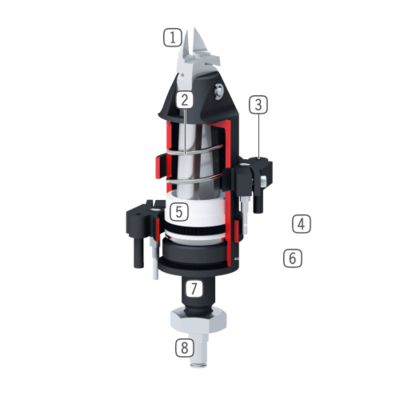

Cutting Tongs

Series ZK1000

- Extremely lightweight

This light weight generally allows the use of a smaller moving axis, reducing the overall costs of the application in the process - Integrated magnetic field sensing

One of the few cutting tongs on the market that can have its position queried and transferred to the control system with process reliability - Decide for yourself!

Sprue or steel wire: The variety of cutting geometries and materials ensure you always find the correct cuttings

Series features

5 million maintenance-free cycles (max.)

5 million maintenance-free cycles (max.) Spring opening O

Spring opening O IP30

IP30 Magnetic field sensor

Magnetic field sensor

- Cutting insert

flexible applicable due to specific cutting geometry - Return spring

to open the cuttings - Mounting clamp

mounting and positioning of magnetic field sensors - Magnetic field sensor

for position sensing - Drive

single-acting pneumatic cylinder - Housing

Hard-coated aluminum alloy - Mounting and positioning

via fit, thread and lock nut - Energy supply