Robust and precise

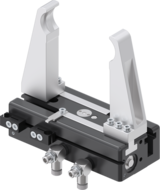

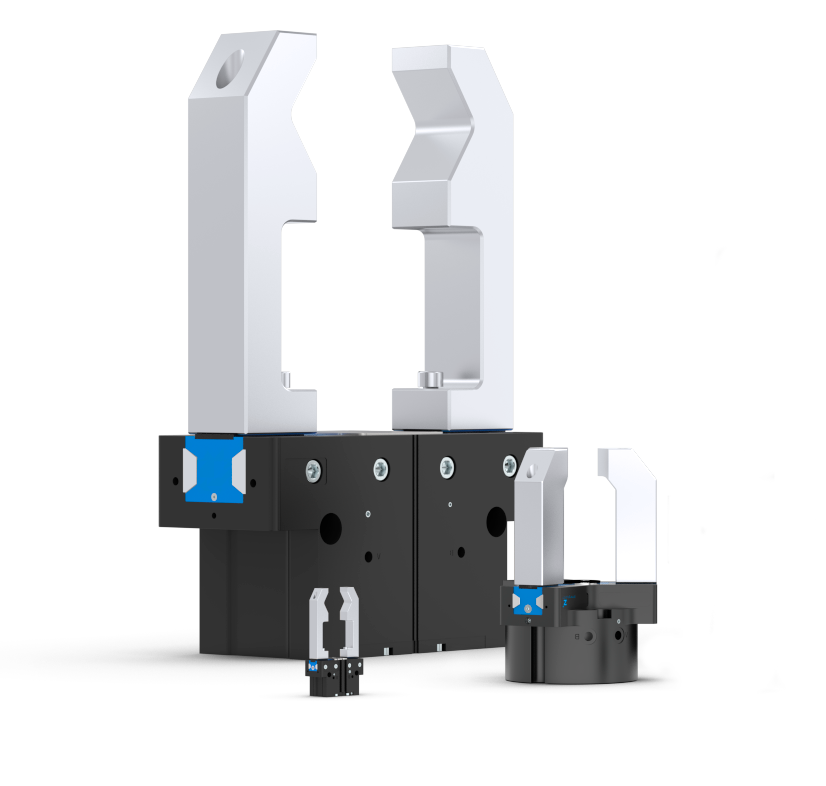

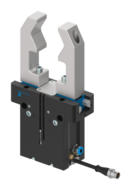

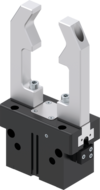

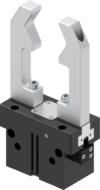

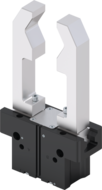

Series GPP5000

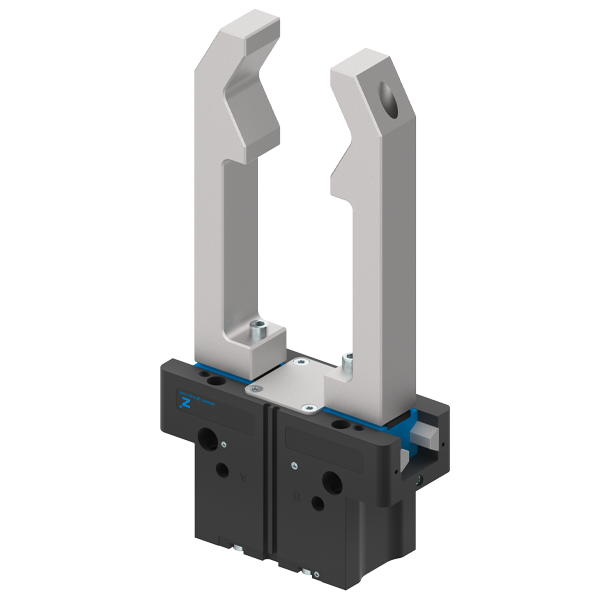

Series GPD5000

Top of the class – Steel Linear Guide

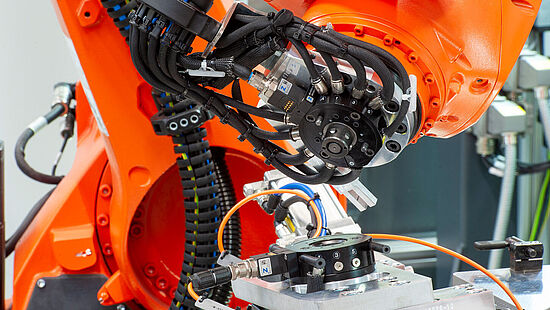

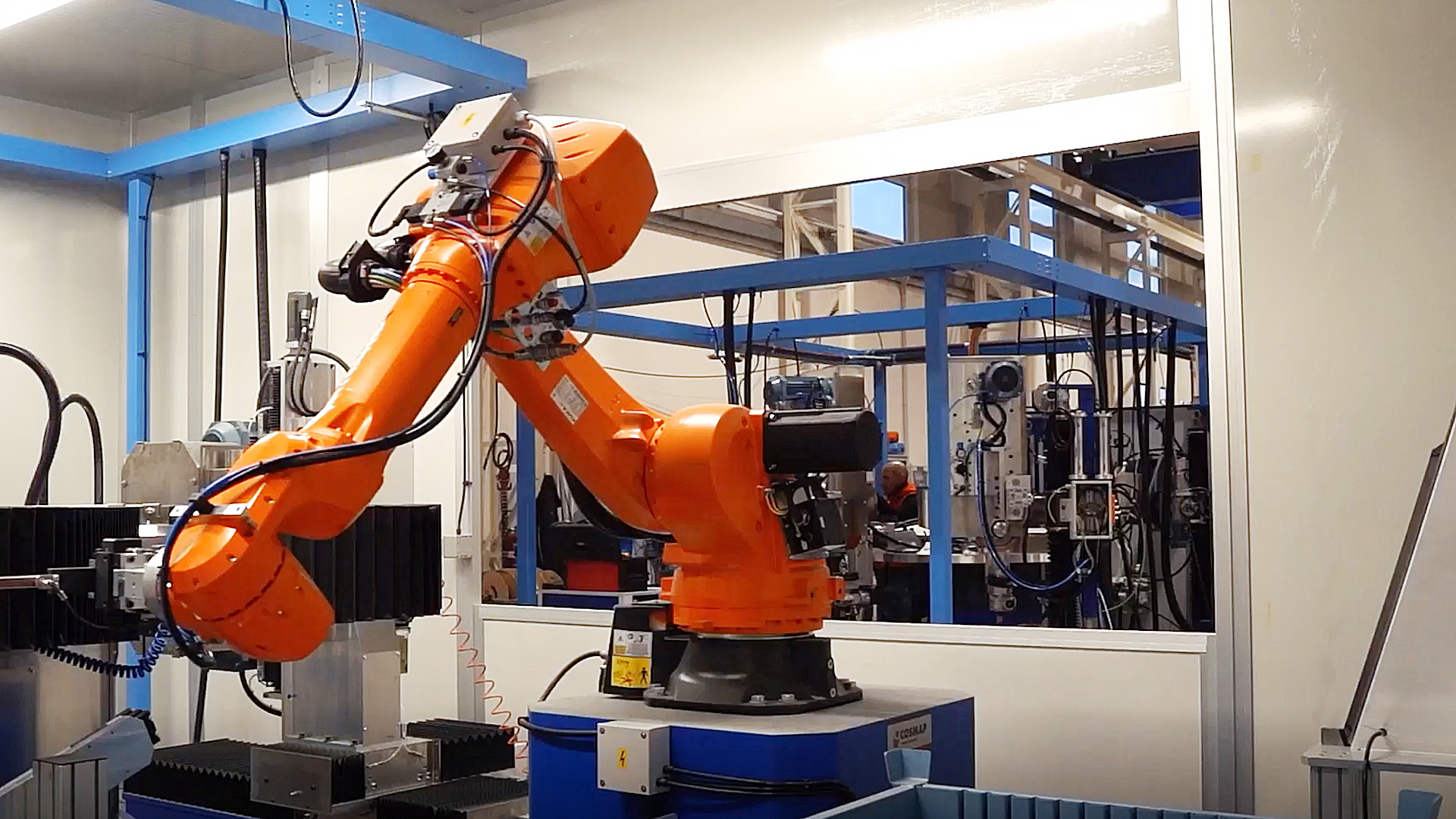

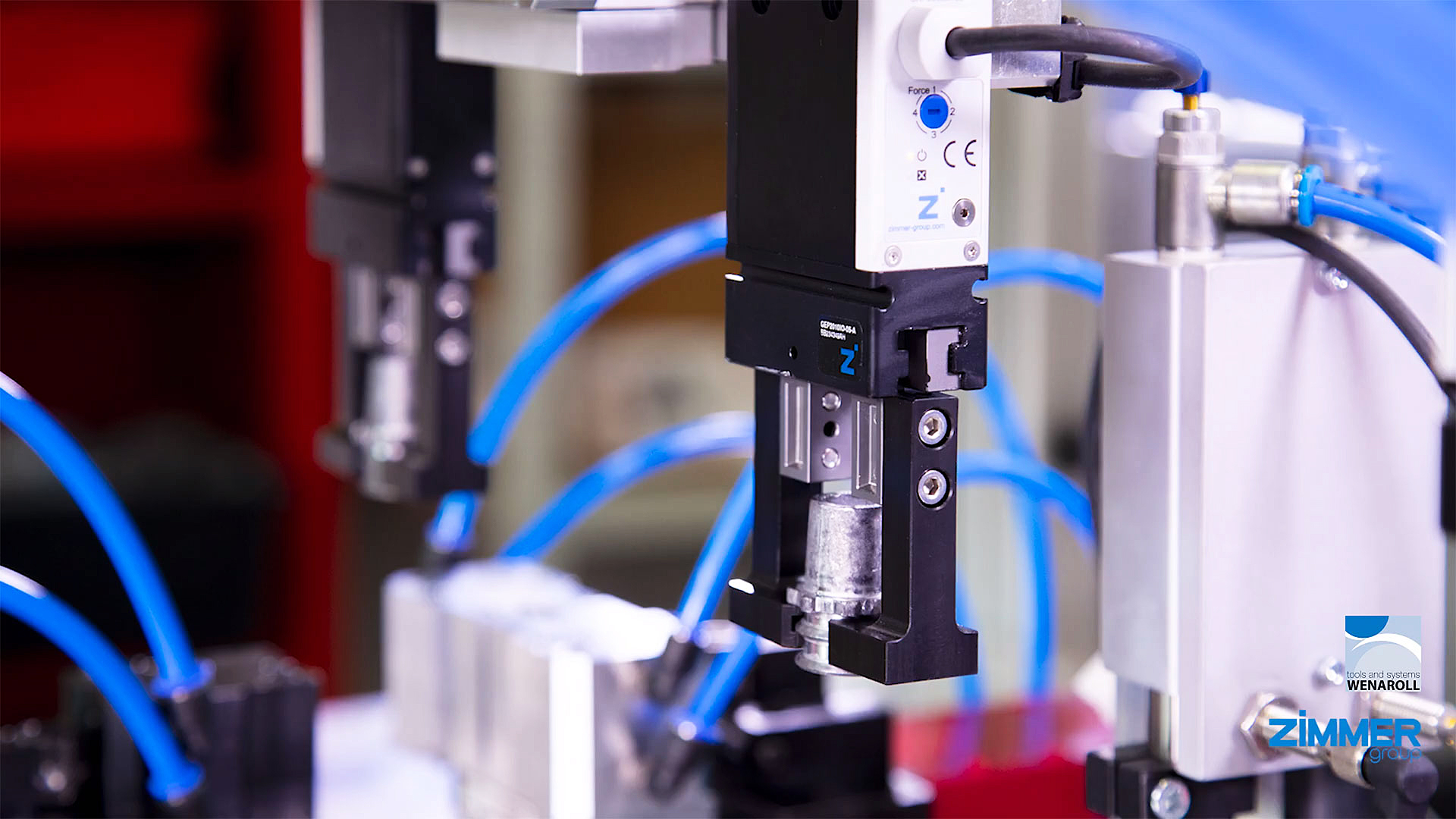

Our multi-award-winning premium pneumatic grippers from Series GPP5000 and GPD5000 with the extremely robust steel-on-steel profile slot guide are designed for universal use and provide an outstanding high functional reliability and durability. Fast, precise and with high gripping forces, they offer the right solution for every application!

Would you like advice on the gripper series with Steel Linear Guide? Then write us!

Your benefits

The advantages of the series at a glance

Advantages that make the difference

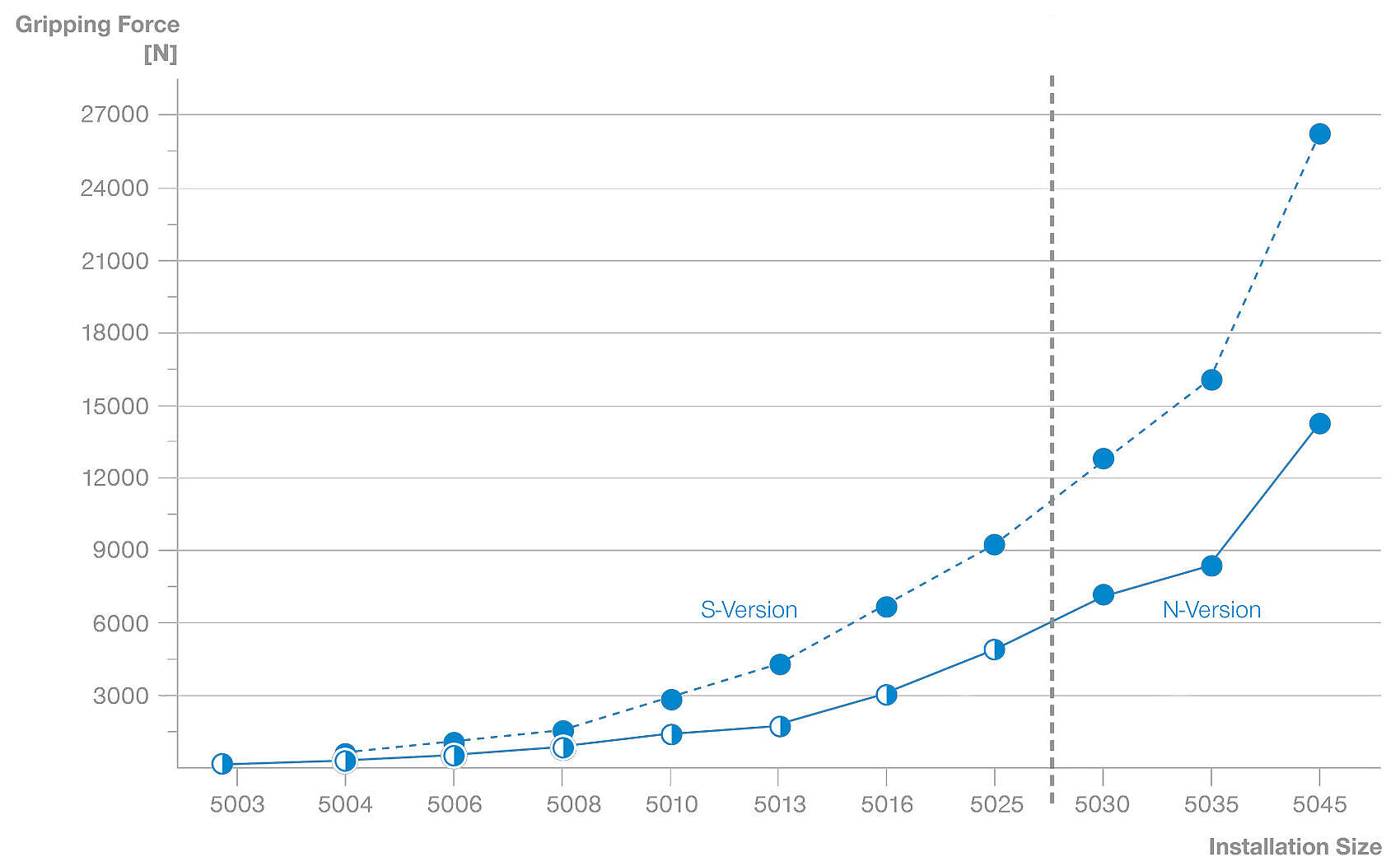

Gripping force of the GPP5000 and GPP5000AL series at a glance

100%

of all applications can be covered with Series GPP5000.

Over

100%

more gripping force at the same installation size with the S variant.

Up to

45%

price advantage by choosing a smaller installation size with the same force.

The premium grippers

Designed for universal use

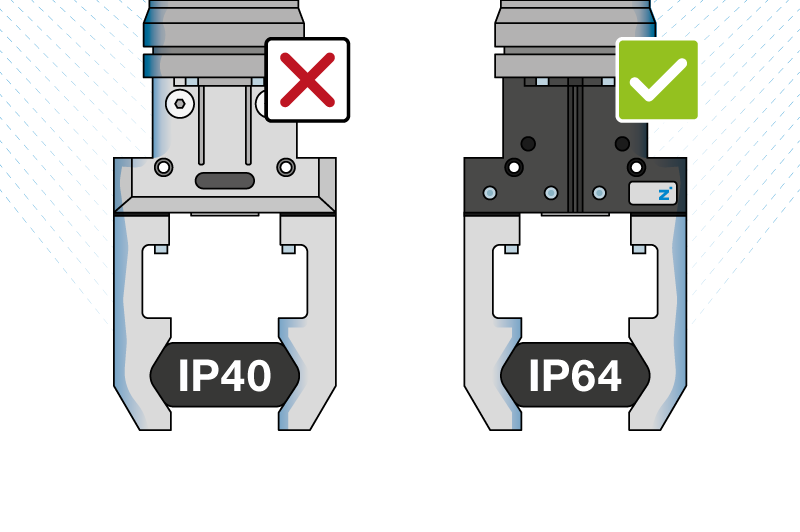

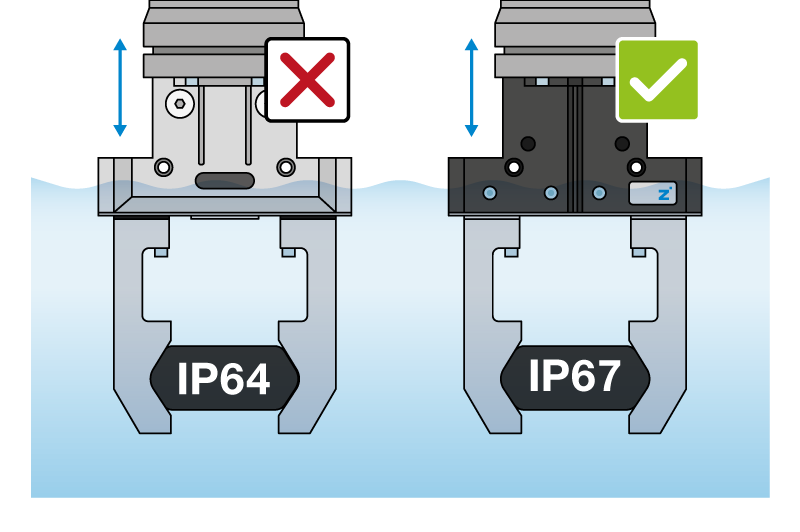

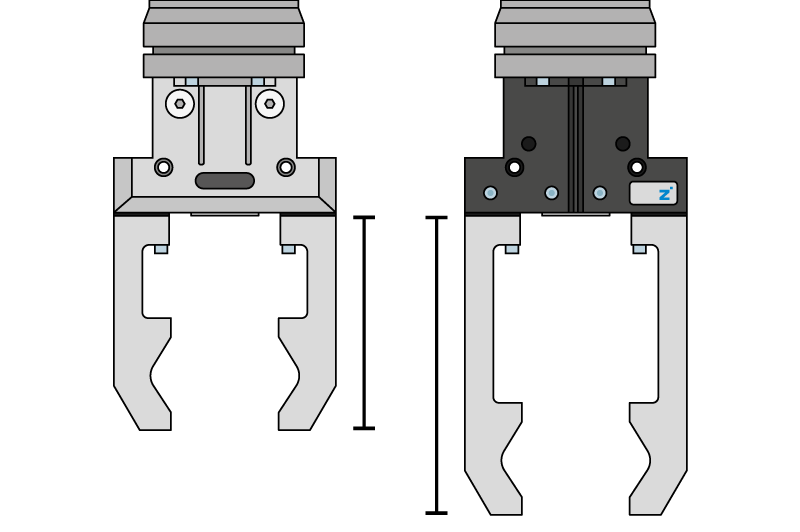

They are protected against corrosion and, with IP64, are ideally equipped to withstand the harshest environmental conditions. If this is not enough, the series offers protector versions and temperature-resistant versions that even have a protection class of IP67.

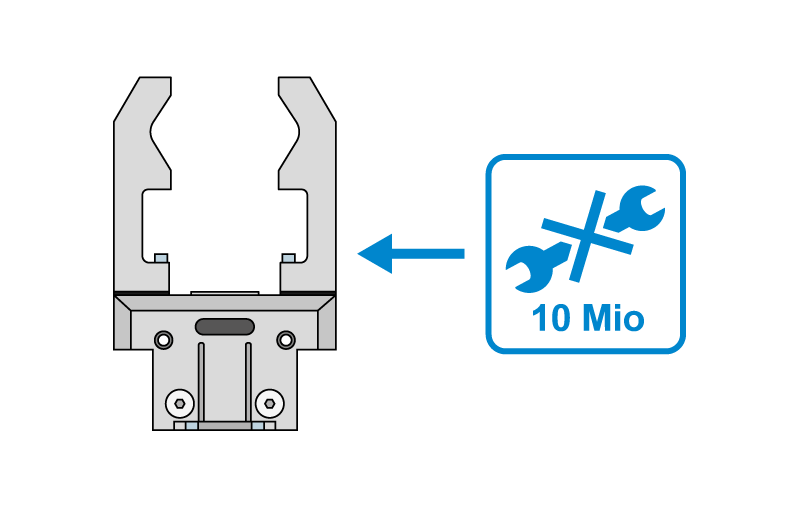

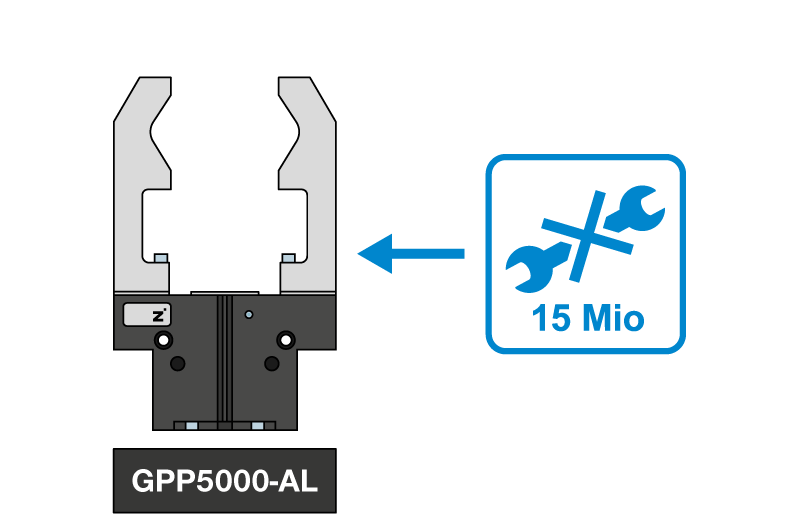

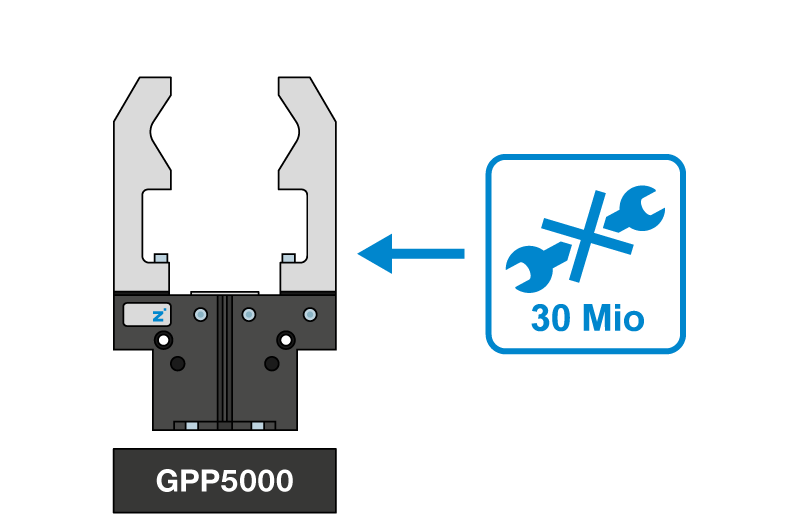

Maintenance free

Series GPP5000 and GPD5000 offer maintenance-free operation of up to 30 million cycles and thus stand for long-term use and maximum system uptime.

The value promise – Consistent and without fine print

While other manufacturers advertise a 36-month warranty, but exclude parts that come into contact with workpieces and wear parts, the Zimmer Group, with its uncompromising "Made in Germany" quality, promises a 24-month warranty for all its GPP and GPD5000 grippers. This applies to ALL PARTS without compromise, no matter how many cycles! With us, your system earns money 24/7.

Certifications

Quality and safety are fundamental elements of our corporate philosophy. Our regularly tested products not only meet the highest quality standards, but also guarantee long-term reliability and safety. This also applies to all series in the 5000 product family.

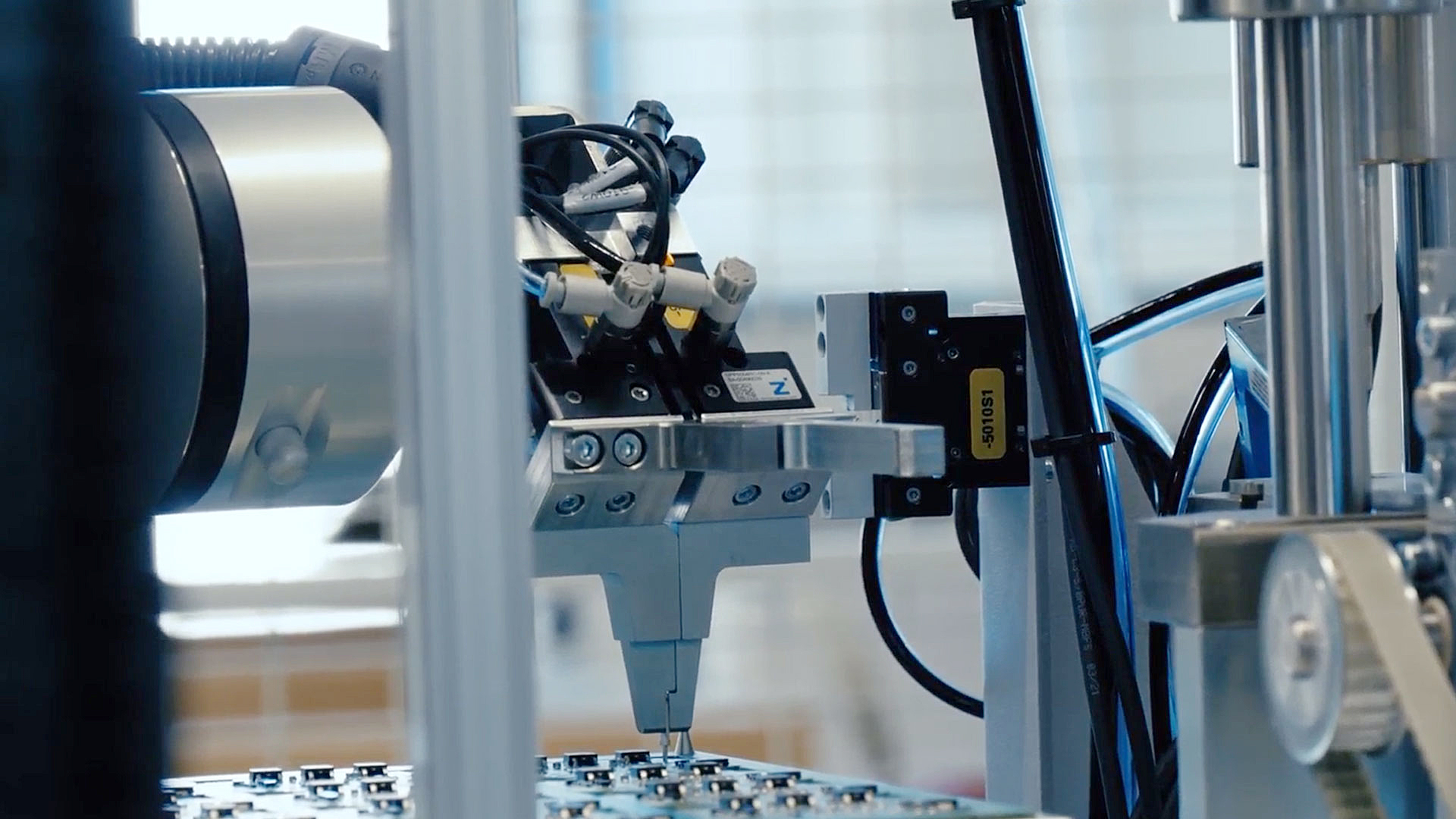

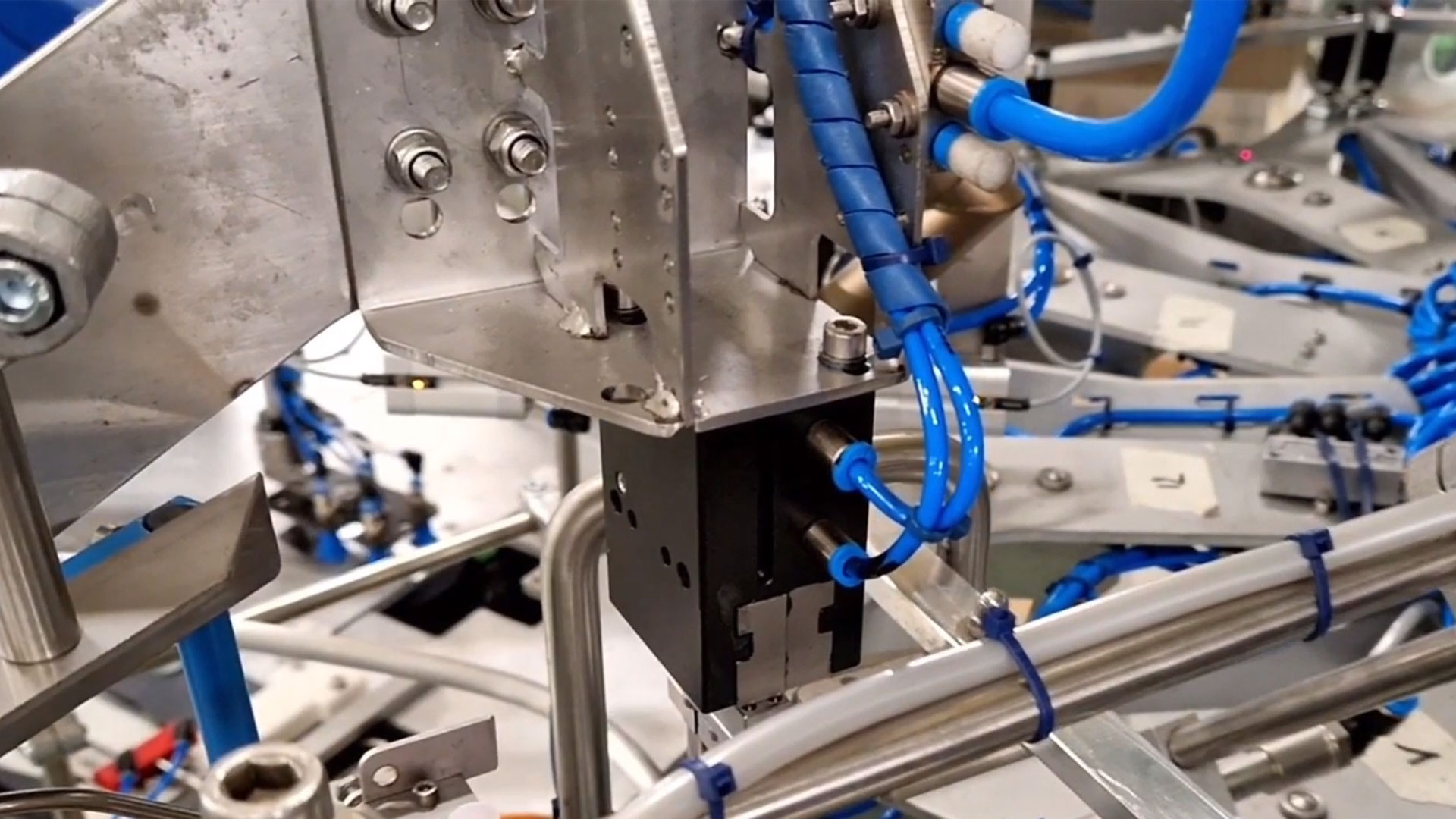

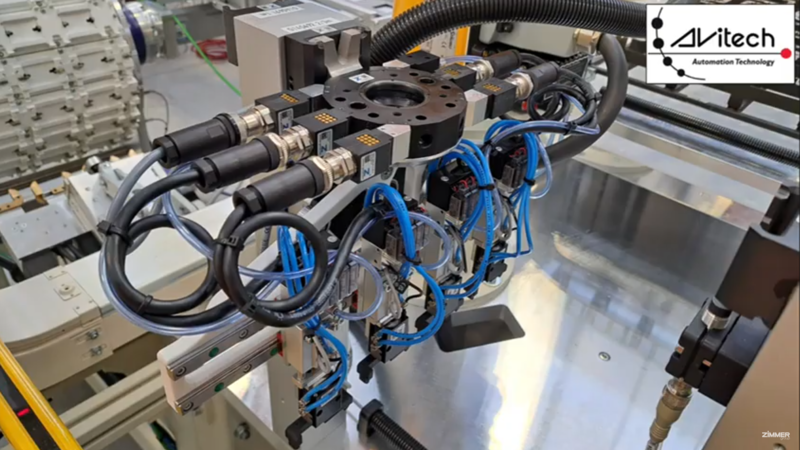

The accessories

If the operating conditions change, the conversion to protector variants can be done with just a few minor adjustments – efficiently, flexibly and without any new design work. Series GPP5000 and GPD5000 are compatible with a wide range of accessories. Special features include the adjustable jaws for tool-free adjustment of the gripping range, exchangeable jaws for quick jaw changes and the precise sensors. This reliably monitors the entire stroke range via IO-Link or with analog signals.

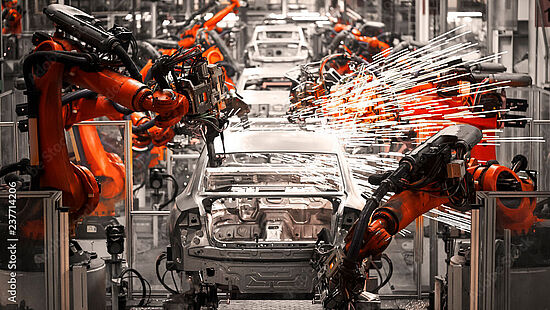

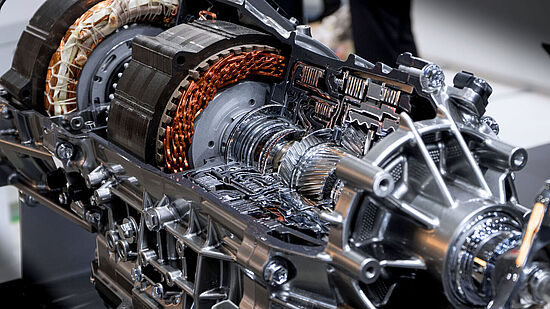

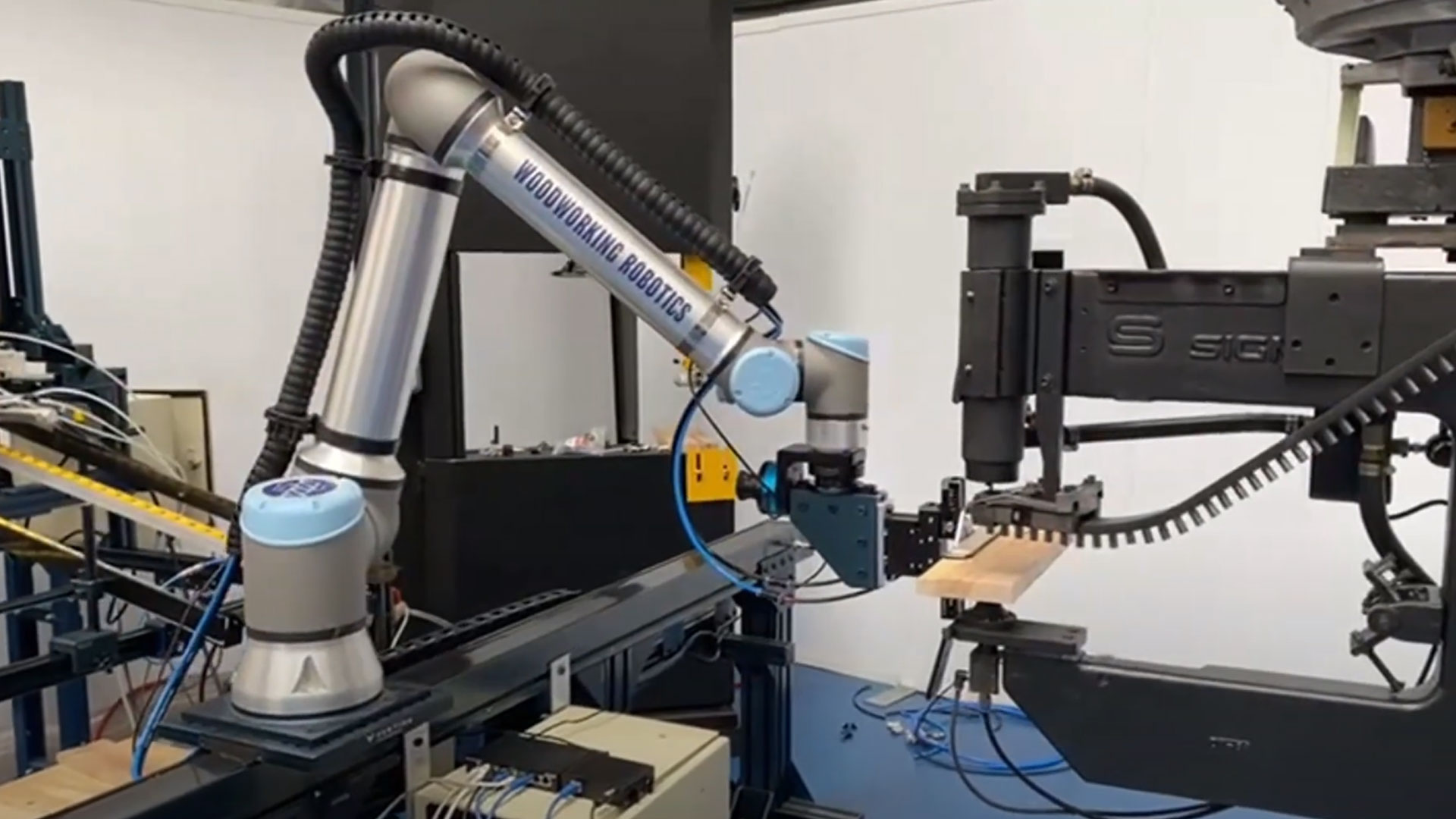

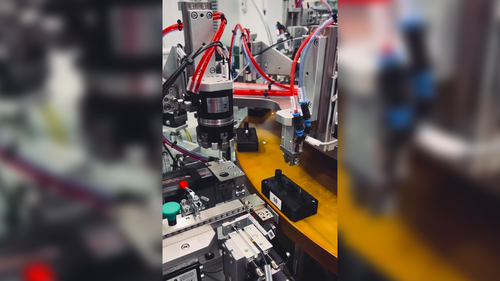

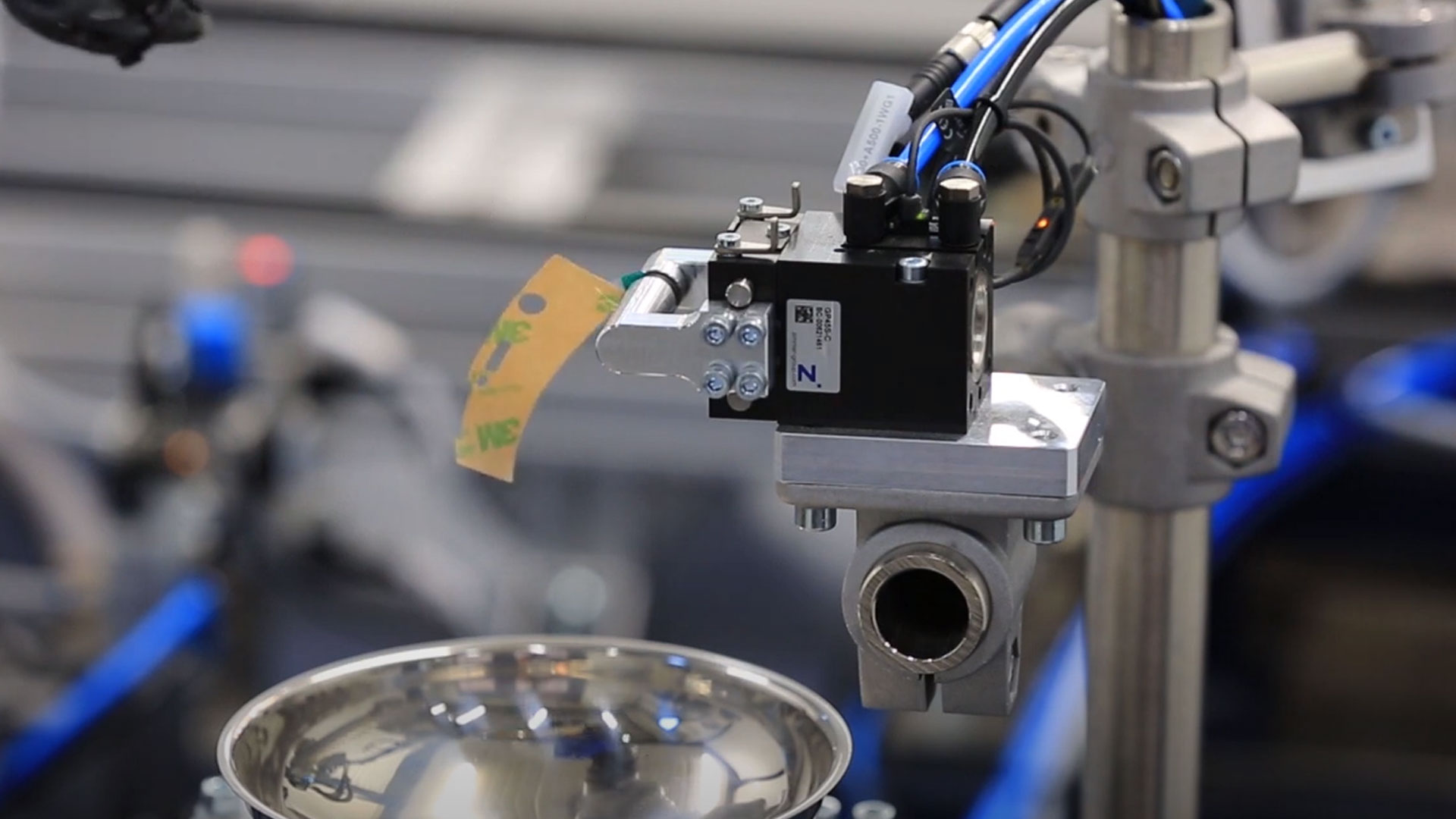

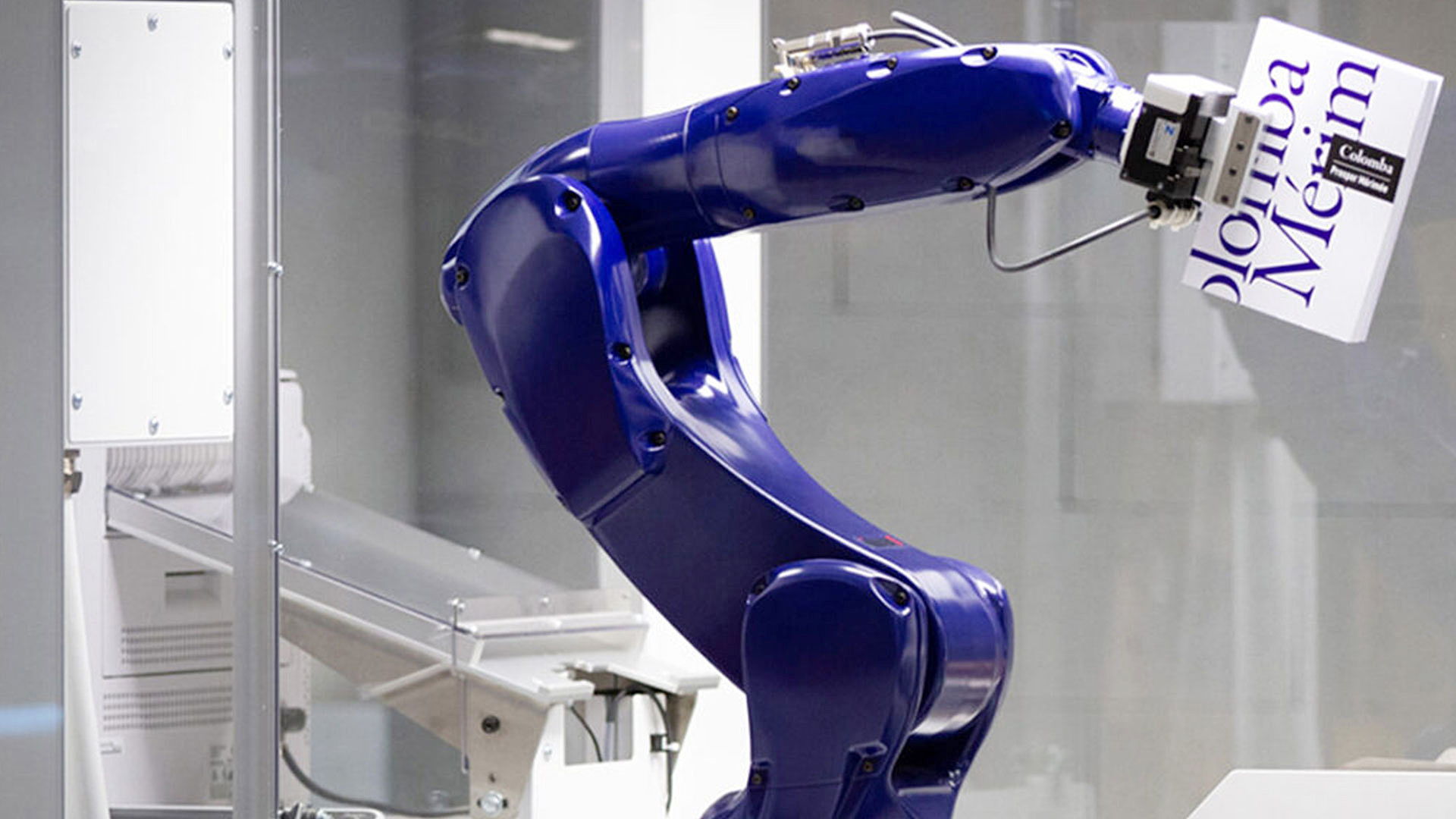

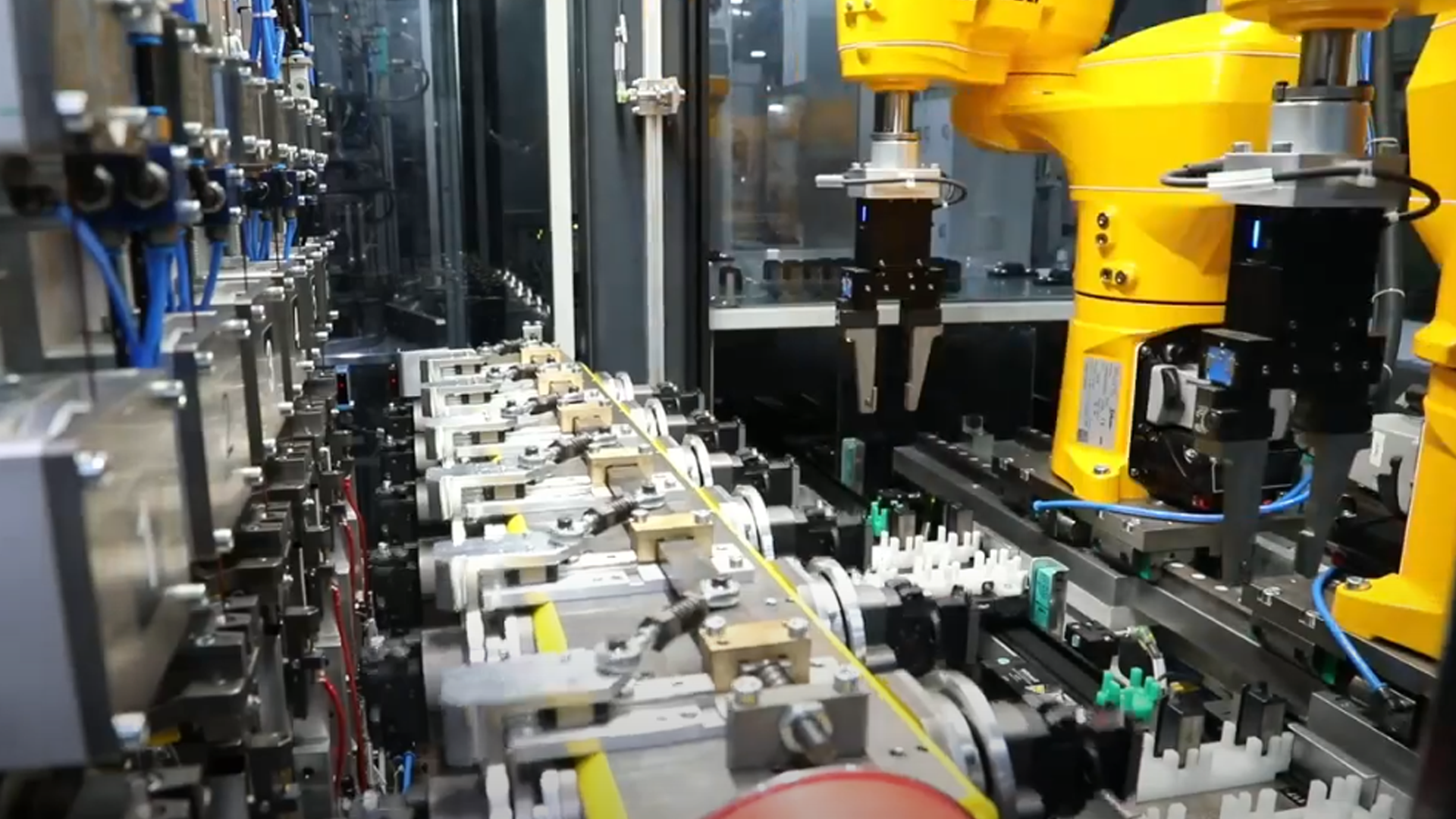

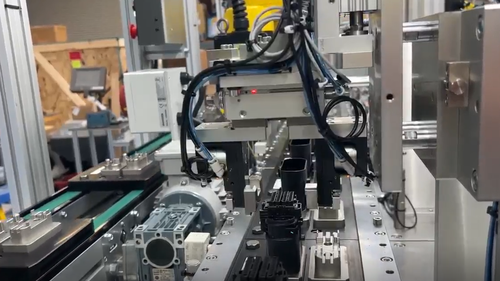

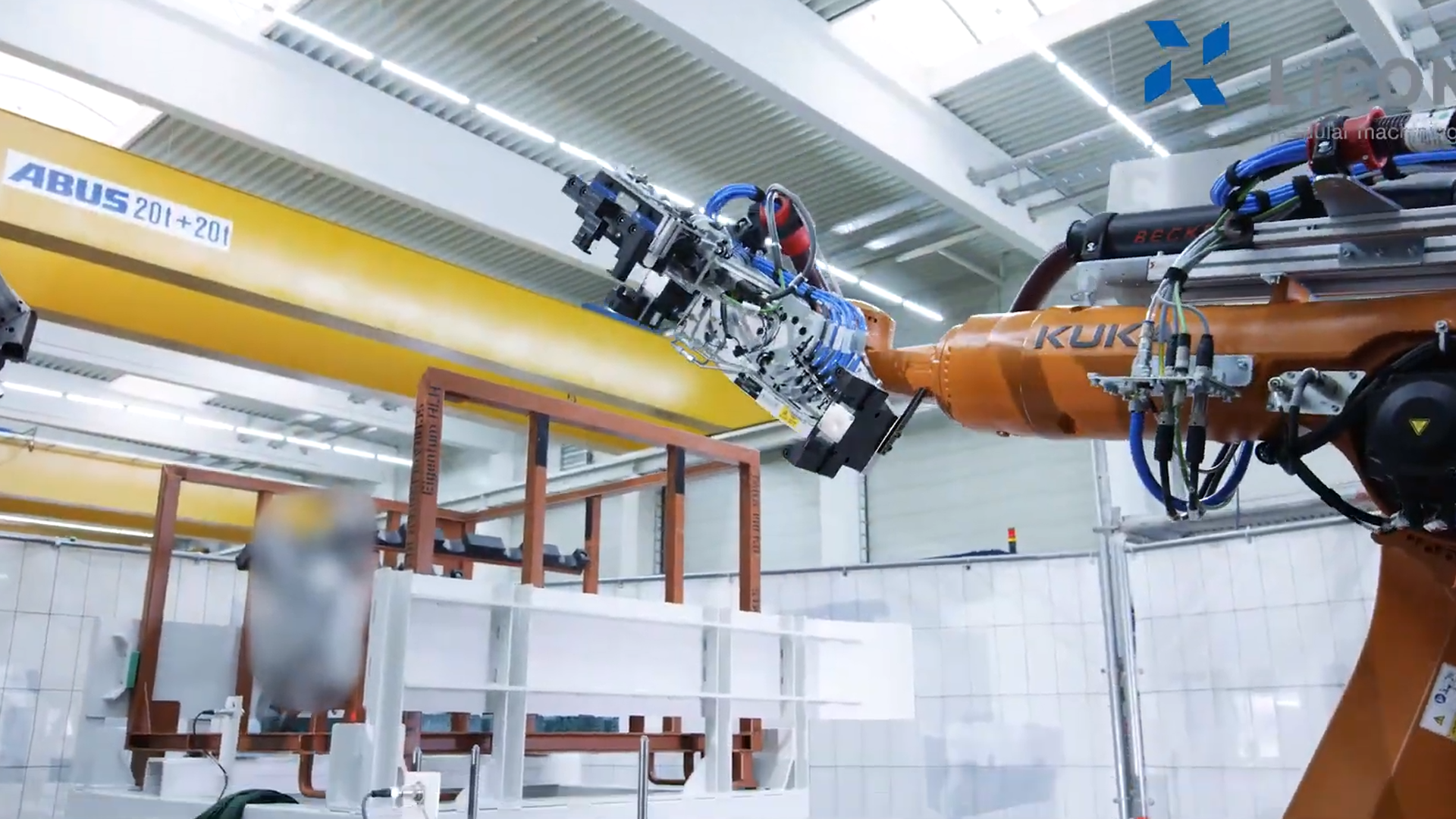

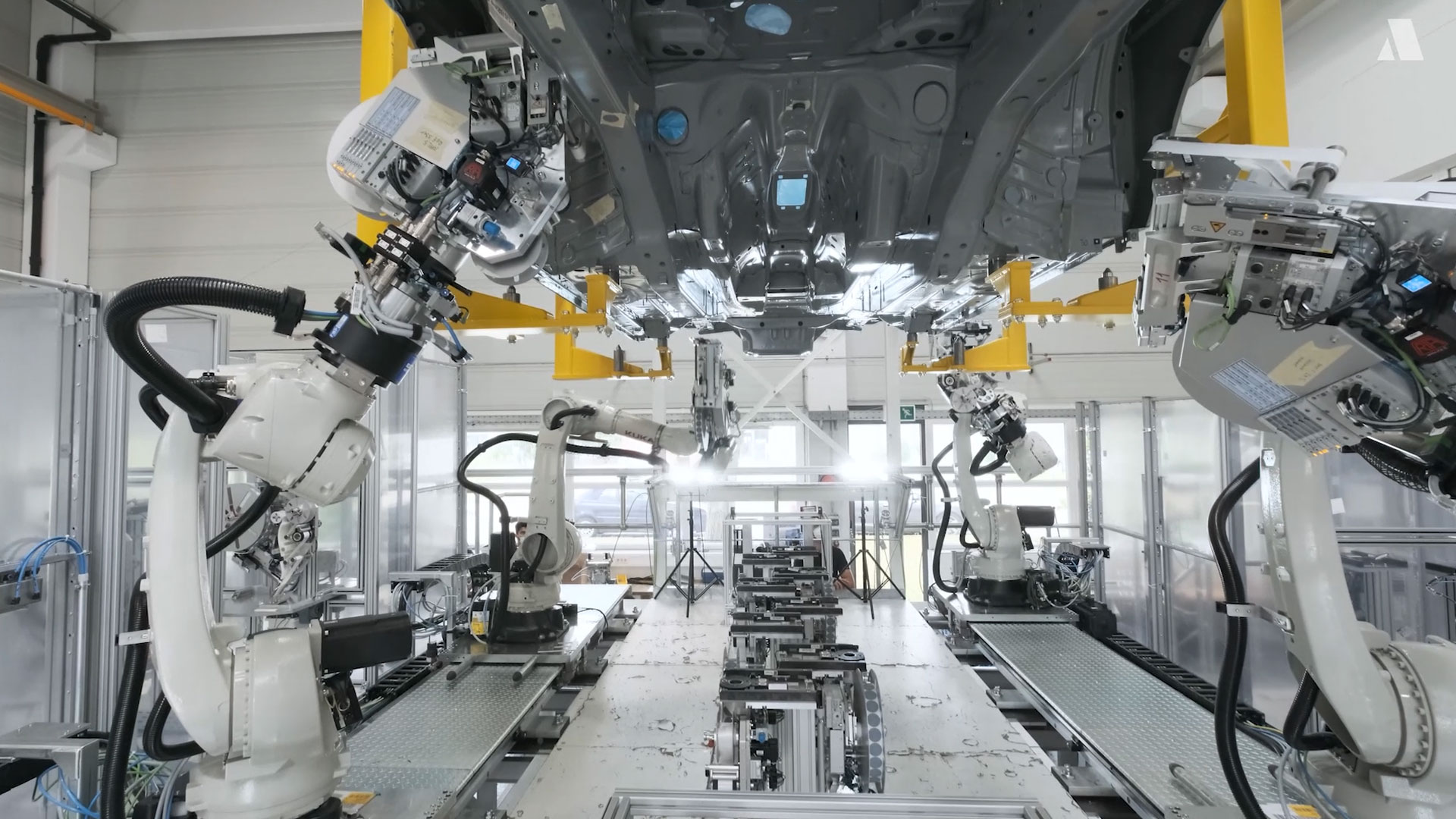

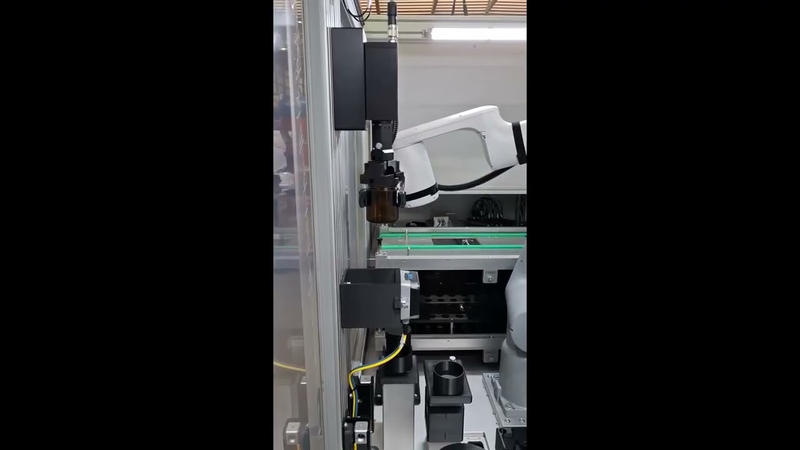

VERSATILE USAGE

PRECISE IN ALL PRODUCTION SITUATIONS

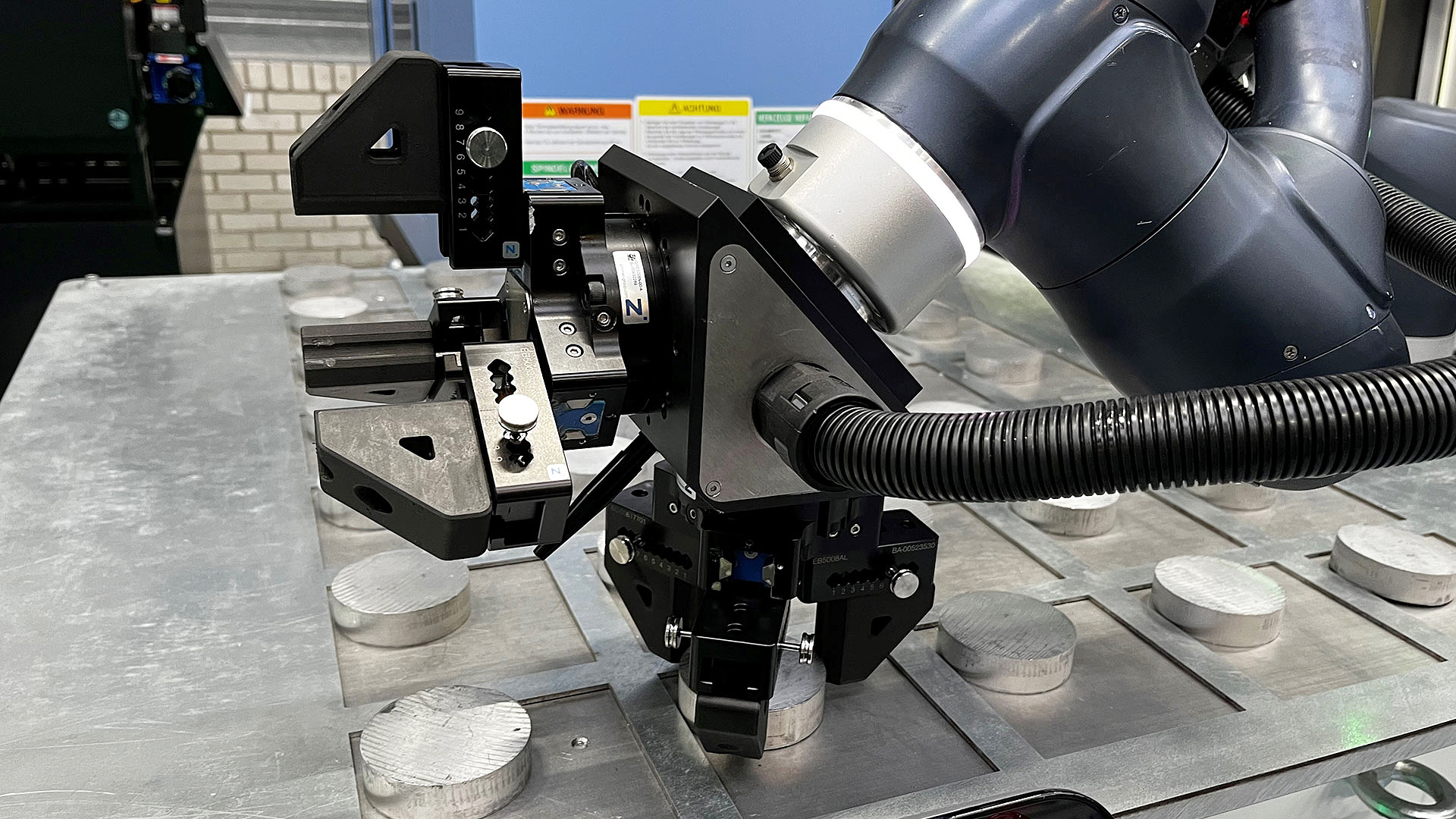

From highly automated manufacturing environments to standardized automotive production or flexible assembly processes – the gripper series GPP5000 and GPD5000 deliver impressive performance and adaptability across a wide range of industries.

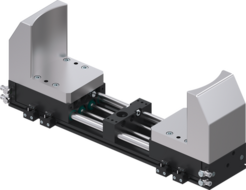

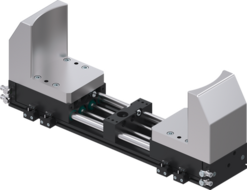

2-Jaw Parallel Grippers with Long Stroke

Series GEH6000IL

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers with Long Stroke

Series GH6000

3-Jaw Concentric Grippers

Series GD300

- Extremely robust T-Slot guide for maximum forces and moments capacity

- Available with optional dust cover for use at extreme conditions

- Extremely robust T-Slot guide for maximum forces and moments capacity

- Available with optional dust cover for use at extreme conditions

2-Jaw Parallel Grippers

Series GEP2000

2-Jaw Parallel Grippers

Series GEP2000

2-Jaw Parallel Grippers

Series GEP2000

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

3-Jaw Concentric Grippers

Series GPD5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GPP5000AL

- Aluminum Linear Guide – The alternative

- Only here – larger stroke, reduced costs

- The value promise – Consistent and without fine print

3-Jaw Concentric Grippers

Series GPD5000AL

- Aluminum Linear Guide – The alternative

- Extensive accessories

- The value promise – Consistent and without fine print

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Aluminum Linear Guide – The alternative

- Only here – larger stroke, reduced costs

- The value promise – Consistent and without fine print

- Aluminum Linear Guide – The alternative

- Extensive accessories

- The value promise – Consistent and without fine print

2-Jaw Parallel Grippers with Long Stroke

Series GEH6000IL

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GEP5000

- Approximately the same gripping force as a comparable pneumatic gripper

- Self locking mechanism in case of power drop

- Same connection hole patterns as a comparable pneumatic gripper

- Approximately the same gripping force as a comparable pneumatic gripper

- Self locking mechanism in case of power drop

- Same connection hole patterns as a comparable pneumatic gripper

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GEP2000

2-Jaw Parallel Grippers

Series GEP2000

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series MGP800

- Integrated position sensing for compact design and to minimized the interfering contour

- Gripper jaws made of ground surfaced and hardened steel ensure precision and a long durability

- Integrated position sensing for compact design and to minimized the interfering contour

- Gripper jaws made of ground surfaced and hardened steel ensure precision and a long durability

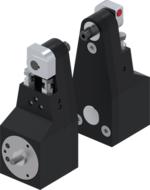

2-Jaw Angular Rotary Grippers

Series DGK

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GEP2000

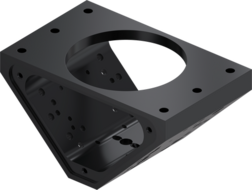

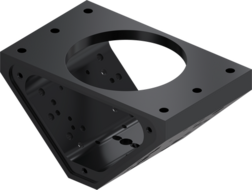

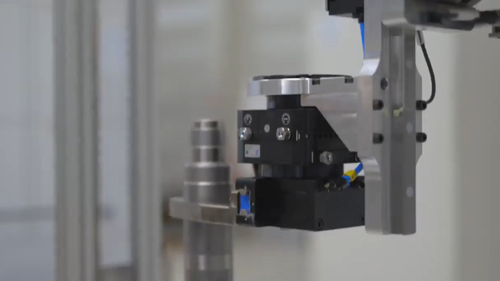

Axis Compensation Modules

Series XYR1000

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK 40 ... TK 200

- Axis compensation in the X-Y plane

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK 40 ... TK 200

- Axis compensation in the X-Y plane

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series MGP800

- Integrated position sensing for compact design and to minimized the interfering contour

- Gripper jaws made of ground surfaced and hardened steel ensure precision and a long durability

- Integrated position sensing for compact design and to minimized the interfering contour

- Gripper jaws made of ground surfaced and hardened steel ensure precision and a long durability

2-Jaw Parallel Grippers with Long Stroke

Series GEH6000IL

O-ring assembly grippers, outer

Series GS

- Expanding stroke adjustable from outside via adusting ring

- T-Slot guide for high forces and moments capacity

- Expanding stroke adjustable from outside via adusting ring

- T-Slot guide for high forces and moments capacity

2-Jaw Parallel Grippers

Series GP

- Dual round guide rods

- Double acting pneumatic cylinder with integrated mechanical gripping force safety device

- Dual round guide rods

- Double acting pneumatic cylinder with integrated mechanical gripping force safety device

2-Jaw Parallel Grippers with Long Stroke

Series GEH6000IL

2-Jaw Parallel Grippers

Series GPP5000IL

- Pneumatic drive combined with IO-Link technology

- Up to 50% cycle time reduction and up to 90% compressed air savings

- Connection via just one pneumatic line and IO-Link cable

- Pneumatic drive combined with IO-Link technology

- Up to 50% cycle time reduction and up to 90% compressed air savings

- Connection via just one pneumatic line and IO-Link cable

3-Jaw Concentric Grippers

Series GPD5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

3-Jaw Concentric Grippers

Series GPD5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

Angle flange

Series WFR

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

Needle gripper

Series ST

- Adjustable stroke via scale ring from 0 to 2 mm or 1.5 mm

- Single-acting pneumatic cylinder with spring return

- Adjustable stroke via scale ring from 0 to 2 mm or 1.5 mm

- Single-acting pneumatic cylinder with spring return

O-ring assembly grippers, outer

Series GS

- Expanding stroke adjustable from outside via adusting ring

- T-Slot guide for high forces and moments capacity

- Expanding stroke adjustable from outside via adusting ring

- T-Slot guide for high forces and moments capacity

3-Jaw Concentric Grippers

Series GPD5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GP400

- High gripping force as a result of optimal direction change of driving force into gripping force

- High gripping force as a result of optimal direction change of driving force into gripping force

Swivel Jaws

Series SB

2-Jaw Parallel Grippers with Long Stroke

Series GPH8000

- Extremely long and heavy gripper fingers possible

- Synchronous, asynchronous and securing the workpiece

- Dirt protection

- Extremely long and heavy gripper fingers possible

- Synchronous, asynchronous and securing the workpiece

- Dirt protection

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GPP5000AL

- Aluminum Linear Guide – The alternative

- Only here – larger stroke, reduced costs

- The value promise – Consistent and without fine print

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Aluminum Linear Guide – The alternative

- Only here – larger stroke, reduced costs

- The value promise – Consistent and without fine print

2-Jaw Parallel Grippers

Series MGP800

- Integrated position sensing for compact design and to minimized the interfering contour

- Gripper jaws made of ground surfaced and hardened steel ensure precision and a long durability

- Integrated position sensing for compact design and to minimized the interfering contour

- Gripper jaws made of ground surfaced and hardened steel ensure precision and a long durability

Tool Changers

Series WWR

- Robot flange with partial mounting circle in accordance with EN ISO 9409-1

- Very high handling weight up to 300 kg

- Robot flange with partial mounting circle in accordance with EN ISO 9409-1

- Very high handling weight up to 300 kg

Tool Changers

Series WWR

- Robot flange with partial mounting circle in accordance with EN ISO 9409-1

- Very high handling weight up to 300 kg

- Robot flange with partial mounting circle in accordance with EN ISO 9409-1

- Very high handling weight up to 300 kg

Rotary Distributors

Series DVR

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK40... TK160

- With 4...8 pneumatic feedthroughs

- With 4...12 electrical feedthroughs

Angle flange

Series WFR

3-Jaw Concentric Grippers

Series GPD5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK40... TK160

- With 4...8 pneumatic feedthroughs

- With 4...12 electrical feedthroughs

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

More than just handling technology

The best service for the best grippers

With the Zimmer Group's international network, you get the benefit of direct local support worldwide. Consistent documentation and a well-designed range of accessories also ensure easy handling

and maintenance.

Hotline

– Your personal contact

– Support for malfunctions, process errors, operating problems

– Error analysis via telephone, video or remote

Repair service

– Repair of defective assemblies

– Repair and maintenance

– General overhaul

– Troubleshooting and servicing

Field Service

– Mechanical & electrical installation

– Mechanical & electrical commissioning

– Production support for optimizations

– Maintenance, repair and inspection

– Troubleshooting

Training

– Operator training

– Troubleshooting and diagnostics

– How to use the HMI

– Maintenance

FAQ – Grippers with Steel Linear Guide

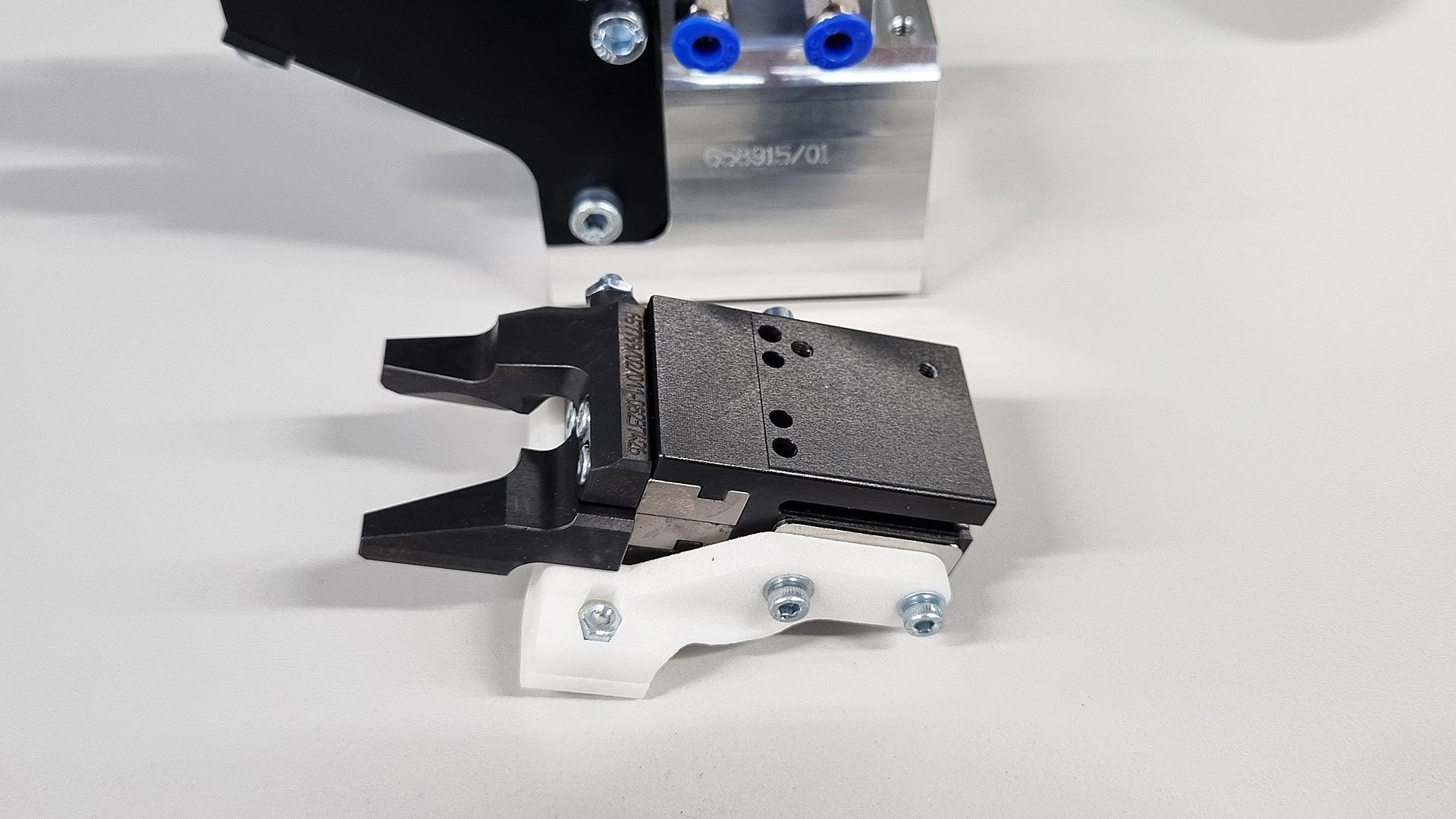

The Steel Linear Guide is an extremely robust steel-on-steel profile slot guide that offers maximum precision and process reliability. This steel guide enables up to 30 million maintenance-free cycles and ensures long-lasting performance even under difficult industrial conditions.

Series 5000 is designed as a universal gripper and is suitable for applications in mechanical and plant engineering, the automotive industry, metal processing and for automated handling and assembly processes of all kinds. Thanks to its high robustness and IP64/67 protection classes, it is also suitable for demanding environments.

The gripper models include the 2-jaw parallel grippers of the pneumatic Series GPP5000 and the 3-jaw concentric grippers GPD5000 – each with Steel Linear Guide for maximum precision and reliability. In addition, there are the pneumatic-intelligent Series GPP5000IL and GPD5000IL, as well as the electric drive Series GEP5000 and GED5000.

The key benefits include:

- High gripping forces and torque absorption

- Maintenance-free over 30 million cycles

- Compatibility with the wide range of accessories from the 5000 family

- Robust sealing and corrosion protection

These features increase process reliability and are proven to reduce operating costs.

Use our Product Finder or get in touch with your personal contact. We can help you determine the right gripper based on the workpiece size, gripping forces, operating conditions and automation requirements.

Yes, in addition to the pneumatic versions, there are also electric or hybrid-controlled grippers that are suitable for applications with high automation requirements. The hybrid-controlled grippers from Series GPP5000IL and GPD5000IL feature an impressive integrated valve technology. The electric grippers in Series GEP5000 and GED5000 allow individual adjustment of the gripping forces. Both variants have integrated sensor technology.