WPR5050F-00-A

Tool Changers

Series WPR5000

- Safer tool changer

Maximum safety due to a spring-loaded piston, self-locking mechanism, optional sensors and other accessories. The Zimmer Group tool changer therefore meets the requirements of Performance Level d, Control Category 3. - Locking kinematics

The innovative locking kinematics with locking bolts and extreme rigidity is the new benchmark for tool changers. The extremely flat design also minimizes the torque load on the robot, which allows smaller and more cost-effective robots to be used. - Endless variety

Regardless of the medium being transferred, with the right energy elements of the WER1500 and WER3000 series you get a standardized transmission of pneumatics, fluidics, electrical signals, power and communication and much more.

Equipment/Options

5 million maintenance-free cycles (max.)

5 million maintenance-free cycles (max.) IP54

IP54 Protected against corrosion

Protected against corrosion Self locking mechanism

Self locking mechanism Magnetic field sensor

Magnetic field sensor

Technical Data

| Connecting flange according EN ISO 9409-1 | TK 50 |

| Type of drive | pneumatic |

| Pneumatic energy transfer | 4 [Quantity] |

| Electrical energy transfer | optional |

| Flow per connector | 275 [l/min] |

| Self locking mechanism when locking | mechanical |

| Locking stroke | 1.5 [mm] |

| Repetition accuracy in Z | 0.01 [mm] |

| Repetition accuracy in X, Y | 0,02 [mm] |

| Joining force | 10 [N] |

| Release force | 10 [N] |

| Offset at coupling max. in X,Y | 1.5 [mm] |

| Operating pressure | 4 ... 10 [bar] |

| Nominal operating pressure | 6 [bar] |

| Operating temperature | 5 ... +80 [°C] |

| Air volume per cycle | 10 [cm³] |

| Moment of inertia | 1.52 [kgcm²] |

| Certifications | LABS / REACH / RoHS |

| Weight | 0.28 [kg] |

Benefits in detail

- Drive

Spring preloaded piston Maximum safety through self-locking Holds loose parts and tools securely even in the event of pressure failure or emergency stop - Mounting for energy element

Lateral connection of the optionally available energy elements for the transmission of fluidics, electrical signals and load, communication, pneumatics and vacuum and much more - Robot flange

partial mounting circle in accordance with EN ISO 9409-1 - Piston position sensing

Integrated sensors optionally available Integrated directly in the tool changer, saves installation space and reduces interfering contours - Locking bolt

All locking parts made of hardened steel - Centering pins

Preloaded centering pins for maximum torsional rigidity - Integrated air feed-through

Air / vaccum transfer Hoseless control possible - Loose part

For installation by the customer - Fix part

For robot side assembly

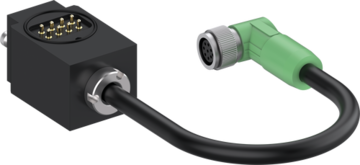

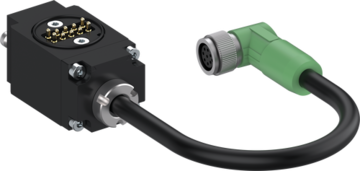

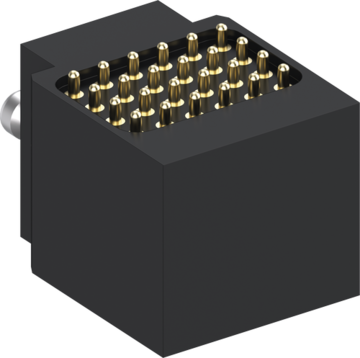

Energy Elements

Transmission mode Communication

Transmission mode electrical