C | |

| GP410XSC-C | |

| GP410XSO-C | |

Installation Size: GP412X | |

| Order-No. | |

| GP412XN-C | |

| GP412XNC-C | |

| GP412XNO-C | |

| GP412XS-C | |

| GP412XSC-C | |

| GP412XSO-C | |

Installation Size: GP416X | |

| Order-No. | |

| GP416XN-C | |

| GP416XNC-C | |

| GP416XNO-C | |

| GP416XS-C | |

| GP416XSC-C | |

| GP416XSO-C | |

Installation Size: GP420X | |

| Order-No. | |

| GP420XN-C | |

| GP420XNC-C | |

| GP420XNO-C | |

| GP420XS-C | |

| GP420XSC-C | |

| GP420XSO-C | |

Installation Size: GP430X | |

| Order-No. | |

| GP430XN-C | |

| GP430XNC-C | |

| GP430XNO-C | |

| GP430XS-C | |

| GP430XSC-C | |

| GP430XSO-C | |

- Robust, lightweight housing

Hard-coated aluminum alloy - Mounting and positioning

mounting possible from several sides for versatile positioning - Energy supply

possible from several sides - Overlapping guide

for maximum forces and moments capacity - Sensing slot

mounting and positioning of magnetic field sensors - Wedge hook mechanism

synchronized the movement of the gripper jaws - Integrated gripping force safety device

spring integrated into cylinder as energy storage - Position sensing

permanent magnet for direct monitoring of piston movement - Mounting block

mounting for inductive proximity switch (10)

2-Jaw Parallel Grippers

Series GPP1000

"Cost-effective"

- Parallel gripper with an unbeatable price/performance ratio

- Gripper jaw set and fixation material included

- Can be configured for spring opening or spring closing

- One installation size, three strokes: 4, 8 and 16 mm per gripper jaw

- Gripping force of 100 N

- Service life of up to 2 million cycles

Installation Size: GPP1104 | |

| Order-No. | |

|---|---|

| GPP1104CO-00-A | |

Installation Size: GPP1108 | |

| Order-No. | |

| GPP1108CO-00-A | |

Installation Size: GPP1116 | |

| Order-No. | |

| GPP1116CO-00-A | |

- Synchronization

via rack and pinion - Intermediate jaws

incl. mounting material included in scope of delivery - Sensing

mounting and positioning of magnetic field sensors - Lightweight housing

Hard-coated aluminum alloy - Single-acting pneumatic cylinder

Spring return - Jaw slave screw

for changing the gripper's direction of force - Energy supply

possible from several sides - Gripper jaw

for connecting the intermediate jaw or an individual gripper finger via centering sleeves

2-Jaw Angular Grippers

Series GZ

"The proven"

- Proven technology

We have more than 20 years of proven reliability, which ensures uninterrupted production for you - Fitted machinable gripper jaws

By machining the supplied gripper jaws, you can quickly acquire a gripper jaw customised to your needs - Smooth stroke configuration

Configure your own unique stroke - regardless of the gripper jaws!

Installation Size: GZ11-18E | |

| Order-No. | |

|---|---|

| GZ11-18E | |

Installation Size: GZ18-23D | |

| Order-No. | |

| GZ18-23D | |

Installation Size: GZ25-35D | |

| Order-No. | |

| GZ25-35D | |

Installation Size: GZ25-35E | |

| Order-No. | |

| GZ25-35E | |

Installation Size: GZ55-65D | |

| Order-No. | |

| GZ55-65D | |

Installation Size: GZ8-16D | |

| Order-No. | |

| GZ8-16D | |

Installation Size: GZ8-16E | |

| Order-No. | |

| GZ8-16E | |

- Adjustable switch cam

direct sensing of gripper jaw movement - Fixing for mounting block

for inductive proximity switch - Steel (C45K) gripper jaw

can be machined to suit individual applications and hardened - Adjusting screw

Infinitely adjustable opening stroke setting of gripper jaw for exact adjustment of the workpiece - Drive

direct drive via plunger pistons - Robust, lightweight housing

Hard-coated aluminum alloy - Mounting and positioning

mounting possible from several sides for versatile positioning - Integrated gripping force safety device

integrated into piston chamber as energy storage (from GZ18-23D up to GZ55-65D)

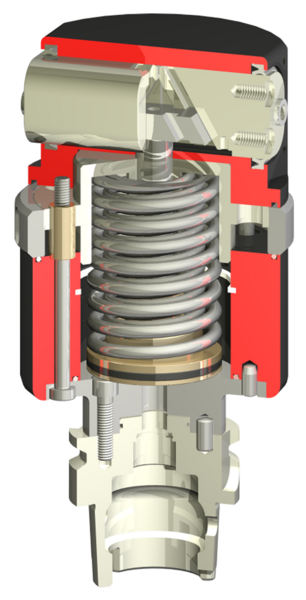

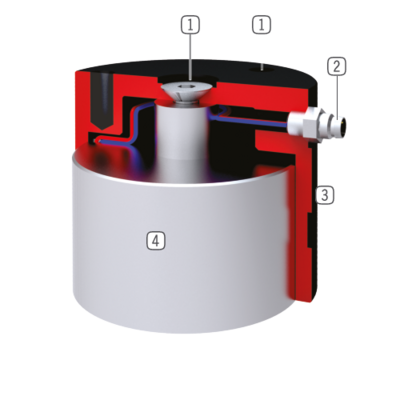

Magnetic gripper

Series HEM1000

- Plug and play

Reduce your installation effort to a minimum by using the single cable solution and the simple control system via plus and minus buttons - Saving energy with pulse control

You only have to supply current briefly when releasing the workpiece; no energy is required when transporting the workpiece - Secure hold during EMERGENCY STOP

The magnet provides full holding force when it is not powered, preventing the loss of the workpiece if there is a voltage drop

- Mounting and positioning

via centering sleeve and thread - Energy supply

standardized interface M8 round plug - Robust, lightweight housing

Hard-coated aluminum alloy - Holding solenoid

with electrical switch off

2-Jaw Parallel Grippers with Long Stroke

Series

- Engineered according to BG/DGUV recommendation

- Certified by BG/DGUV

- Completely flexible positioning of gripper jaws thanks to servo technology

- Brushless drive technology

- Self locking mechanism for save handling even in E-Stop

- Different drive modes like, force mode, position mode, pre-positioned force mode etc.

- 360° LED status indicator

- Bidirectional communication for process-data and service-data (fieldbus open)

Installation Size: HRC-01 | |

| Order-No. | |

|---|---|

| HRC-01-101670 | |

| HRC-01-102270 | |

| HRC-01-102975 | |

| HRC-01-102976 | |

Swivel Jaws

Series SBZ

"The superior"

- Shock absorber with spiral groove technology

Superior end position damping lets you swivel more mass in the shortest amount of time, increasing your machine's component output - Force transmission via gear wheel set

The robust gear wheels stand for precision, reliability and long service life and guarantee smooth operation - Failure-free continuous operation

Our uncompromising "Made in Germany" quality guarantees up to 10 million maintenance-free cycles

Installation Size: SB100 | |

| Order-No. | |

|---|---|

| SB100-180-B | |

| SB100-90-B | |

Installation Size: SB150 | |

| Order-No. | |

| SB150-180 | |

| SB150-90 | |

Installation Size: SB190 | |

| Order-No. | |

| SB190-180 | |

| SB190-90 | |

Installation Size: SB50 | |

| Order-No. | |

| SB50-180-B | |

| SB50-90-B | |

Installation Size: SB74 | |

| Order-No. | |

| SB74-180-B | |

| SB74-90-B | |

- Two way bearing drive shaft

high forces and moments capacity - Drive flange

large size drive flange with end stop and large central hole (from SB150) - Force transfer

stable gear wheel set precise, reliable, durable - Position sensing

inquiry of end positions 0° and 90° (or180°) via inductive proximity switch adjustable on rotatable switch cam - Drive

double-acting pneumatic cylinder - Air flow control valve

for speed regulation (included in the delivery) - Mounting and positioning

mounting possible from several sides for versatile positioning - Integrated and patented hydraulic shock absorbers

adjustable end position damping

Separators

Series VEE9200

- 250 cycles per minute

If speed is the key, nothing beats this unit. This lets you increase your component output and lower your unit costs, - Saving energy with pulse control

You only have to supply current briefly when retracting and extending the plunger. No energy is required at the end positions - Plug and play

Reduce your design and programming effort to a minimum with the integrated control system and the 2-position query

- Energy supply

standardized interface M12 round connector - Drive

via Pot magnet and coil bobbin according to the coil system principle energy consumption only at impulse <25 ms - Position sensing

integrated Hallsensor 2 positions monitorable - Status control

optical LED position display - Tapped rod

Aluminium hardcoated - Mounting and positioning

mounting possible from several sides for versatile positioning - Robust, lightweight housing

Hard-coated aluminum alloy - Mounting

individual seperator finger mounting

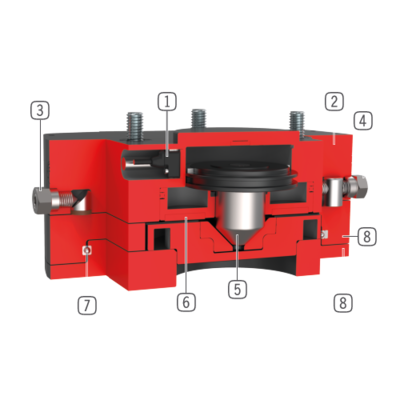

Axis Compensation Modules

Series XYR1000

- Adjustable balancing force and stroke

Using adjusting screws, you can adjust the properties of the equalizer optimally to your application in the shortest amount of time - Flat design

This structure reduces the moment load for your robot to a minimum and makes it possible to use smaller and more affordable sizes - Can be fixed in place centrally or de-centrally

Depending on the requirement, you can clamp or centrally lock the equalizer position. An aid for optimal processes

- Piston position sensing

via magnetic field sensor included in scope of delivery - Robust, lightweight housing

Hard-coated aluminum alloy partial mounting circle in accordance with EN ISO 9409-1 lowest overall height - Compensation force

adjustable via adjustment screw - Compensation stroke

infinitely variable (from size 1063 upwards) - Locking piston

centrical via cone - Eccentrical locking

via pneumatic piston with frictional contact - Linear guide

for highest force and moments capacity - Compensation plate

to balance position errors in XY- direction