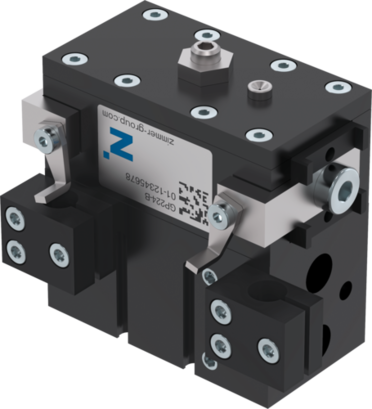

GP224S-B

2-Jaw Parallel Grippers

Series GP200

"The variable"

- Smooth stroke configuration

An adjusting screw allows you to adjust the stroke to your specific application - Proven technology

We have more than 20 years of proven reliability, which ensures uninterrupted production for you - Dirt protection

Using the scrapers on the guides, you can reliably use the gripper even under the harshest conditions

Equipment/Options

10 million maintenance-free cycles (max.)

10 million maintenance-free cycles (max.) Spring closing C

Spring closing C IP40

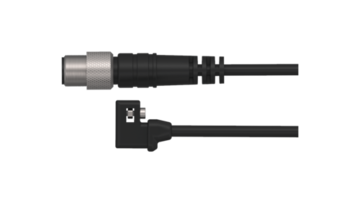

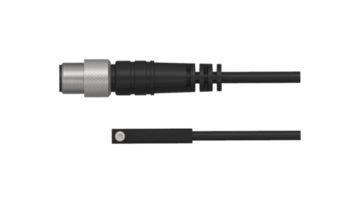

IP40 Magnetic field sensor

Magnetic field sensor Inductive sensor

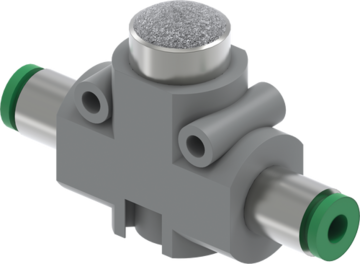

Inductive sensor Purged air

Purged air

Technical Data

| Stroke per jaw | 6 [mm] |

| Gripping force in closing | 335 [N] |

| Gripping force secured by spring min. | 35 [N] |

| Closing time | 0.06 [s] |

| Opening time | 0.06 [s] |

| Repetition accuracy +/- | 0.05 [mm] |

| Operating pressure | 5 ... 8 [bar] |

| Nominal operating pressure | 6 [bar] |

| Operating temperature | +5 ... +80 [°C] |

| Air volume per cycle | 12 [cm³] |

| Approvals | LABS / REACH / RoHS |

| Protection to IEC 60529 | IP40 |

| Weight | 0.44 [kg] |

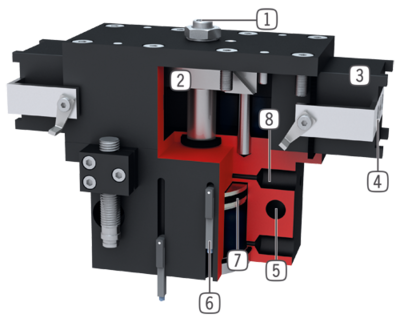

Benefits in detail

- Stroke adjustment

infinitely adjustable in „open“ movement adjusting screw in delivery - Wedge hook mechanism

synchronized the movement of the gripper jaws high force transfer - Square guide

high forces and moments capacity - Gripper jaw

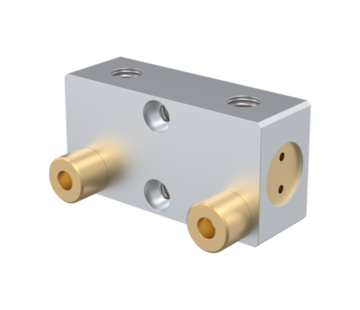

individual gripper finger mounting - Mounting and positioning

mounting possible from several sides for versatile positioning - Sensing slot

mounting and positioning of magnetic field sensors - Drive

double-acting pneumatic cylinder - Energy supply

possible from several sides