HM1046NC

Magnetic gripper

Series HM1000

- Secure hold during EMERGENCY STOP

Magnets attached to springs ensure your workpiece remains secure, even during a drop in pressure - Contact plate that increases friction value

The replaceable O-ring ensures the high dynamics in your application and protection of your workpiece - Residual holding force < 1N

The demagnetised contact surface safeguards the process reliability of dropping off your workpiece

Equipment/Options

5 million maintenance-free cycles (max.)

5 million maintenance-free cycles (max.) IP30

IP30

Technical Data

| Retention force max. | 65 [N] |

| Operating pressure | 3 ... 8 [bar] |

| Nominal operating pressure | 6 [bar] |

| Operating temperature | 5 ... +80 [°C] |

| Air volume per cycle | 9 [cm³] |

| Approvals | LABS / REACH / RoHS |

| Protection to IEC 60529 | IP30 |

| Weight | 0.25 [kg] |

Benefits in detail

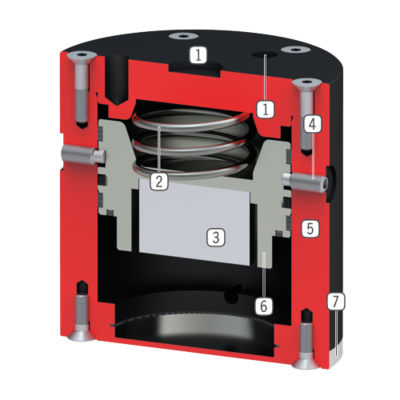

- Mounting and positioning

via centering sleeve and thread - Spring

for piston return secured holding even in drop pressure - Permanent magnet

requires no power supply high holding forces - Transport safeguarding

- Robust, lightweight housing

Hard-coated aluminum alloy - single-acting pneumatic cylinders

only one pneumatic line required Spring return - Contact plate

easy replaceable embedded O-ring to increase the friction coefficient