ZiMo is the solution for cost-effective and straightforward process automation for everyone, from small businesses to large companies – ZiMo is the solution.

The Zimmer Group's flexible robot cell allows for mobile and easy commissioning, with impressively quick integration into your processes. Whether machine loading and unloading, pick & place tasks or quality assurance – ZiMo supports you exactly where you need a helping hand. You have free choice of a wide variety of accessories and receive the package tailored to your needs. Get in touch with us, we would be happy to advise you!

FAST RETURN ON INVESTMENT

STAFF SHORTAGE AS A COST TRAP

The ongoing shortage of skilled workers is creating organizational challenges for many companies and causing significant costs. Shortages in staff lead to production delays, quality losses and restricted growth. ZiMo offers effective relief here: Automated processes help alleviate staff shortages and significantly reduce the workload of valuable skilled workers. This improves the utilization of your resources, increases planning reliability and creates room for growth. This makes automation the strategic answer to the current challenges facing the industry.

Personnel support

ZiMo takes over monotonous or physically demanding tasks – instead of replacing personnel, the robot cell adds to your existing capacities.

Increased revenue

Higher production availability with the same workforce makes it possible to process more orders in less time – a direct lever for increasing revenue.

Maximized profit

Reduced personnel costs, higher product quality and increased utilization of capacity lead to a better contribution margin and secure your competitive edge in the long run.

Quality assurance

ZiMo reduces rejection rates and ensures consistently high product quality thanks to standardized processes and repeatable procedures.

Increased production

ZiMo can be operated without personnel in additional shifts, thereby increasing production capacity without requiring additional space or personnel.

Reduced costs

Low operating costs, low maintenance requirements and high energy efficiency contribute to a noticeable reduction in the total cost of ownership (TCO) – for a sustainable reduction in your budget planning.

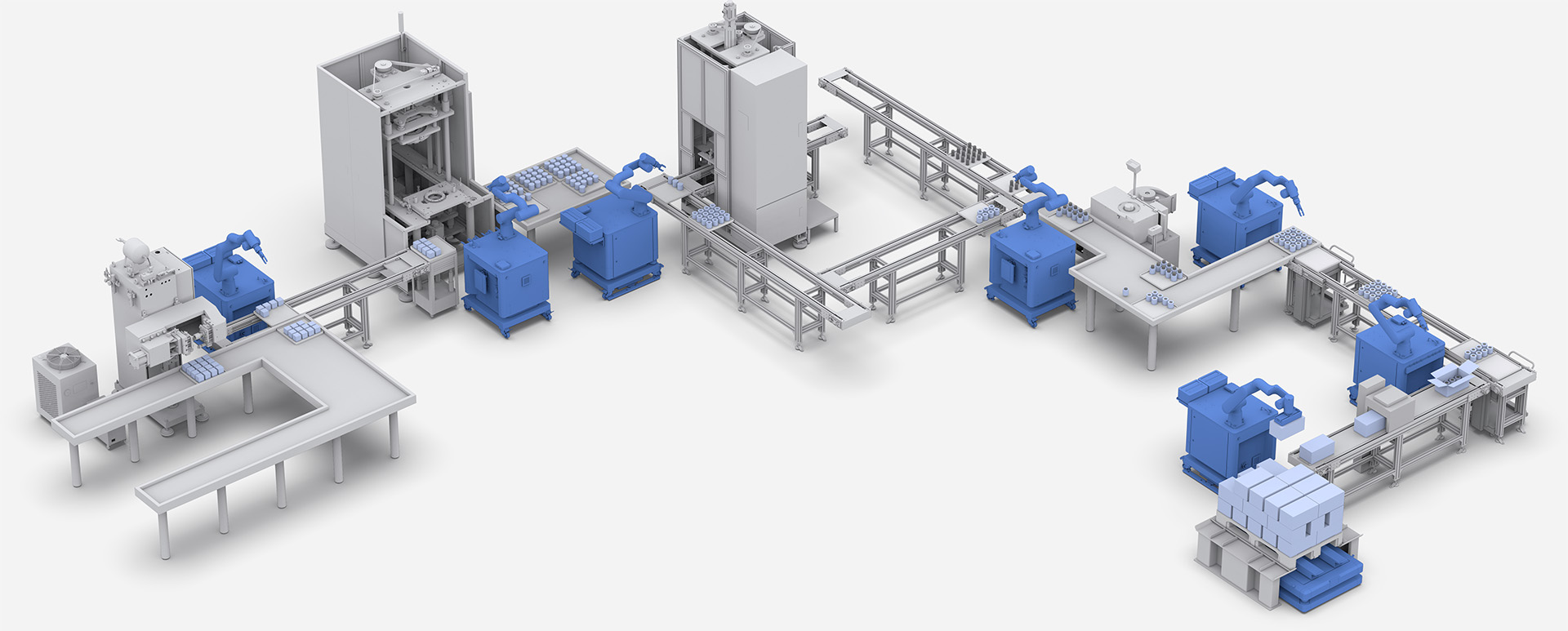

VARIABLE STRUCTURE, VERSATILE APPLICATIONS

ACCESSORIES AND OPTIONS

Thanks to the wide portfolio of available accessories and options, you can adapt ZiMo to your individual needs and requirements. The variable setup and fast changeover times guarantee maximum flexibility in your processes and enormous potential for modernizing your production sequences.

Expand the platform of the flexible robot cell with interfaces and components such as application-specific end effectors, robot sets, safety scanners, storage stations for small load carriers and much more. The Zimmer HMI option offers you the convenience of easy commissioning and control. With the optional remote maintenance, your ZiMo gets regular updates and optimizations. This saves you valuable time and resources, allowing you to focus fully on areas of production that offer real added value for your company.

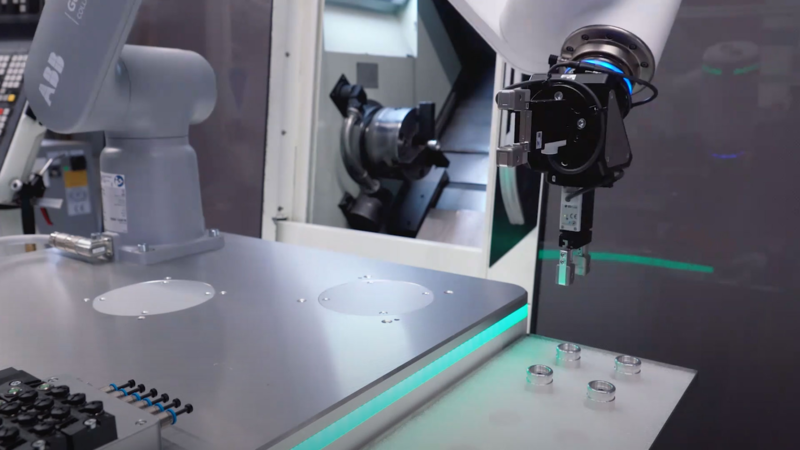

AUTOMATION FOR EVERY APPLICATION

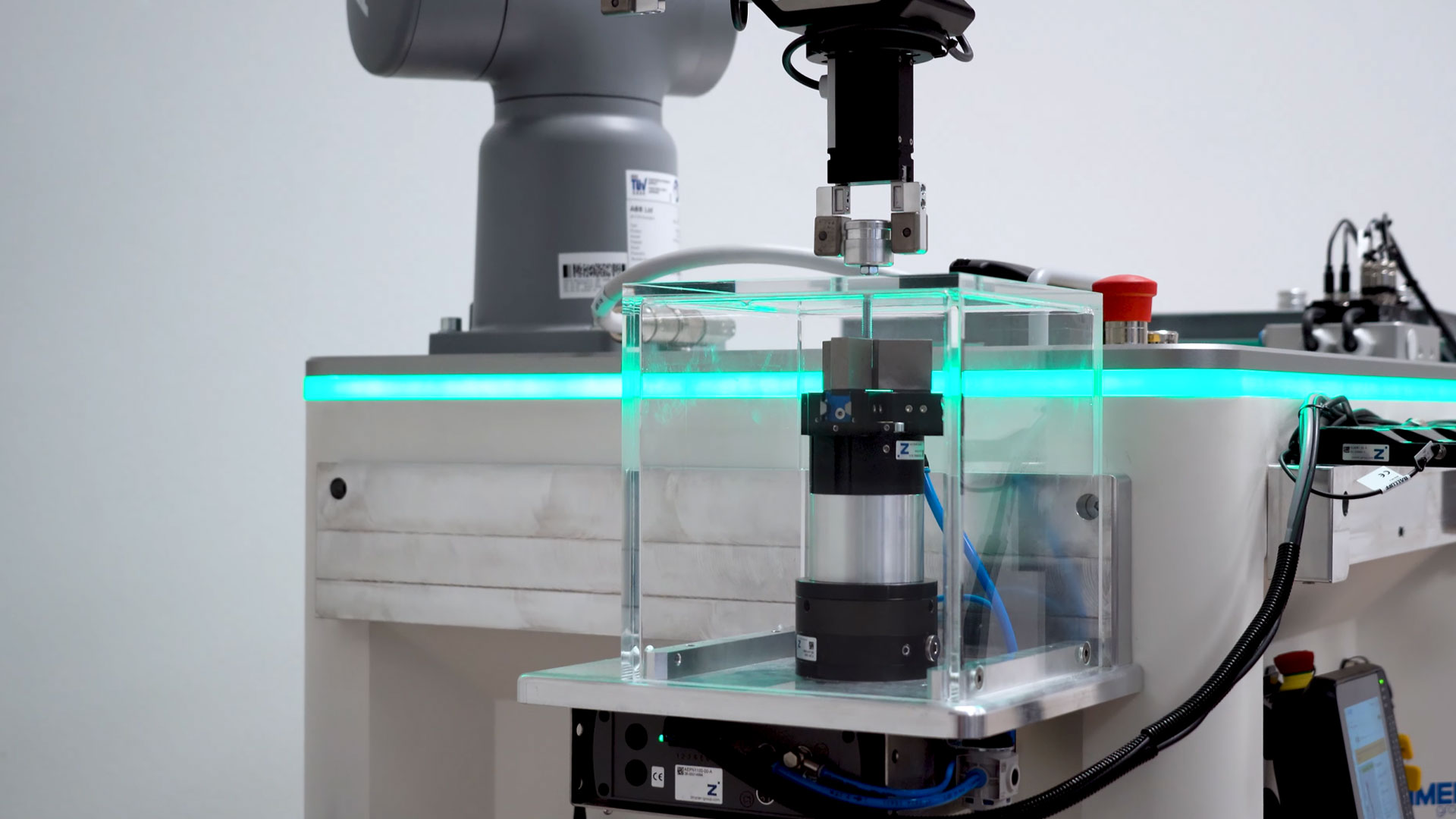

VARIABLE FOR ALL PRODUCTION SITUATIONS

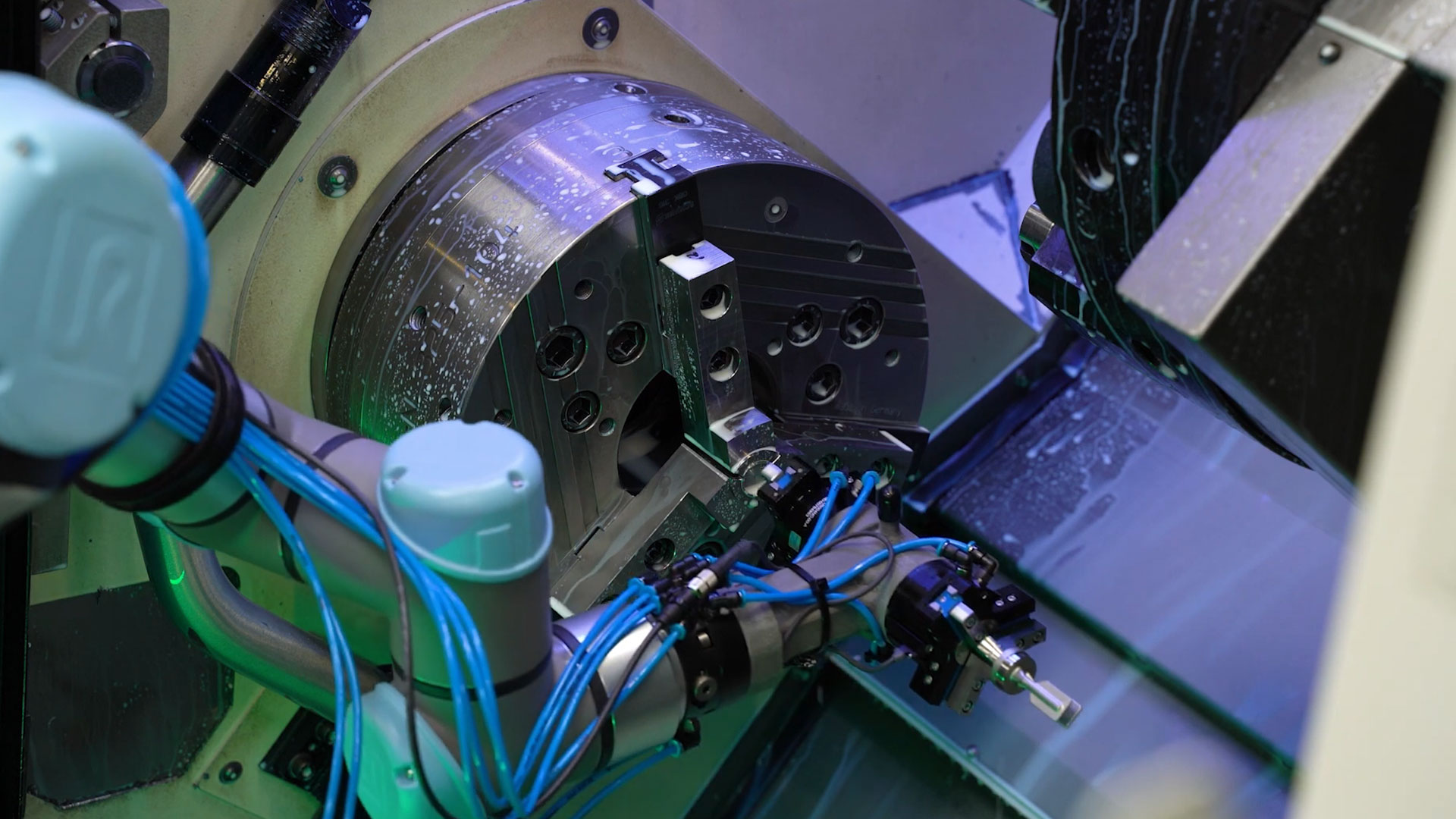

As an interface between humans and robots, the flexible ZiMo robot cell paves the way to automation for small and medium-sized companies and helps large factories optimize their processes. At the same time, there are no barriers to the use of the intuitive, mobile handling system. This includes repetitive loading and unloading of tooling machines or machine tending, logistics and pick & place applications as well as complex assembly tasks that need increased safety. ZiMo performs monotonous tasks of low to high repetition cycles with maximum accuracy. It not only allows you to reduce the costs of production processes, but also takes the load off valuable skilled workers and still ensures stable machining processes.

Integration into production

Two variants

Easy Automation

Simple integration

With Easy Automation, you get an all-round carefree package. The Zimmer HMI gives you easy control, including remote maintenance. At the same time, you benefit from the wide range of options and accessories.

- Shortage of skilled workers? No problem: Compensate for short-term staff shortages

- Flexible with various robots: Compatible with a wide range of robot types

- Immediately ready for production: Ready-made function blocks for easier commissioning and use

- Endless possibilities: Experienced programmers have the opportunity to go deeper. This means that the system can be expanded to include every conceivable function and interface on request.

- Worldwide service and support: Support where you need it thanks to remote maintenance

- Fast return on investment: Investment pays for itself after just 1.5 years

Platform Kit

Configurable as required

Would you like to program ZiMo completely by yourself? With the Platform Kit, you get the base module with or without PLC and can configure the robot cell entirely according to your requirements.

- Customizable to your brand: Ideal for integrators and partners

- Compatible with almost all common robots: Integrate the robot of your choice

- Maximum flexibility: Wide range of equipment and options

- Fully customizable configuration: No restrictions in the application

Easy Automation (Series ZiMo2000)

What is included?

Base module

- Base frame on four lifting rollers with locking feet

- Tabletop fully finished to customer specifications

- Control cabinet including fan / ventilation grille

- Prepared interface (pneumatically/electrically)

- Basic electrical equipment

- Status display (LED strip)

- Docking bar with "present" query

- Integrated brackets for accessories

Engineering

- Conformity assessment procedure with corresponding certification

CE CERTIFication possible

Full service

- Integration and commissioning possible

- Remote maintenance

- Comprehensive services

Ready-to-start programming with Zimmer HMI + control panel

- Intuitive controls

- No programming knowledge required

Robot

- Compatible with a wide range of robot manufacturers

Integrated end effector portfolio (configurable)

- A selection of 2-jaw parallel grippers, 3-jaw concentric grippers, 2-jaw angular grippers, vacuum suction cups or the MATCH ecosystem, preconfigured robot sets

- Pneumatic, electric, vacuum, IO-Link

Options (configurable)

- Safety scanner

- Storage station for MATCH components

- Interfaces (Digital Safety I/O, Euromap 67, passive distributor, IO-Link, pneumatics)

- Battery-operated, autonomous thanks to transport with Miles, safety interface, integration in fleet management system and Mosaic

Platform Kit (Series ZiMo1000)

What is included?

Base module

- Base frame on four lifting rollers with locking feet

- Tabletop partially machined

- Control cabinet including fan / ventilation grille

- Prepared interface (pneumatically/electrically)

- Basic electrical equipment

- Status display (LED strip)

- Docking bar with "present" query

- Integrated brackets for accessories

Engineering

- For checking the integration of new robot models, for example

Service

- For mechanics

- When purchasing the PLC, support at the control level is available as an option (excluding robot programming)

Customer programming with the support of Zimmer software packages

- ZiMo PLC + PLC modules for easy integration of ZiMo options and the Zimmer Group portfolio

- Zimmer Comfort Apps, Zimmer GuideZ

Robot

- Compatible with almost all robot manufacturers

Complete end effector portfolio (configurable)

- Gripping and vacuum components, MATCH ecosystem, tool changers, axis compensators, collision protection, adapter plates, sensors and accessories, preconfigured robot sets

- Pneumatic, electric, vacuum

Options (configurable)

- Safety scanner

- Storage station for MATCH components

- Interfaces (Digital Safety I/O, Euromap 67, passive distributor, IO-Link, pneumatics)

INTUITIVE CONTROL VIA ZIMMER HMI

Versatility that is hard to beat: Our Zimmer HMI gives you a simple and intuitive introduction to the world of automation. The interface is designed so intuitively, partly due to the preconfigured function blocks, that no programming knowledge is required to put the function blocks together. For new components, all available configurations can be called up and used via an integrated database. In addition, the control system offers many flexible expansion options, giving even experienced programmers convincing advantages. Should you still have any questions, our support team is available at any time to provide secure and fast remote maintenance.

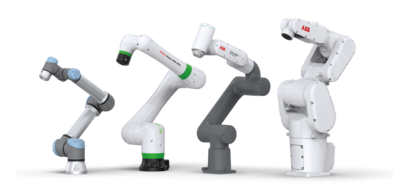

Robot

Robot selection for Easy Automation

ZiMo can be combined with a large number of common cobot models. With Easy Automation, you benefit from a thorough compatibility check including stability analysis. Here’s a complete list of compatible preconfigured robots:

Robot selection for Platform Kit

You can combine the Platform Kit with robots from almost any manufacturer, so it fits right into your existing setup. We would be happy to help you check how to integrate new robot models. Please contact us!

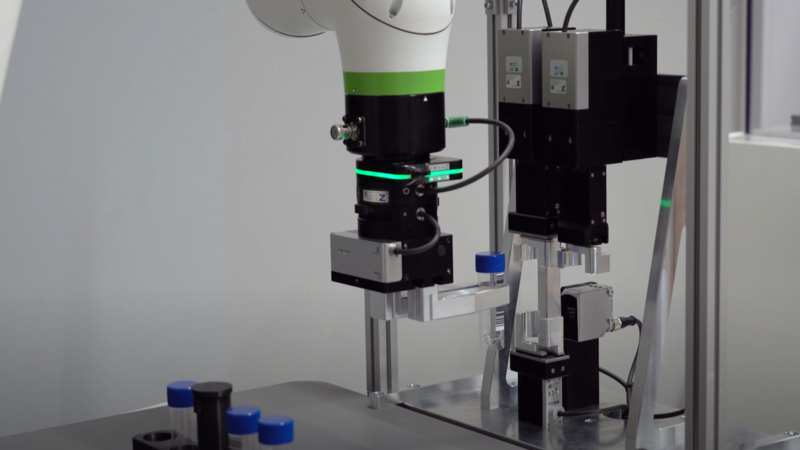

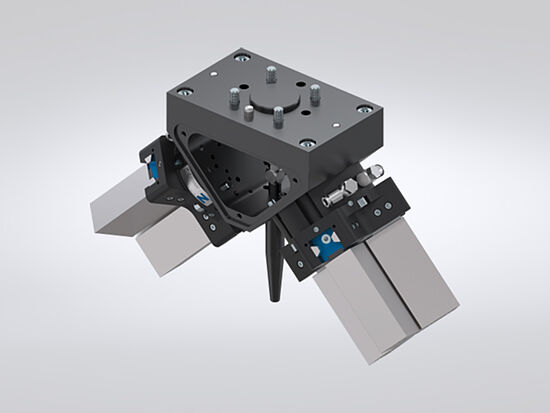

End effectors

With over four decades of experience in the field of handling and robotics, we offer you the necessary expertise and variety of end effectors to meet your specific requirements.

1. Electric handling components

Precise, energy-efficient and low-maintenance – ideal for flexible gripping tasks with variable force control.

2. Pneumatic handling components

Robust and powerful – proven for dynamic applications with high cycle rates.

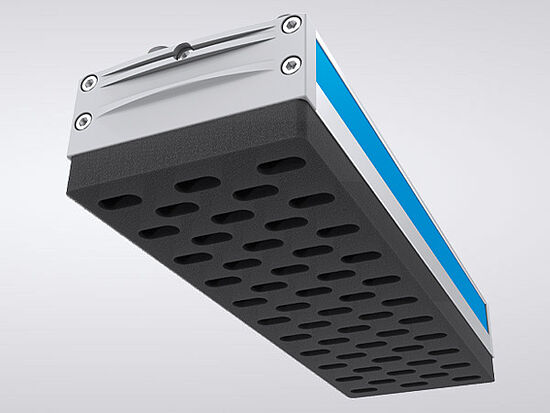

3. Vacuum components

Ideal for flat or sensitive components – for safe and gentle handling of a wide range of materials.

4. MATCH end-of-arm ecosystem

One system, many options – with a standardized interface concept for fast tool changes and maximum flexibility.

5. Preconfigured robot sets

Ready for immediate use – perfectly coordinated combinations of robotics and grippers to get your project up and running quickly.