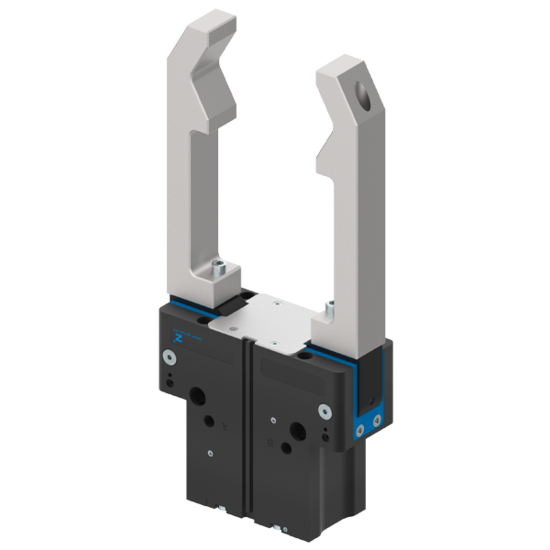

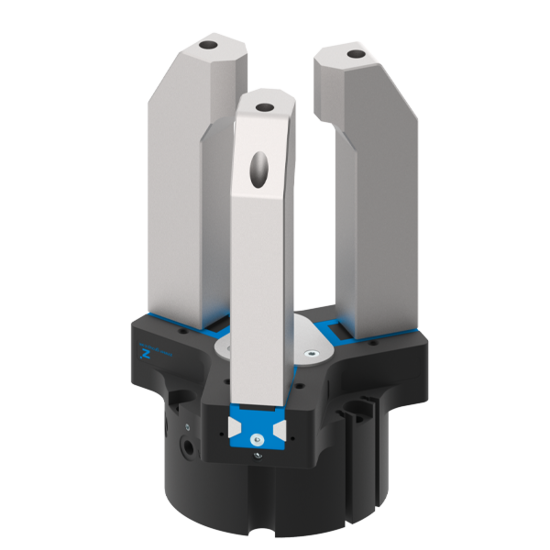

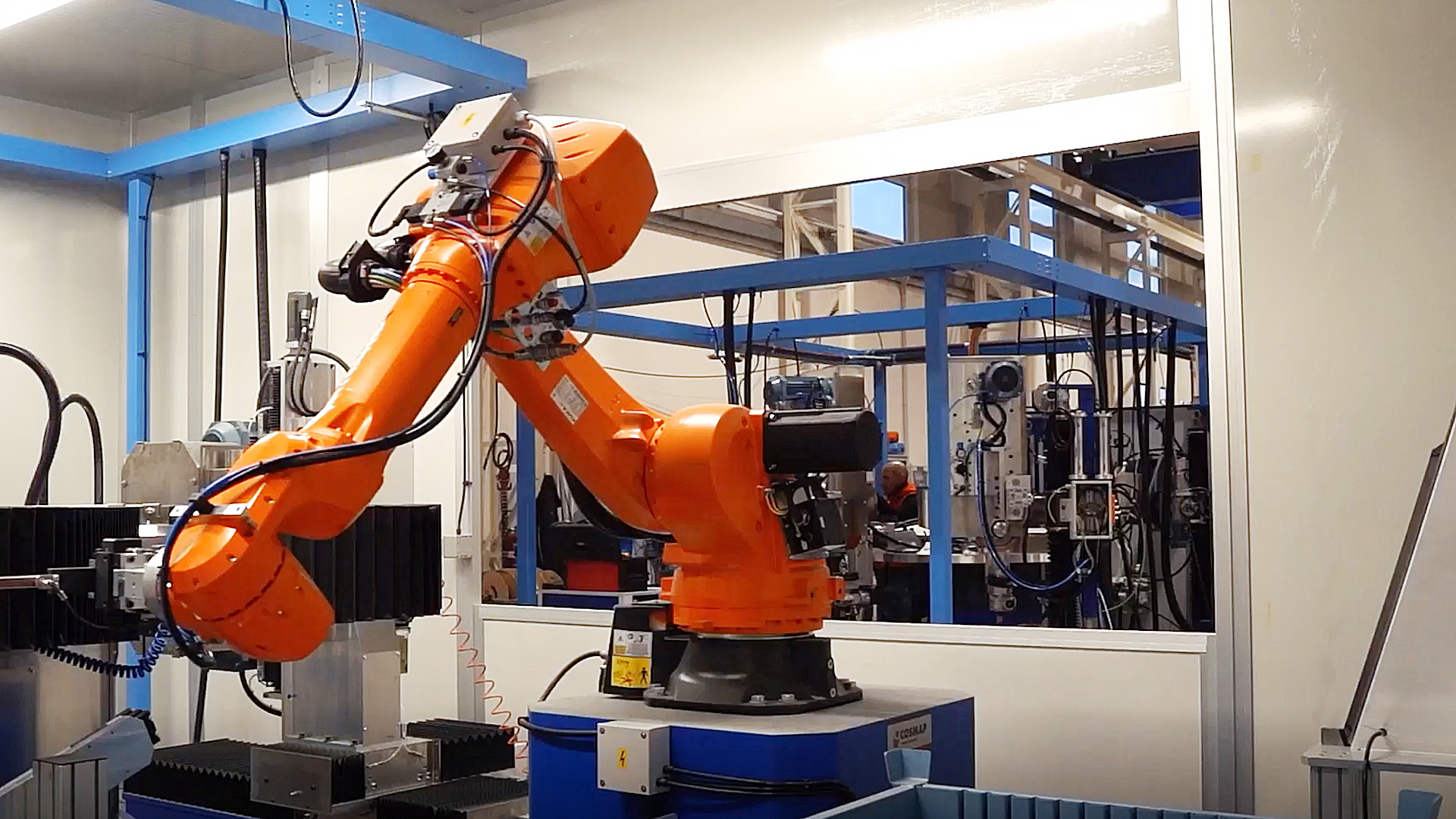

Universal grippers from product family 5000

The multi-award-winning premium pneumatic grippers from the 5000 product family with their extremely robust, hard-coated steel-in-steel profile groove guide can truly take on any role. Designed for genuine universal use, they have a range of features (speed, high gripping forces, long gripper finger lengths) depending on the variant and therefore offer the right solution for every application!

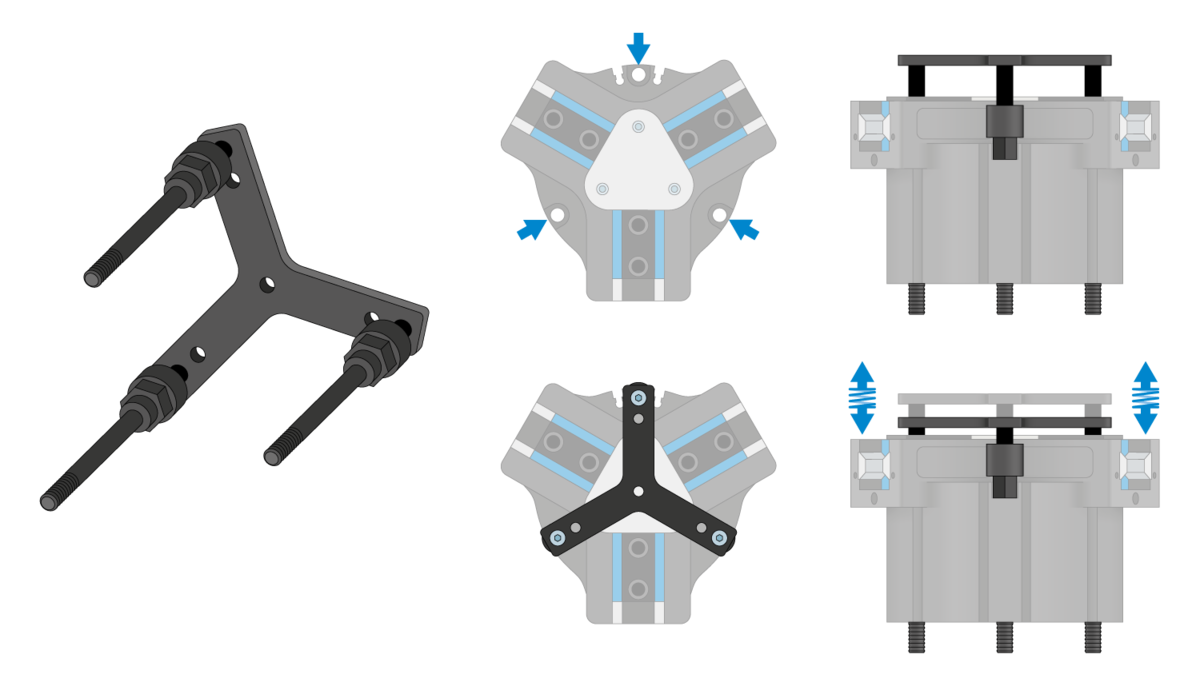

Universal grippers, perfect for any application. From angular grippers to concentric grippers and parallel grippers – with the 5000 family, the choice is yours!

Your benefits

- Aluminum or Steel Linear Guide – reliable and precise guide for any application

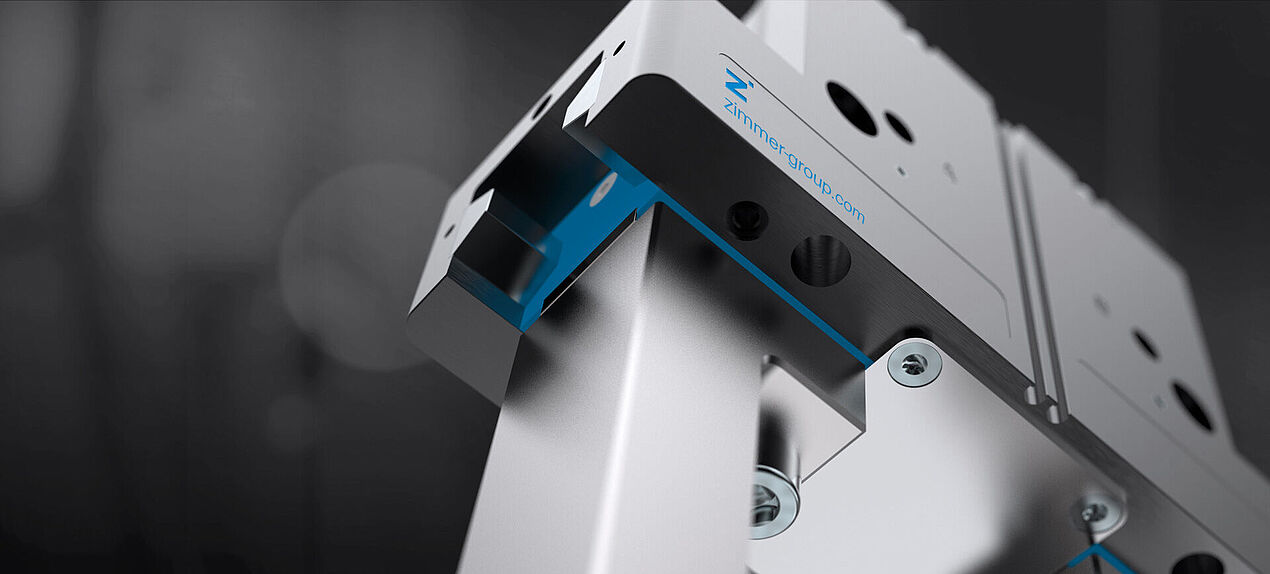

- Corrosion protected and sealed up to IP67 – for the toughest environment parameters

- Up to 30 million cycles with no maintenance required – worry-free production

- Pneumatic, pneumatically intelligent, electrical – flexible with three drive concepts

- One mounting pattern for three drive concepts – no engineering effort when replacing

Range of applications

- For medium to highly contaminated environments

- Protection class IP64/67

- Clean room class 5/6

- S variant with increased gripping force

- Corrosion-protected and temperature-resistant

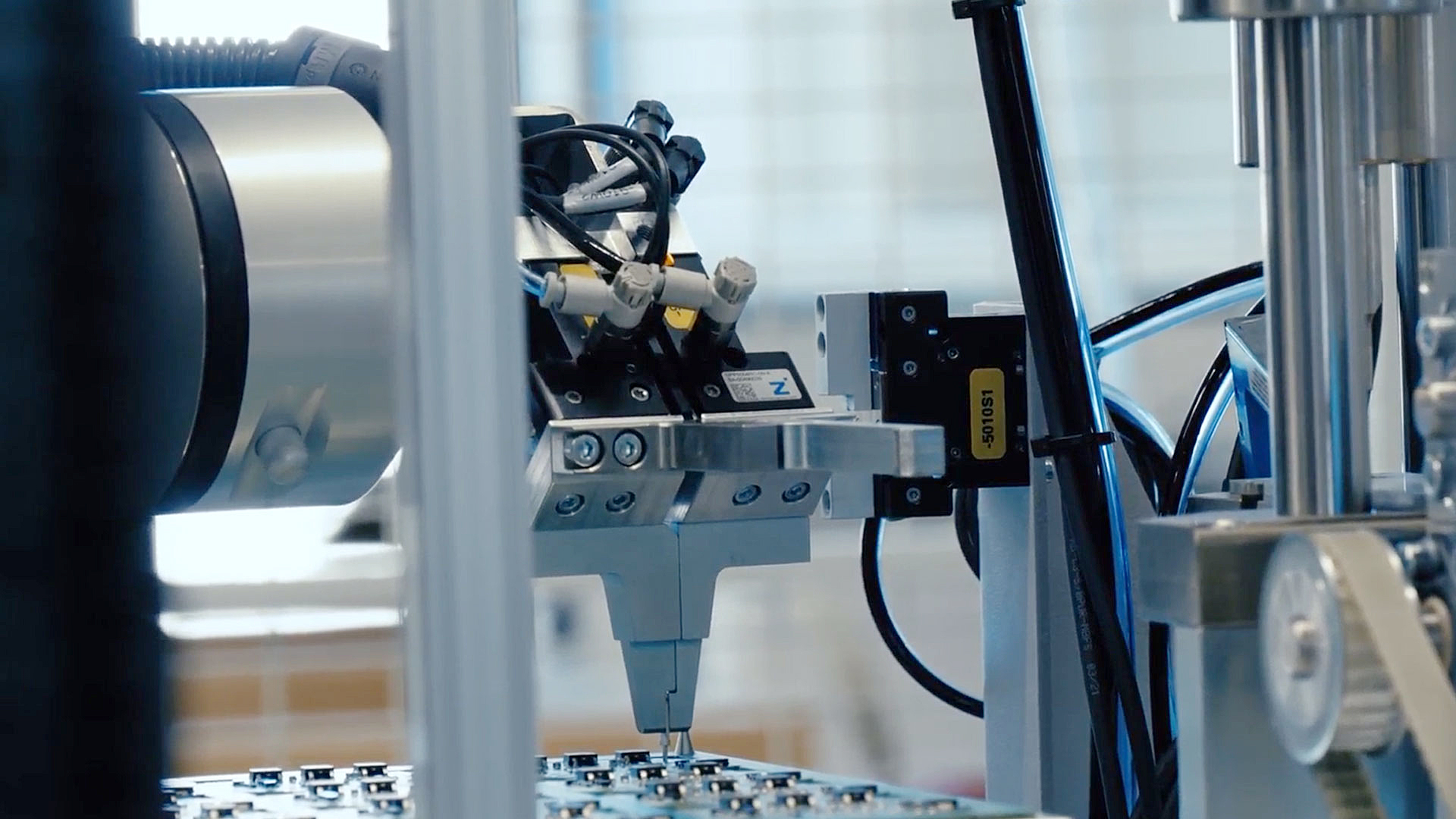

SEALED TIGHT – DESPITE ANY CHALLENGES

All Series 5000 premium grippers are corrosion-protected and sealed to IP64 as standard, i.e. they are dust-tight and protected against spray water from all sides. If a protector is used, they even have an ingress protection class of IP67 (dust-tight and protection against temporary submersion).

ENDURANCE CHAMPIONS

Thanks to their low friction coefficients, compact structure and excellent emergency running properties, the Series 5000 grippers can handle at least 30 million cycles without maintenance. This is an excellent choice for a reliable, continuous and fail-safe production process!

EQUIPPED FOR THE FUTURE

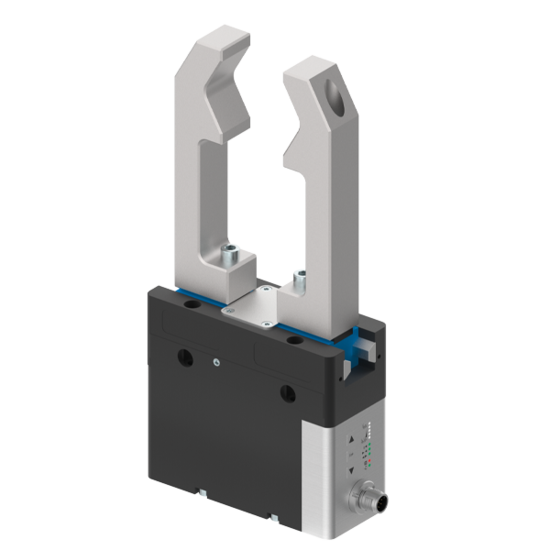

Are you Industrie 4.0-ready and looking for the right gripper? Then we recommend our Series 5000 -IL variant. These pneumatic-electric IO-Link hybrid grippers are ideal for users who are taking the step into the Industrie 4.0 world of gripping but do not want to do without a pneumatic drive. A sensor system is integrated into the gripper that detects the position of the gripper jaws in the range of +- 0.05 millimeters. This not only enables process monitoring, but also, for example, the identification of workpieces based on their diameter. In addition, a total of 32 workpiece data records can be programmed into the grippers.

You can find out how to integrate the IO-Link gripper into your PLC environment step-by-step here:

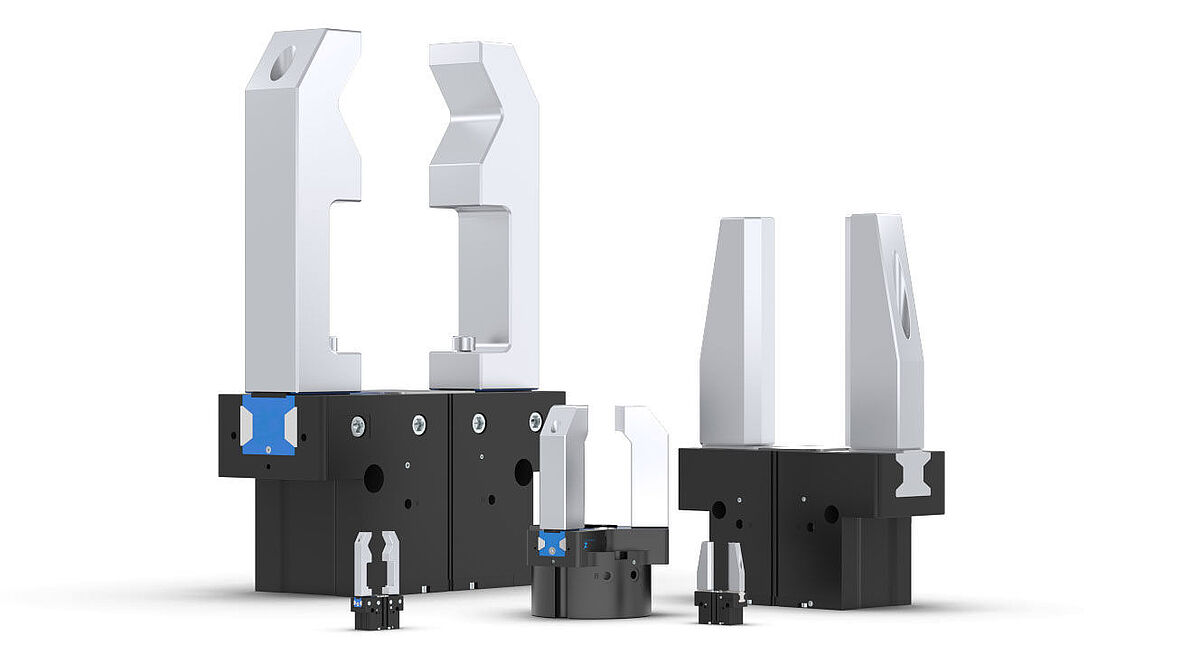

THE CHOICE IS YOURS

In addition to our grippers with a steel-on-steel profile groove guide (Steel Linear Guide), you also have the option of choosing a model with a steel-aluminum profile groove guide (Aluminum Linear Guide). These grippers are particularly interesting for price-conscious customers who do not want to do without the proven quality of the Zimmer Group. Technically, the GPP/GPD5000AL grippers with their steel-aluminum profile groove guide outperform all T-slot grippers and are at least on a par with grippers with multi-tooth guides in the market environment. With its uncompromising “Made in Germany” quality, the Zimmer Group guarantees up to 15 million cycles without maintenance.

BENCHMARK – REAL DIFFERENCES

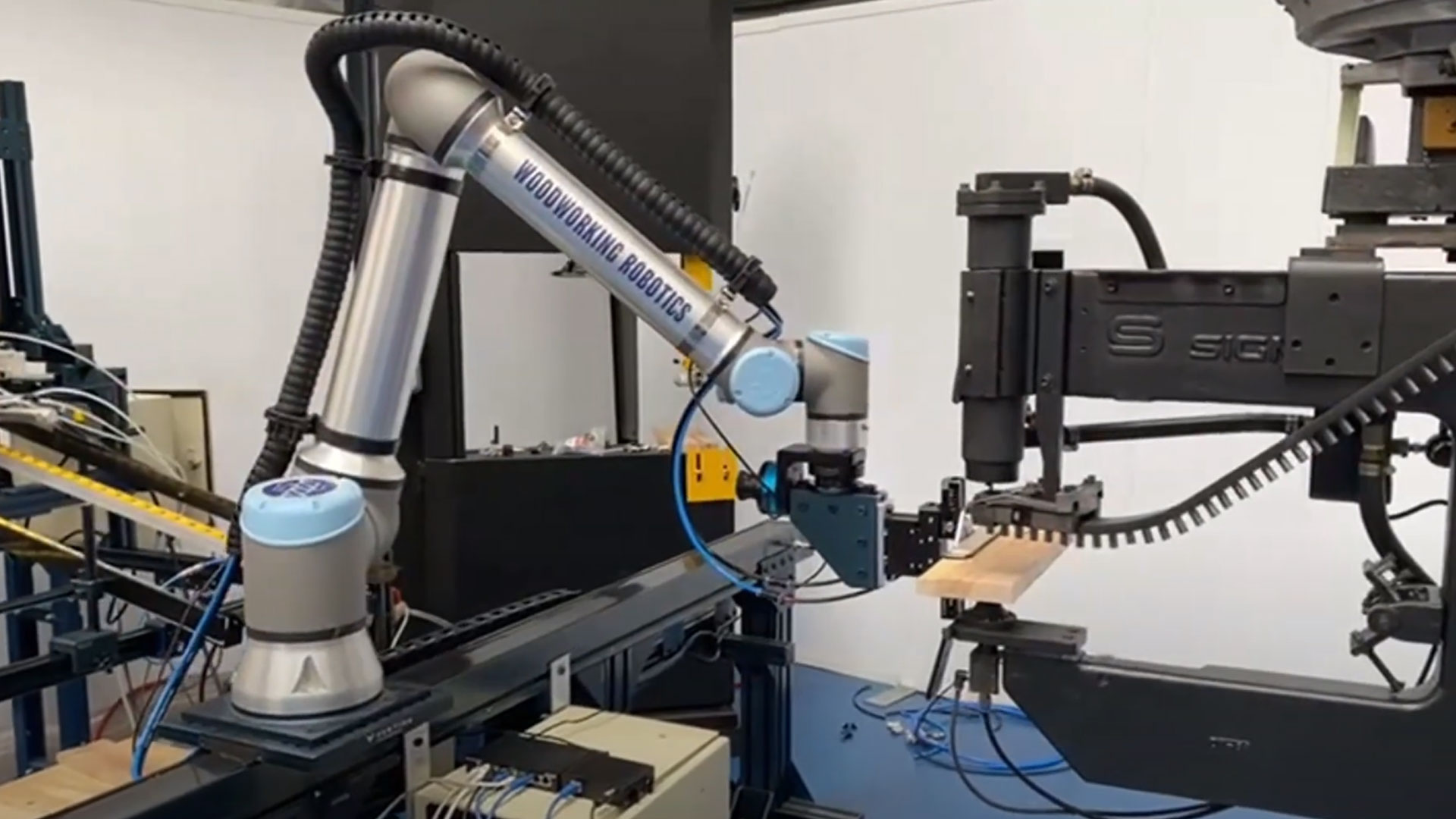

Our 5000 gripper series features unsurpassed robust performance and is our 24/7 solution – unlimited continuous operation with maximum system availability. We're not alone in thinking that, for all these reasons and more, these grippers are BETTER THAN THE REST! Need proof? No problem! Here you can read what our customers are saying about our 5000 series grippers.

Accessories

Series 5000 grippers feature a variety of detailed solutions that make everyday use easier. In addition, we offer a wide range of gripper accessories such as universal, adjusting or exchangeable jaws as well as pressure pieces that greatly reduce the loads on grippers that occur during the joining process, for example.

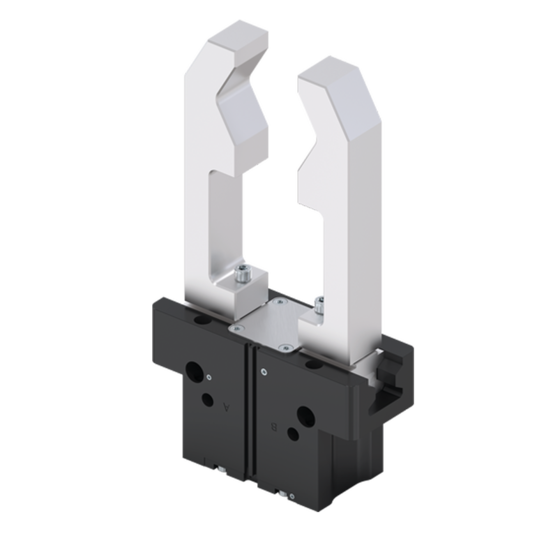

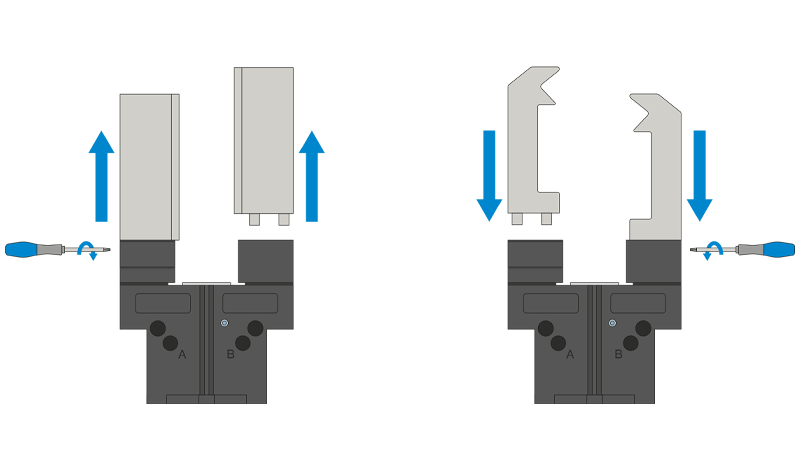

UNIVERSAL JAWS – UB5000

Can be used immediately or for individual customization

The gripper jaw blanks are available in aluminum (AL) and steel (ST) versions and are mounted directly to the gripper using the screws included in the scope of delivery. The necessary fits for the centering sleeves are already provided. One universal jaw is required per gripper jaw.

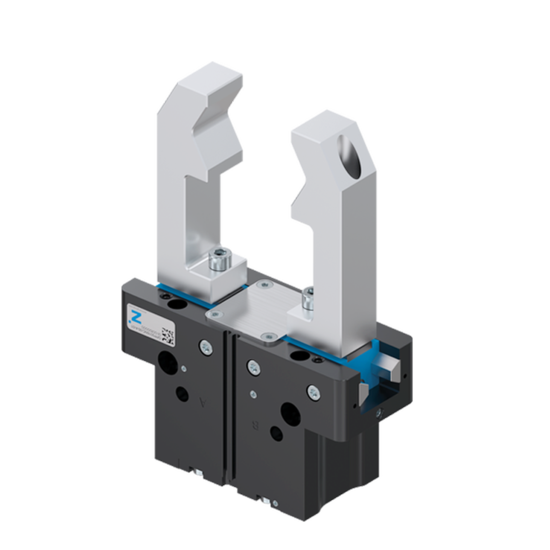

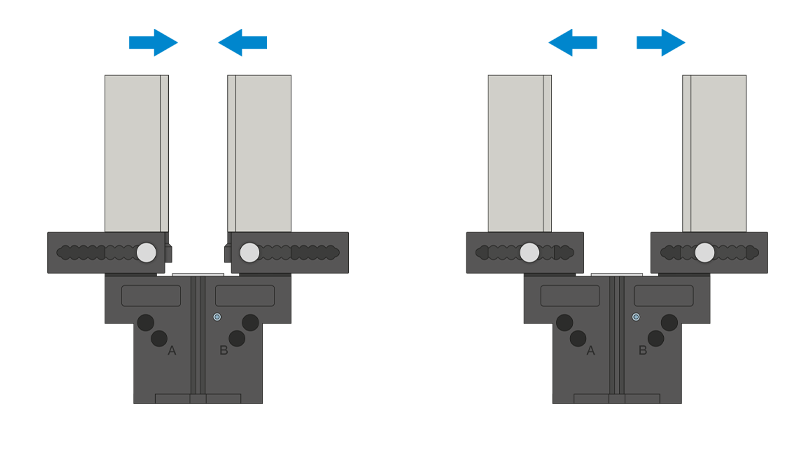

ADJUSTMENT JAWS – EB5000

For tool-free adaptation of the gripper range

By manually activating the locking mechanism, which is pre-tensioned by a spring, the adjustment jaw can be moved within a grid of detent notches that has a number scale. Depending on the forces and torques that apply, the adjustment jaws are available in aluminum (AL) and steel (ST) versions. One adjustment jaw is required for each gripper jaw.

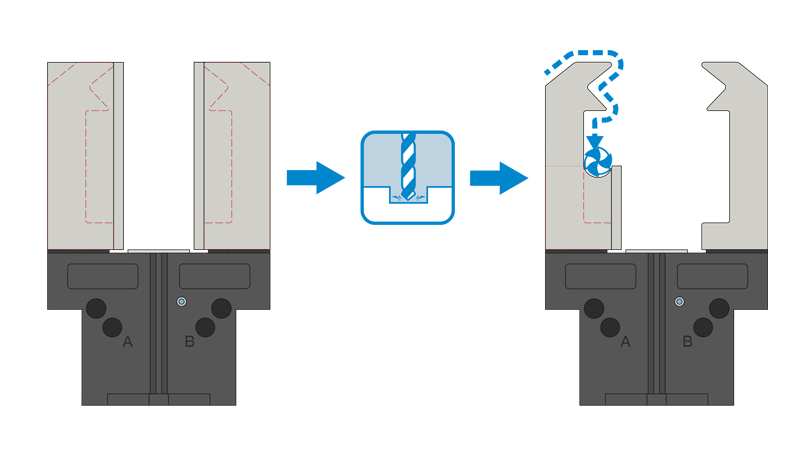

EXCHANGEABLE JAWS – WB5000

Enable fast change of individual gripper fingers

For each gripper jaw, a fixed part and at least one loose part set is needed, depending on the number of gripper fingers to be changed. Manual locking via the Torx wrench supplied with the fixed part can be performed from two sides.

PRESSURE PIECE – ADS5000

Only available for SERIES GPD

When the gripper fingers are open, the pressure piece is used for spring-supported positioning of the workpiece against a limit stop. This greatly reduces the loads on the gripper that arise during joining.