Zimmer Group at AUTOMATICA 2025

Visit us at our booths: Hall A5, Booth 202 & Hall A4, Booth 316

From June 24 to 27, we will be at automatica with two booths full of innovations for smart automation solutions. Discover modular robot technology, mobile assistance systems, and intelligent automation components—live in action. Whether flexible robot cells, autonomous transport systems, or powerful drive technology: we focus on solutions that make your production more efficient, flexible, and future-proof.

Two booths. One goal: your automation of tomorrow.

Come by, be inspired, talk to our experts, and experience forward-looking technologies!

AUDIOGUIDE

Flexible robot cell

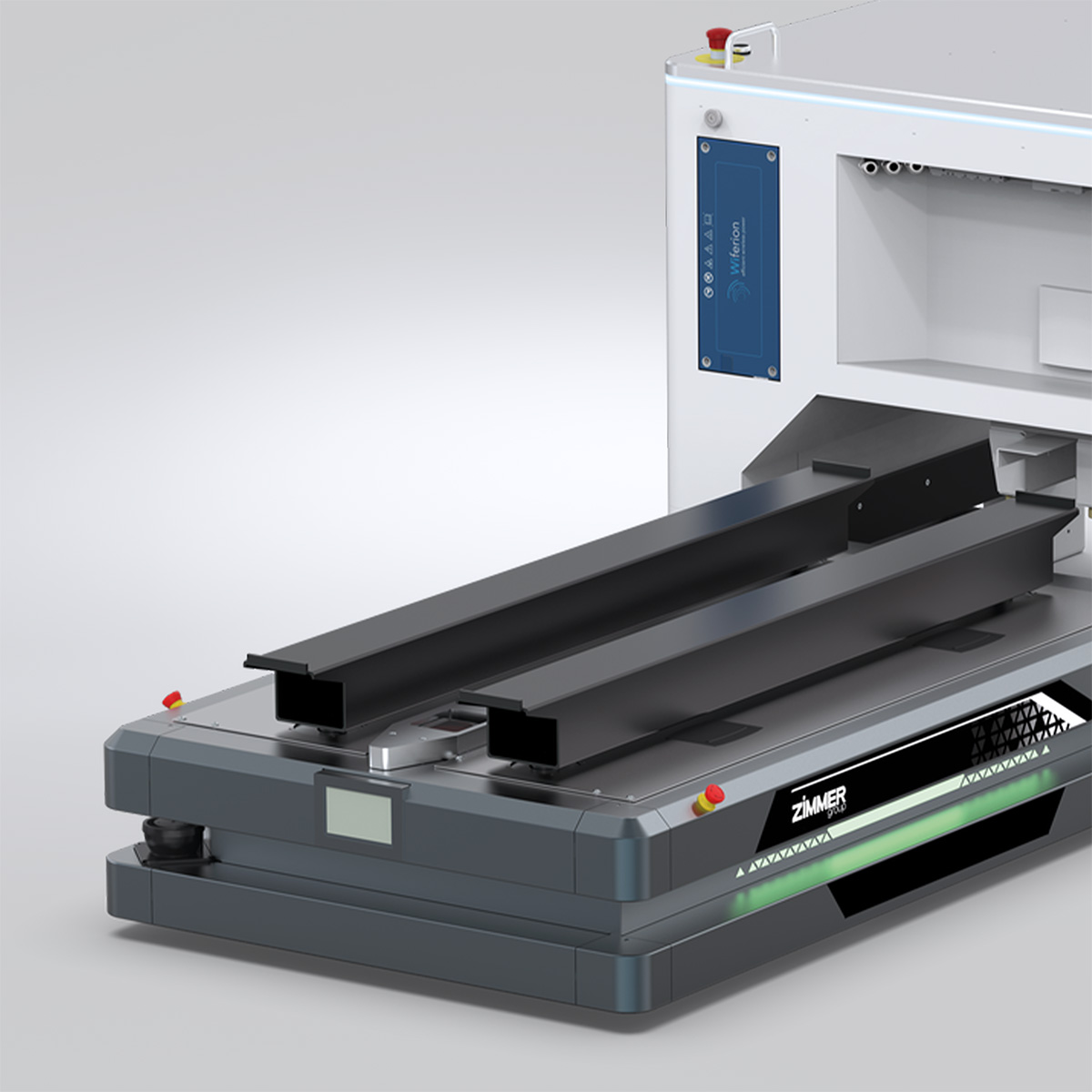

Flexible and mobile with ZiMo

The flexible robot cell ZiMo enables mobile and easy commissioning and impresses with its quick integration into your processes. Take advantage of the potential of unmanned additional shifts, increase your production capacity, and relieve your employees in a targeted manner. This allows you to improve productivity, quality, and flexibility—without any expansion of space.

Audio guide

ZiMo with AMR

Autonomous material flow meets flexible automation. Upon receiving an order from the fleet management system, ZiMo is automatically navigated by an AMR to the machine tool. It brings the raw parts with it in an unsorted box. With the help of a vision system, ZiMo performs precise bin picking. After successful calibration, ZiMo loads the machine independently, ensuring continuous unmanned operation.

See it at booth 316, hall A4.

ZiMo with Angle Flange

Safe part replacement efficiently implemented. Equipped with two KLT boxes, ZiMo takes over the entire handling of raw and finished parts. Using an angle flange and matching end effectors, it removes the finished workpiece, inserts the new raw part, and neatly sorts the finished part into a separate box. Thanks to an intelligent safety monitoring system, ZiMo reliably detects human proximity and stops automatically if necessary.

See it at booth 316, hall A4

ZiMo with rotary gripper

Modular platform for customized applications. This version shows ZiMo with the FANUC CRX robot and integrated control with function modules. The new REP2000 parallel rotary gripper can be seen here in two applications: as a decapper with Z-compensation and as a rotary gripper in combination with the sealed GEP2006IL. The components are controlled via the GuideZ app. ZiMo demonstrates how flexible automated applications can be customized.

On display at booth 202, hall A5

ZiMo with magnetic field sensor

In the fourth variant, the UR5e robot is used with the WPR5050 tool changer. Two approaches to position compensation are shown: the proven XYR1050-B mechanical axis compensation and an innovative solution with a magnetic field sensor. While the mechanical compensation compensates for existing deviations, the magnetic field sensor detects the exact position in advance without contact, thus preventing misalignments before they occur.

See it at booth 202, hall A5

Autonomous mobile robots

Master intralogistics processes with MILES

Autonomous mobile robots (AMRs) are revolutionizing intralogistics and increasing efficiency in numerous areas. The AMR Miles from Zimmer Group optimizes your intralogistics and makes the transport of goods and materials more efficient than ever before. Miles with a lifting unit offers a wide range of customization options that can handle almost any challenge. The parts to be transported can be flexibly adapted. Despite its small size and compact design, the system, equipped with a lift, can transport loads of up to 3,500 kg.

Audio guide

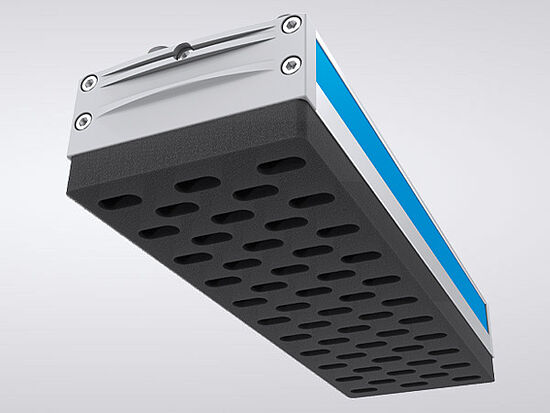

Intelligent vacuum handling

Powerful vacuum gripping system for processing systems

Experience our new vacuum gripping system – specially developed for sorting systems in woodworking. With high precision and dynamics, it ensures safe, material-friendly handling of workpieces of various sizes.

Highlights:

- 3 powerful flat grippers for reliable picking of workpieces weighing up to 60 kg

- Handling of component sizes between 240 x 120 mm and 2800 x 1300 mm

- Low gripper weight (max. 40 kg)

- Height of less than 30 mm to enable the smallest possible compartment spacing

- Dives into a rack with vertically standing components up to 650 mm when the neighboring compartments are fully loaded

Audio guide

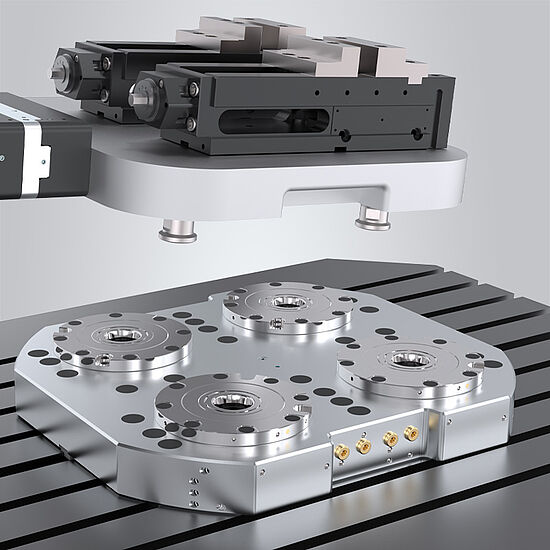

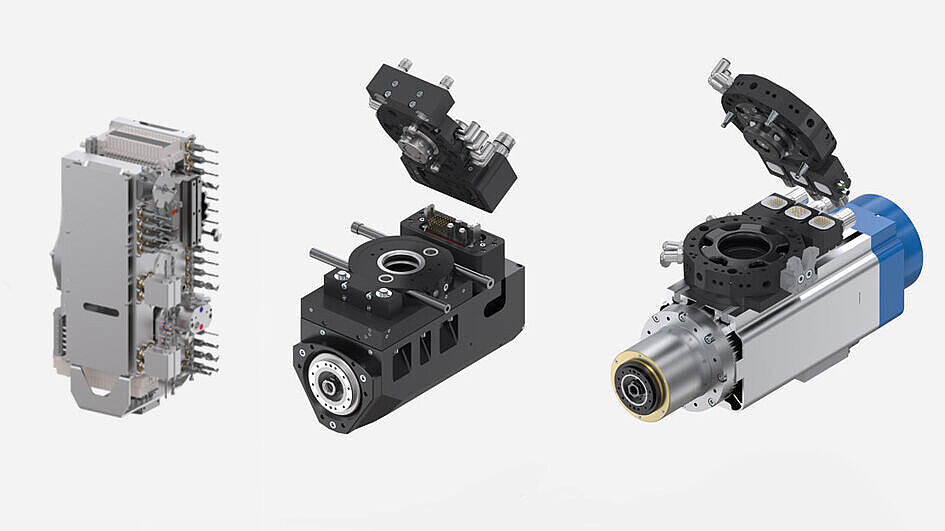

Pallet changer and zero-point clamping system

Safe handling

The new zero-point clamping system of the SPN series, in the “ED” version, allows for electrical status moni-toring of the clamping states (open and clamped) as well as the presence of a component. This is a key fea-ture for automated manufacturing processes where process reliability and real-time monitoring are crucial. You benefit from a highly functional zero-point clamping system designed for efficiency, compatibility, and safety without compromise.

With the pallet changer, Zimmer Group is expanding its range of zero-point clamping systems. In addition to changing pallets in machine tools, it offers a wide range of possibilities in the field of automation, such as handling components in gantries or on robots with high repeat accuracy.

Audio guide

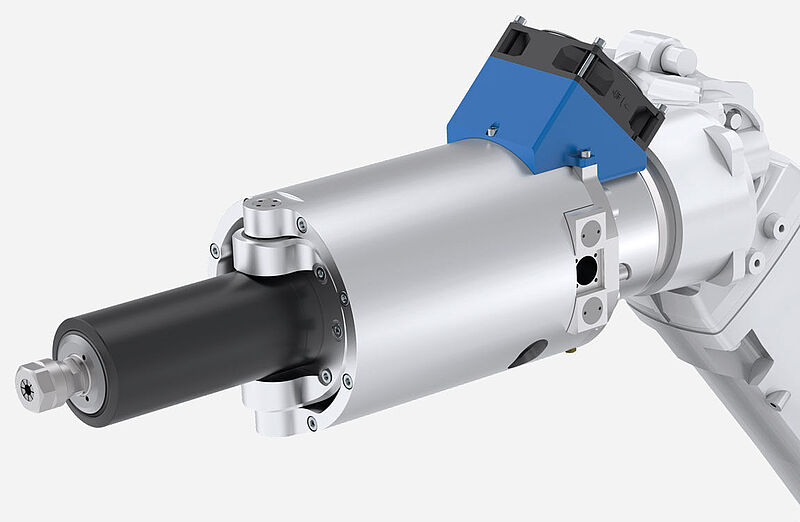

Deburring and machining

Motor spindles and multifunction units

Robotic deburring of components is becoming increasingly important and is emerging as a key technology across many industries. The electric, air-cooled motor spindle for deburring tasks is flexibly deployable thanks to its variable speed control. To meet the growing demand, Zimmer Group is developing tailored electric solutions specifically designed for the requirements of modern deburring processes. Automated changeover processes with matching tool changers will also be demonstrated at the trade fair stand. This opens up completely new possibilities in machining with motor spindles and multifunction units.

Audio guide

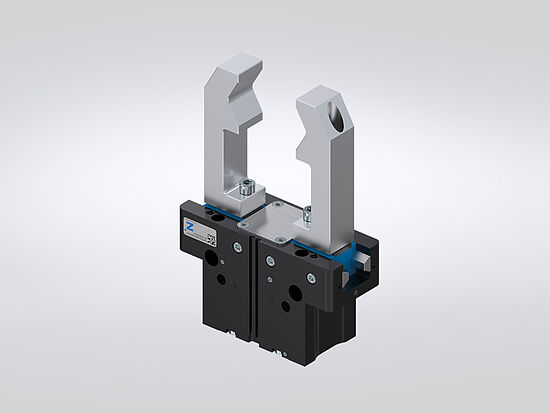

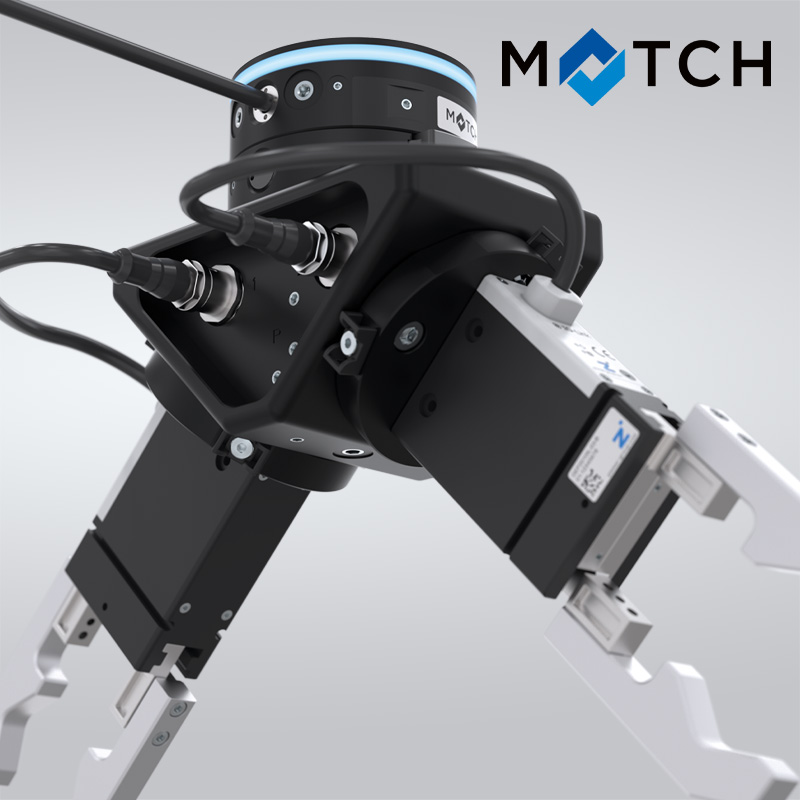

End-of-Arm-Tools

Application-specific system grippers

They are the heart of robot automation: end-of-arm tools. They are used across industries to perform a wide variety of tasks: gripping, testing, assembling, and much more. As an industry partner with many years of experience, we understand your requirements for modern EOATs, whether in mechanical engineering, the (electrical) automotive and supplier industries, foundries, or the electrical, plastics, or consumer goods industries. With gripping systems from Zimmer Group, we can optimize the equipment of any robot make and significantly increase the functionality and efficiency of your robot.

Audio guide

HEAVY-DUTY AXIS COMPENSATION MODULE

Robust robot technology

One important component in these system grippers is the heavy-duty compensation system. Zimmer Group is presenting new products in this area at automatica: With the new heavy-duty axis compensation systems in the XYR9000 series, Zimmer Group is setting new standards in industrial automation. They offer exceptional robustness for loads from 500 kg to 2,000 kg without compromising on precision and flexibility. The series enables axis compensation in the X and Y directions and can be combined with other axis compensators of the same size.

Audio guide

Components for automation

Over four decades of experience

For 45 years, Zimmer Group has been providing excellent solutions in automation technology, including handling and vacuum technology, robotics, clamping and braking elements, damping and machine technology. As a leading manufacturer and supplier of hydraulic, pneumatic, and electrical components, we have in-depth industry knowledge to support you as a long-term, reliable, and competent partner. Safety and quality are core elements of our corporate philosophy.