WWR1200F

Werkzeugwechsler

Serie WWR1000

- Sicherer Halt bei Druckabfall

Die Kombination von Federspeicher und einer hohen Übersetzung garantiert Ihnen eine sichere Maschine - Handlingsgewichte von bis zu einer Tonne

Selbst mit dem größten Robotern können Sie mit diesem Wechsler prozesssicher automatisierte Wechselvorgänge durchführen - Unerschöpfliche Vielfalt an Medienüberträgern

Egal welches Medium Sie übertragen wollen, wir haben vieles schon einmal umgesetzt und werden auch für Ihre Anforderungen die passende Lösung finden!

Technische Daten

| Anschlussflansch nach EN ISO 9409-1 | TK 200 |

| Energieübertragung elektrisch | optional |

| Energieübertragung fluidisch | optional |

| Selbsthemmung beim Verriegeln | mechanisch |

| Verriegelungshub | 1 [mm] |

| Wiederholgenauigkeit +/- | 0.02 [mm] |

| Achsversatz beim Koppeln max. in X, Y | 3 [mm] |

| Betriebsdruck | 6 ... 8 [bar] |

| Nennbetriebsdruck | 6 [bar] |

| Betriebstemperatur | 5 ... +80 [°C] |

| Zylindervolumen pro Zyklus | 83 [cm³] |

| Gewicht | 15 [kg] |

| Empfohlenes Handlingsgewicht | 1000 [kg] |

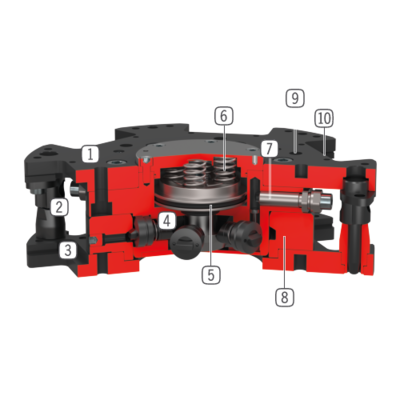

Aufbau im Schnitt

- Festteil

Zur roboterseitigen Montage - Zentrierbolzen

Verdrehsicherung und Positionierung für Losteil - Losteil

Zur werkzeugseitigen Montage - Verriegelungsbolzen

der Verriegelungshülse angepasst - Antrieb

doppeltwirkender Pneumatikzylinder - Integrierte Feder

Energiespeicher bei Druckabfall - Kolbenstellungsabfrage

Über induktiven Näherungsschalter - Verriegelungshülse

- Roboterflansch

Teilkreis nach EN ISO 9409-1 - Befestigung Energieelement

Energieelemente

Übertragungsart Kommunikation

| Anschlussgewinde | Anzahl Fluidkupplungen | Anzahl Kontakte | ||

|---|---|---|---|---|

| WER3000FIL01-00 |  | M12 | 5 | |

| WER3000FIL01-09-A |  | M12 | 5 | |

| WER3000FPB01-00 |  | M12 | 5 | |

| WER3000FPN01-00 |  | M12 | 4 | |

| WER3000FPN01-09-A |  | M12 | 4 | |

| WER3000FIL01-18-A |  | M12 | 4 |

Übertragungsart elektrisch

| Anschlussgewinde | Anzahl Fluidkupplungen | Anzahl Kontakte | ||

|---|---|---|---|---|

| WER3000FLA01-00-A |  | M8 | 1 | |

| WER3000FLA06-00 |  | M23 | 5+PE | |

| WER3000FLA08-00 |  | M23 | (3+PE) / 4 | |

| WER3000FSI11-20-A |  | M23 | 11+1 | |

| WER3000FSI11-21-A |  | M23 | 11+1 | |

| WER3000FSI12-00 |  | M23 | 12 | |

| WER3000FSI12-09-A |  | M23 | 12 | |

| WER3000FSI14-01-A |  | M23 | 14+5 Sensorik | |

| WER3000FSI14-02-A |  | M23 | 14+5 Sensorik | |

| WER3000FSI14-16-A |  | M23 | 14+5 Sensorik | |

| WER3000FSI14-17-A |  | M23 | 14+5 Sensorik | |

| WER3000FSI18-20-A |  | M23 | 18+1 | |

| WER3000FSI18-21-A |  | M23 | 18+1 | |

| WER3000FSI19-00 |  | M23 | 19 | |

| WER3000FSI19-09-A |  | M23 | 19 | |

| WER4000FLA03-05-A |  | 3 | ||

| WER3000FSI08-18-A |  | M12 | 8+2 | |

| WER3000FLA01-27-A |  | 1 |

Übertragungsart fluidisch

| Anschlussgewinde | Anzahl Fluidkupplungen | Anzahl Kontakte | ||

|---|---|---|---|---|

| WER3000FFL01-03-A |  | G1/4" | 1 | |

| WER4000FFL01-13-A |  | G1/2" | 1 | |

| WER4000FFL02-13-A |  | G1/2" | 2 | |

| WER4000FFL04-13-A |  | G1/2" | 4 |

Übertragungsart pneumatisch

| Anschlussgewinde | Anzahl Fluidkupplungen | Anzahl Kontakte | ||

|---|---|---|---|---|

| WER3000FPL01-04 |  | G3/8" | 1 | |

| WER3000FPL02-03 |  | G1/4" | 2 | |

| WER3000FPL04-06-A |  | G1/8" | 4 | |

| WER4000FPL06-06-A |  | G1/8" | 6 | |

| WER4000FPL15-12-A |  | M5 | 15 |