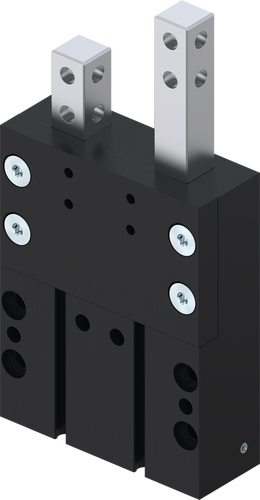

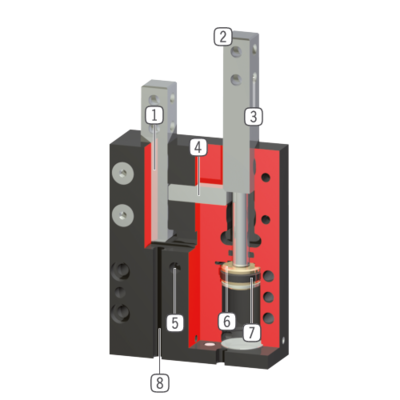

Separators

Series VE

- Mechanical forced control

Guarantees process reliability for your application since only one workpiece can be separated and guided through at a time - Decide for yourself!

Sensing via magnetic field sensors or inductive proximity switches: Unlike the benchmark, you are free to choose! - Failure-free continuous operation

Our uncompromising "Made in Germany" quality guarantees up to 10 million maintenance-free cycles

Series features

10 million maintenance-free cycles (max.)

10 million maintenance-free cycles (max.) IP40

IP40 Magnetic field sensor

Magnetic field sensor Inductive sensor

Inductive sensor

- Square guide

rugged, high forces and moments capacity - Tapped rod

hardened steel - Mounting

individual seperator finger mounting - Locking

integrated, mechanical locking - Energy supply

possible from several sides - Drive

two double-acting pneumatic cylinders - Permanent magnet

installed in piston area - Sensing

groove for positioning of the magnetic field sensor

| Use

Advantage

| Details | ||

| Use

Advantage

| Details |