System reference

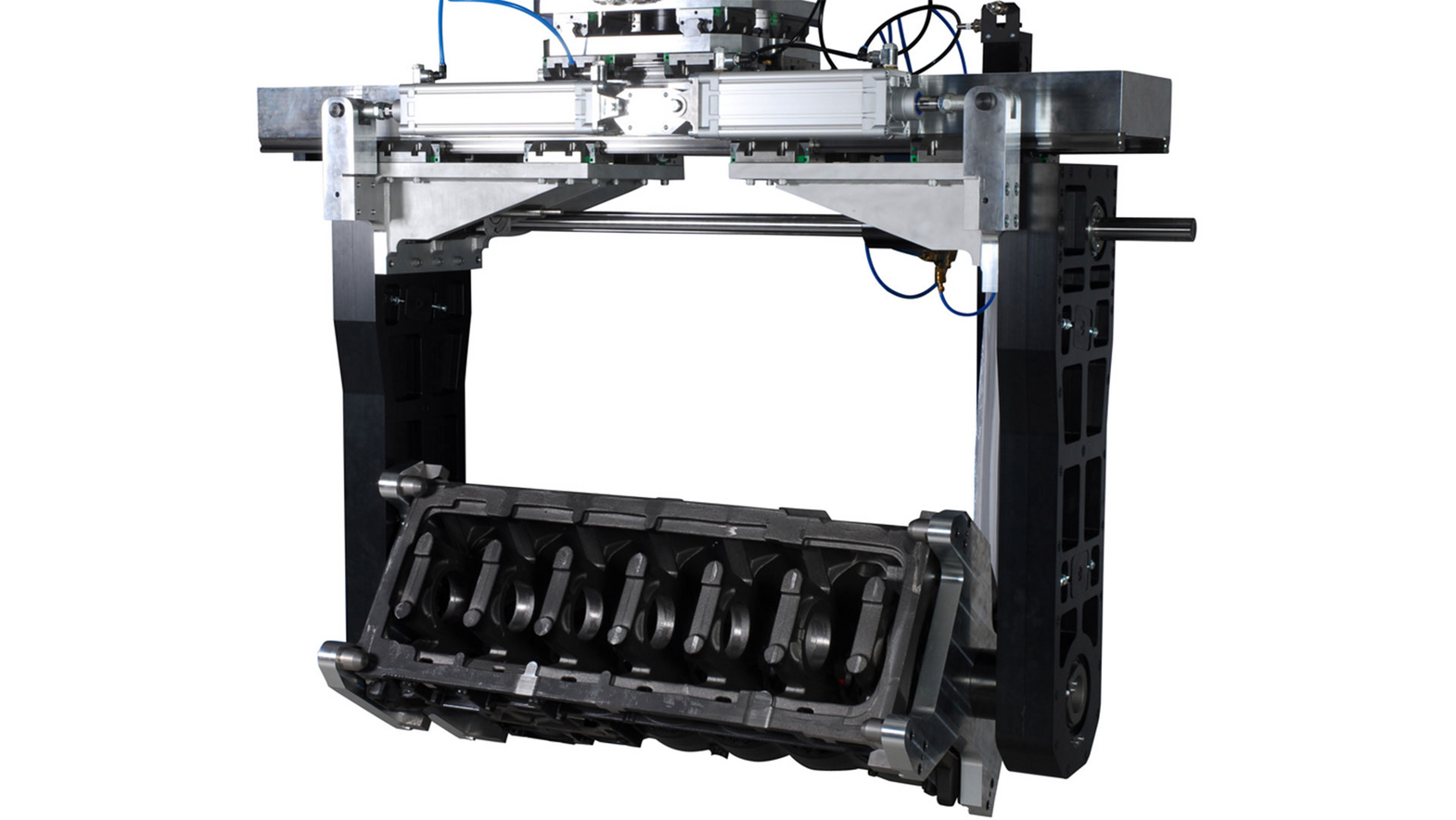

Gripper for combustion engine

System solutions | Mobility | Automobile | Drive train for combustion engines

Challenge

For linking tooling machines, the workpiece needed to be moved to different clamping positions. To do this, the workpiece needed to be turned (reoriented) in the gripper. The challenge here was primarily the high workpiece weight of 450 kg combined with the large flight circle.

Solution

A gripper with a rugged basic drive was developed in a linear guide design. Special long swivel jaws, which are driven by a servo motor, were developed for swiveling the parts. Furthermore, the gripper is equipped with an XY axis compensation module to compensate for position inaccuracies when depositing or picking up items.

Highlights and technical data

IP40

IP40 Pneumatic

Pneumatic Drive AC servo motor

Drive AC servo motor Position maintenance by means of clamping element

Position maintenance by means of clamping element

Technical Data

| Drive type | PNEUELE |

| Max. gripping force | 7000 [N] |

| Gripping concept | FORM |

| Gripping safety device | KLE |

| Max. stroke | 480 [mm] |

| IP class | IP40 |

| System weight | 500 [kg] |

| Max. workpiece weight | 400 [kg] |

| Max. workpiece temperature | 80 [°C] |