OPTIONAL ACCESSORIES

Automatic lock (Coming soon)

- For quick and easy retrofitting to all SPN zero-point clamping systems

- Suitable for standard and advanced zero-point clamping systems

- Automatically submerges when the clamping pin is inserted

- Dirt and chips are effectively prevented from entering the zero-point clamping system

- Blow-out function of the advanced series is retained

Centering pin

- Positions in all three directions of the X, Y and Z coordinate system, thereby forming the zero point for the device to be secured in place.

You can find the accessories under the products.

Product

Locking pin

- Protects the pin from opening when not in use

- Included in the scope of delivery

Sword pins

- Can compensate for a change in length in one direction of the X or Y coordinate system while positioning in the other two directions

Retention pin

- Can compensate for changes in length in the X and Y directions of the coordinate system

CLAMPING PIN ARRANGEMENT

CONFIGURATIONS

In order to best redirect the forces of the device to be clamped, the displayed arrangement of clamping pins is recommended. This arrangement makes it possible to compensate for geometry errors that emerge from production tolerances or thermal expansion:

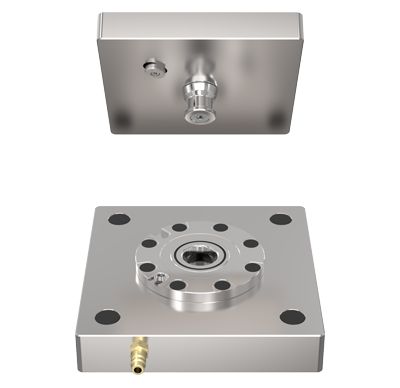

Configuration with one zero-point clamping system

When one zero-point clamping system is used, only one centering pin is needed. The centering pin secures the position in all three directions of the X, Y, Z coordinate system, thereby forming the zero point for the device to be secured in place. Two integrated rotation locks facilitate torque support around the pin axis.

Configuration with two zero-point clamping systems

When two zero-point clamping systems are used, a centering pin and a sword pin are needed. The sword pin can compensate for a change in length in one direction while absorbing the forces in the other two directions. It must be positioned so that it can support the torques applied around the centering pin in the Z direction.

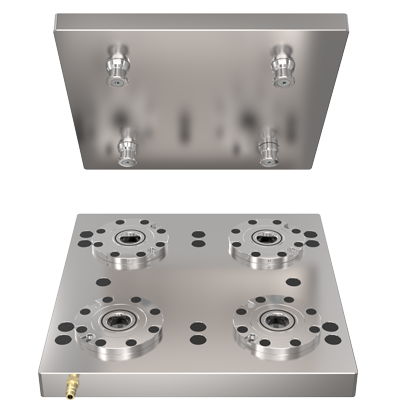

Configuration with four or more zero-point clamping systems

When using four or more zero-point clamping systems, retention pins are required in addition to the centering and sword pins. The retention pin can only absorb forces in the Z direction. It compensates for changes in length in the X and Y direction.