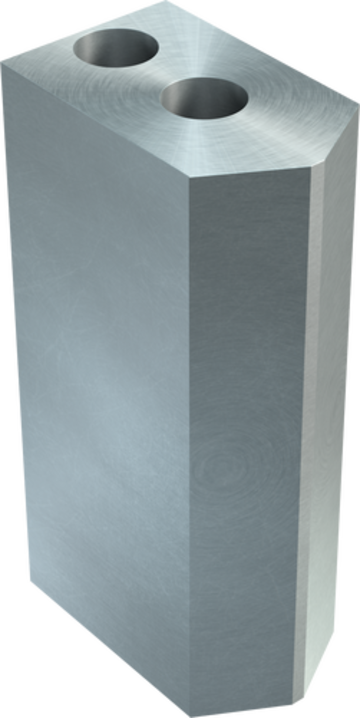

GEH6140IL-03-B

2-Jaw Parallel Grippers with Long Stroke

Series GEH6000IL

"Highest performance"

- 5 million maintenance-free cycles

- Integrated sensing via IO-Link

- Servo drive with integrated controller

Brushless drive technology, position, speed and force control guarantee the highest amount of functionality - IO-Link on board

In addition to the unshielded single-cable solution, the future-proof, hot-pluggable activation provides you with a wide variety of travel profiles for easy implementation into your control system - Gentle yet powerful

Power version -03 for handling heavy workpieces with mechanical self-locking and version -31 for gently gripping of delicate parts

Equipment/Options

5 million maintenance-free cycles (max.)

5 million maintenance-free cycles (max.) Integrated sensing

Integrated sensing IP54

IP54 Self locking mechanism

Self locking mechanism Positionable

Positionable Gripping force adjustable

Gripping force adjustable Powerful

Powerful IO-Link

IO-Link Cleanroom-certified

Cleanroom-certified

Technical Data

| Control | IO-Link |

| Drive | BLDC motor |

| Stroke per jaw, adjustable | 40 [mm] |

| Nominal gripping force | 1800 [N] |

| Gripping force min. | 150 [N] |

| Current consumption max. | 5 [A] |

| Self locking mechanism | mechanical |

| Dead weight of mounted gripper finger max. | 1 [kg] |

| Length of the gripper fingers max. | 160 [mm] |

| Minimum positioning path per jaw | 1 [mm] |

| Positioning speed per jaw max. | 50 [mm/s] |

| Repetition accuracy +/- | 0.02 [mm] |

| Operating temperature | 5 ... +50 [°C] |

| Clean room applications according to DIN EN ISO 14644-1 | 4 |

| Certifications | CE / UKCA / LABS / REACH / RoHS |

| Protection to IEC 60529 | IP54 |

| Weight | 1.9 [kg] |

Individualizations

| Use

Advantage

| Details | ||

| Use

Advantage

| Details | ||

| Use

Advantage

| Details |

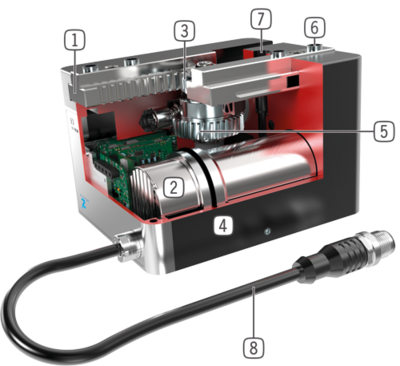

Benefits in detail

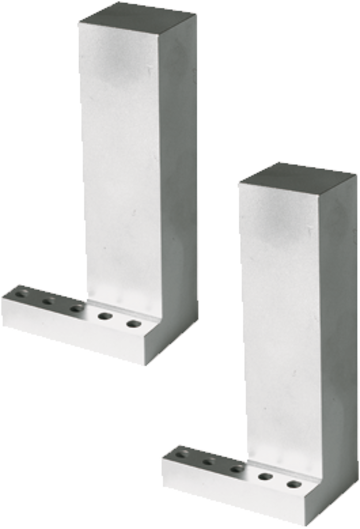

- Precise T-Slot guide

high forces and moments capacity - Drive

Brushless DC servomotor - Rack and pinion gear

synchronized the movement of the gripper jaws high force transfer - Robust, lightweight housing

Hard-coated aluminum alloy - Helical worm gear

self locking mechanism in case of power drop (only version -03) - Removable centering sleeves

quick and economical positioning of the gripper fingers - Mounting and positioning

mounting possible from several sides for versatile positioning - Energy supply

standardized connector

Certifications

UL-CERTIFICATION GEH6000

TÜV-CERTIFICATION GEH6000