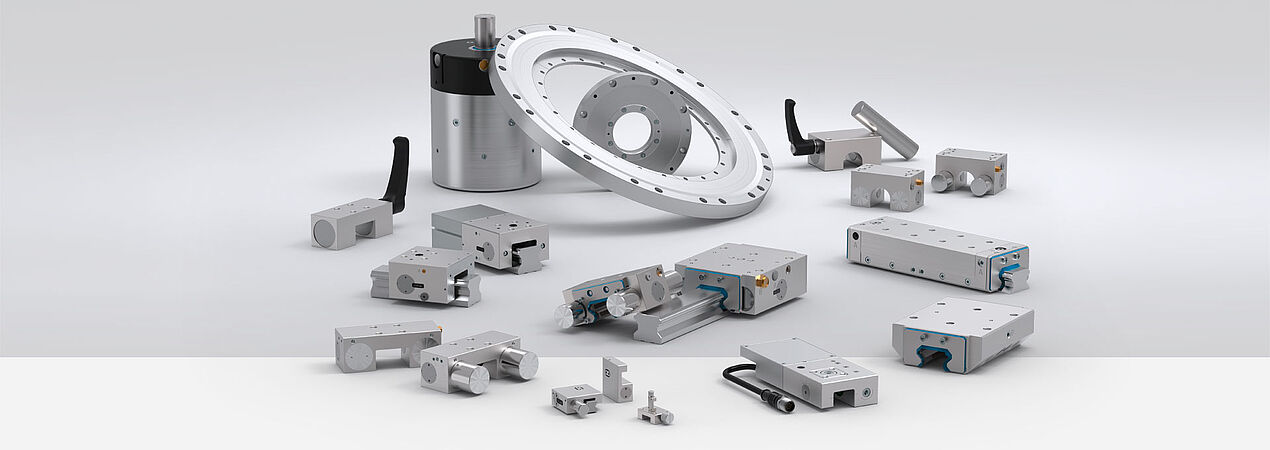

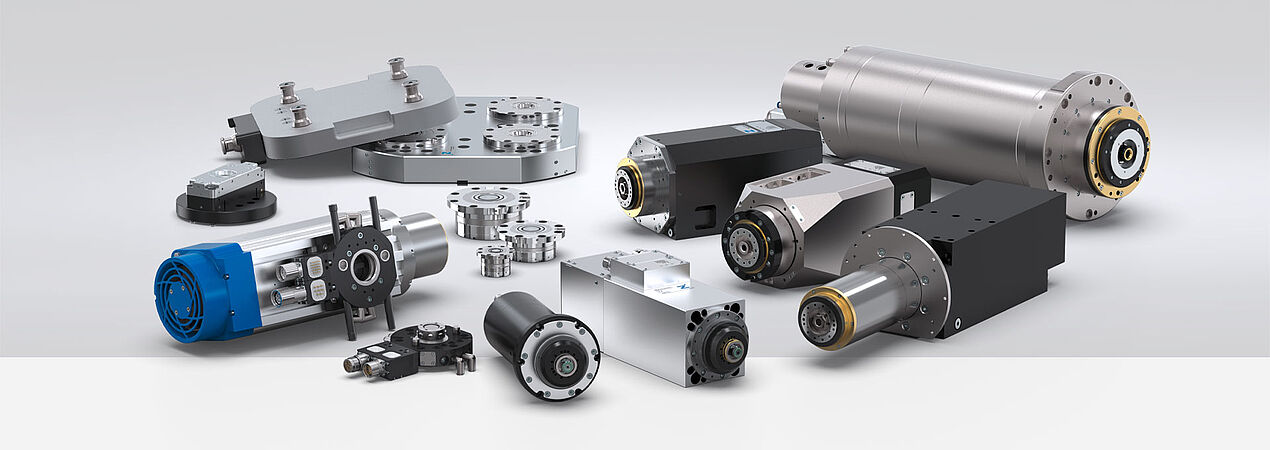

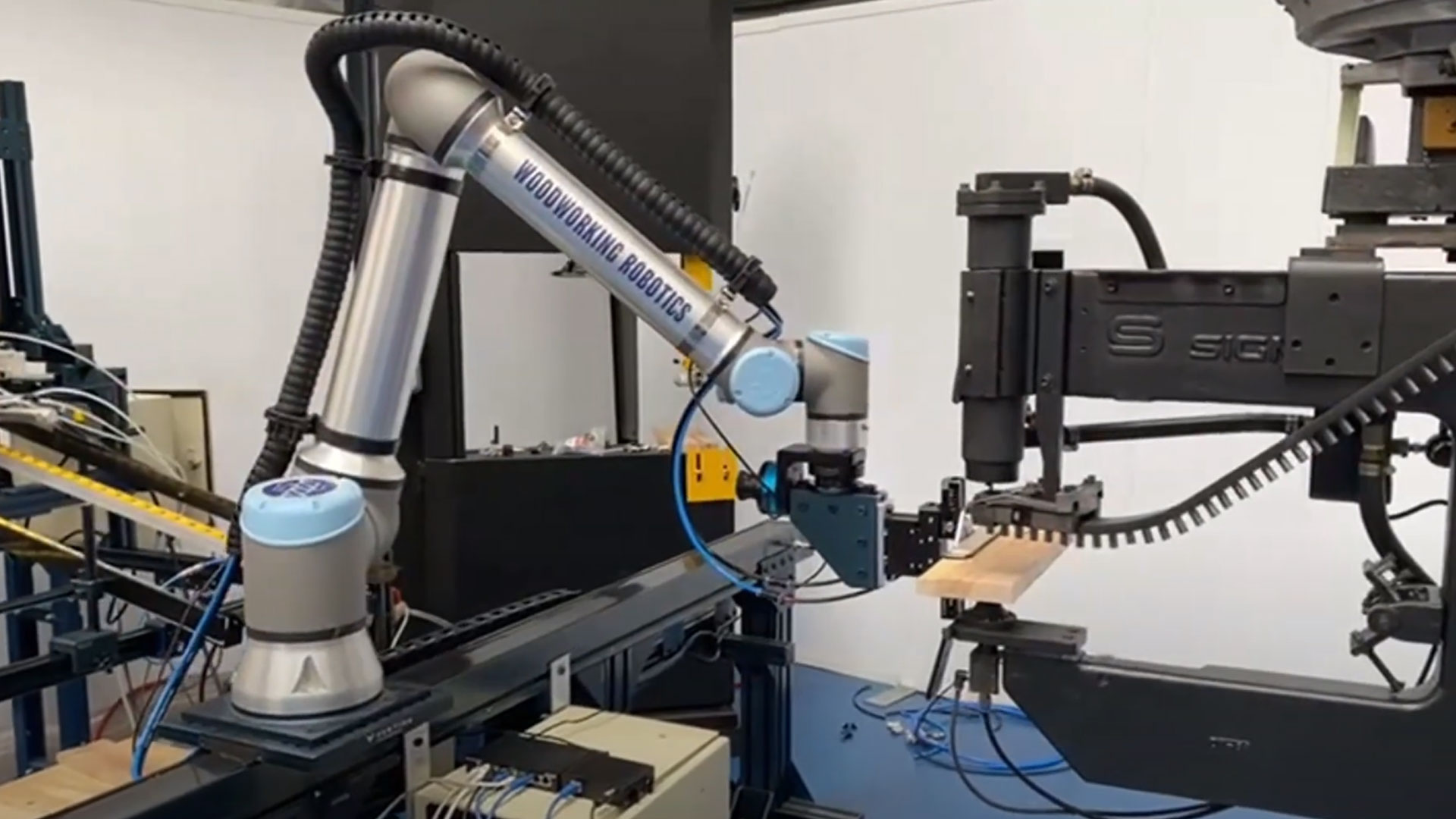

Components

Discover the diversity of our components from the fields of handling, robotics, industrial communication, clamping and braking technology, damping and mechanical engineering. The best way to find the right product for your application quickly and easily is to use our Product Finder!

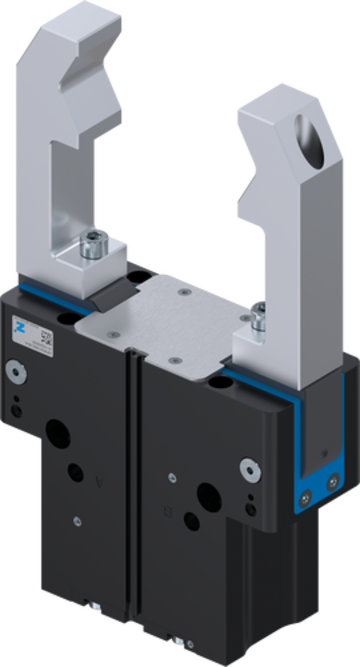

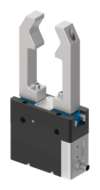

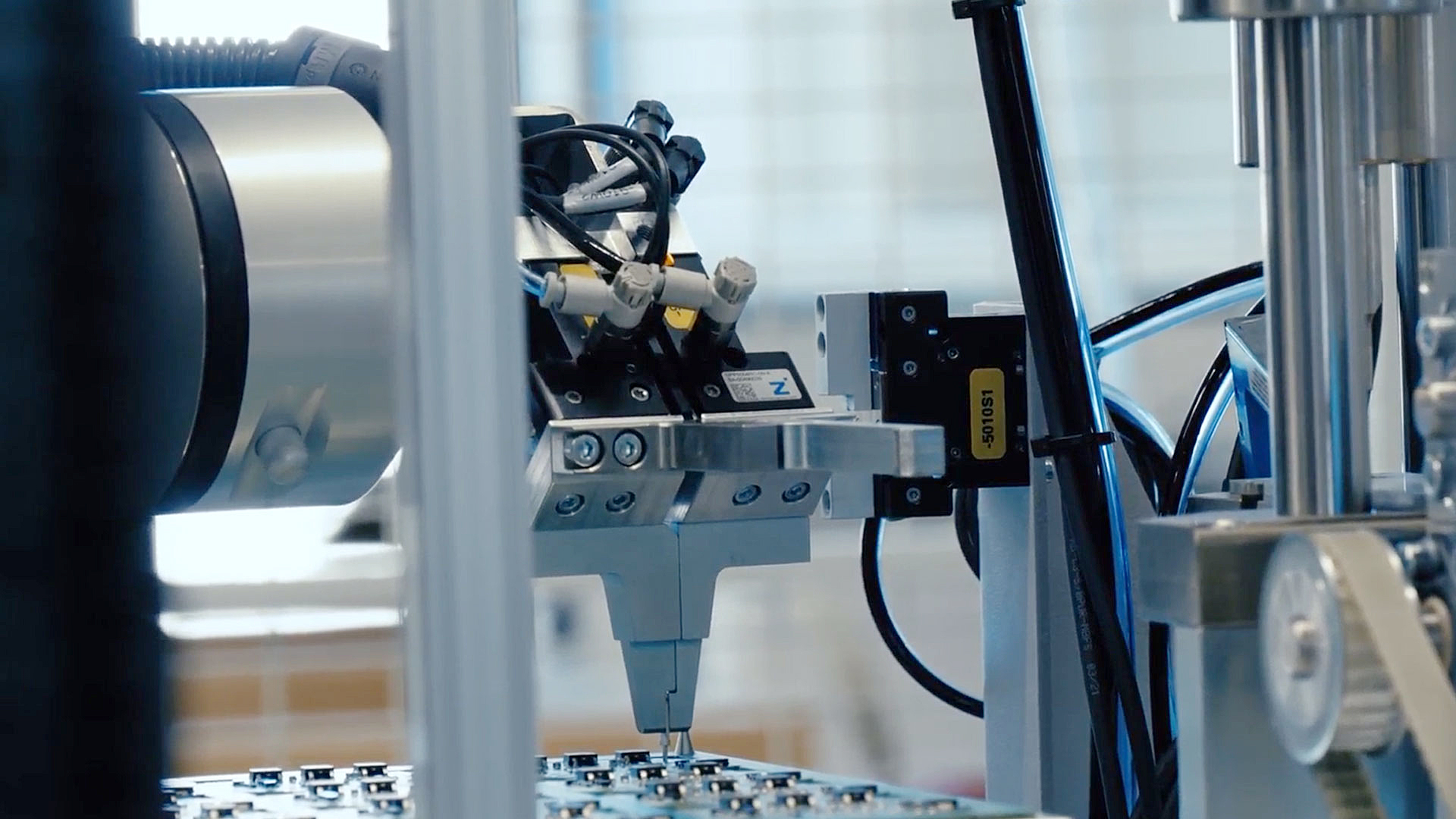

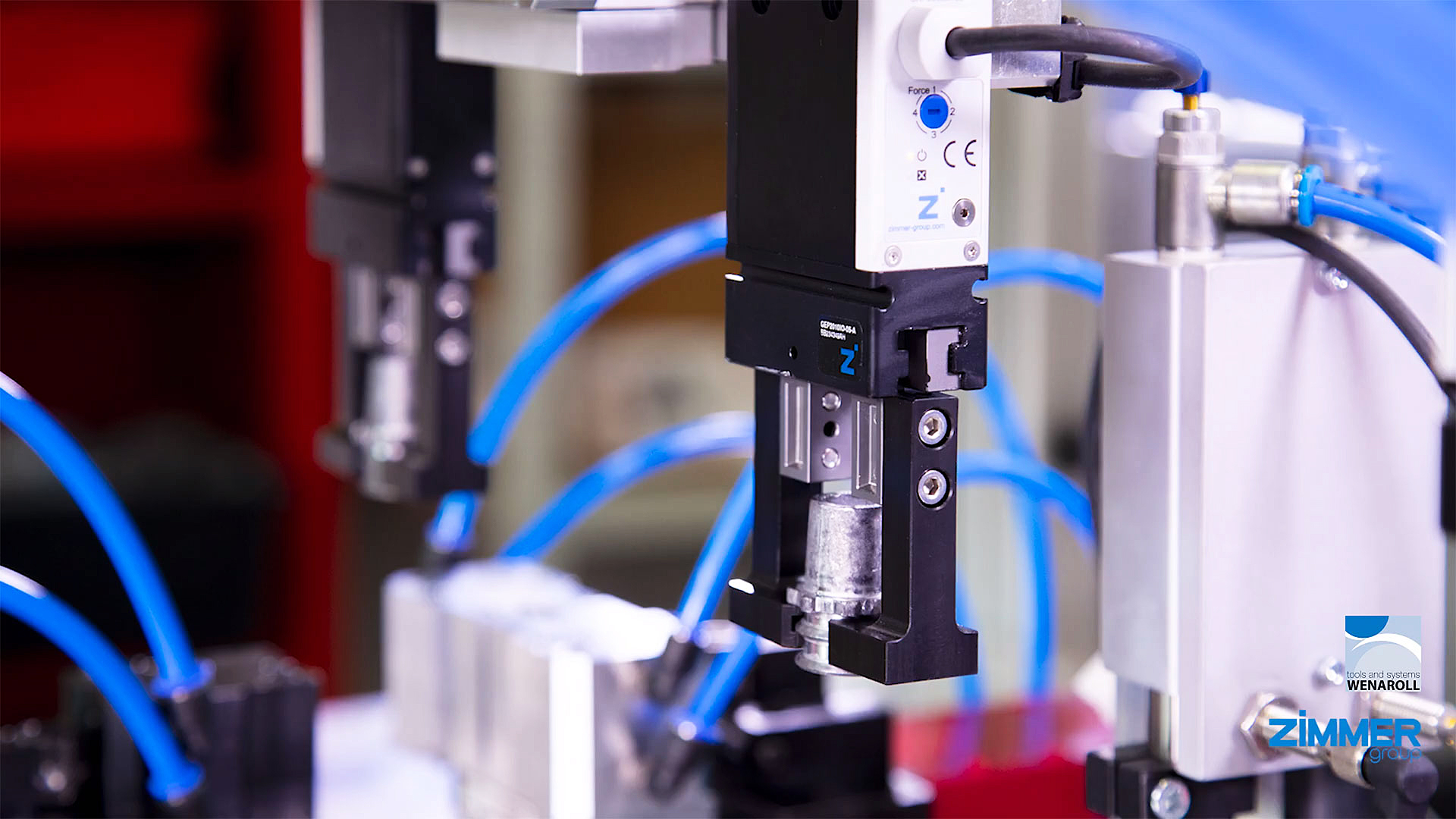

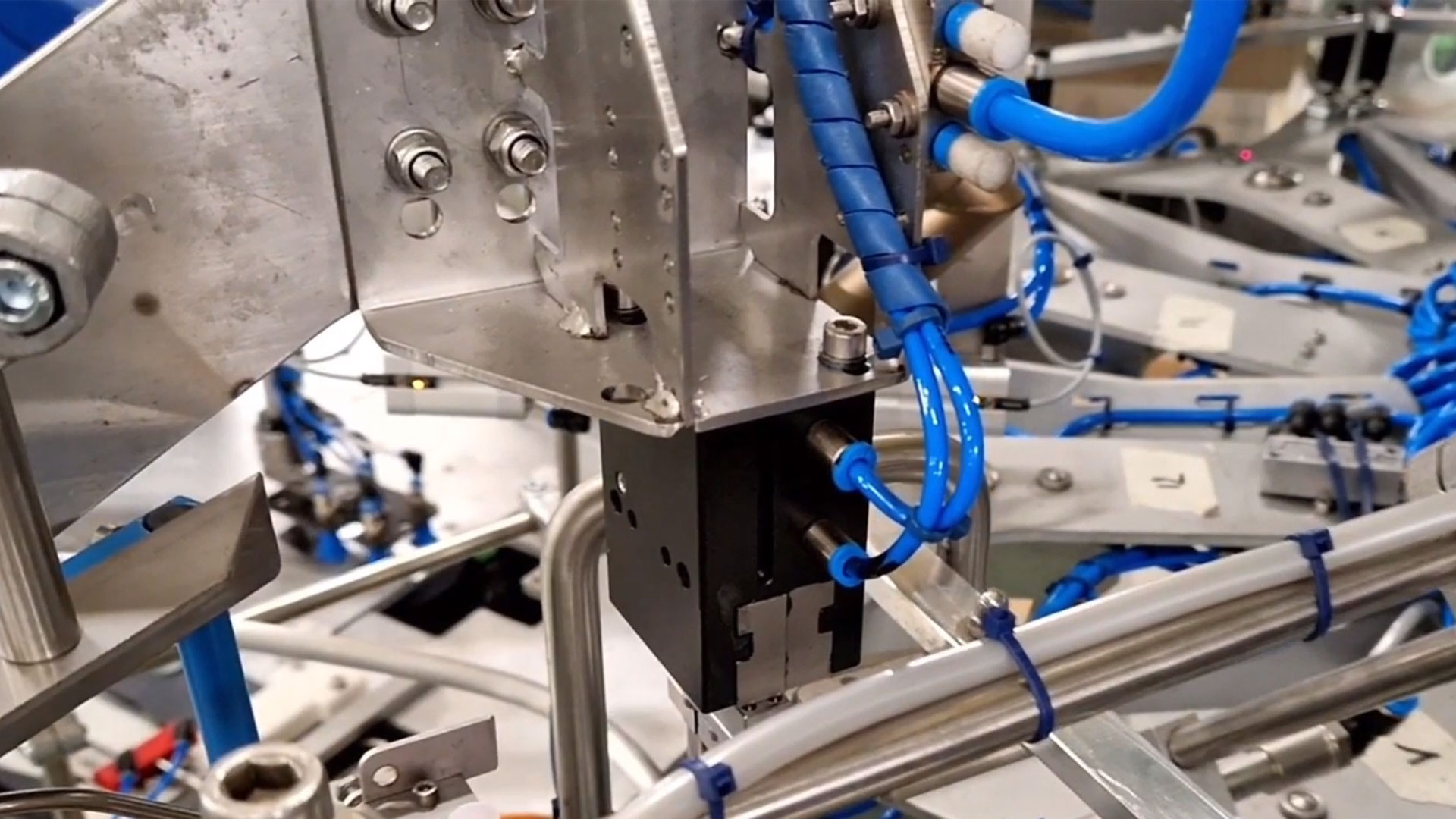

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

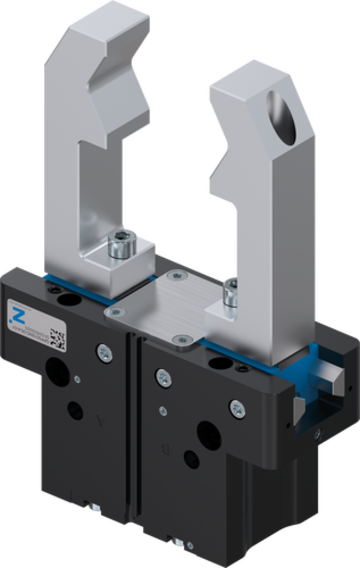

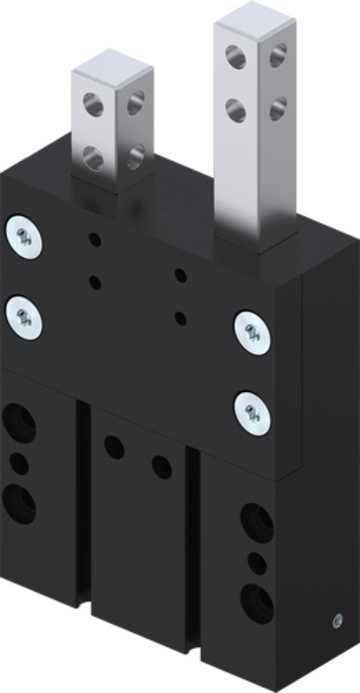

2-Jaw Parallel Grippers with Long Stroke

Series GEH6000IL

2-Jaw Parallel Grippers with Long Stroke

Series GEH6000IL

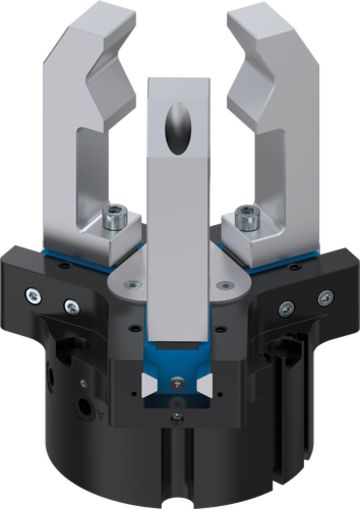

3-Jaw Concentric Grippers

Series GD300

- Extremely robust T-Slot guide for maximum forces and moments capacity

- Available with optional dust cover for use at extreme conditions

- Extremely robust T-Slot guide for maximum forces and moments capacity

- Available with optional dust cover for use at extreme conditions

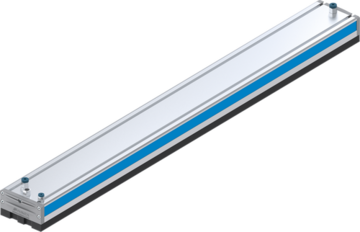

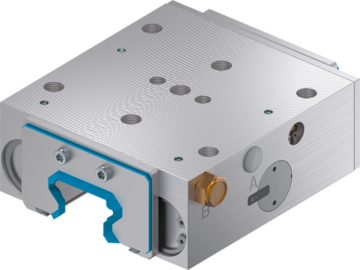

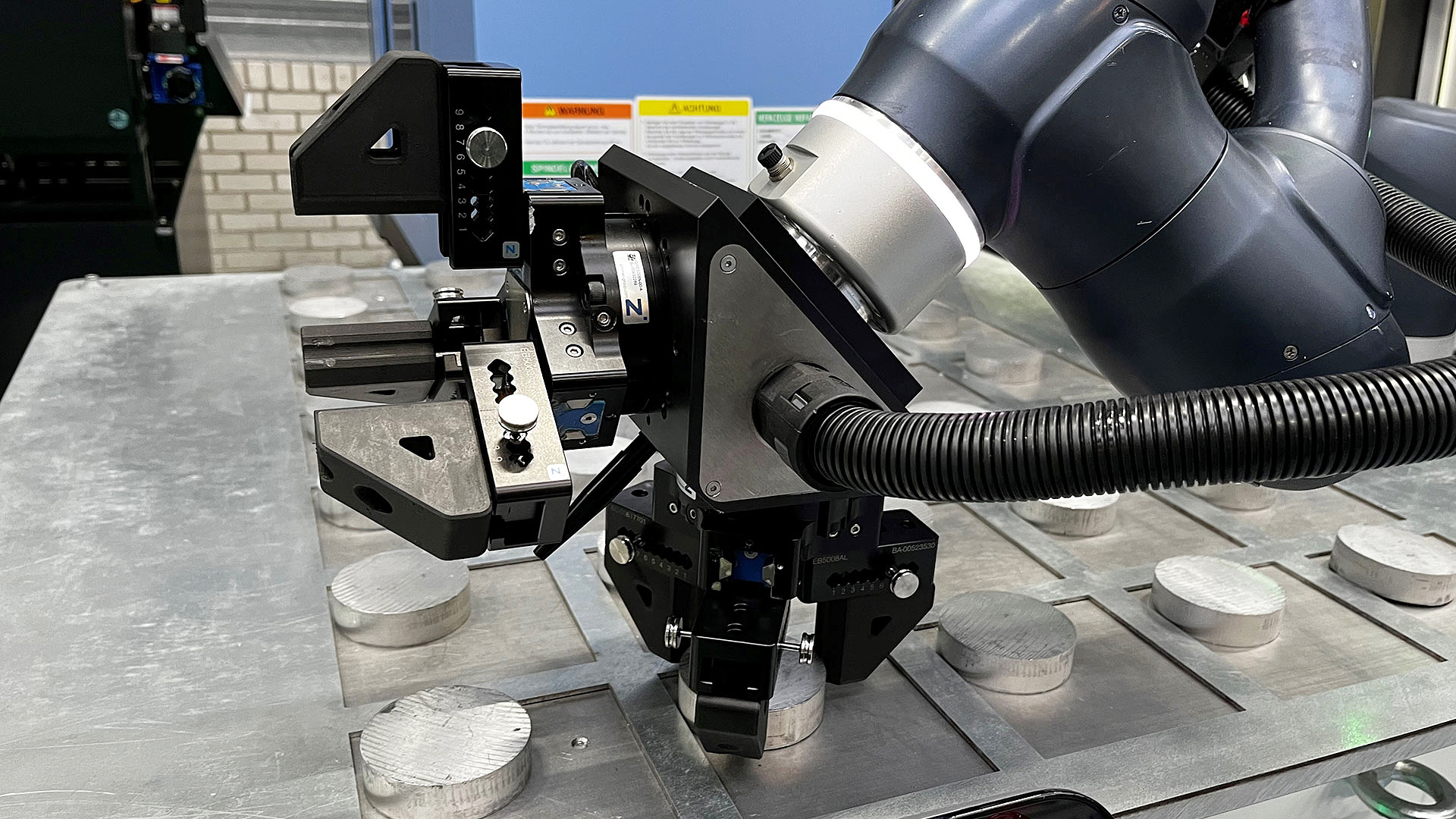

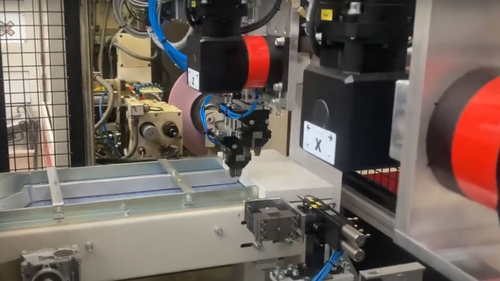

Pallet changer

Series SPP

- Maximum clamping and holding force

- Slim design for maximum utilization of the machine space

- Sensing of clamping state and pallet presence

- Reliable handling thanks to cleaning function and spring accumulator

- Maximum clamping and holding force

- Slim design for maximum utilization of the machine space

- Sensing of clamping state and pallet presence

- Reliable handling thanks to cleaning function and spring accumulator

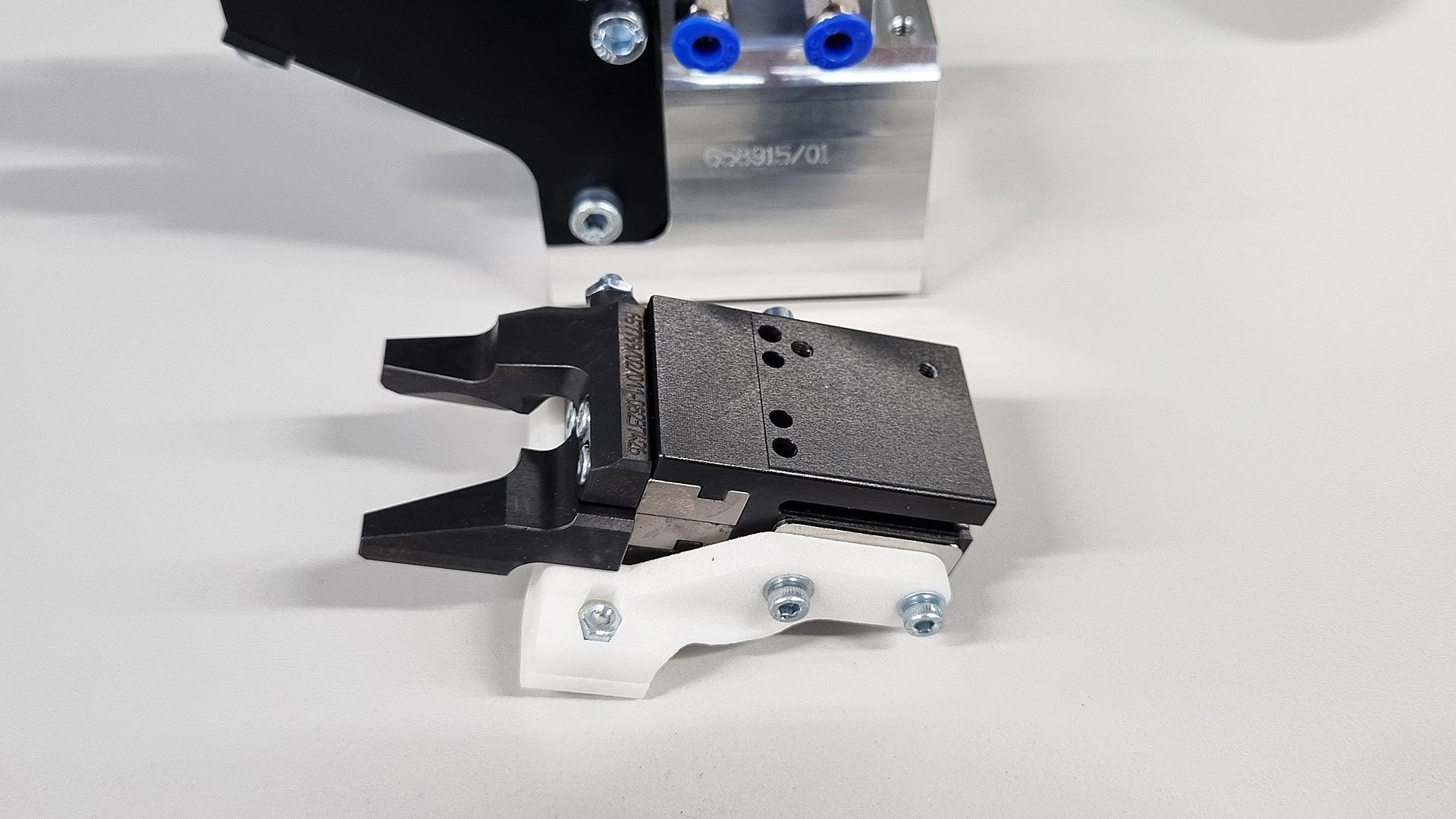

2-Jaw Parallel Grippers

Series GEP2000

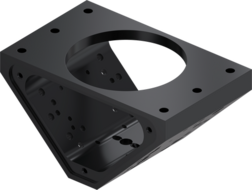

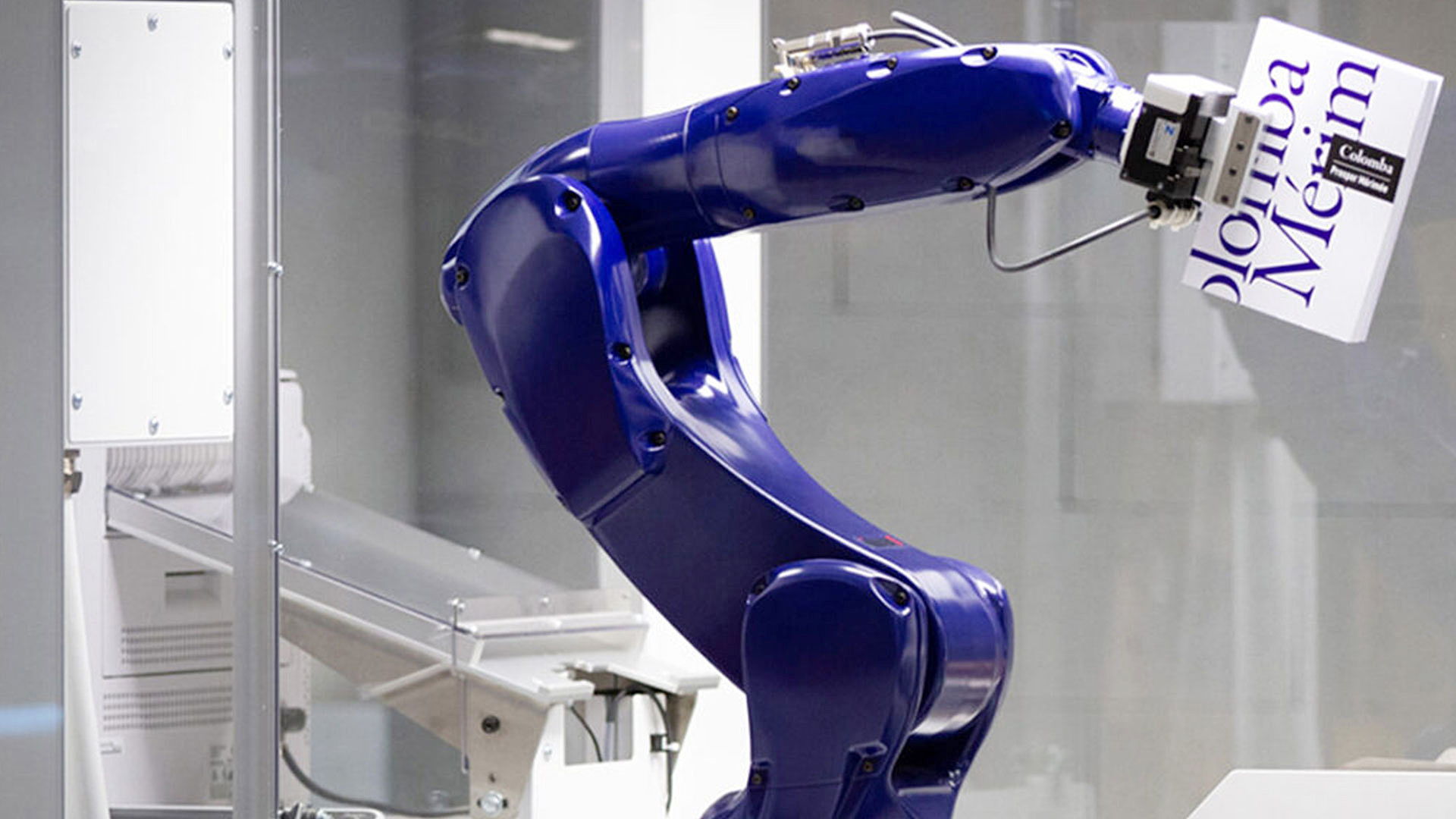

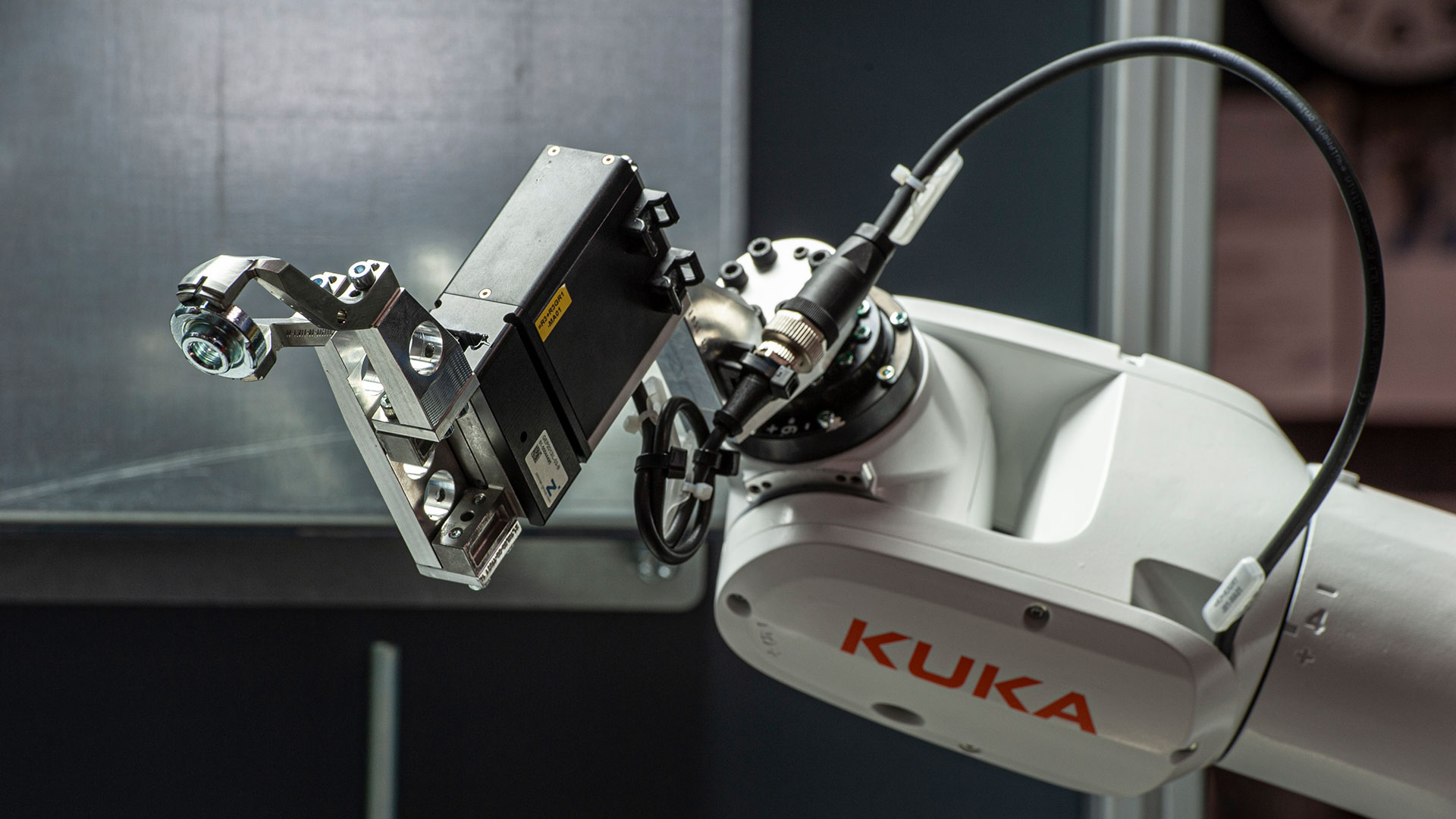

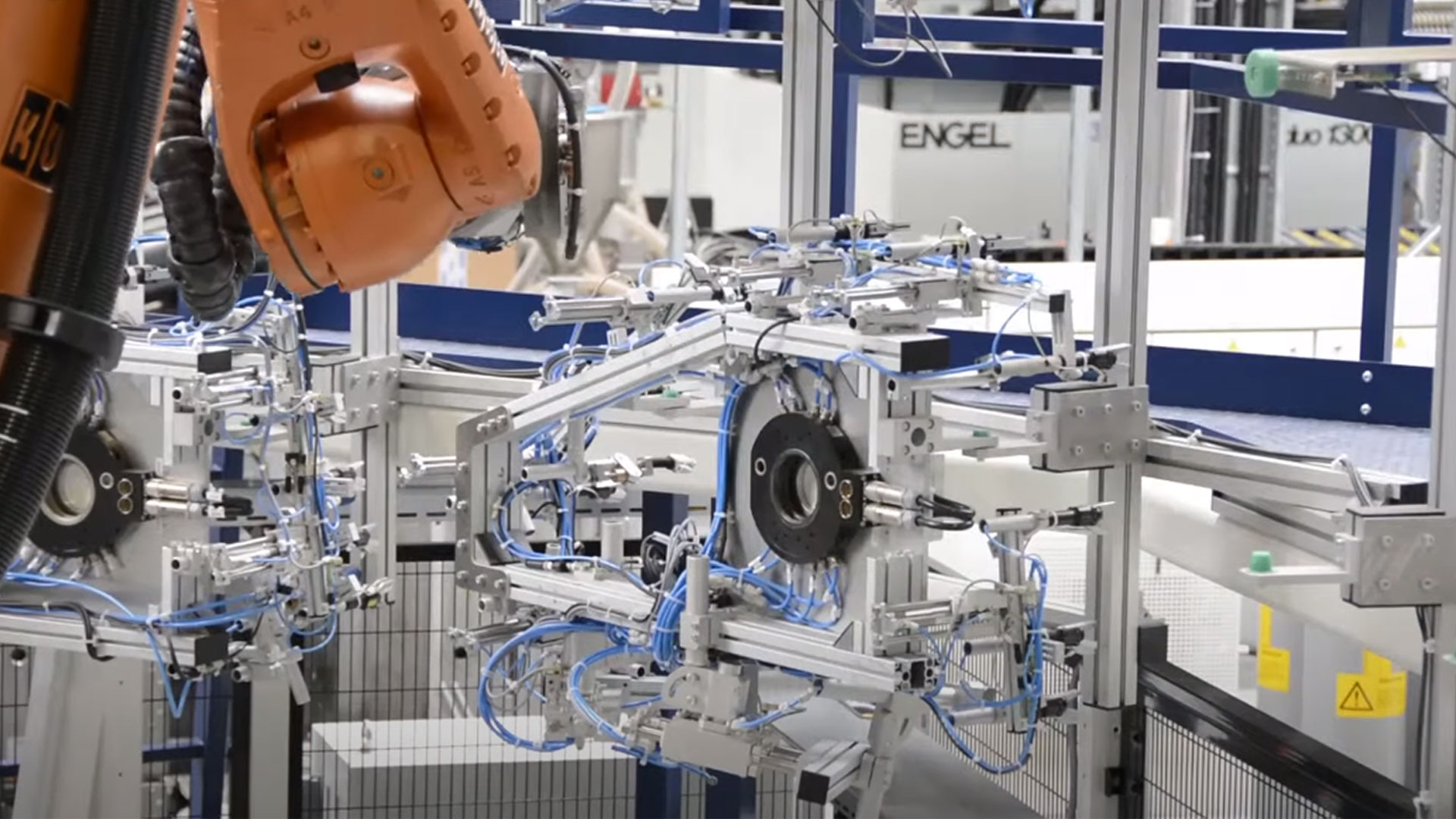

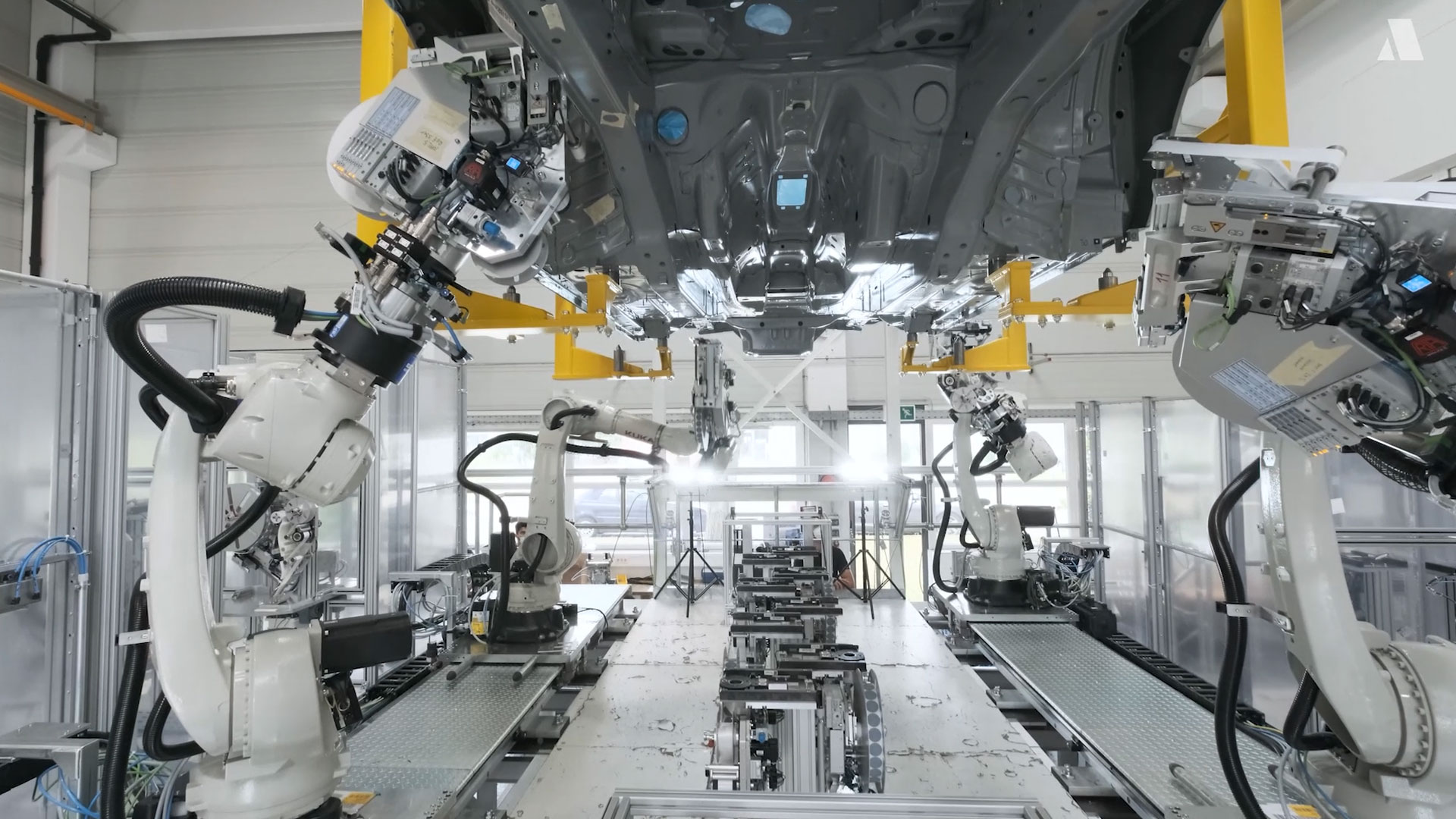

Tool Changers

Series WWR

- Robot flange with partial mounting circle in accordance with EN ISO 9409-1

- Very high handling weight up to 300 kg

- Robot flange with partial mounting circle in accordance with EN ISO 9409-1

- Very high handling weight up to 300 kg

2-Jaw Parallel Grippers

Series GEP2000

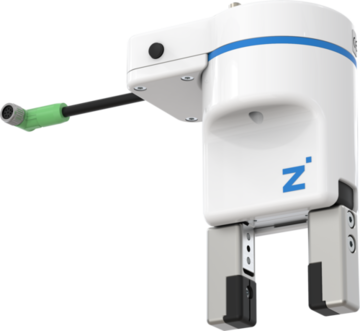

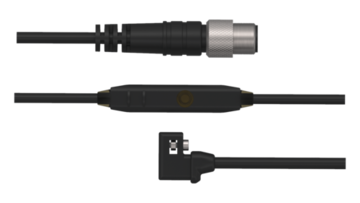

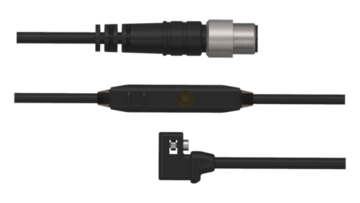

Bridge Communication Module

Series BCM

- Wireless range of point-to-point communication up to 10 m, up to 30 m with unobstructed view

- Scalable, simple expansion of further grippers by logging on to the master

- Industrial design

- IP67 certified

- Wireless range of point-to-point communication up to 10 m, up to 30 m with unobstructed view

- Scalable, simple expansion of further grippers by logging on to the master

- Industrial design

- IP67 certified

2-Jaw Parallel Grippers

Series GEP5000

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GEP2000

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series MGP800

- Integrated position sensing for compact design and to minimized the interfering contour

- Gripper jaws made of ground surfaced and hardened steel ensure precision and a long durability

- Integrated position sensing for compact design and to minimized the interfering contour

- Gripper jaws made of ground surfaced and hardened steel ensure precision and a long durability

2-Jaw Angular Rotary Grippers

Series DGK

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GEP2000

2-Jaw Parallel Grippers

Series MGP800

- Integrated position sensing for compact design and to minimized the interfering contour

- Gripper jaws made of ground surfaced and hardened steel ensure precision and a long durability

- Integrated position sensing for compact design and to minimized the interfering contour

- Gripper jaws made of ground surfaced and hardened steel ensure precision and a long durability

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

Flat Swivel Units

Series SF-C

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

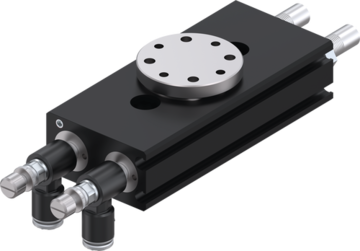

Rotary Distributors

Series DVR

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK40... TK160

- With 4...8 pneumatic feedthroughs

- With 4...12 electrical feedthroughs

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK40... TK160

- With 4...8 pneumatic feedthroughs

- With 4...12 electrical feedthroughs

2-Jaw Parallel Grippers with Long Stroke

Series GEH6000IL

2-Jaw Parallel Grippers

Series GEP2000

2-Jaw Parallel Grippers

Series GP

- Dual round guide rods

- Double acting pneumatic cylinder with integrated mechanical gripping force safety device

- Dual round guide rods

- Double acting pneumatic cylinder with integrated mechanical gripping force safety device

2-Jaw Parallel Grippers with Long Stroke

Series GEH6000IL

3-Jaw Concentric Grippers

Series GPD5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

Tool Changers

Series FWR

- DGUV certified collaborative grippers

- Servo drive with integrated controller

- Sensitive version

- IO-Link control

- Use in combination with LWR fixed parts (IO-Link/RS485)

- Optimal for applications of larger workpieces as well as different dimensions due to servo technology

- DGUV certified collaborative grippers

- Servo drive with integrated controller

- Sensitive version

- IO-Link control

- Use in combination with LWR fixed parts (IO-Link/RS485)

- Optimal for applications of larger workpieces as well as different dimensions due to servo technology

3-Jaw Concentric Grippers

Series GPD5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

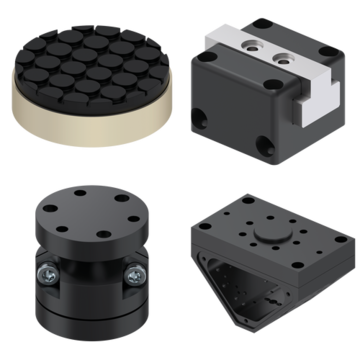

Angle flange

Series WFR

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

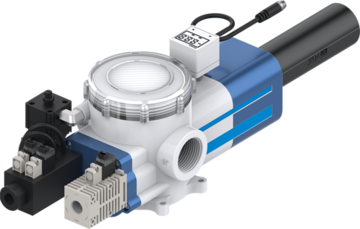

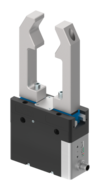

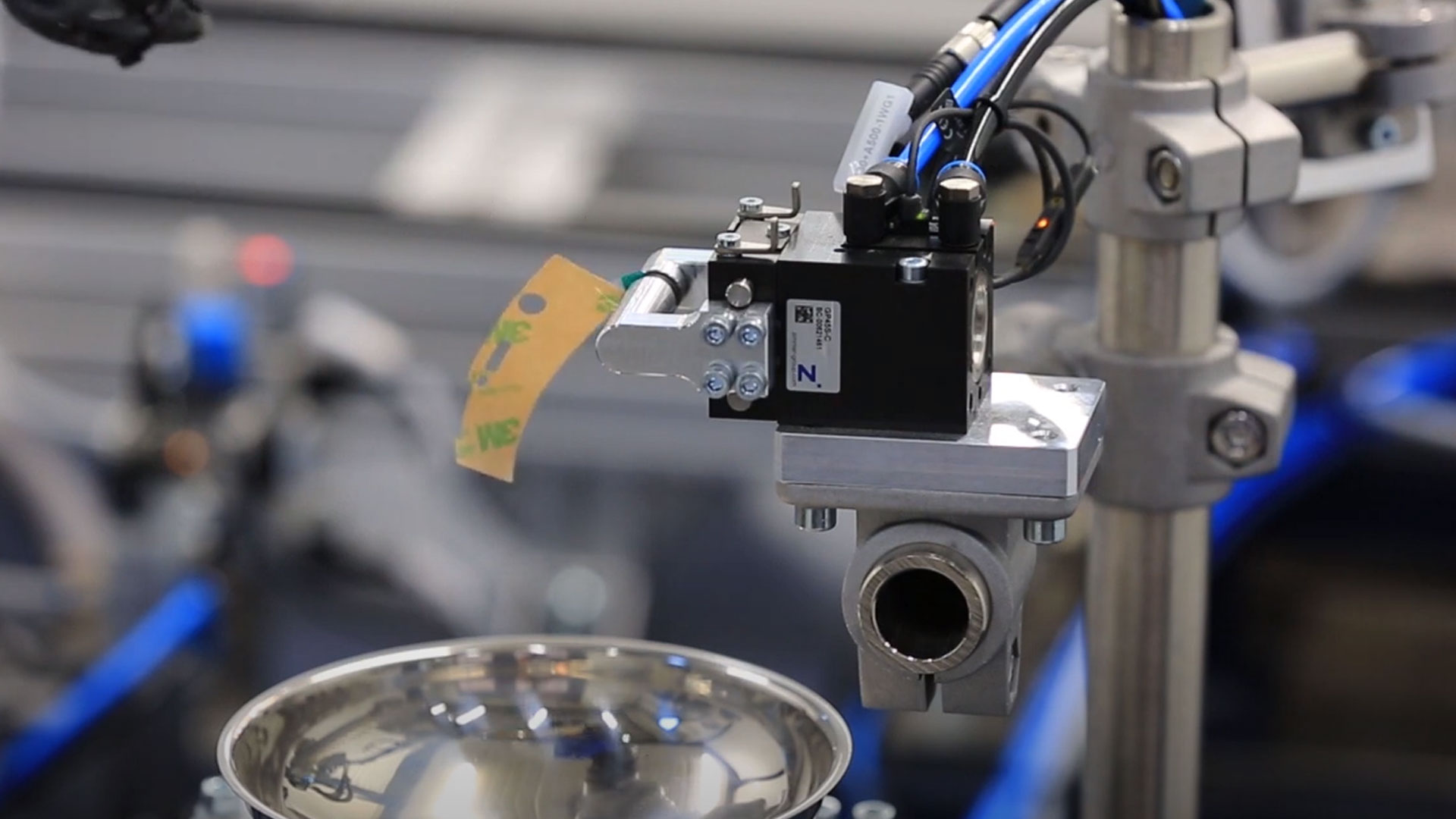

Needle gripper

Series ST

- Adjustable stroke via scale ring from 0 to 2 mm or 1.5 mm

- Single-acting pneumatic cylinder with spring return

- Adjustable stroke via scale ring from 0 to 2 mm or 1.5 mm

- Single-acting pneumatic cylinder with spring return

O-ring assembly grippers, outer

Series GS

- Expanding stroke adjustable from outside via adusting ring

- T-Slot guide for high forces and moments capacity

- Expanding stroke adjustable from outside via adusting ring

- T-Slot guide for high forces and moments capacity

2-Jaw Parallel Grippers

Series GP400

- High gripping force as a result of optimal direction change of driving force into gripping force

- High gripping force as a result of optimal direction change of driving force into gripping force

2-Jaw Parallel Grippers

Series GEP2000

Tool Changers

Series WWR

- Robot flange with partial mounting circle in accordance with EN ISO 9409-1

- Very high handling weight up to 300 kg

- Robot flange with partial mounting circle in accordance with EN ISO 9409-1

- Very high handling weight up to 300 kg

Flat Swivel Units

Series SF-C

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

2-Jaw Parallel Grippers

Series GP

- Dual round guide rods

- Double acting pneumatic cylinder with integrated mechanical gripping force safety device

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

- Dual round guide rods

- Double acting pneumatic cylinder with integrated mechanical gripping force safety device

Tool Changers

Series WWR

- Robot flange with partial mounting circle in accordance with EN ISO 9409-1

- Very high handling weight up to 300 kg

- Robot flange with partial mounting circle in accordance with EN ISO 9409-1

- Very high handling weight up to 300 kg

Tool Changers

Series WWR

- Robot flange with partial mounting circle in accordance with EN ISO 9409-1

- Very high handling weight up to 300 kg

- Robot flange with partial mounting circle in accordance with EN ISO 9409-1

- Very high handling weight up to 300 kg

Tool Changers

Series WWR

- Robot flange with partial mounting circle in accordance with EN ISO 9409-1

- Very high handling weight up to 300 kg

- Robot flange with partial mounting circle in accordance with EN ISO 9409-1

- Very high handling weight up to 300 kg

Rotary Distributors

Series DVR

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK40... TK160

- With 4...8 pneumatic feedthroughs

- With 4...12 electrical feedthroughs

Angle flange

Series WFR

3-Jaw Concentric Grippers

Series GPD5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK40... TK160

- With 4...8 pneumatic feedthroughs

- With 4...12 electrical feedthroughs

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GEP2000